First Example of Unsaturated Poly(Ester Amide)s Derived From Itaconic Acid and Their Application as Bio-Based UV-Curing Polymers

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Methods

2.3. Measurements

2.4. Synthesis of Bio-Based Oligoester (OE)

2.5. Oligoesteramidesynthesis (OEA)

2.6. Transesterification to the Poly(Ester Amide)s (PEAs)

2.7. Pseudo One-Pot Synthesis of Poly(Ester Amides)

3. Results and Discussion

3.1. Synthesis of Poly(Esteramide)s Via Transesterification Approach

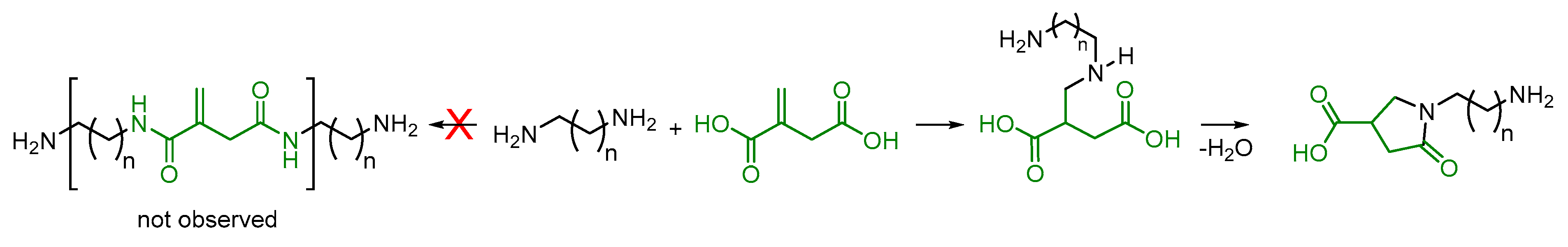

3.2. Synthesis of Poly(Esteramide)S Via In-Situ Formed Bis(Ester Amide)s

3.3. IR and NMR Analysis

3.4. GPC Measurements

3.5. Viscosity

3.6. UV-Curing Behaviour

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gandini, A.; Coelho, D.; Silvestre, A.J.D. Reversible click chemistry at the service of macromolecular materials. Part 1: Kinetics of the Diels–Alder reaction applied to furan–maleimide model compounds and linear polymerizations. Eur. Polym. J. 2008, 44, 4029–4036. [Google Scholar] [CrossRef]

- Schneiderman, D.K.; Hillmyer, M.A. 50th Anniversary Perspective: There Is a Great Future in Sustainable Polymers. Macromolecules 2017, 50, 3733–3749. [Google Scholar] [CrossRef]

- Hillmyer, M.A. The promise of plastics from plants. Science 2017, 358, 868–870. [Google Scholar] [CrossRef]

- Zhu, Y.; Romain, C.; Williams, C.K. Sustainable polymers from renewable resources. Nature 2016, 540, 354. [Google Scholar] [CrossRef]

- Werpy, G.T.P. Top Value Added Chemicals from Biomass. In U.S. Department of Energy: Energy Efficiency and Renewable Energy; U.S. Department of Energy: Oak Ridge, TN, USA, 2004. [Google Scholar]

- Willke, T.; Vorlop, K.D. Biotechnological production of itaconic acid. Appl. Microbiol. Biotechnol. 2001, 56, 289–295. [Google Scholar] [CrossRef]

- Krull, S.; Lünsmann, M.; Prüße, U.; Kuenz, A. Ustilago Rabenhorstiana—An Alternative Natural Itaconic Acid Producer. Fermentation 2020, 6, 4. [Google Scholar] [CrossRef]

- Saha, B.C.; Kennedy, G.J. Phosphate limitation alleviates the inhibitory effect of manganese on itaconic acid production by Aspergillus terreus. Biocatal. Agric. Biotechnol. 2019, 18, 101016. [Google Scholar] [CrossRef]

- Chakraborty, S.; Ju, L.; Galuska, A.A.; Moore, R.B.; Turner, S.R. Suspension polymerization of itaconic acid diesters. J. Appl. Polym. Sci. 2018, 135, 46417. [Google Scholar] [CrossRef]

- Inciarte, H.; Orozco, M.; Fuenmayor, M.; Lopez-Carrasquero, F.; Oliva, H. Comb-like copolymers of n-alkyl monoitaconates and styrene. E-Polymers 2006. [Google Scholar] [CrossRef]

- Lopez-Carrasquero, F.; de Ilarduya, A.M.; Cardenas, M.; Carrillo, M.; Arnal, M.L.; Laredo, E.; Torres, C.; Mendez, B.; Muller, A.J. New comb-like poly(n-alkyl itaconate)s with crystalizable side chains. Polymer 2003, 44, 4969–4979. [Google Scholar] [CrossRef]

- Retuert, J.; Pedram, M.Y.; Martinez, F.; Jeria, M. Soluble Itaconic Acid–Ethylene Glycol Polyesters. Bull. Chem. Soc. Jpn. 1993, 66, 1707–1708. [Google Scholar] [CrossRef]

- Arrighi, V.; McEwen, I.J.; Holmes, P.F. Dielectric Relaxations in Poly(di-n-alkyl itaconate)s. Macromolecules 2004, 37, 6210–6218. [Google Scholar] [CrossRef]

- Robert, T.; Friebel, S. Itaconic acid-a versatile building block for renewable polyesters with enhanced functionality. Green Chem. 2016, 18, 2922–2934. [Google Scholar] [CrossRef]

- Pellis, A.; Hanson, P.A.; Comerford, J.W.; Clark, J.H.; Farmer, T.J. Enzymatic synthesis of unsaturated polyesters: functionalization and reversibility of the aza-Michael addition of pendants. Polym. Chem. 2019, 10, 843–851. [Google Scholar] [CrossRef]

- Mehta, L.B.; Wadgaonkar, K.K.; Jagtap, R.N. Synthesis and characterization of high bio-based content unsaturated polyester resin for wood coating from itaconic acid: Effect of various reactive diluents as an alternative to styrene. J. Dispers. Sci. Technol. 2019, 40, 756–765. [Google Scholar] [CrossRef]

- Li, P.; Ma, S.; Dai, J.; Liu, X.; Jiang, Y.; Wang, S.; Wei, J.; Chen, J.; Zhu, J. Itaconic Acid as a Green Alternative to Acrylic Acid for Producing a Soybean Oil-Based Thermoset: Synthesis and Properties. ACS Sustain. Chem. Eng. 2017, 5, 1228–1236. [Google Scholar] [CrossRef]

- Dai, J.Y.; Ma, S.Q.; Teng, N.; Dai, X.Y.; Shen, X.B.; Wang, S.; Liu, X.Q.; Zhu, J. 2,5-Furandicarboxylic Acid- and Itaconic Acid-Derived Fully Biobased Unsaturated Polyesters and Their Cross-Linked Networks. Ind. Eng. Chem. Res. 2017, 56, 2650–2657. [Google Scholar] [CrossRef]

- Brännström, S.; Malmström, E.; Johansson, M. Biobased UV-curable coatings based on itaconic acid. J. Coat. Technol. Res. 2017, 14, 851–861. [Google Scholar] [CrossRef]

- Schoon, I.; Kluge, M.; Eschig, S.; Robert, T. Catalyst Influence on Undesired Side Reactions in the Polycondensation of Fully Bio-Based Polyester Itaconates. Polymers 2017, 9, 693. [Google Scholar] [CrossRef]

- Patil, D.M.; Phalak, G.A.; Mhaske, S.T. Design and synthesis of bio-based UV curable PU acrylate resin from itaconic acid for coating applications. Des. Monomers Polym. 2017, 20, 269–282. [Google Scholar] [CrossRef]

- Dai, J.; Ma, S.; Wu, Y.; Han, L.; Zhang, L.; Zhu, J.; Liu, X. Polyesters derived from itaconic acid for the properties and bio-based content enhancement of soybean oil-based thermosets. Green Chem. 2015, 17, 2383–2392. [Google Scholar] [CrossRef]

- Goerz, O.; Ritter, H. Polymers with shape memory effect from renewable resources: Crosslinking of polyesters based on isosorbide, itaconic acid and succinic acid. Polym. Int. 2013, 62, 709–712. [Google Scholar] [CrossRef]

- Guo, B.; Chen, Y.; Lei, Y.; Zhang, L.; Zhou, W.Y.; Rabie, A.B.M.; Zhao, J. Biobased Poly(propylene sebacate) as Shape Memory Polymer with Tunable Switching Temperature for Potential Biomedical Applications. Biomacromolecules 2011, 12, 1312–1321. [Google Scholar] [CrossRef] [PubMed]

- Robert, T.; Eschig, S.; Biemans, T.; Scheifler, F. Bio-based polyester itaconates as binder resins for UV-curing offset printing inks. J. Coat. Technol. Res. 2019, 16, 689–697. [Google Scholar] [CrossRef]

- Farmer, T.J.; Clark, J.H.; Macquarrie, D.J.; Ogunjobi, J.K.; Castle, R.L. Post-polymerisation modification of bio-derived unsaturated polyester resins via Michael additions of 1,3-dicarbonyls. Polym. Chem. 2016, 7, 1650–1658. [Google Scholar] [CrossRef]

- Farmer, T.; James MacQuarrie, D.; William Comerford, J.; Pellis, A.; Clark, J. Insights into Post-polymerisation Modification of Bio-based Unsaturated Itaconate and Fumarate Polyesters via Aza-Michael Addition: Understanding the Effects of C=C Isomerisation. J. Polym. Sci. Part A Polym. Chem. 2018, 56, 1935–1945. [Google Scholar] [CrossRef]

- Winkler, M.; Lacerda, T.M.; Mack, F.; Meier, M.A.R. Renewable Polymers from Itaconic Acid by Polycondensation and Ring-Opening-Metathesis Polymerization. Macromolecules 2015, 48, 1398–1403. [Google Scholar] [CrossRef]

- Guarneri, A.; Cutifani, V.; Cespugli, M.; Pellis, A.; Vassallo, R.; Asaro, F.; Ebert, C.; Gardossi, L. Functionalization of Enzymatically Synthesized Rigid Poly(itaconate)s via Post-Polymerization Aza-Michael Addition of Primary Amines. Adv. Synth. Catal. 2019, 361, 2559–2573. [Google Scholar]

- Paytash, P.L.; Sparrow, E.; Gathe, J.C. The Reaction of Itaconic Acid with Primary Amines. J. Am. Chem. Soc. 1950, 72, 1415–1416. [Google Scholar] [CrossRef]

- Wang, Z.; Wei, T.; Xue, X.; He, M.; Xue, J.; Song, M.; Wu, S.; Kang, H.; Zhang, L.; Jia, Q. Synthesis of fully bio-based polyamides with tunable properties by employing itaconic acid. Polymer 2014, 55, 4846–4856. [Google Scholar] [CrossRef]

- Nsengiyumva, O.; Miller, S.A. Synthesis, characterization, and water-degradation of biorenewable polyesters derived from natural camphoric acid. Green Chem. 2019, 21, 973–978. [Google Scholar] [CrossRef]

- Pérocheau Arnaud, S.; Andreou, E.; Pereira Köster, L.V.G.; Robert, T. Selective Synthesis of Monoesters of Itaconic Acid with Broad Substrate Scope: Biobased Alternatives to Acrylic Acid? ACS Sustain. Chem. Eng. 2020, 8, 1583–1590. [Google Scholar] [CrossRef]

| Sample | PEA Composition OE/OEA | % Amide (Theoretical) | % Amide a (Determined) |

|---|---|---|---|

| PEA-001 | 95/5 | 0.7 | n.d. b |

| PEA-002 | 90/10 | 1.4 | 2.1 |

| PEA-003 | 80/20 | 2.8 | 2.5 |

| PEA-004 | 70/30 | 4.2 | 4.0 |

| PEA-005 | 60/40 | 5.6 | 5.7 |

| Reference | IA | DMA | HMDA | HDO | % Amide (Theoretical) | % Amide a (Determined) | % Isomerization b |

|---|---|---|---|---|---|---|---|

| PEA-101 | 0.8 | 0.2 | 0.068 | 1.282 | 2.9 | 3.8 | 22 |

| PEA-102 | 0.7 | 0.3 | 0.13 | 1.22 | 5.4 | 7.1 | 6 |

| PEA-103 | 0.5 | 0.5 | 0.23 | 1.12 | 9.1 | 8.4 | 40 |

| Copolymers | DBD (mmol/g) | ΔHtheo (J/g) | ΔHexp (J/g) | C (%) | RoP (s−1/1000) |

|---|---|---|---|---|---|

| OE | 4.13 | 250.3 | 145.3 | 58.0 | 21.4 |

| PEA-001 | 3.92 | 237.8 | 135.6 | 57.0 | 19.7 |

| PEA-002 | 3.71 | 225.3 | 143.8 | 63.8 | 19.6 |

| PEA-003 | 3.30 | 200.2 | 143.0 | 71.4 | 17.4 |

| PEA-004 | 2.89 | 175.2 | 120.8 | 69.0 | 16.0 |

| PEA-005 | 2.48 | 150.2 | 87.7 | 58.4 | 8.5 |

| PEA-101 | 3.0 | 151.7 | 93.9 | 61.9 | 7.7 |

| PEA-102 | 2.5 | 103.1 | 59.3 | 57.5 | 6.0 |

| PEA-103 | 1.7 | 182.0 | 93.7 | 51.5 | 7.2 |

| PEA | No. of Curing Runs | Surface Appearance |

|---|---|---|

| PEA-001 | 5 | dry |

| PEA-002 | 5 | dry |

| PEA-003 | 5 | dry |

| PEA-004 | 5 | sticky |

| PEA-005 | 10 | very sticky |

| PEA-101 | 5 | sticky |

| PEA-102 | 5 | sticky |

| PEA-103 | 10 | sticky |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ouhichi, R.; Pérocheau Arnaud, S.; Bougarech, A.; Abid, S.; Abid, M.; Robert, T. First Example of Unsaturated Poly(Ester Amide)s Derived From Itaconic Acid and Their Application as Bio-Based UV-Curing Polymers. Appl. Sci. 2020, 10, 2163. https://doi.org/10.3390/app10062163

Ouhichi R, Pérocheau Arnaud S, Bougarech A, Abid S, Abid M, Robert T. First Example of Unsaturated Poly(Ester Amide)s Derived From Itaconic Acid and Their Application as Bio-Based UV-Curing Polymers. Applied Sciences. 2020; 10(6):2163. https://doi.org/10.3390/app10062163

Chicago/Turabian StyleOuhichi, Rim, Sacha Pérocheau Arnaud, Abdelkader Bougarech, Souhir Abid, Majdi Abid, and Tobias Robert. 2020. "First Example of Unsaturated Poly(Ester Amide)s Derived From Itaconic Acid and Their Application as Bio-Based UV-Curing Polymers" Applied Sciences 10, no. 6: 2163. https://doi.org/10.3390/app10062163

APA StyleOuhichi, R., Pérocheau Arnaud, S., Bougarech, A., Abid, S., Abid, M., & Robert, T. (2020). First Example of Unsaturated Poly(Ester Amide)s Derived From Itaconic Acid and Their Application as Bio-Based UV-Curing Polymers. Applied Sciences, 10(6), 2163. https://doi.org/10.3390/app10062163