Water-Covered Roof Versus Inverted Flat Roof on the Mediterranean Coast: A Comparative Study of Thermal and Energy Behavior

Abstract

:Featured Application

Abstract

1. Introduction

1.1. Dynamic Behavior Versus Static Behavior

1.2. Roofing in Construction Envelopes

1.3. Reservoir Roofs and Water-Covered Roofs

1.4. Objectives

- Analyze whether incorporating materials in the construction section implies a possible accumulation of heat and regulation over time of indoor air temperature variations.

- Confirm whether water-covered roofs, which present greater thermal inertia than inverted flat roofs, improve thermal behavior.

- Quantify the values of thermal loads and energy demand for heating and cooling, in order to approximate the feasibility of this type of roofing in climates such as that of the Spanish Mediterranean coast in subsequent studies.

2. Description of the Two Case Studies: The Inverted Roof and Water-Covered Roof

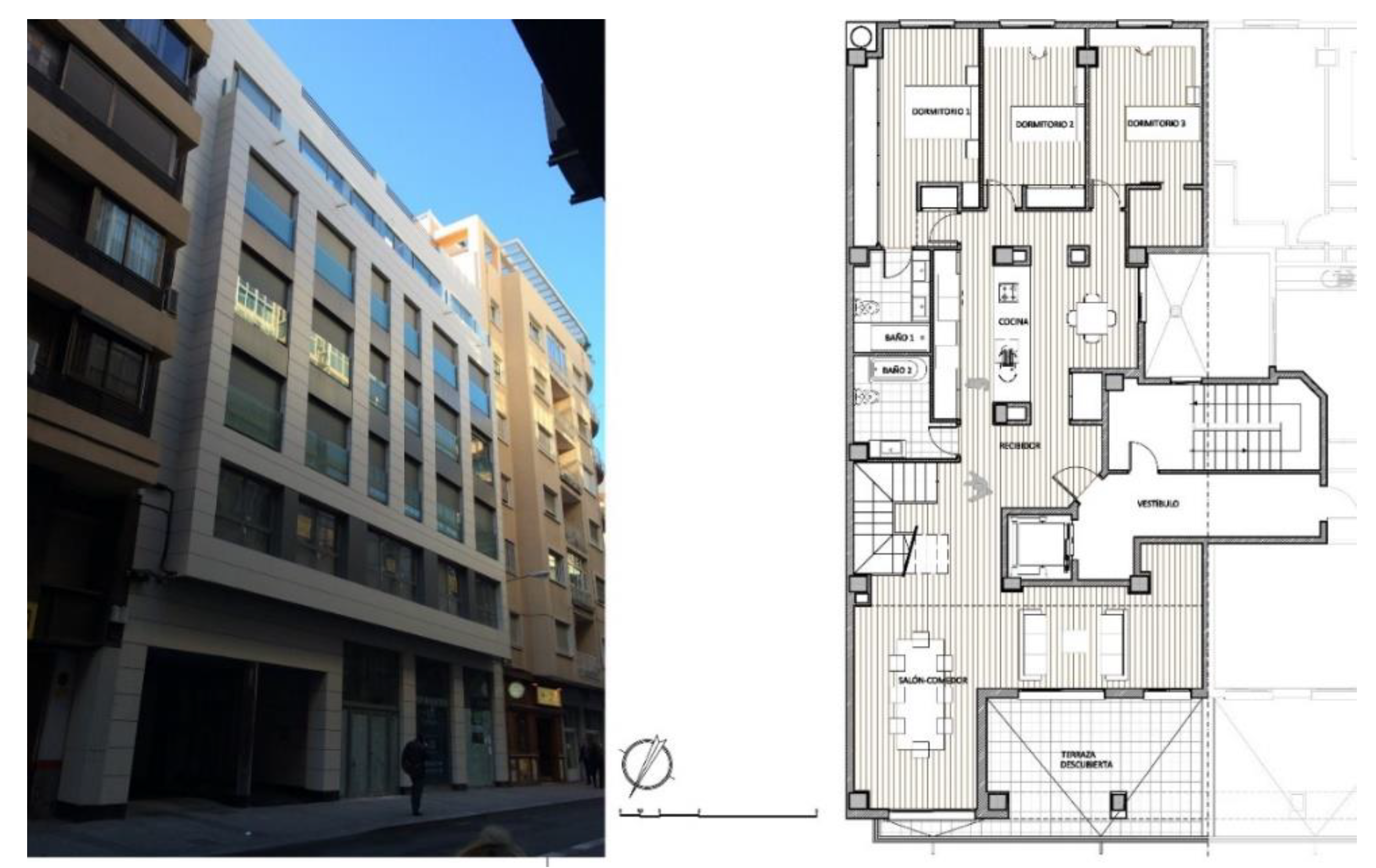

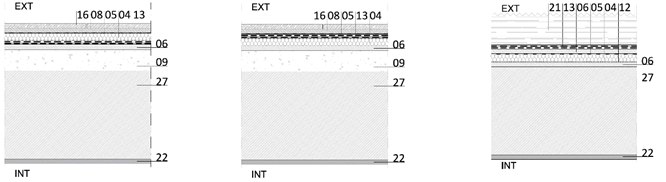

2.1. Walkable Inverted Flat Roof of a Housing Block

2.2. Water-Covered Flat Roof, MUA Building: Museum of the University of Alicante

3. Methods

3.1. Monitoring Both Roofs

3.2. Description of the Calibration Process

3.3. Description of the Roofs Analyzed According to Modifications to Existing Roofs

3.4. Calculation of Thermal Parameters in Dynamic Regime

3.4.1. Static and Dynamic Thermal Transmittance

3.4.2. Thermal Capacity in Dynamic Regime

3.4.3. Effusivity and Decrement Factor

3.4.4. Diffusivity and Time Lag

3.4.5. Thermal Admittance

3.5. Energy Demand Value Obtained by Simulation

3.5.1. Loft Flat in the City Centre of ALICANTE

3.5.2. Sempere Exhibition Hall at the MUA

- Heating period: from November to April.

- Cooling period: from May to October.

- Pre-set temperatures: 23 °C in summer and 21 °C in winter.

- During periods of low activity at Christmas, Easter and in August, the machines were stopped.

4. Results

4.1. Static and Dynamic Thermal Transmittance

4.2. Thermal Capacity in Dynamic Regime

4.3. Effusivity and Decrement Factor

4.4. Time Lag and Diffusivity

4.5. Thermal Admittance

4.6. Energy Demand According to the Energy Simulation

5. Conclusions

- Internal thermal capacities were similar, with a minimum variation of 5.7%.

- The outer thermal capacity of the water-covered roofs was 45% higher than the roofs with a stone or terrazzo finish.

- Decrement factor increased by about 9%.

- Time lag was reduced by 31%–34%.

- The internal thermal admittance value was virtually homogeneous in all sections. It only varied for values close to 0.05 W/m2K, so it was not a significant value.

- External thermal admittance was 35%–42% higher.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Roof Values (Residential (R) | |

| Roof Values (Museum (M) | |

| Thermal conductivity, | |

| Density, | |

| Specific heat capacity, | |

| Static thermal transmittance, | |

| Dynamic thermal transmittance, | |

| Total thermal resistance, | |

| Thermal resistances for each material layer defined, | |

| Surface thermal resistances corresponding to indoor and outdoor air, | |

| Material layer thickness, | |

| Heat flow density, | |

| Incoming thermal flow, | |

| Temperature | |

| Thermal capacity per surface unit, | |

| Decrement factor, | |

| Thermal effusivity, | |

| Time lag, (h) | |

| Thermal diffusivity | |

| Thermal admittance, (W/(m2K) | |

| acH | Air changes per hour, |

References

- IDAE. Ministerio para la Transición Ecológica. Consumos Energéticos por Ramas del Sector Servicios y Fuentes Energéticas Expresados en Unidades Energéticas. Available online: https://www.idae.es/sites/default/files/estudios_informes_y_estadisticas/cons_servic_2017_info_supl_web_ok.xls (accessed on 12 March 2019).

- IDAE. Ministerio para la Transición Ecológica. Consumo para usos y energías del sector residencial (2010–2015). Available online: https://www.idae.es/sites/default/files/estudios_informes_y_estadisticas/cons_usos_resid_eurostat_web_2010-17_ok.xlsx (accessed on 12 March 2019).

- European Commission. Directive 2010/31/EU of European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings (recast). Off. J. Eur. Union 2010, 18, 2010. [Google Scholar]

- Echarri, V.; Espinosa, A.; Rizo, C. Thermal Transmission through Existing Building Enclosures: Destructive Monitoring in Intermediate Layers versus Non-Destructive Monitoring with Sensors on Surfaces. Sensors 2017, 17, 2848. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aste, N.; Angelotti, A.; Buzzetti, M. The influence of the external walls thermal inertia on the energy performance of well insulated buildings. Energy Build. 2009, 41, 1181–1187. [Google Scholar] [CrossRef]

- Verbeke, S.; Audenaert, A. Thermal inertia in buildings: A review of impacts across climate and building use. Renew. Sustain. Energy Rev. 2018, 82, 2300–2318. [Google Scholar] [CrossRef]

- Aznar, F.; Echarri, V.; Rizo, C.; Rizo, R. Modelling the thermal behaviour of a building facade using deep learning. PLoS ONE 2018, 13, e0207616. [Google Scholar] [CrossRef] [Green Version]

- Serra, J.; Tenorio, J. Experiencia española de transición: Desde la dispersa normativa de la edificación prescriptiva hacia el nuevo Código Técnico de la Edificación 2006, una norma moderna y unificada, enfocada hacia las prestaciones. Rev. Ing. 2015, 38, 42–47. [Google Scholar] [CrossRef] [Green Version]

- Bienvenido-Huertas, D.; Rubio-Bellido, C.; Pérez-Ordóñez, J.L.; Oliveira, M.J. Automation and optimization of in-situ assessment of wall thermal transmittance using a Random Forest algorithm. Build. Environ. 2020, 168, 106479. [Google Scholar] [CrossRef]

- Orden FOM/588/2017 del 15 de junio, por la que se actualiza el Documento Básico de Ahorro de Energía DB-HE (Publicado en: «BOE» núm. 149, de 23 de junio de 2017); Spanish Ministry of Public Works and Transport: Madrid, Spain, 2017.

- Bienvenido-Huertas, D.; Moyano, J.; Rodriguez-Jimenez, C.E.; Marin, D. Applying an artificial neural network to assess thermal transmittance in walls by means of the thermometric method. Appl. Energy 2019, 233, 1–14. [Google Scholar] [CrossRef]

- Domínguez, M.; Santamaría, S. Importancia de la inercia térmica de los cerramientos. ConArquitectura 2001, 3, 49–56. [Google Scholar]

- Turégano, J.A.; Hernández, M.A.; Garcia, F. La inercia de los edificio y su incidencia en las condiciones de confort como refuerzo de los aportes de carácter pasiva. Conarquitectura 2003, 08, 65–80. [Google Scholar]

- Caro, R.; Sendra, J.J. Evaluation of indoor environment and energy performance of dwellings in heritage buildings. The case of hot summers in historic cities in Mediterranean Europe. Sustain. Cities Soc. 2020, 52, 101798. [Google Scholar] [CrossRef]

- Kaska, O.; Yumrutas, R. Comparison of experimental and theoretical results for the transient heat flow through multilayer walls and flat roofs. Energy 2008, 33, 1816–1823. [Google Scholar] [CrossRef]

- Al-Sanea, S.A. Thermal performance of building roof elements. Build. Environ. 2002, 37, 665–675. [Google Scholar] [CrossRef]

- Ben-Nakhi, A.; Mahmoud, A.M.; Mahmoud, M.A.; Al Dashti, A. Improving thermal performance of the roof enclosure of heavy construction buildings. Appl. Energy 2008, 85, 911–930. [Google Scholar] [CrossRef]

- Sharifi, A.; Yamagata, Y. Roof ponds as passive heating and cooling systems: A systematic review. Appl. Energy 2015, 160, 336–357. [Google Scholar] [CrossRef]

- Naticchia, B.; Fernandez-Gonzalez, A.; Carbonari, A. Bayesian Network model for the design of roofpond equipped buildings. Energy Build. 2007, 39, 258–272. [Google Scholar] [CrossRef]

- Neila, F.J.; Bedoya, C.; Acha, C.; Olivieri, F.; Barbero, M. Las cubiertas ecológicas de tercera generación: Un nuevo material constructive. Inf. Constr. 2008, 60, 15–24. [Google Scholar]

- Kruger, E.; Fernandes, L.; Lange, S. Thermal performance of different configurations of a roof pond-based system for subtropical conditions. Build. Environ. 2016, 107, 90–98. [Google Scholar] [CrossRef]

- Kuehni, S.M.S.; Bou-Zeid, E.; Webb, C.; Shokri, N. Roof cooling by direct evaporation from a porous layer. Energy Build. 2016, 127, 521–528. [Google Scholar] [CrossRef] [Green Version]

- Pearlmutter, D.; Berliner, P. Experiments with a ‘psychrometric’ roof pond system for passive cooling in hot-arid regions. Energy Build. 2017, 144, 295–302. [Google Scholar] [CrossRef]

- Sabzi, D.; Haseli, P.; Jafarian, M.; Karimi, G.; Taheri, M. Investigation of cooling load reduction in buildings by passive cooling options applied on roof. Energy Build. 2015, 109, 135–142. [Google Scholar] [CrossRef]

- Tan, C.L.; Tan, P.Y.; Wong, N.H.; Takasuna, H.; Kudo, T.; Takemasa, Y.; Lim, C.V.J.; Chua, H.X.V. Impact of soil and water retention characteristics on green roof thermal performance. Energy Build. 2017, 152, 830–842. [Google Scholar] [CrossRef]

- Scharf, B.; Zluwa, I. Case study investigation of the building physical properties of seven different green roof systems. Energy Build. 2017, 151, 564–573. [Google Scholar] [CrossRef]

- Tian, Y.; Bai, X.; Qi, B.; Sun, L. Study on heat fluxes of green roofs based on an improved heat and mass transfer model. Energy Build. 2017, 152, 175–184. [Google Scholar] [CrossRef]

- Morakinyo, T.E.; Dahanayake, K.W.D.; Kalani, C.; Ng, E.; Chow, C.L. Temperature and cooling demand reduction by green-roof types in different climates and urban densities: A co-simulation parametric study. Energy Build. 2017, 145, 226–237. [Google Scholar] [CrossRef]

- Schweitzer, O.; Erell, E. Evaluation of the energy performance and irrigation requirements of extensive green roofs in a water-scarce Mediterranean climate. Energy Build. 2014, 68, 25–32. [Google Scholar] [CrossRef]

- Silva, C.M.; Gloria Gomes, M.; Silva, M. Green roofs energy performance in Mediterranean climate. Energy Build. 2016, 116, 318–325. [Google Scholar] [CrossRef]

- Hong, T.; Kim, J.; Koo, C. LCC and LCCO2 analysis of green roofs in elementary schools with energy saving measures. Energy Build. 2012, 45, 229–239. [Google Scholar] [CrossRef]

- Zhao, D.; Aili, A.; Yin, X.; Tan, G.; Yang, R. Roof-integrated radiative air-cooling system to achieve cooler attic for building energy saving. Energy Build. 2019, 203, 109453. [Google Scholar] [CrossRef]

- Berardi, U.; La Roche, P.; Almodóvar, J.M. Water-to-air-heat exchanger and indirect evaporative cooling in buildings with green roofs. Energy Build. 2017, 151, 406–417. [Google Scholar] [CrossRef]

- Echarri Iribarren, V.; Espinosa Fernández, A.; Galiano Garrigós, A. Energy efficiency on flooded roofs: The University of Alicante Museum. WIT Trans. Eng. Sci. 2016, 106, 163. [Google Scholar]

- Leon, A.L.; Munoz, S.; Leon, J.; Bustamante, P. Monitoring environmental and energy variables in the construction of subsidised housing: Cros-Pirotecnia building in Sevilla. Inf. Constr. 2010, 62, 67–82. [Google Scholar] [CrossRef] [Green Version]

- Coakley, D.; Raftery, P.; Keane, M. A review of methods to match building energy simulation models to measured data. Renew. Sustain. Energy Rev. 2014, 37, 123–141. [Google Scholar] [CrossRef] [Green Version]

- Barrios, G.; Huelsz, G.; Rojas, J. Thermal performance of envelope wall/roofs of intermittent air-conditioned rooms. Appl. Ther. Eng. 2012, 40, 1–7. [Google Scholar] [CrossRef]

- Moujalled, B.; Oumeziane, Y.A.; Moissette, S.; Bart, M.; Lanos, C.; Samri, D. Experimental and numerical evaluation of the hygrothermal performance of a hemp lime concrete building: A long term case study. Build. Environ. 2018, 136, 11–27. [Google Scholar] [CrossRef]

- Aste, N.; Leonforte, F.; Manfren, M.; Mazzon, M. Thermal inertia and energy efficiency—Parametric simulation assessment on a calibrated case study. Appl. Energy 2015, 145, 111–123. [Google Scholar] [CrossRef]

- Pisello, A.L.; Cotana, F. The thermal effect of an innovative cool roof on residential buildings in Italy: Results from two years of continuous monitoring. Energy Build. 2014, 69, 154–164. [Google Scholar] [CrossRef]

- Ahmad, A.; Maslehuddin, M.; Al-Hadhrami, L.M. In situ measurement of thermal transmittance and thermal resistance of hollow reinforced precast concrete walls. Energy Build. 2014, 84, 132–141. [Google Scholar] [CrossRef]

- El Bachawati, M.; Manneh, R.; Belarbi, R.; El Zakhem, H. Real-time temperature monitoring for Traditional gravel ballasted and Extensive green roofs: A Lebanese case study. Energy Build. 2016, 133, 197–205. [Google Scholar] [CrossRef]

- Heo, Y.; Choudhary, R.; Augenbroe, G.A. Calibration of building energy models for retrofit analysis under uncertainty. Energy Build. 2012, 47, 550–560. [Google Scholar] [CrossRef]

- Stavrakakis, G.M.; Androutsopoulos, A.V.; Vyorykka, J. Experimental and numerical assessment of cool-roof impact on thermal and energy performance of a school building in Greece. Energy Build. 2016, 130, 64–84. [Google Scholar] [CrossRef]

- Kontoleon, K.J.; Theodosiou, T.G.; Tsikaloudaki, K.G. The influence of concrete density and conductivity on walls’ thermal inertia parameters under a variety of masonry and insulation placements. Appl. Energy 2013, 112, 325–337. [Google Scholar] [CrossRef]

- Ozel, M. Effect of insulation location on dynamic heat-transfer characteristics of building external walls and optimization of insulation thickness. Energy Build. 2014, 72, 288–295. [Google Scholar] [CrossRef]

- Marietta, L.; Evola, G.; Giuga, M. Using the dynamic thermal properties to assess the internal temperature swings in free running buildings. A general model and its validation according to ISO 13792. Energy Build. 2015, 87, 57–65. [Google Scholar] [CrossRef]

- Thermal Performance of Buildings Components—Dynamic Thermal Characteristics—Calculation Methods; ISO 13786:2017; International Organization for Standardization: Geneva, Switzerland, 2017.

- Nowoswiat, A.; Skrzypczyk, J.; Krause, P.; Steidl, T.; Winkler-Skalna, A. Estimation of thermal transmittance based on temperature measurements with the application of perturbation numbers. Heat Mass Transf. 2018, 54, 1477–1489. [Google Scholar] [CrossRef] [Green Version]

- Documento de Apoyo al Documento Básico Ahorro de energía, DA DB-HE/1, Cálculo de Parámetros Característicos de la Envolvente (2015). Available online: https://www.codigotecnico.org/images/stories/pdf/ahorroEnergia/DA-DB-HE-1-Calculo_de_parametros_caracteristicos.pdf (accessed on 16 January 2019).

- Kotsiris, G.; Androutsopoulos, A.; Polychroni, E.; Nektarios, P.A. Dynamic U-value estimation and energy simulation for green roofs. Energy Build. 2012, 45, 240–249. [Google Scholar] [CrossRef]

- Gasparella, A.; Pernigotto, G.; Baratieri, M.; Baggio, P. Thermal dynamic transfer properties of the opaque envelope: Analytical and numerical tools for the assessment of the response to summer outdoor conditions. Energy Build. 2011, 43, 2509–2517. [Google Scholar] [CrossRef]

- Rossi, M.; Rocco, V.M. External walls design: The role of periodic thermal transmittance and internal areal heat capacity. Energy Build. 2014, 68, 732–740. [Google Scholar] [CrossRef]

- Solé Bonet, J. Cálculos de las Características Térmicas de Elementos Constructivos en Régimen Dinámico. Herramienta Informática: Hoja de Cálculo Excel, Ursa Cálculo Térmico EN 6946 y EN 12354.xls., Barcelona. 2011. Available online: http://aipex.es/descargas.php?s=7&id=151 (accessed on 18 September 2018).

- Fathipour, R.; Hadidi, A. Analytical solution for the study of time lag and decrement factor for building walls in climate of Iran. Energy 2017, 134, 167–180. [Google Scholar] [CrossRef]

- Mazzeo, D.; Oliveti, G.; Arcuri, N. Influence of internal and external boundary conditions on the decrement factor and time lag heat flux of building walls in steady periodic regime. Appl. Energy 2016, 164, 509–531. [Google Scholar] [CrossRef]

- Ruivo, C.R.; Ferreira, P.M.; Vaz, D.C. On the error of calculation of heat gains through walls by methods using constant decrement factor and time lag values. Energy Build. 2013, 60, 252–261. [Google Scholar] [CrossRef]

- Sun, C.; Shu, S.; Ding, G.; Zhang, X.; Hu, X. Investigation of time lags and decrement factors for different building outside temperatures. Energy Build. 2013, 61, 1–7. [Google Scholar] [CrossRef]

- Alarcon, M.; Alhama, F.; Gonzalez-Fernandez, C.F. Transient conduction in a fin-wall assembly with harmonic excitation—Network thermal admittance. Heat Transf. Eng. 2002, 23, 31–43. [Google Scholar] [CrossRef]

- Shaik, S.; Gorantla, K. Setty, Ashok Babu Talanki Puttaranga Investigation of Building Walls Exposed to Periodic Heat Transfer Conditions for Green and Energy Efficient Building Construction. In Proceedings of the 3rd International Conference on Innovations in Automation and Mechatronics Engineering 2016, Iciame 2016, Vallabh Vidhyanagar, India, 5–6 February 2016; pp. 496–503. [Google Scholar]

- Saboor, S.; Babu, A.T.P. Effect of Air Space Thickness within the External Walls on the Dynamic Thermal Behaviour of Building Envelopes for Energy Efficient Building Construction. In Proceedings of the International Conference on Alternative Energy in Developing Countries and Emerging Economies, Bangkok, Thailand, 28–29 May 2015; pp. 766–771. [Google Scholar]

- Najim, K.B. External load-bearing walls configuration of residential buildings in Iraq and their thermal performance and dynamic thermal behaviour. Energy Build. 2014, 84, 169–181. [Google Scholar] [CrossRef]

- Evangelisti, L.; Guattari, C.; Asdrubali, F. Influence of heating systems on thermal transmittance evaluations: Simulations, experimental measurements and data post-processing. Energy Build. 2018, 168, 180–190. [Google Scholar] [CrossRef]

- Crawley, D.B.; Hand, J.W.; Kurnmert, M.; Griffith, B.T. Contrasting the capabilities of building energy performance simulation programs. Build. Environ. 2008, 43, 661–673. [Google Scholar] [CrossRef] [Green Version]

- Design Builder Software. Design Builder EnergyPlus Simulation Documentation for Design Builder V. 4.5.; Design Builder Sortware Ltd.: Stroud, UK, 2015. [Google Scholar]

- Orden FOM/588/2017, de 15 de Junio, por la que se Actualiza el Documento Básico DB-HS Salubridad, Sección HS 3, Calidad del aire Interior, del Código Técnico de la Edificación, Aprobado por Real Decreto 314/2006, de 17 de Marzo. (Publicado en: «BOE» núm. 149, de 2 de Junio de 2017) Madrid, Spanish Ministry of Public Works and Transport. 2017. Available online: https://www.codigotecnico.org/images/stories/pdf/salubridad/DccHS.pdf (accessed on 4 December 2018).

- Feijo-Munoz, J.; Pardal, C.; Echarri, V.; Fernandez-Aguera, J.; Assiego de Larriva, R.; Montesdeoca Calderin, M.; Poza-Casado, I.; Angel Padilla-Marcos, M.; Meiss, A. Energy impact of the air infiltration in residential buildings in the Mediterranean area of Spain and the Canary islands. Energy Build. 2019, 188, 226–238. [Google Scholar] [CrossRef]

- Real Decreto 314/2006 de 17 de Marzo por el que se Aprueba el Código Técnico de la Edificación, CTE. (Publicado en: «BOE» núm. 74, de 28 de Marzo de 2006, pp. 11816–11831). Madrid, Spanish Ministry of Housing. 2006. Available online: http://www.codigotecnico.org/images/stories/pdf/realDecreto/RD3142006.pdf (accessed on 16 April 2019).

- Bienvenido-Huertas, D.; Fernandez Quinones, J.A.; Moyano, J.; Rodriguez-Jimenez, C.E. Patents Analysis of Thermal Bridges in Slab Fronts and Their Effect on Energy Demand. Energies 2018, 11, 2222. [Google Scholar] [CrossRef] [Green Version]

- AnTherm—Analysis of Thermal Behaviour of Building Constructions with Heat and Vapour Bridges. Program for Energy Simulation by Kornicki Dienstleistungen in EDV & IT, Vienna. 2016. Available online: http://www.antherm.at/antherm/EN/ (accessed on 18 September 2018).

- Echarri-Iribarren, V.; Sotos-Solano, C.; Espinosa-Fernandez, A.; Prado-Govea, R. The Passivhaus Standard in the Spanish Mediterranean: Evaluation of a House’s Thermal Behaviour of Enclosures and Airtightness. Sustainability 2019, 11, 3732. [Google Scholar] [CrossRef] [Green Version]

- Sanchez-Ostiz, A.; Monge-Barrio, A.; Domingo-Irigoyen, S.; Gonzalez-Martinez, P. Design and experimental study of an industrialized sunspace with solar heat storage. Energy Build. 2014, 80, 231–246. [Google Scholar] [CrossRef]

| QR_1_ Inverted flat roofs _Total thickness = 0.467 m | |||

|---|---|---|---|

| Horizontal Construction and Upward Flow | Thickness (m) |  | |

| Outside environment | |||

| 16 | Paving file | 0.015 | |

| 08 | Mortar bed | 0.015 | |

| 05 | Membrane: Non-woven geotextile Thermosol | 0.001 | |

| 04 | Thermal insulation: XPS [0.032 W/[mK]] | 0.030 | |

| 13 | Water proofing membrane: LBM-30-FV, LBM-40-FP | 0.006 | |

| 06 | Mortar bed | 0.015 | |

| 09 | Aerated concrete | 0.070 | |

| 27 | Reinforced concrete | 0.300 | |

| 22 | Trim and plaster | 0.015 | |

| Inside environment | |||

| QM_1_ Roofs Flooded with Water _Total thickness = 0.724 m | |||

|---|---|---|---|

| Horizontal Construction and upward Flow | Thickness (m) |  | |

| Outside environment | |||

| 21 | Water | 0.100 | |

| 13 | Water proofing membrane: LBM-30-FV, LBM-40-FP | 0.006 | |

| 05 | Membrane: Non-woven geotextile Thermosol | 0.001 | |

| 42 | Reinforced concrete | 0.100 | |

| 43 | Galvanized steel sheet | 0.002 | |

| 25 | Air gaps. No ventilated R=0.28 | 0.500 | |

| 23 | Plasterboard | 0.015 | |

| Inside environment | |||

| Nomenclature, QR: Roof (Q), Residential (R) Interior environment, (INT): QR,INT. Indoor ambient temperature sensor, (°C). Nº of sensors installed: 1. Constructive section: QR,0,1,2,3,4,5,6,7. Surface temperature sensor, (°C). Nº of sensors installed: 8. Outdoor environment (EXT): QR,EXT. Exterior ambient temperature sensor, (°C) and relative humidity (%). Number of sensors installed: 1. QR,SOLAR. Solar radiation sensor, (W/m2). Number of sensors installed: 1. |

| Nomenclature, QM: Roof (Q), Museum (M) Interior environment, (INT): QM,INT. Indoor ambient temperature sensor, (°C ). Nº of sensors installed: 1. Constructive section: QM,1,2,3. Surface temperature sensor, (°C). Number of sensors installed: 3. Outdoor environment (EXT): QM,EXT,MUA. Exterior ambient temperature sensor, (°C) and relative humidity (%). Number of sensors installed: 1. QM,SOLAR. Solar radiation sensor, (W/m2). Number of sensors installed: 1. |

| Roof of Loft Flat. Housing Block | ||

|---|---|---|

| Original Roof | Proposed Roofs | |

| QR_1 | QR_2 | QR_2.1_0.15 |

| Inverted walkable flat roof | Walkable conventional flat roof | Conventional water-covered roof, water sheet 15 cm thick |

| ||

| Exhibition Hall roof. University Museum of Alicante | ||

|---|---|---|

| Original roof | Proposed roofs | |

| QM_1 | QM_2 | QM_2.1_0.15 |

| Water-covered roof | Walkable conventional flat roof | Conventional water-covered roof, water sheet 15 cm thick |

| ||

| Material | (W/m K) | (W/m K3) | ||

|---|---|---|---|---|

| 04 | Thermal insulation: XPS [0.032 W/[mK]] | 0.032 | 37.5 | 1450 |

| 05, 12 | Membrane: Non-woven geotextile Thermosol | 0.05 | 120 | 1300 |

| 06, 08 | Mortar bed | 0.88 | 2100 | 1050 |

| 09 | Aerated concrete | 0.12 | 400 | 896 |

| 13 | Water proofing membrane: LBM-30-FV, LBM-40-FP | 0.23 | 1100 | 1800 |

| 16 | Paving file | 1.3 | 1700 | 800 |

| 18 | Marble | 3.5 | 2700 | 858 |

| 21 | Water | 0.6 | 1000 | 4190 |

| 22 | Trim and plaster | 0.570 | 1150 | 830 |

| 23 | Plasterboard | 0.250 | 825 | 790 |

| 25 | Air gaps. No ventilated R = 0.28 W/[mK] | 1785 | 1100 | 1010 |

| 27 | Reinforced concrete type 1 | 2 | 2285 | 1000 |

| 42 | Reinforced concrete type 2 | 2.3 | 2400 | 1150 |

| 43 | Galvanized steel sheet | 50 | 7800 | 450 |

| Loft Flat Roofs. Housing Block | Exhibition Hall Roofs. MUA | ||||

|---|---|---|---|---|---|

| Static Thermal Transmittance U and Dynamic Thermal Transmittance Yie | |||||

| Sections | Static U, W/m2K | Dynamic Yie, W/m2K | Sections | Static U, W/m2K | Dynamic Yie, W/m2K |

| QR_1 | 0.518 | 0.058 | QM_1 | 0.470 | 0.040 |

| QR_2 | 0.518 | 0.063 | QM_2 | 0.470 | 0.043 |

| QR_2.1_0.15 | 0.629 | 0.016 | QM_2.1_0.15 | 0.558 | 0.011 |

| Loft Flat Roofs. Housing Block | Exhibition Hall Roofs. MUA | ||||

|---|---|---|---|---|---|

| Thermal Capacity in Transient State κ1, κ2 | |||||

| Sections | Per outside surface unit, κ2, KJ/m2K | Per indoor surface unit, κ1, KJ/m2K | Sections | Per outside surface unit, κ2, KJ/m2K | Per indoor surface unit, κ1, KJ/m2K |

| QR_1 | 54.461 | 80.004 | QM_1 | 82.050 | 34.226 |

| QR_2 | 59.840 | 80.074 | QM_2 | 89.089 | 32.803 |

| QR_2.1_0.15 | 129.001 | 78.983 | QM_2.1_0.15 | 129.105 | 32.222 |

| Material | Effusivity, s1/2W/m2°C | Decrement Factor % | |

|---|---|---|---|

| 04 | Thermal insulation: XPS [0.032W/[mK]] | 34.641 | 17.82 |

| 05,12 | Membrane: Non-woven geotextile Thermosol | 88.318 | 1.06 |

| 06,08 | Mortar bed | 1286.782 | 12.41 |

| 08 | |||

| 09 | Aerated concrete | 219.089 | 53.80 |

| 13 | Water proofing membrane: LBM-30-FV, LBM-40-FP | 502.991 | 7.62 |

| 16 | Paving file | 1486.607 | 9.85 |

| 18 | Marble | 3074.085 | 12.42 |

| 21 | Water | 1585.560 | 90.88 |

| 22 | Trim and plaster | 809.630 | 12.08 |

| 23 | Plasterboard | 454.148 | 15.18 |

| 25 | Air gaps. No ventilated R=0.28 | 5.00 | 6.93 |

| 27 | Reinforced concrete (reticular) | 1603.122 | 76.61 |

| 42 | Reinforced concrete | 2349.468 | 46.05 |

| 43 | Galvanized steel sheet | 13,247.641 | 0.32 |

| Loft Flat Roofs. Housing Block | Exhibition Hall Roofs. MUA | ||

|---|---|---|---|

| Decrement Factor, % | |||

| Sections | Sections | ||

| QR_1 | 88.82% | QM_1 | 92.14% |

| QR_2 | 87.89% | QM_2 | 89.66% |

| QR_2.1_0.15 | 97.45% | QM_2.1_0.15 | 97.77% |

| Material | Diffusivity, m2/s | ||

|---|---|---|---|

| 04 | Thermal insulation: XPS [0.032W/[mK]] | 8.53 × 10−7 | 0.75 |

| 05,12 | Membrane: Non-woven geotextile Thermosol | 3.21 × 10−7 | 0.04 |

| 06,08 | Mortar bed | 4.68 × 10−7 | 0.51 |

| 09 | Aerated concrete | 3.00 × 10−7 | 2.95 |

| 13 | Water proofing membrane: LBM-30-FV, LBM-40-FP | 2.09 × 10−7 | 0.30 |

| 16 | Paving file | 7.64 × 10−7 | 0.40 |

| 18 | Marble | 1.30 × 10−6 | 0.51 |

| 21 | Water | 2.09 × 10−7 | 9.15 |

| 22 | Trim and plaster | 4.95 × 10−7 | 0.49 |

| 23 | Plasterboard | 3.03 × 10−7 | 0.63 |

| 25 | Air gaps. No ventilated R = 0.28 | 2.48 × 10−5 | 6.93 |

| 27 | Reinforced concrete (reticular) | 1.55 × 10−6 | 5.55 |

| 42 | Reinforced concrete | 9.58 × 10−7 | 2.36 |

| 43 | Galvanized steel sheet | 1.42 × 10−5 | 0.32 |

| Loft Flat Roofs. Housing Block | Exhibition Hall Roofs. MUA | ||

|---|---|---|---|

| Time Lag, h | |||

| Sections | Sections | ||

| QR_1 | 11.456 | QM_1 | 11.252 |

| QR_2 | 11.492 | QM_2 | 11.341 |

| QR_2.1_0.15 | 17.345 | QM_2.1_0.15 | 16.265 |

| Loft Flat Roofs. Housing Block | Exhibition Hall Roofs. MUA | ||||||

|---|---|---|---|---|---|---|---|

| Thermal Admittance Y11, Y12 | |||||||

| Sections | External | Internal | Sections | External | Internal | ||

| QR_1 | 3.947 | 5.766 | QM_1 | 9.471 | 2.282 | ||

| QR_2 | 4.335 | 5.766 | QM_2 | 6.454 | 2.342 | ||

| QR_2.1_0.15 | 9.392 | 5.751 | QM_2.1_0.15 | 9.392 | 2.344 | ||

| Thermal Loads kWh/year | Annual Energy Demand kWh/m2 year | ||||||

|---|---|---|---|---|---|---|---|

| Heating | Cooling | Total loads | Heating | Cooling | Total | ||

| Total | Transmission on roof | ||||||

| QR_1 | 2829.5 | 4617.9 | 7447.4 | 1414.9 | 23.424 | 36.636 | 60.060 |

| QR_2 | 2842.6 | 4706.1 | 7548.7 | 1435.1 | 23.705 | 38.148 | 61.853 |

| QR_2.1_0.15 | 2548.5 | 4228.2 | 6776.7 | 1287.0 | 20.222 | 33.991 | 54.213 |

| QM_1 | 14,560.3 | 23,741.8 | 38,301.8 | 7278.2 | 42.394 | 75.366 | 117.760 |

| QM_2 | 15,256.4 | 24,681.7 | 39,938.1 | 7398.3 | 43.449 | 78.726 | 122.175 |

| QM_2.1_0.15 | 12,795.5 | 21,785.4 | 34,580.9 | 6621.4 | 38.708 | 65.627 | 104.335 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Espinosa-Fernández, A.; Echarri-Iribarren, V.; Sáez, C.A. Water-Covered Roof Versus Inverted Flat Roof on the Mediterranean Coast: A Comparative Study of Thermal and Energy Behavior. Appl. Sci. 2020, 10, 2288. https://doi.org/10.3390/app10072288

Espinosa-Fernández A, Echarri-Iribarren V, Sáez CA. Water-Covered Roof Versus Inverted Flat Roof on the Mediterranean Coast: A Comparative Study of Thermal and Energy Behavior. Applied Sciences. 2020; 10(7):2288. https://doi.org/10.3390/app10072288

Chicago/Turabian StyleEspinosa-Fernández, Almudena, Víctor Echarri-Iribarren, and Claudio A. Sáez. 2020. "Water-Covered Roof Versus Inverted Flat Roof on the Mediterranean Coast: A Comparative Study of Thermal and Energy Behavior" Applied Sciences 10, no. 7: 2288. https://doi.org/10.3390/app10072288