1. Introduction

Generally, the robotic mechanisms can be categorized into three main groups: the open-loop mechanism, the closed-loop mechanism and the hybrid mechanism. A robot of the first group is usually designed with an end-effector connected to a fixed base by means of a single serial kinematic chain. Meanwhile, each robot of the second group is a mechanism which is usually composed of a moving end-effector connected to a fixed base by at least two kinematic chains, such as the parallel robots. A hybrid manipulator is a mechanism which is usually composed of some open-loop kinematic chains combined with some closed-loop linkages [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30,

31,

32,

33,

34].

The main advantages of the serial robots are the large workspace, the high dexterity of the end-effector and the large non-singular range of the joint variables. However, the robots of this group suffer from several drawbacks, such as relatively low stiffness and accuracy, low nominal load/weight ratio and heavy structure [

21]. Therefore, in the last decades, several types of robots having closed-loop kinematic chains have been investigated in order to obtain better kinematic performances. The main advantages of these robots are low weight, compact structure, better accuracy and stiffness. Nevertheless, this robot group also have some disadvantages, such as a small workspace, a complex mechanical design and a complex procedure for dynamic modelling and control. For these reasons, in recent years, great attention has been paid to the development of hybrid robots which have combined advantages of the serial robots and the closed-loop architectures. More and more hybrid robots are designed and developed to meet the increasing demand for a wide spectrum of hybrid robotic applications [

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30].

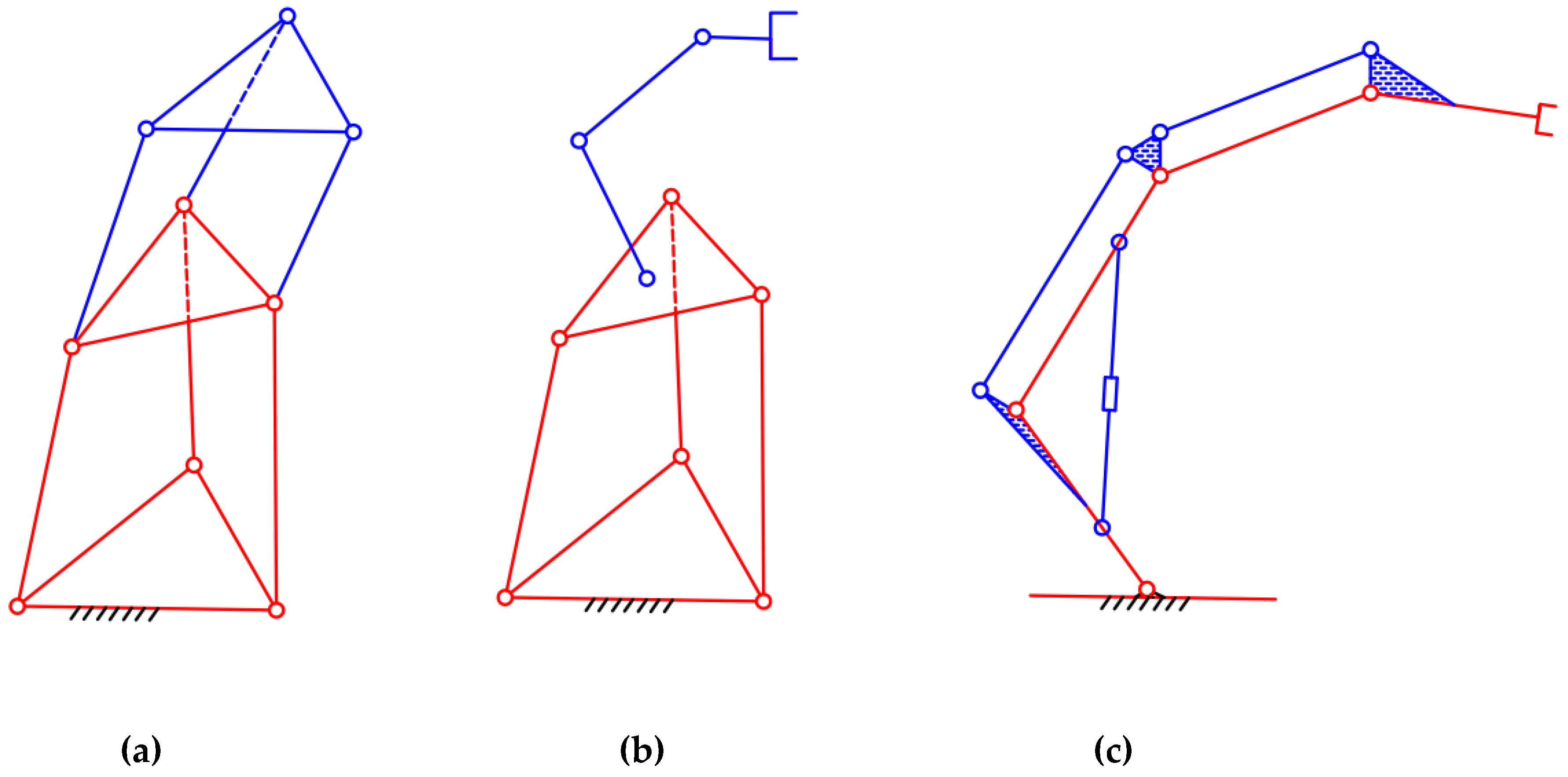

In practice, the hybrid robots have been designed in a large variety of kinematic configurations and structures, and they can be classified into three main classes as follows:

The first class (Class I) includes all the hybrid robots whose structure has several parallel modules connected in series [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10] (

Figure 1a).

Class II consists of the hybrid robots which have a basic parallel module combined with a serial manipulator [

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24] (

Figure 1b).

Class III is a family of the hybrid robots which are composed of some local closed-loop chains appended to a main serial mechanism [

25,

26,

27,

28,

29,

30,

31,

32,

33] (

Figure 1c).

It is clearly seen that the main architecture of a hybrid robot Class I or II is a parallel mechanism. Other parallel modules or serial links are connected to such the main structure to complete a hybrid serial-parallel robot.

Different from the robots Class I and II, each hybrid robot Class III is usually designed with a serial module as the main structure of a robot. To provide with desirable mechanical advantages for a hybrid robot, some local closed-loop mechanisms are added to the main serial module. For example, when designing manipulators which suffer a heavy payload and operate in a large workspace, parallelograms were added and hydraulic cylinders were used for driving some revolute joints of the manipulators [

26,

28,

29,

30,

31]. The addition of parallelograms to the main arm is to increase the rigidity of the robot, and also to restrict the orientation of the end- effector as desired. The use of the hydraulic cylinders is to increase the structural stiffness and to avoid the counterweights for the robot structure. The parallelograms and cylinders and other links of the serial arm naturally compose local closed loops of the entire robot mechanism. Other examples of using local closed-loop linkages to optimize the design and control for a robot can be found in [

26,

27,

28,

29,

30,

31,

32,

33,

34].

In recent decades, a huge number of hybrid robot prototypes and products have been designed and developed [

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30]. The dynamic modelling and control for some of these complex robots have been addressed as well. However, to develop a generic method for formulating the dynamic model of a generalized hybrid robot mechanism is challenging.

In the literature, there have been efforts that focused on the kinematic modelling of the hybrid robots Class I [

1,

2,

3,

4,

5]. The kinematic modelling and analysis of two serially connected parallel mechanisms were investigated in [

1]. In [

2], the kinematic redundancy issue of a serial-parallel manipulator was addressed. The Screw theory and the Jacobian approach were applied for the kinematic modelling of a serial-parallel robot [

3,

4]. In particular, the dynamics and the structural stiffness models of some specific hybrid robots Class I were formulated and analysed [

6,

7,

8,

9].

There have also been attempts working on the modelling and analysis of the hybrid robots Class II [

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21]. A real-time implementation of path planning, trajectory generation, and servo control for a hybrid manipulation was presented in [

11]. The kinematic modelling, the kinematic design, the workspace modelling and other aspects related to the kinematics of the hybrid robots Class II were studied [

12,

13,

14,

15,

16,

17]. The dynamic modelling and analysis of the robots Class II were also investigated [

18,

19]. In addition, the structural synthesis and the stiffness of the hybrid robots of this class were studied [

20,

21,

22].

Apart from the aforementioned works, there have been investigations that emphasized on design and development of the hybrid robots Class III [

25,

26,

27,

28,

29,

30,

31,

32,

33]. A valuable comparison of the conventional serial robot architectures and the hybrid robots Class III was presented in [

34]. In the research [

25], some theoretical issues related to the kinematic modelling of multi closed-loop mechanisms were addressed. In addition, some closed-form solutions to the kinematics problem of individual hybrid robots Class III were presented in [

26,

27,

28]. These solutions played an important role in validating the design of the robots. The workspace and mobility analysis were also investigated in [

28,

29]. Other aspects related to the design analysis of heavy-duty robots were presented in [

30,

31]. The control issues were studied in [

32,

33]. It is noticeable that the dynamic modelling of a hybrid manipulator Class III (forestry robot) was investigated in [

33]. However, the effects of the local closed-loops on the dynamic responses of this robotic system were overlooked.

Most of the efforts working on the hybrid robots Class III mainly focused on the design and control of some individual robots for the kinematical aspects. Though the dynamic modelling of the robots was addressed in a few researches, e.g., [

33], however, the mass and inertia of the local closed-loop linkages that have significant effects on the robot motion were neglected; the geometrical and kinematical constraints due to the presence of the local closed-loop linkages were usually ignored. Moreover, little attention has been paid to the development of a general method for the kinematic and dynamic modelling of this robot class. Therefore, in this paper, a new method for designing the kinematic chain and formulating the dynamic model of the hybrid robots is developed. First, a generic scheme for the kinematic design of a generalized hybrid robot mechanism is proposed. In this scheme, the generalized hybrid mechanism is synthesized with m local closed-loop linkages appended to a general n-link serial manipulator. Each locally closed linkage is regarded as a four bars mechanism which is made up of two successive links of the main serial arm, and other two added links. Second, the kinematic equation for the generalized hybrid mechanism and constraint equations for the closed loops are derived in a generalized case. Third, a Lemma about the relationship among the generalized velocities of the hybrid robots is proven, which is useful for transforming the dynamic equation and constraint equations into a minimal and compact form. Last, the kinematic and dynamic modelling of a real robot prototype are presented to demonstrate and validate the proposed method. It is shown clearly that, since the kinematic and dynamic modelling of a hybrid robot take into account the constraint equations and the dynamic effects of all the local closed loops, the kinematics and dynamics models of a hybrid robot are formulated in a better and more accurate manner. Therefore, the method proposed in this study is advantageous and plays a crucial role in the development of hybrid robot products.

2. Kinematics of a Generalized Mechanism for The Hybrid Robots Class III

Let us consider a manipulator which is designed with n serial links

and m local closed-loop mechanisms

, (

) as shown in

Figure 2. The serial chain of n links is the main mechanism of the robot arm, and the closed-loop mechanisms are designed as sub-mechanisms appended to the main one. The degree of freedom number (DOFs) of the designed robot equals the DOFs of the main mechanism,

. The presence of the local closed-loop mechanisms does not change the DOFs of the robot.

Each local closed mechanism

is designed with two successive links

and

of the main arm and other two appended links

and

. See

Figure 2 and

Figure 3. In other words, each local closed-loop mechanism is designed as a four bar linkage which is composed of the links

,

,

and

. In a local closed chain linkage, the link

is a local base link, and the remained links

,

and

move relative to the base link

.

As shown in

Figure 3, there exists four types of the local closed-loops, Type A, B, C and D, which can be designed by combining a couple of successive links

and

of the main arm and other two links

and

added to the robot architecture.

In a local closed-loop Type A (

Figure 3a), the two links

and

are added to the main arm, and the output link is a link

. Meanwhile in Type B (

Figure 3b), the two links

and

are inserted in between the links

and

, but the output link is the link

. When a loop Type B is added to the main kinematic chain, the link

is inserted in between

and

.

When the two links

and

are not connected together, there exists two more combinations of the links

,

,

and

as shown in

Figure 3c,d. In a loop Type C, the output link is

, meanwhile in Type D, the output link is

.

For all four types of the local linkages, the base link is , and the formation of all the closed-loop mechanisms does not change the DOFs of the robot.

Let us consider the main kinematic chain of the hybrid robot. In

Figure 2,

is the reference frame, and

to

are the local coordinate systems which are attached to all the links of the main arm. Let us denote

as the vector of joint variables on the main arm, correspondingly.

As usual, the geometric and kinematic parameters of a link

are denoted as

,

,

and

. By using the Denavit–Hartenberg notation, the transformation matrix for the end-effector (EEF) can be calculated as follows:

where

is the transformation matrix for a link

.

In other words,

can be expressed as follows:

where

is the rotation matrix, and

is the translation vector for the EEF. Equation (2) describes the kinematic relationship of the robot. If we denote

as the posture of the EEF in

, where

is the position and

the orientation of the EEF, the kinematic equation can be written as follows:

Let us consider all the local-closed loops Type A, B, C or D, which can be added to the main kinematic chain, as shown in

Figure 3. The presence of a closed chain Type A does not change Equation (1). However, Equation (1) must be recalculated if a closed loop Type B, C or D is designed for the robot.

For a local linkage Type B, since a link

is inserted in between

and

, the transformation matrix

in Equation (1) must be recalculated as follows:

For a local linkage Type C and D, the matrix

is replaced by the following matrix:

In particular, for a linkage Type D, not only

is re-calculated with Equation (5), but also the matrix

must be re-calculated as follows:

Note that the variables and in Equations (4)–(6) can be determined with respect to via the two constraint equations of a corresponding closed-loops , which will be presented later in the next section.

Constraint equations

Different from the formulation of the kinematics model for a serial robot, the formulation of the hybrid kinematics models of the hybrid robots Class III must take into account the constraints due to the presence of the local closed-loops.

As discussed before, each linkage

includes two sub-kinematic chains that move relative to the base link. For example, as shown in

Figure 4a, the first sub-chain of a linkage Type A is the link

, and the second sub-chain includes the two link

and

. Obviously, the two sub-chains of a linkage are closed at an intersection point M (see

Figure 4).

In order to derive the constraint equation for a loop , the position of the point M are determined along the two sub-chains.

On one hand, the point M,

represented in the coordinate

of the link

, can be determined via the position and orientation of the link

that can be calculated relative to the base link

. On the other hand, the point M,

expressed in

, can be calculated through the position and orientation of the link

. Consequently, the constraint equation for a loop Type A and B can be yielded as follows:

For a loop Type C and D the constraint equation can be written as follows:

Note that, for a closed-loop Type A or Type C, the point M coincides the point , thus . In addition, for a closed-loop Type B or Type D, .

In essence, Equations (7) and (8) can be rewritten as three constraint equations corresponding to three axes of the coordinate system

. However, among such the three constraint equations, there exist only two independent ones, since all the closed-loops under consideration are planar four bar linkages. As a consequence, corresponding to a loop

, the two independent constraint equations can be written as follows:

For every local linkage, only one joint variable among , and is independent. The kinematic relationships among , and are determined via the two constraint equations, Equation (9), for each closed-loop . Therefore, in the case that, instead of , the variable or is selected as the independent joint variable of , the variable in the transformation matrix in Equation (1) must be changed by the variable or , respectively, where the functions and can be determined with respect to the kinematic relationships among , and .

3. Dynamic Modelling of the Hybrid Robots Class III

is the vector of independent generalized coordinates which are selected among joint variables of the main arm, and joint variables of closed-loops. In other words, is the vector of all active joint variables.

is the vector of dependent generalized coordinates.

is the vector of all generalized coordinates of the robot system.

is the vector of constraint equations.

is the vector of applied torques/forces.

By using the Lagrangian formulation, the equations of motion including constraint equations for the robot can be written as follows:

Note that the size of the global matrices and is . The global mass matrix must be formulated with respect to all the links of the robot including links of the serial chain and links added to local closed-loops.

The global mass matrix is calculated as follows:

where

and

are the mass and inertia of a link

. The translational and rotational Jacobian matrices are calculated as

and

, where

is the centre of mass, and

is the angular velocity of a link

, respectively.

The Coriolis and centrifugal matrix is calculated by using Cristoffel notation.

The matrix

is calculated as follows:

where the total potential energy of the entire system is calculated as

The Jacobian matrix is derived with respect to constraint equations as , and is the vector of Lagrangian Multipliers.

It is clear that the system of DAE equations seen in Equation (11) consists of differential equations of second order and constraint equations . Moreover, Equation (10) has not only independent variables , but also dependent variables and unknown Lagrangian Multipliers . Therefore, if using this complex system of DAEs to analyse the dynamics behaviour and to design a control law for the robot, the time complexity of the formulation and computation will be increased dramatically. For this reason, it is necessary to transform Equation (10) into a more compact form in which the Lagrangian Multipliers should be cancelled, and the number of the differential equations is minimized.

By using the following Lemma, differential equations of second order, Equation (10), can be transformed into only differential equations of second order which are expressed in terms of only independent generalized coordinates, not including Lagrangian Multipliers .

Lemma. Consider a generalized hybrid robot mechanism Class III which has independent joint variables and dependent joint variables . The relationship between and is expressed as , in which the matrix is explicitly calculated as , where is an identity matrix of appropriate dimension, and , where is the constraint equation.

As a consequence of this Lemma, the following important relationships, Equations (14) and (15), can be proved easily.

In Equation (14), the Jacobian matrix

can be expressed as follows:

Note that Equations (14) and (15) play a very important role in transforming the complex system Equation (10) into a minimal form. With respect to Equations (14) and (15), multiplying

with both sides of Equation (10) yields

where

,,, and .

Different from the complex ADEs system in Equation (10), which has differential equations with the presence of dependent variables , and unknown Lagrangian Multipliers , the minimal form of the dynamic equation, Equation (17), consists of only differential equations which are expressed for independent generalized coordinates only. Moreover, the matrix form of Equation (17) is similar to the form of any dynamic equation that is usually written for a conventional industrial robot. Hence, by using Equation (17), the dynamic analysis and control law computation for any complex hybrid robot Class III can be implemented in an effective and simplified manner.

Proof of the Lemma. Taking a time derivative of the constraint equation

yields

Substituting Equation (16) into Equation (18) obtains

Rewriting the relationship

in the following form:

Note that is an identity matrix and is an unknown matrix which needs to be proved.

With respect to Equation (20), the vector

can be expressed as follows:

Multiplying

with both sides of Equation (21) yields

Substituting Equation (22) into Equation (19) yields

Finally, substituting Equation (24) into Equation (20) yields

Equation (25) completes the proof. □

4. Example: Kinematic and Dynamic Modelling of a Real Robot

In this section, the kinematic and dynamic modelling of a newly designed hybrid robot Class III are presented. The robot was designed and implemented with the purpose of handling material for a hot forging press shop floor. The 3D design of the robot and the robot prototype are shown in

Figure 5a,b, respectively. The functional tests of the robot prototype and the numerical simulation of the kinematic and dynamic responses shows clearly the effectiveness and advantages of the method proposed in this study.

The kinematic diagram of the robot is presented in

Figure 6, which is designed with 4 serial links

, and 4 local closed loops

(

Figure 7). The reference frame

is located on the ground. The coordinate systems

,

,

and

are located on the serial links.

The joint variables of the main serial chain are

(

Figure 6).

Each local closed loop presented in

Figure 7 is a four-bar linkage which is made up of two serial links (in red colour) and other two additional links (in green colour). Note that

and

are the loops of Type A;

and

are the loops of Type B.

The loop

includes the link

,

,

and

. The joint variables of the loop are

,

and

. The loop

consists of

,

,

and

. The joint variables of the loop are

,

and

. The loop

consists of

,

,

and

. The joint variables of the loop are

,

and

. The loop

consists of

,

,

and

. The joint variables of the loop are

,

and

.

Table 1 presents the Denavit–Hartenberg notations of the four loops.

Table 2 presents the dynamics parameters of the robot.

The length of the links are given as follows: ; ; ; ; ; ; ; ; ; ; ; .

Note that , , , , , , , , , , and are 12 generalized coordinates of the robot, in which

is the vector of 4 independent generalized coordinates,

is the vector of 8 dependent generalized coordinates and

is the vector of all 12 generalized coordinates of the robot.

Constraint equations

By using the formulation Equation (7), the constraint equations can be derived for 4 closed loops as follows:

Kinematics of the robot

By using the formulation Equation (1), the transformation matrix for the end-effector is calculated as follows:

Since

and

are the loops of Type B, by applying Equation (4), the matrices

and

are recalculated as follows:

Finally, the position of the end-effector

is yielded as follows:

Note that all the joint variables and the position of the end-effector in Equations (34)–(39) must be functions of time . However, to simplify the representation of such the complex equations, the term is truncated.

In order to verify the formulation of the kinematics model, the following numerical experiments were carried out:

1. Calculate the trajectory of the end effector

, with the input data is given as

,

and

.

Figure 8 shows the curves of

.

2. Take the data

obtained in Step 1 as the input for the inverse kinematic analysis, and calculate the displacement of the joints

,

and

. The results are shown in

Figure 9.

It is clearly shown in

Figure 9 that the curves

,

and

obtained in Step 2 match exactly the given data

,

and

, respectively. This demonstrates and validates the proposed kinematic modelling method.

Dynamic Modelling and Analysis of the Robot

The dynamic equation of this robot can be derived directly by using the formulation Equation (17). In order to formulate ,, and , the matrices , , and must be computed.

In this manner,

can be calculated with Equation (11), where the masses

are given in

Table 2, and the inertias

can be calculated based on the geometrical dimension of the links given in

Table 2 as well. In Equation (11), the Jacobian matrices are calculated as

and

, where the centre of mass

and the angular velocity

are calculated and presented in the

Appendix A. Based on all the components of

, the matrix

is then calculated by using Cristoffel notation.

The component

is calculated with Equation (13), where the total potential energy of the robot,

, is calculated and presented in the

Appendix A also.

The matrix

is calculated with Equation (25), where the Jacobian matrices

and

are presented in the

Appendix A, respectively.

Finally, all the terms of Equation (17) can be formulated properly that can be used for the dynamic analysis and the control law computation. In the following example, we demonstrate an inverse dynamic solution

that was calculated with respect to a input data given as follows:

,

,

and

. The responses of

are shown in

Figure 10.

It has shown that instead of the complex governing equations seen in Equation (10), the minimal form of the dynamic Equation (17) can be used directly for computation of the control (the inverse dynamic analysis) for the robot. In addition, analysing the dynamic model of a hybrid robot does not need to take into account the unknown Lagrangian Multipliers .