Performance Comparison and Evaluation of Two Small Chili Pepper Harvester Prototypes That Attach to Walking Cultivators

Abstract

:1. Introduction

2. Materials and Methods

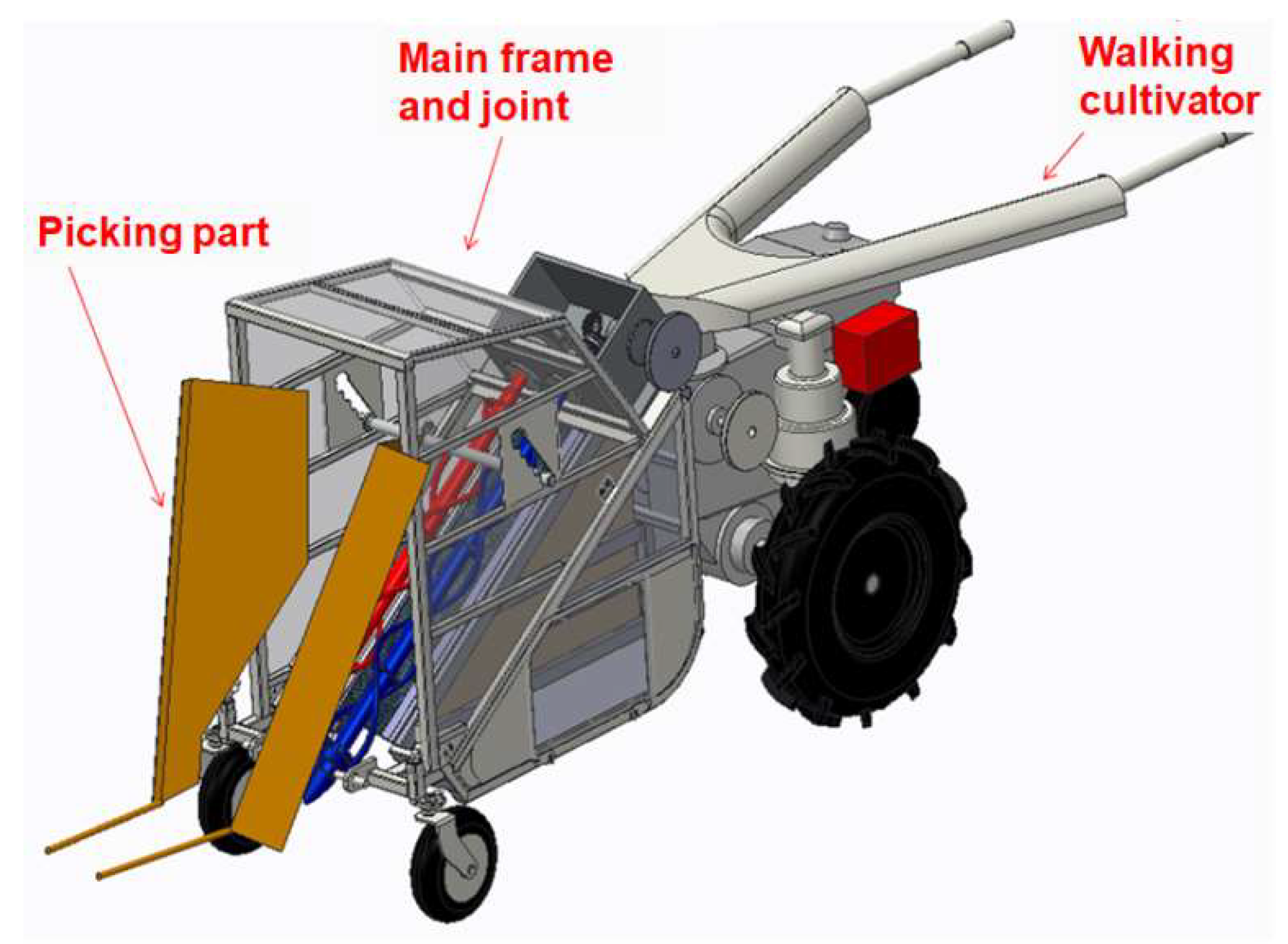

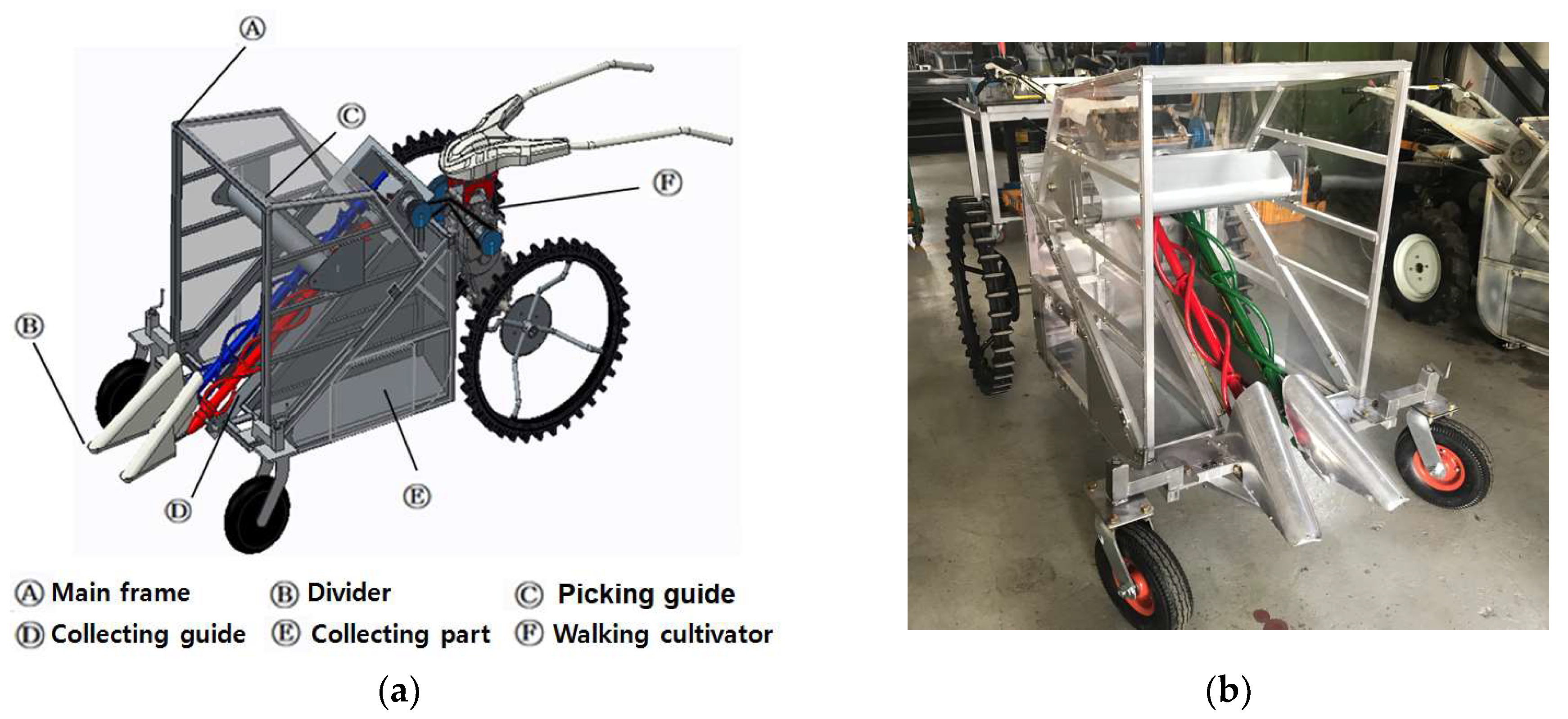

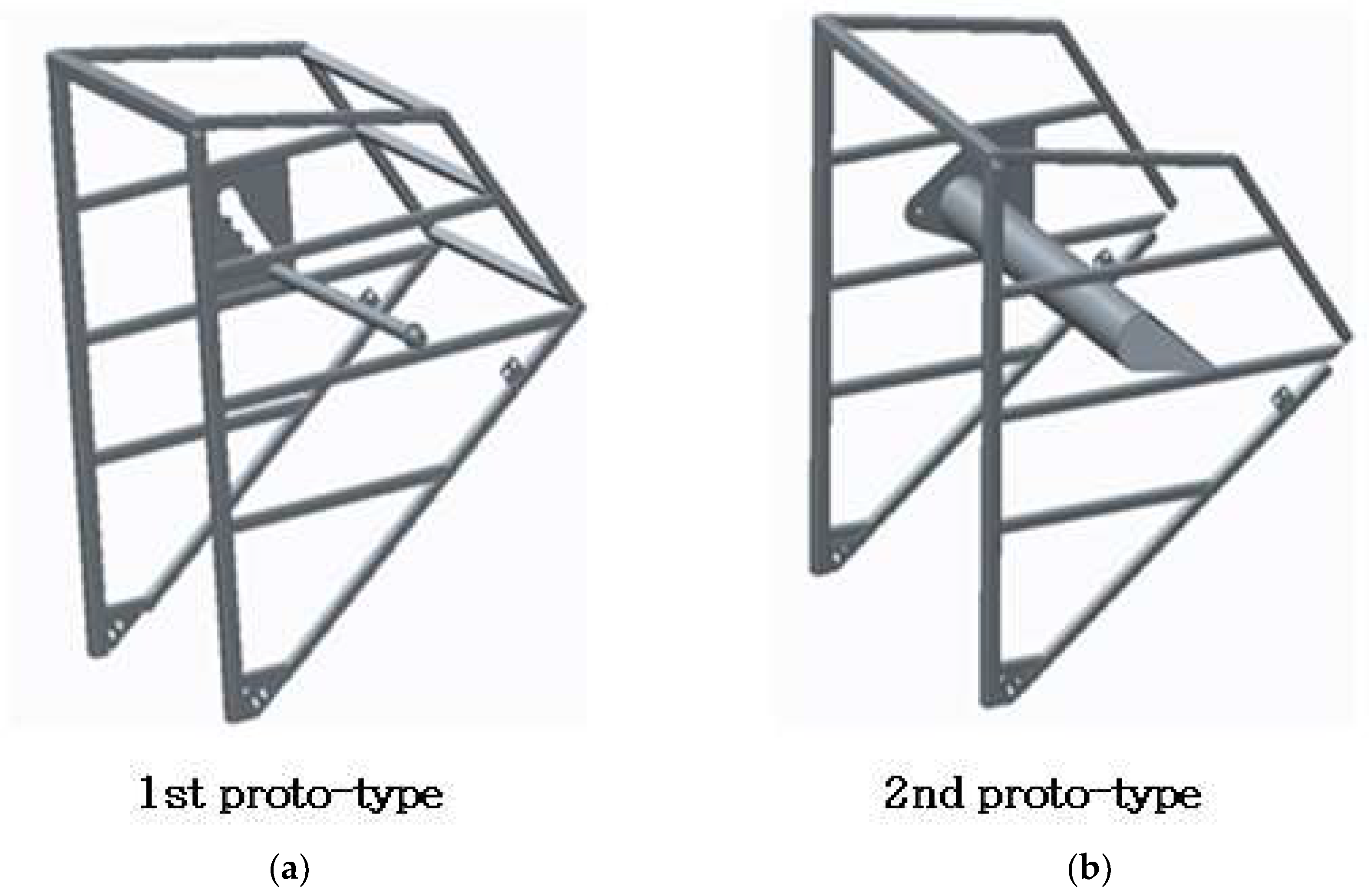

2.1. Small Chili Pepper Harvesters Attached to Walking Cultivators

2.1.1. Walking Cultivator

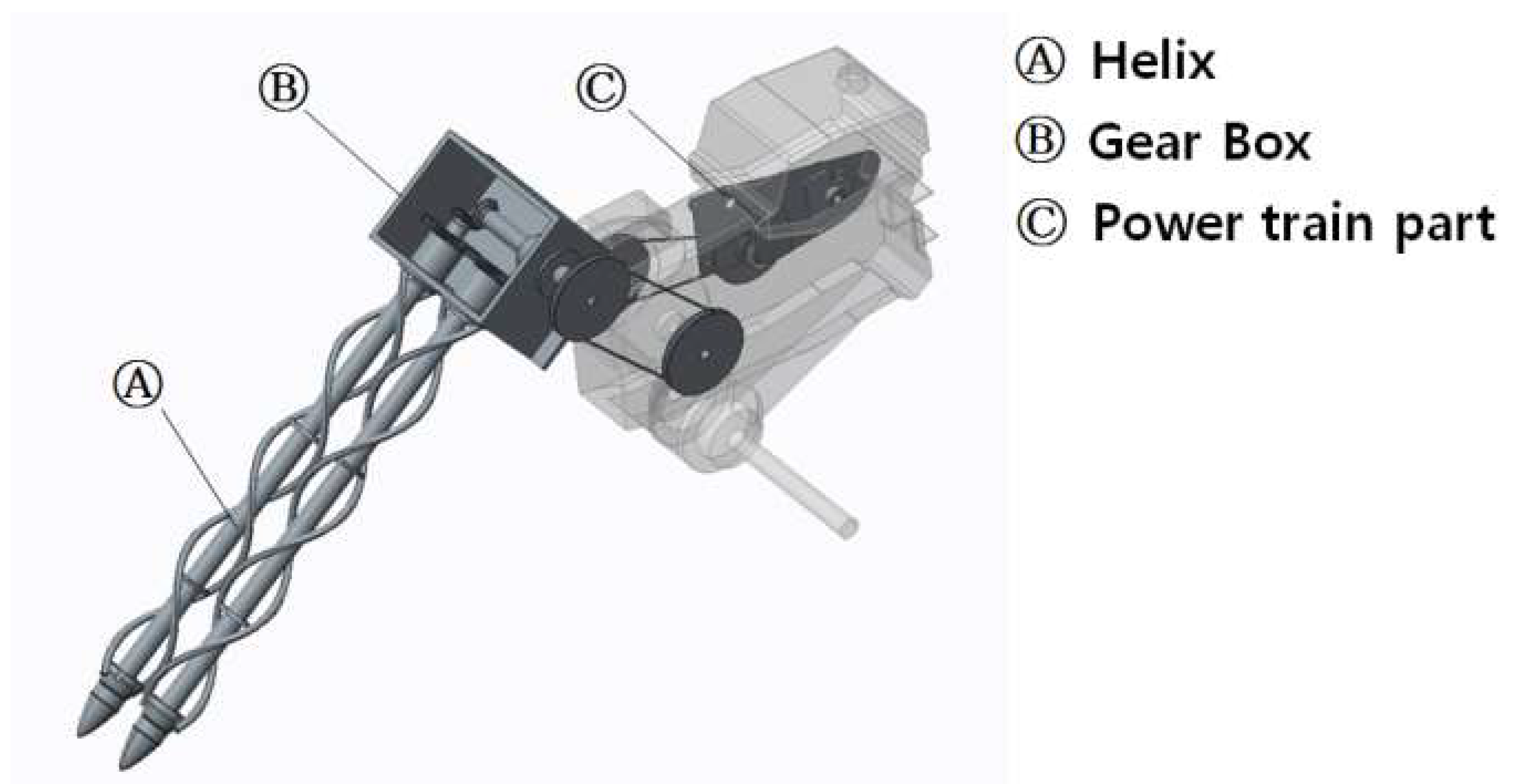

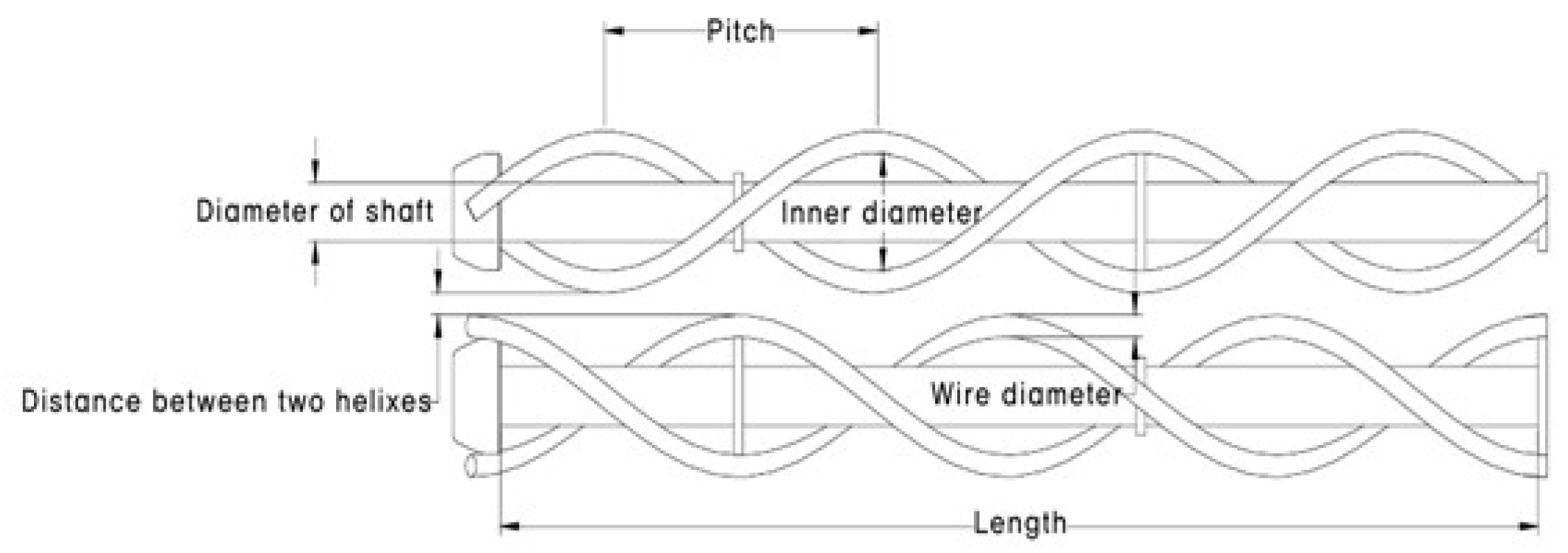

2.1.2. Production of Helix’s Helical Shaft and Setting of Rotation Speed

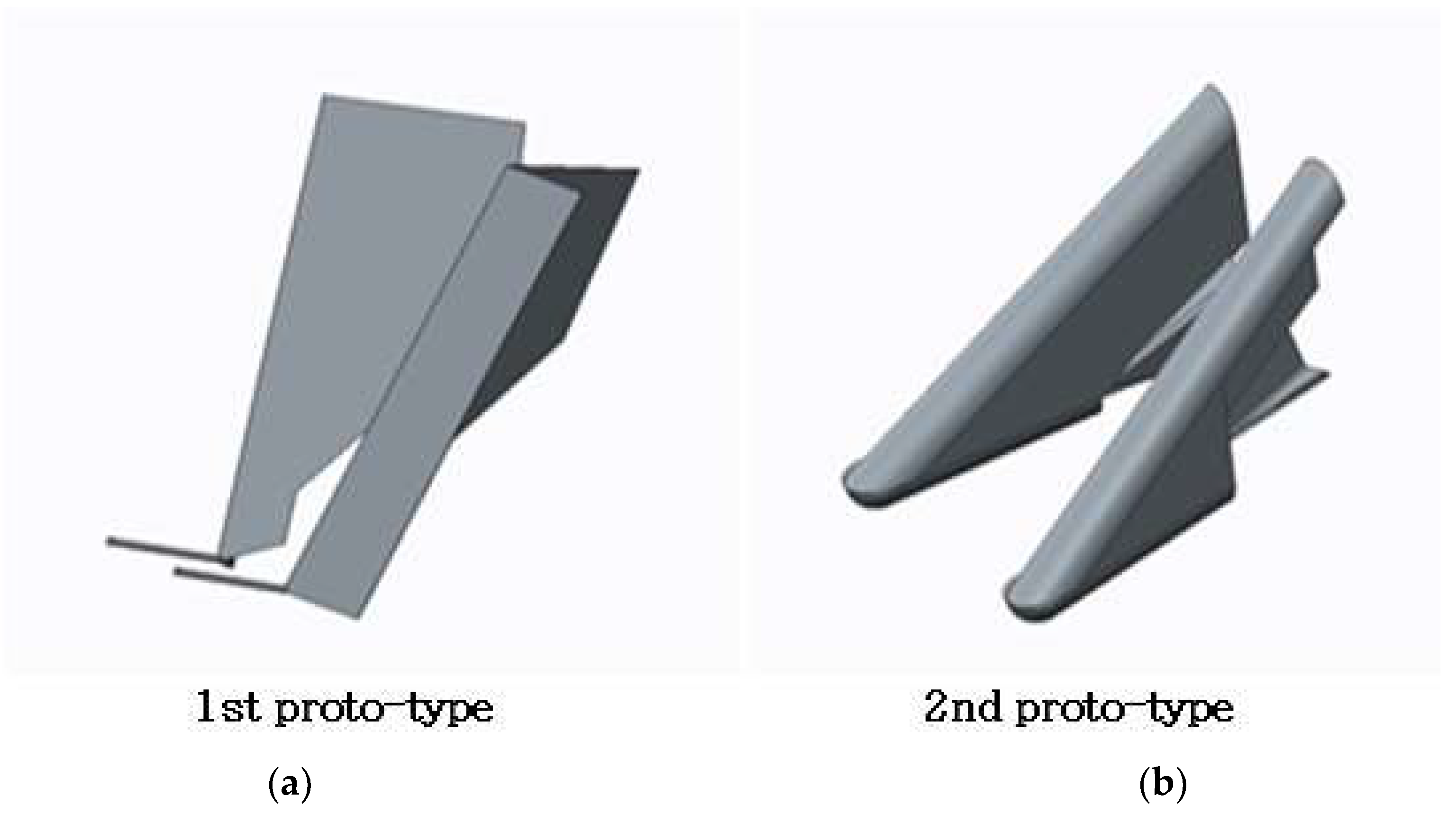

2.1.3. Shapes of Divider and Picking Guide

2.2. Test Sample

2.3. Field Test Method

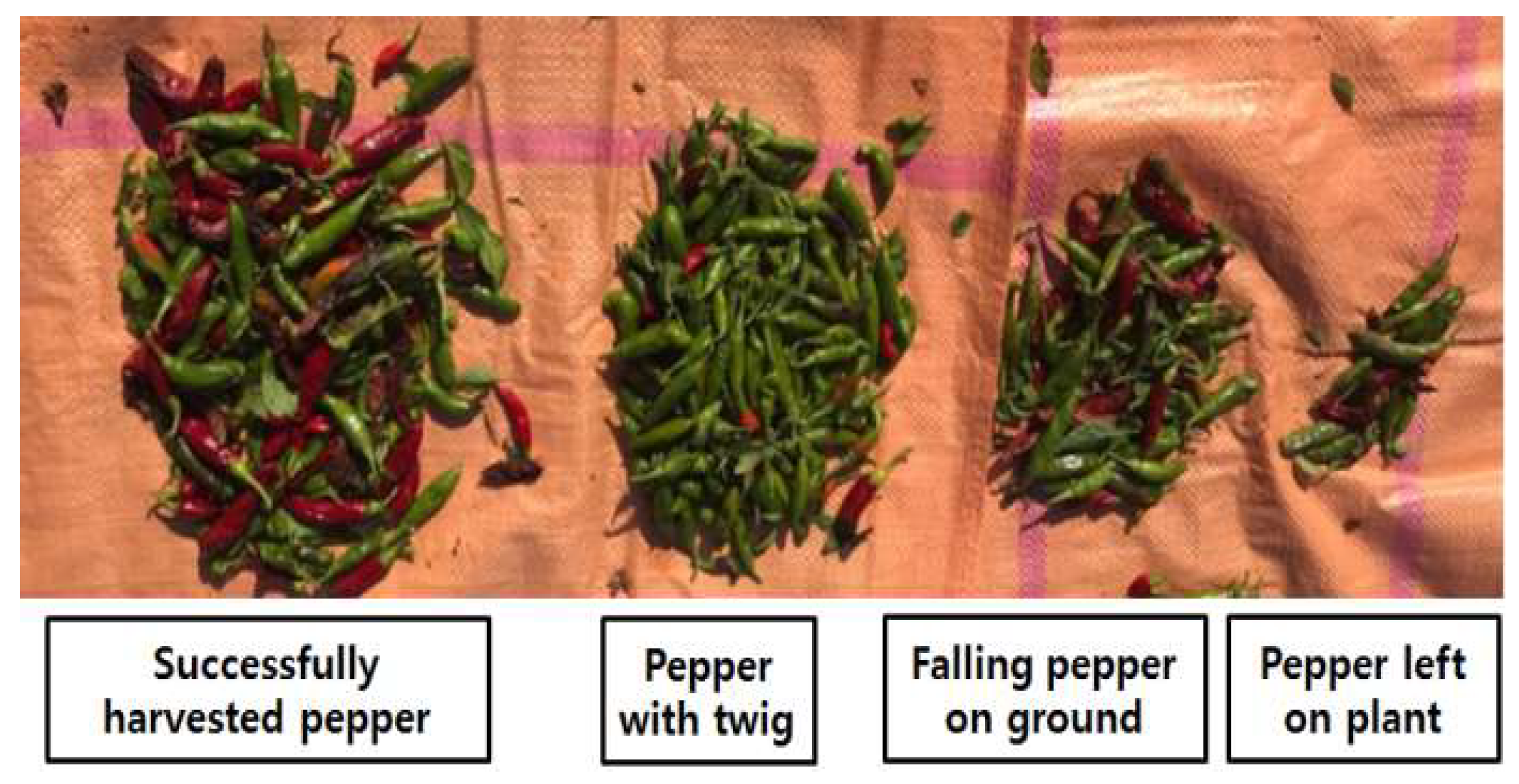

2.4. Analysis Method

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Current State of Farm Mechanization. Statistics Korea. Available online: http://www.index.go.kr/potal/main/EachDtlPageDetail.do?idx_cd=1288 (accessed on 5 March 2020).

- Chung, K.M.; Hwang, J.M. Quality of single-Harvested red peppers by harvest time and fruit grade. Korean J. Food Sci. Technol. 2002, 34, 919–923. [Google Scholar]

- Jung, J.; Cho, M.; Cho, Y. Fruit quality of once-Over harvest pepper (Capsicum annuum) cultivar ‘Saengryeg No. 211’ and ‘Saengryeg No. 213’. Korean J. Hortic. Sci. Technol. 2006, 24, 205–209. [Google Scholar]

- Nam, J.S.; Byun, J.H.; Kim, T.H.; Kim, M.H.; Kim, D.C. Measurement of mechanical and physical properties of pepper for particle behavior analysis. J. Biosyst. Eng. 2018, 43, 173–184. [Google Scholar]

- Mashall, D.E.; Boese, B.N. Breeding capsicum for mechanical harvest. Part 2-Equipment. In Proceedings of the 10th Eucarpia Meeting on Genetics and Breeding of Capsicum and Eggplant, Avignon, France, 7–11 September 1998. [Google Scholar]

- Choi, Y. Development of Machine Harvester for Pepper. PhD Thesis, Chonnam National University, Gwangju, Korea, February 2006. [Google Scholar]

- Funk, P.A.; Walker, S.J. Evaluation of five green chile cultivars utilizing five different harvest mechanisms. Appl. Eng. Agric. 2010, 26, 955–964. [Google Scholar] [CrossRef]

- Kang, K.S.; Park, H.S.; Park, S.J.; Kang, Y.S.; Kim, D.C. Study on optimal working conditions for picking head of self-Propelled pepper harvester by factorial test. J. Biosyst. Eng. 2016, 41, 12–20. [Google Scholar] [CrossRef] [Green Version]

- Nam, J.S.; Kang, Y.S.; Kim, S.B.; Kim, D.C. Factorial experiment for drum-type secondary separating part of self-propelled pepper harvester. J. Biosyst. Eng. 2017, 42, 242–250. [Google Scholar]

- Jo, Y.J.; Kang, Y.S.; Nam, J.S.; Choe, J.S.; Inoue, E.; Okayasu, T.; Kim, D.C. Performance analysis for a card cleaner type separating system of pepper harvester. J. Fac. Agric. Kyushu Univ. 2018, 63, 103–111. [Google Scholar]

- Byum, J.H.; Nam, J.S.; Choe, J.S.; Inoue, E.; Okayasu, T.; Kim, D.C. Analysis of the separating performance of a card cleaner for pepper harvester using EDEM software. J. Fac. Agric. Kyushu Univ. 2018, 63, 347–354. [Google Scholar]

- Park, S.H.; Park, S.J.; Kang, Y.S.; Kang, Y.S.; Kim, D.C. Development of Self-Propelled Pepper Harvester (I)-Field Test of Crop Divider-. In Proceedings of the Korean Society for Agricultural Machinery, Buan-gun, Korea, 29–30 October 2015. [Google Scholar]

- Park, S.H.; Kang, K.S.; Park, S.J.; Kang, Y.S.; Kim, D.C. Development of Self-Propelled Pepper Harvester (II)-Gross Harvester Efficiency Depending on Cultivar-. In Proceedings of the Korean Society for Agricultural Machinery, Jeonju-si, Korea, 28–29 April 2016. [Google Scholar]

- Kang, K.S. An Experimental Study on Performance Analysis of Picking Head for Pepper Harvester. Master’s Thesis, Chonbuk National University, Jeonju, Korea, June 2016. [Google Scholar]

- Kim, S.B. The Performance Evaluation of a Small Pepper Harvester Attaching a Walking Cultivator. Master’s Thesis, Chonbuk National University, Jeonju, Korea, February 2018. [Google Scholar]

| Item | AMC-900SM | KMC-750 |

|---|---|---|

| Weight (kg) | 112 | 155 |

| Rated power (kW) | 6.7 | 7.4 |

| Power take-off speed (rpm) | 714–1350 | 650–1300 |

| Working speed at first gear (m/s) | 0.28 | 0.25 |

| Rotational speed of helix when attaching each prototype (rpm) | 400–500 | 510–730 |

| Helix Factor | Parameter |

|---|---|

| Type of helix | Double helix |

| Pitch of helix | 450 mm |

| Length of helix | 900 mm |

| Wire diameter of helix | 15 mm |

| Inner diameter of helix | 80 mm |

| Diameter of Shaft | 34 mm |

| Distance between two helixes | 16 mm |

| Prototype | Variety | Rotational Speed of Helix (RPM) | AVE/SD | HE 1 (%) | SHR 2 (%) | PTR 3 (%) | PLR 4 (%) | GLR 5 (%) | DR 6 (%) |

|---|---|---|---|---|---|---|---|---|---|

| First version | AR | 500 | AVE 7 | 75.8 | 63.9 | 18.0 | 11.0 | 16.9 | - |

| Legend | SD 8 | 5.6 | 6.2 | 7.8 | 3.2 | 2.1 | - | ||

| Jeokyoung | 500 | AVE | 81.9 | 64.7 | 17.3 | 5.7 | 12.3 | - | |

| SD | 4.6 | 12.3 | 12.9 | 2.3 | 2.7 | - | |||

| Second version | 510 | AVE | 78.0 | 46.2 | 31.2 | 8.9 | 13.0 | 0.7 | |

| SD | 8.1 | 5.5 | 7.0 | 2.2 | 7.4 | 0.6 | |||

| AR | 610 | AVE | 86.2 | 46.2 | 38.1 | 7.0 | 6.9 | 2.3 | |

| Legend | SD | 1.6 | 8.8 | 8.4 | 2.1 | 2.7 | 1.2 | ||

| 730 | AVE | 91.7 | 45.6 | 44.3 | 1.9 | 6.3 | 2.3 | ||

| SD | 5.7 | 5.4 | 11.1 | 0.6 | 5.2 | 1.2 | |||

| 510 | AVE | 87.2 | 64.0 | 21.4 | 8.0 | 3.5 | 2.0 | ||

| SD | 0.9 | 5.6 | 4.9 | 3.6 | 1.8 | 1.0 | |||

| Jeokyoung | 610 | AVE | 93.8 | 63.5 | 28.2 | 2.8 | 3.5 | 2.0 | |

| SD | 3.2 | 15.5 | 17.1 | 2.2 | 1.7 | 2.0 | |||

| 730 | AVE | 95.3 | 70.1 | 23.1 | 1.2 | 3.5 | 2.3 | ||

| SD | 2.7 | 4.4 | 5.2 | 0.5 | 2.7 | 0.6 |

| Item | Source | DF | ANOVA SS | Mean Square | F Value | Pr > F |

|---|---|---|---|---|---|---|

| HE 1 | Variety | 1 | 214.7282 | 214.7282 | 10.78 | 0.0065 |

| Rotational speed (rpm) | 2 | 365.1086 | 182.5543 | 9.16 | 0.0038 | |

| Variety*rpm | 2 | 22.3976 | 11.1988 | 0.56 | 0.5843 | |

| Error | 12 | 239.0906 | 19.9242 | |||

| Total | 17 | 841.3251 | ||||

| SHR 2 | Variety | 1 | 1780.0555 | 1780.0556 | 25.43 | 0.0003 |

| Rotational speed (rpm) | 2 | 32.4444 | 16.2222 | 0.23 | 0.7966 | |

| Variety*rpm | 2 | 44.4444 | 22.2222 | 0.32 | 0.7339 | |

| Error | 12 | 840.0000 | 70.0000 | |||

| Total | 17 | 8696.9444 | ||||

| PLR 3 | Variety | 1 | 17.0917 | 17.0917 | 3.78 | 0.0755 |

| Rotational speed (rpm) | 2 | 142.9982 | 71.4991 | 15.83 | 0.0004 | |

| Variety*rpm | 2 | 11.0023 | 5.5011 | 1.22 | 0.3299 | |

| Error | 12 | 54.1964 | 4.5163 | |||

| Total | 17 | 225.2888 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, T.-H.; Kim, D.-C.; Cho, Y. Performance Comparison and Evaluation of Two Small Chili Pepper Harvester Prototypes That Attach to Walking Cultivators. Appl. Sci. 2020, 10, 2570. https://doi.org/10.3390/app10072570

Kim T-H, Kim D-C, Cho Y. Performance Comparison and Evaluation of Two Small Chili Pepper Harvester Prototypes That Attach to Walking Cultivators. Applied Sciences. 2020; 10(7):2570. https://doi.org/10.3390/app10072570

Chicago/Turabian StyleKim, Tae-Hyeong, Dae-Cheol Kim, and Yongjin Cho. 2020. "Performance Comparison and Evaluation of Two Small Chili Pepper Harvester Prototypes That Attach to Walking Cultivators" Applied Sciences 10, no. 7: 2570. https://doi.org/10.3390/app10072570

APA StyleKim, T.-H., Kim, D.-C., & Cho, Y. (2020). Performance Comparison and Evaluation of Two Small Chili Pepper Harvester Prototypes That Attach to Walking Cultivators. Applied Sciences, 10(7), 2570. https://doi.org/10.3390/app10072570