Abstract

Smart manufacturing is considered as a new paradigm that makes work smarter and more connected, bringing speed and flexibility through the introduction of digital innovation. Today, digital innovation is closely linked to the “sustainability” of companies. Digital innovation and sustainability are two inseparable principles that are based on the concept of circular economy. Digital innovation enables a circular economy model, promoting the use of solutions like digital platforms, smart devices, and artificial intelligence that help to optimize resources. Thus, the purpose of the research is to present a systematic literature review on what enabling technologies can promote new circular business models. A total of 31 articles were included in the study. Our results showed that realization of the circular economy involved two main changes: (i) managerial changes and (ii) legislative changes. Furthermore, the creation of the circular economy can certainly be facilitated by innovation, especially through the introduction of new technologies and through the introduction of digital innovations.

1. Introduction

Today, the manufacturing industry is aiming to improve competitiveness through innovative technologies, the so-called enabling technologies with the aim of promoting new growth in the industrial sector [1,2]. Competitiveness, innovation, and sustainability represent strategic levers for global economic development. In this regard, the attention of the industrial and academic community is to analyze how digital manufacturing systems will push companies toward “sustainability” and a “circular economy” [3]. In fact, as recognized by several authors, innovation and sustainability are two crucial issues for the present and future generations of smart manufacturing systems [4,5]. Indeed, the extraction of natural resources, excessive waste production, and global warming are problems known to all [6]. In this regard, emerging searches have shown how a circular model to reuse waste has a positive influence on improving the entire supply chain to manufacture products [7,8,9], while others have focused on the impacts of digital technologies in the domain of manufacturing, optimization processes, and scheduling problems [10,11] to solve the problem of industrial pollution and a waste of resources. It is a vitally important issue worldwide. As a matter of fact, according to the study published by the United Nations Inter Governmental Panel on Climate Change, only 12 years remain to limit the devastating effects linked to climate change, rethinking production, and consumption patterns on a global scale to take into account the concept of finite limit of resources [12]. Exploiting the digital technologies underlying the Fourth Industrial Revolution to promote the introduction of a circular economy can be a first step toward the development of responsible production and consumption [13]. In fact, the adoption of digital technologies such as artificial intelligence (AI), additive manufacturing (AM), and cyber-physical systems could promote circular economy models, helping to generate value by increasing energy efficiency, extending the useful life of products, component materials, and recovering the value at the end of the cycle [14]. In this scenario, the European Innovation Council Accelerator (EIC) supports innovations that promote the implementation of the European Green Deal. In particular, the EIC supports over 1100 “green” companies for a total of over € 550 million. This represents almost 25% of all companies supported by the EIC. Most of the “green” companies, which produce green technologies and products, are young: almost half of them were founded between 2012 and 2017. Green innovators attracted around € 730 million in private investment after receiving the grant, which means that every € 1 invested in green companies by the EIC mobilized € 1.72 in private investment. Most of the private investments were made in the energy, power, and business software sectors [15]. Furthermore, all the member states of the United Nations signed the 2030 agenda in 2015, though introducing concrete actions on a global scale seems difficult to achieve. Although there are all these initiatives, there remains a common disagreement. In fact, during the last Conference of Parties in Madrid (COP25), an agreement was not reached on the markets of CO2 [16]. Despite a timid appeal for more ambitious efforts and a call for the urgent need to increase cuts in climate-changing gas emissions, all decisions have been postponed to the next meeting (COP26 in Glasgow). However, where national (and above all supranational) policies do not seem to be able to produce the desired results, companies can begin to take a first step toward sustainable production (and consumption) models, implementing circular economy models, and using digital technologies as a starting point [17]. A new paradigm, a change of mindset, is needed [18]. Developing new efficiency models around the digital world represents an opportunity for growth from a social and economic point of view [19,20,21], a topic that is still underexplored. Thus, the purpose of this research was to analyze how the development of digital technologies could promote circular economy models. In this regard, a systematic literature review (SLR) approach was proposed. The use of a SLR represents a very useful scientific tool for summarizing the state-of-the-art of a specific topic. It uses systematic methods to collect secondary data and provides useful ideas for the scientific community [22]. In the present research, SLR was used as through a “protocol”, it is possible to define a specific objective of investigation, to describe literature review sources, and select primary studies. Definitely, a protocol for a systematic review describes the rationale for the review, the objectives, and the methods that will be used to locate, select, and critically appraise studies, and to collect and analyze data from the included studies [23]. Although, SLR does not represent a scientific innovation, it is valuable since in a single document, it provides a complete, exhaustive summary of previous works produced on a specific topic [24]. The main output of our research is the first categorization of recent literature to analyze the state-of-the-art.

The rest of the paper is organized as follows. Section 2 defines the methodology used in the study; Section 3 presents the results and the classification of selected documents; and Section 4 discusses the findings. Section 5 outlines the challenges and future directions that have emerged from the analysis of the literature Finally, Section 6 provides implications for research and future developments.

2. Materials and Methods

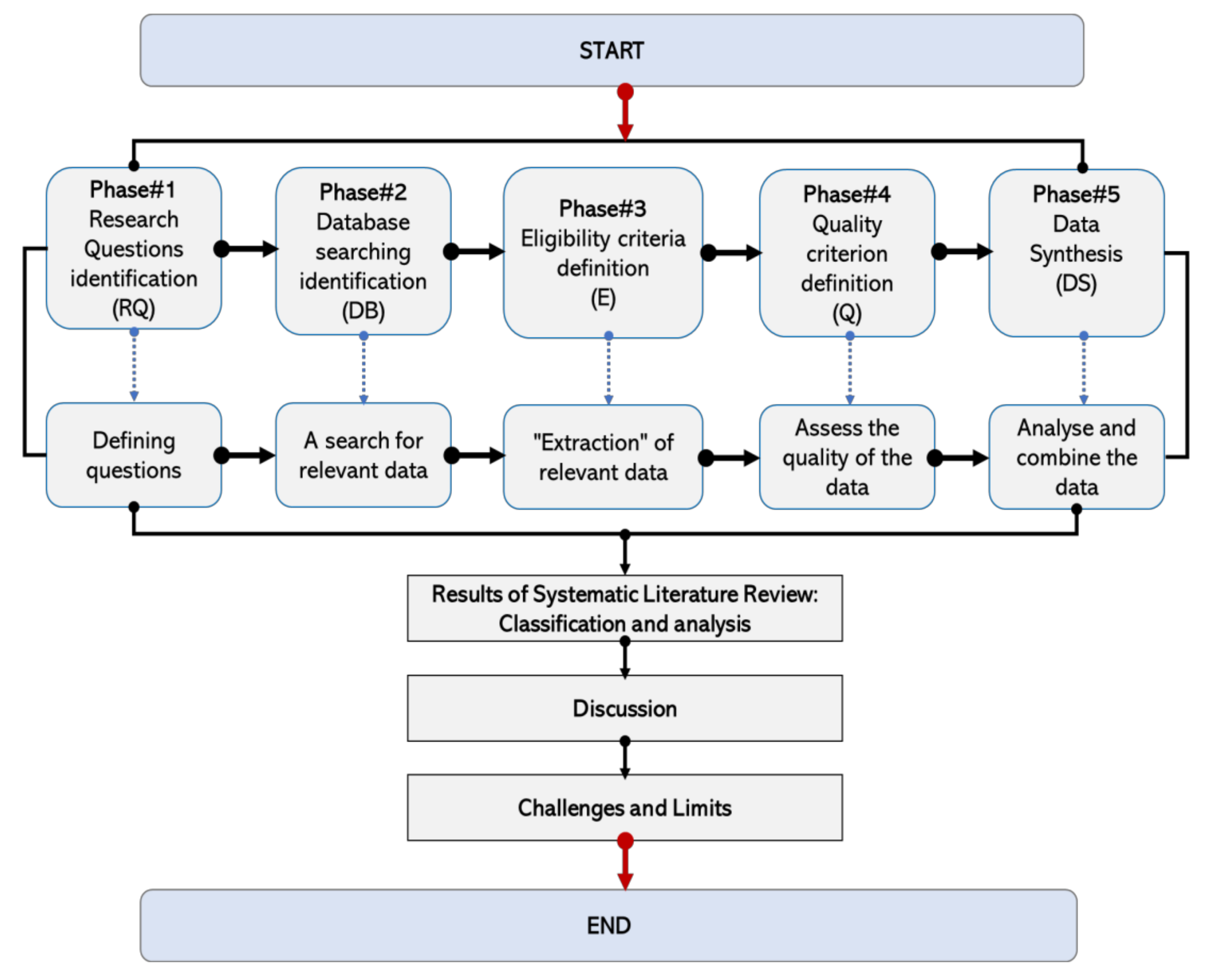

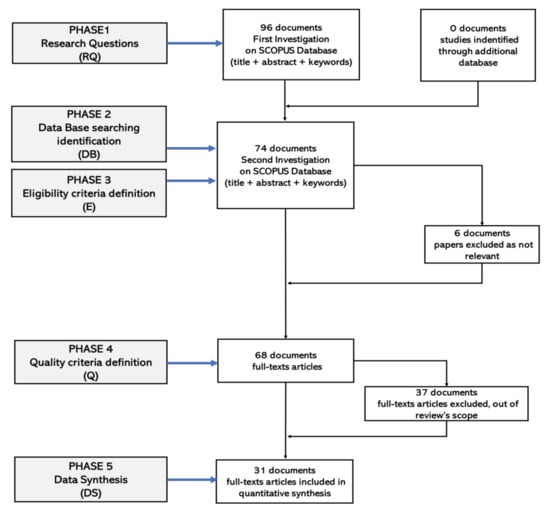

A systematic literature review (SLR) is used to identify and evaluate the state-of-the-art of a specific theme. The use of a systematic literature review (SLR) represents a very useful scientific tool for summarizing the state-of-the-art of a specific topic. It uses systematic methods to collect secondary data and provides useful ideas for the scientific community [25]. In detail, it is a secondary scientific research tool that aims to summarize data from primary research tools, for example, with an exhaustive review of the scientific literature relating to a given topic and with particular attention to the sources, which must be highly referenced to identify, highlight, and evaluate, in high quality research, all the evidence relevant to a specific scientific hypothesis. Definitively, the SLR aims to carry out a survey of research with the same scopes and evaluate them critically. It provides a sort of “summary” of the state-of-the-art in a specific subject area. Using the SLR method, the bibliometric research results are disclosed and the process of sample construction is described. A rigorous SLR is based on transparency and clarity. Thus, a SLR follows a specific protocol in order to identify research questions to focus the search, select a database to use, define exclusion criteria, and quality criteria in order to analyze only documents relevant to the goal. In the following sections, some further details are given. The SLR protocol helps to plan and document methods used for review. This means that it is possible to avoid arbitrary decisions while conducting revisions and to reduce the duplication problem. The process of SLR can be seen in Figure 1. In detail, a SLR starts by implementing five phases: Phase #1 “Research Questions identification (RQ)”; Phase #2 “Database searching identification (DB)”; Phase #3 “Eligibility criteria definition (E”); Phase #4 “Quality criterion definition (Q)”; and Phase #5 “Data Synthesis (DS)”. Afterward, the main results of the process are classified and analyzed. Then, the discussion follows the results, and the definition of challenges and limits. A description of each phase is detailed below while the classification and analysis, discussion, challenges and limitations are explained in the following Section 3, Section 4, Section 5, respectively.

Figure 1.

The main phases of the systematic literature review protocol (author’s elaboration).

2.1. Phase #1: Research Questions Identification (RQ)

Like an experimental investigation, a systematic review is conducted on defined research questions that aim to define the investigation scenario as best as possible. The main goal of our survey was to answer the question “How can digital innovation enable new circular business models to help achieve smart sustainable production?”.

This question materialized when investigating the topic on smart manufacturing systems and applied industrial technologies in the context of sustainability. In this regard, the main research questions, which were the basis of the survey, are here summarized:

- RQ1. How relevant is the scientific community interest about digital manufacturing systems to reduce time and cost and improve the efficiency of most processes?

- RQ2. What principles and technologies might unlock the potentials of circular economy (CE) and sustainable manufacturing?

- RQ3. In a new digitalized society and business sector how strategic is promoting research for innovation, sustainable solutions, and sustainable lifestyles?

- RQ4. What is the contribution coming from novel theories, researches, and case study?

- RQ5. Which industrial sectors are more involved and sensitive to CE applications?

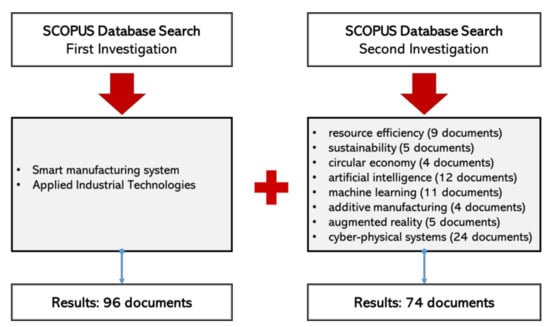

2.2. Phase #2: Data Base Searching Identification (DB)

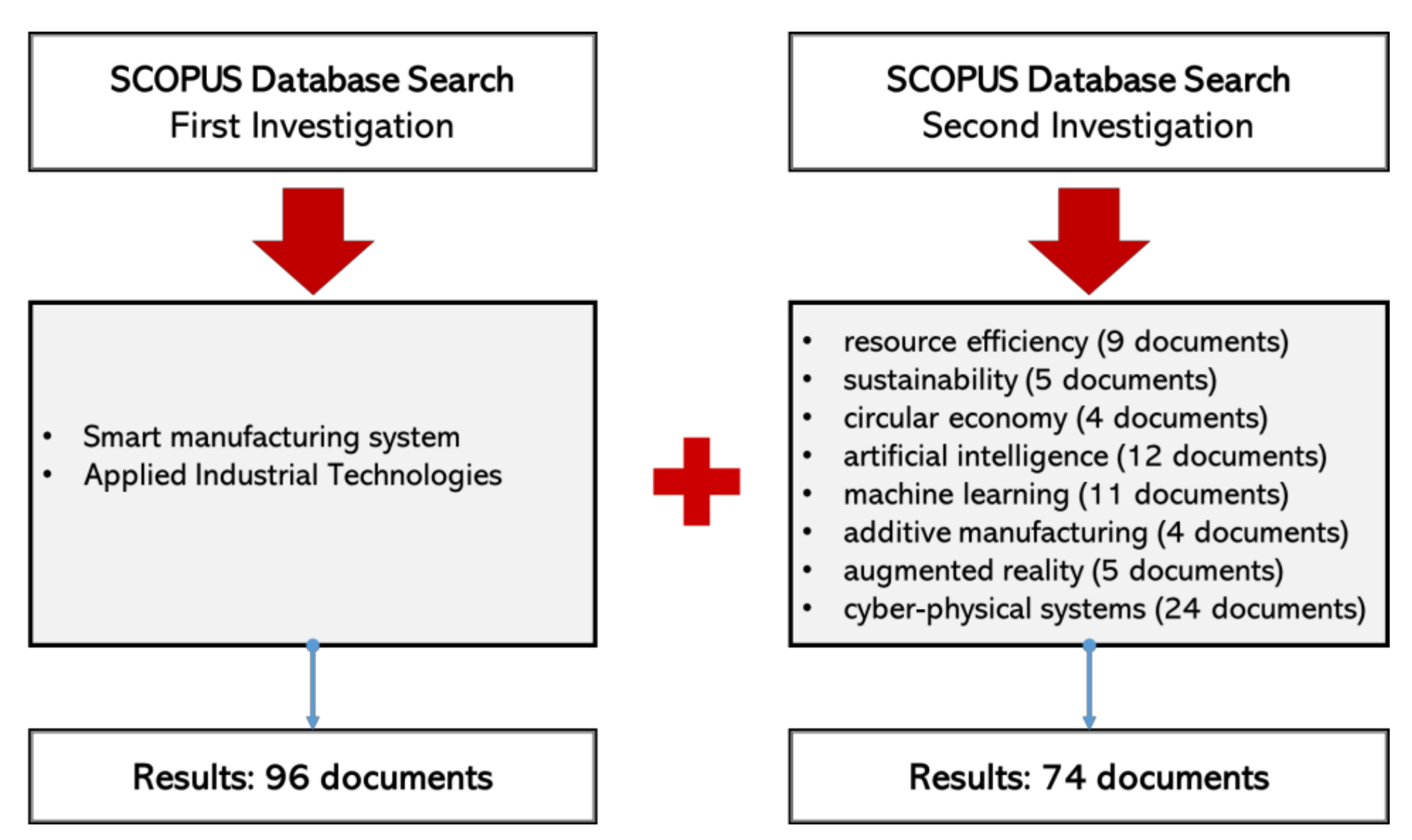

The aim was to identify as many studies on the topic of interest in order to have a complete and exhaustive list of papers in relation to all possible sources. In this regard, bibliometric data were collected from the Scopus database, the largest abstract and citation database of peer-reviewed literature. Scopus supports a Boolean syntax, which is a type of search that allows users to combine keywords with operators such as AND, NOT, and OR to further produce more relevant results. As can be seen from Figure 2, we started the search investigation with the general keywords “Smart manufacturing system” AND “Applied Industrial Technologies”, which were processed as: (TITLE-ABS-KEY (smart AND manufacturing AND system) AND TITLE-ABS-KEY (applied AND industrial AND technologies)). Only articles in which the string was found in (1) article title, or in (2) abstract or in (3) keywords were analyzed. At first, the analysis on Scopus pointed out 96 documents from 1985 to 2020. However, considering our specific research interest, the search investigation was refined by applying additional filters. In detail, we carried out a second investigation adding another eight keywords as follows:

Figure 2.

Scheme of the query and related results.

- (TITLE-ABS-KEY (Smart Manufacturing Systems) AND TITLE-ABS-KEY (Applied Industrial Technologies) AND TITLE-ABS-KEY (resource efficiency)).

- (TITLE-ABS-KEY (Smart Manufacturing Systems) AND TITLE-ABS-KEY (Applied Industrial Technologies) AND TITLE-ABS-KEY (sustainability)).

- (TITLE-ABS-KEY (Smart Manufacturing Systems) AND TITLE-ABS-KEY (Applied Industrial Technologies) AND TITLE-ABS-KEY (circular economy)).

- (TITLE-ABS-KEY (Smart Manufacturing Systems) AND TITLE-ABS-KEY (Applied Industrial Technologies) AND TITLE-ABS-KEY (artificial intelligence)).

- (TITLE-ABS-KEY (Smart Manufacturing Systems) AND TITLE-ABS-KEY (Applied Industrial Technologies) AND TITLE-ABS-KEY (machine learning)).

- (TITLE-ABS-KEY (Smart Manufacturing Systems) AND TITLE-ABS-KEY (Applied Industrial Technologies) AND TITLE-ABS-KEY (additive manufacturing)).

- (TITLE-ABS-KEY (Smart Manufacturing Systems) AND TITLE-ABS-KEY (Applied Industrial Technologies) AND TITLE-ABS-KEY (augmented reality)).

- (TITLE-ABS-KEY (Smart Manufacturing Systems) AND TITLE-ABS-KEY (Applied Industrial Technologies) AND TITLE-ABS-KEY (cyber-physical systems)).

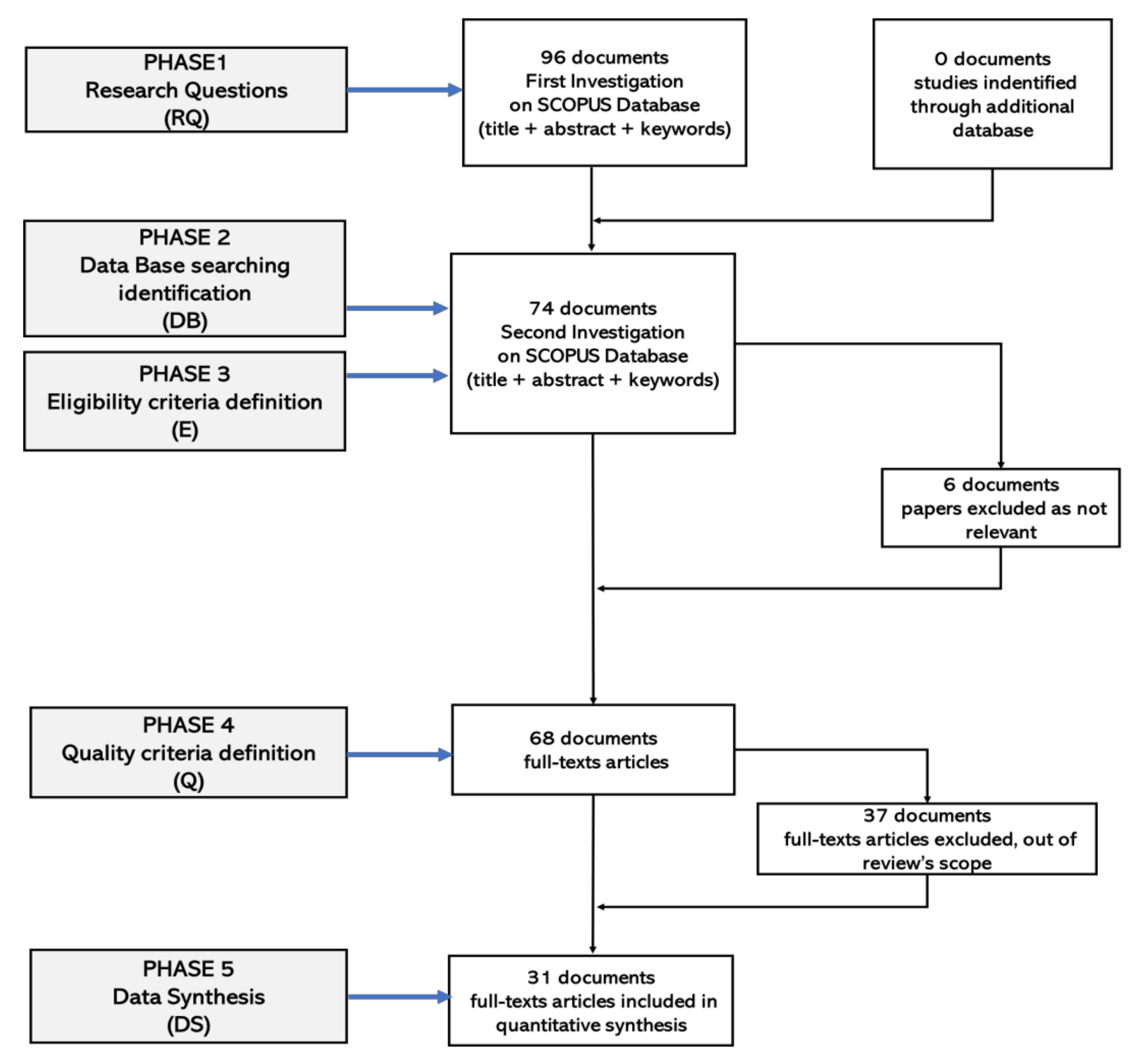

Thus, the second set of keywords returned a total of 74 documents between 1985 to 2020, which were reduced, as summarized in Figure 3. Final results of the Scopus surveys can be seen in Figure 2.

Figure 3.

Flow diagram for the selection of documents based on Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA).

2.3. Phase #3: Eligibility Criteria Definition (E)

Automatic searches could inappropriately consider search results. Thus, documents not related to research questions and database searching identification were excluded. In the same way, documents were not considered that did not explore policies and practices adopted in different countries/regions in the field of smart manufacturing. Thus, some exclusion criteria were identified and are summarized as follows:

- E1: Documents not related to smart manufacturing system AND applied industrial technologies.

- E2: Documents not related to sustainable manufacturing.

- E3: Documents not related to enabling technology.

- E4: Duplicate documents.

Similarly, we identified some inclusion criteria, as follows:

- I1: Documents published only English.

- I2: Documents published in peer-reviewed international journals or conferences.

2.4. Phase #4: Quality Criteria Definition (Q)

The criterion chosen to have a meaningful review was based on articles that must deal with these topics from applicative, experimental, and theoretical point of view. In the present study, two criteria were defined, that is:

- Q1: Documents in the context of smart manufacturing using different sustainability methodologies and approaches.

- Q2: Documents in the context of smart manufacturing using different enabling technology.

- Q3: Documents with impact factor, SCImago Journal Rank or CiteScore.

2.5. Phase #5: Data Synthesis (DS)

According to the above sections, the documents were identified and checked for eligibility and relevance to form an inclusion set [26,27]. In the present study, the selection of documents was conducted using PRISMA standard (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) [28] in order to ensure transparency and replicability of the research. Figure 3 summarizes the selection of our documents based on PRISMA.

3. Results of Systematic Literature Review: Classification and Analysis

This section presents and discusses the finding of the review. First, an overview of the selected 31 studies is presented. All papers have been classified. The full list of analyzed papers is shown in Appendix Table A1. Quantitative evidence of the study was analyzed considering the following issues:

- Documents by type.

- Publication by years.

- Country analysis.

- Subject area.

- Research area analysis.

- Most collaborative authors.

- Most productive authors.

An explanation and comments were provided for each paper. In addition, a summary of the study characteristics was addressed.

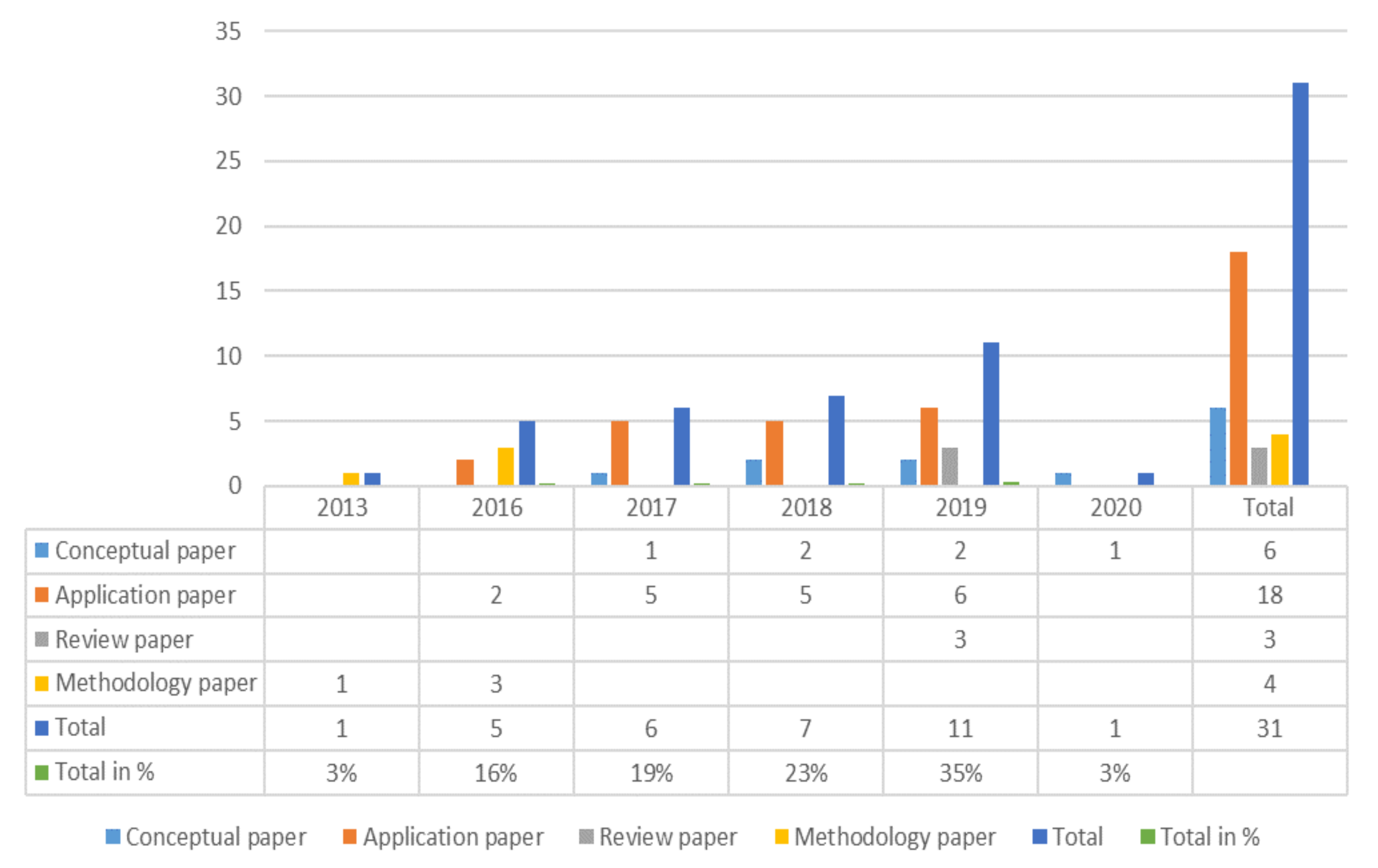

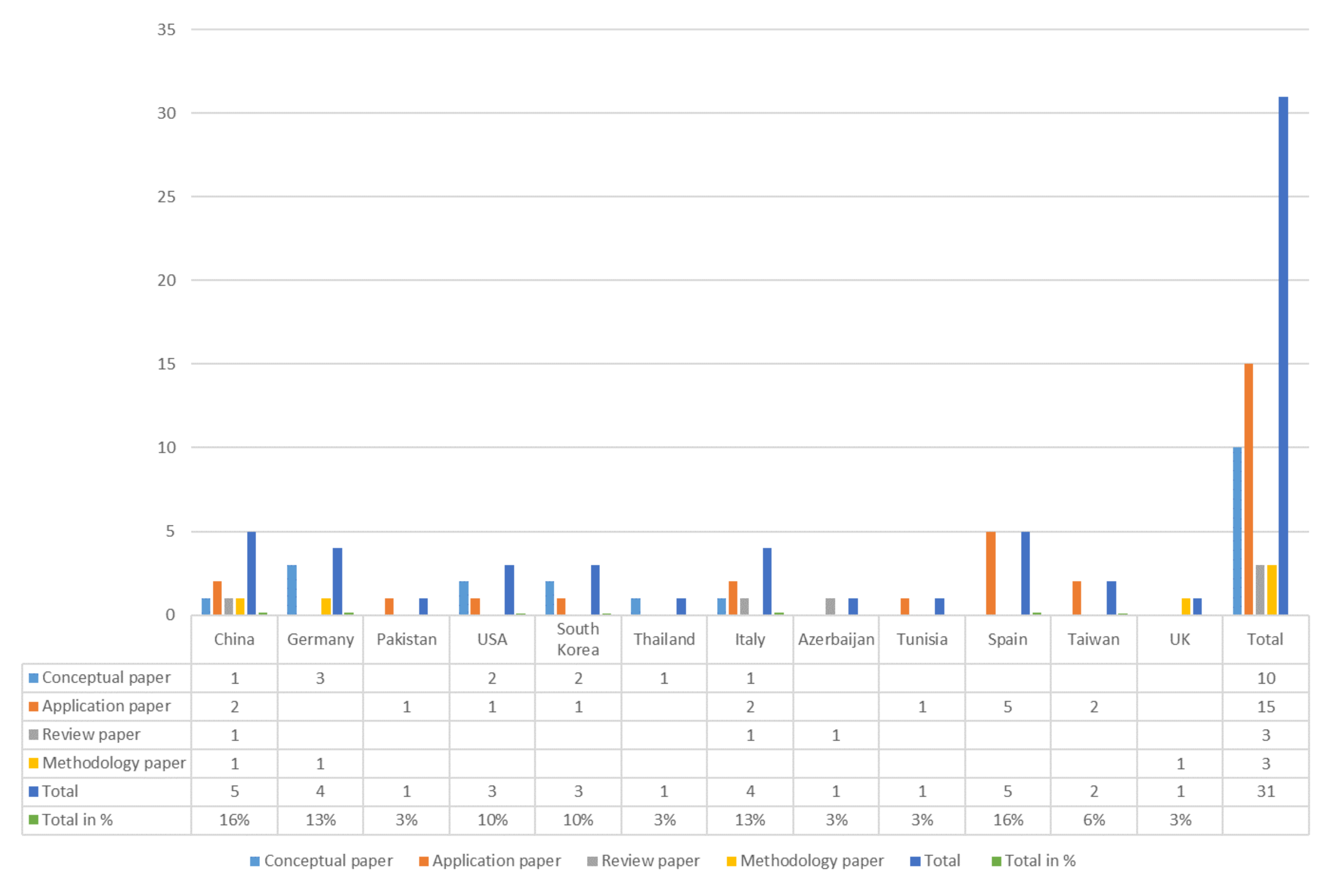

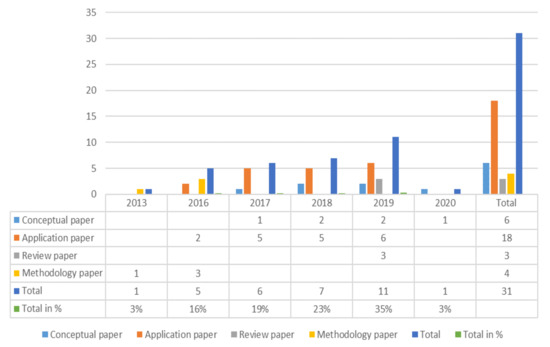

3.1. Documents by Types

The analysis of documents by type pointed out the following distribution: articles (16; 52%); conference papers (14; 45%); and short survey (1;3%). Furthermore, it emerged that nine (29%) papers were published as open access. The remaining part, equal to 22 documents (71%), was not published as open access. Then, 31 papers were classified based on research type matter. Figure 4 shows the distribution of the group of papers as a function of the publication year. An interesting aspect is that application papers have been published with good continuity since 2016.

Figure 4.

Distribution of the type of papers as a function of the publication year (source: Scopus).

Figure 5 shows the classification of the type of papers as a function of the geographic distribution. It should be noted that most of the application papers have been published in Spain, which also represent the only type of publication in this country. Other countries had a more heterogeneous distribution.

Figure 5.

Classification of the type of papers as a function of the geographic distribution (source: Scopus).

Table 1 presents the journals ranked by their Citescore, Scimago index, and impact factor. The ranking of journals highlights the average citations received per document (CiteScore 2018); the weighted citations received by the serial that depends on subject field and prestige of the citing serial (SJR 2018), and the average number of citations received in a year by papers published in the journal during the two preceding years (Impact Factor 2018). Citations were calculated using data from 30 April 2019 (as stated on Scopus).

Table 1.

Journal ranking (source: Scopus).

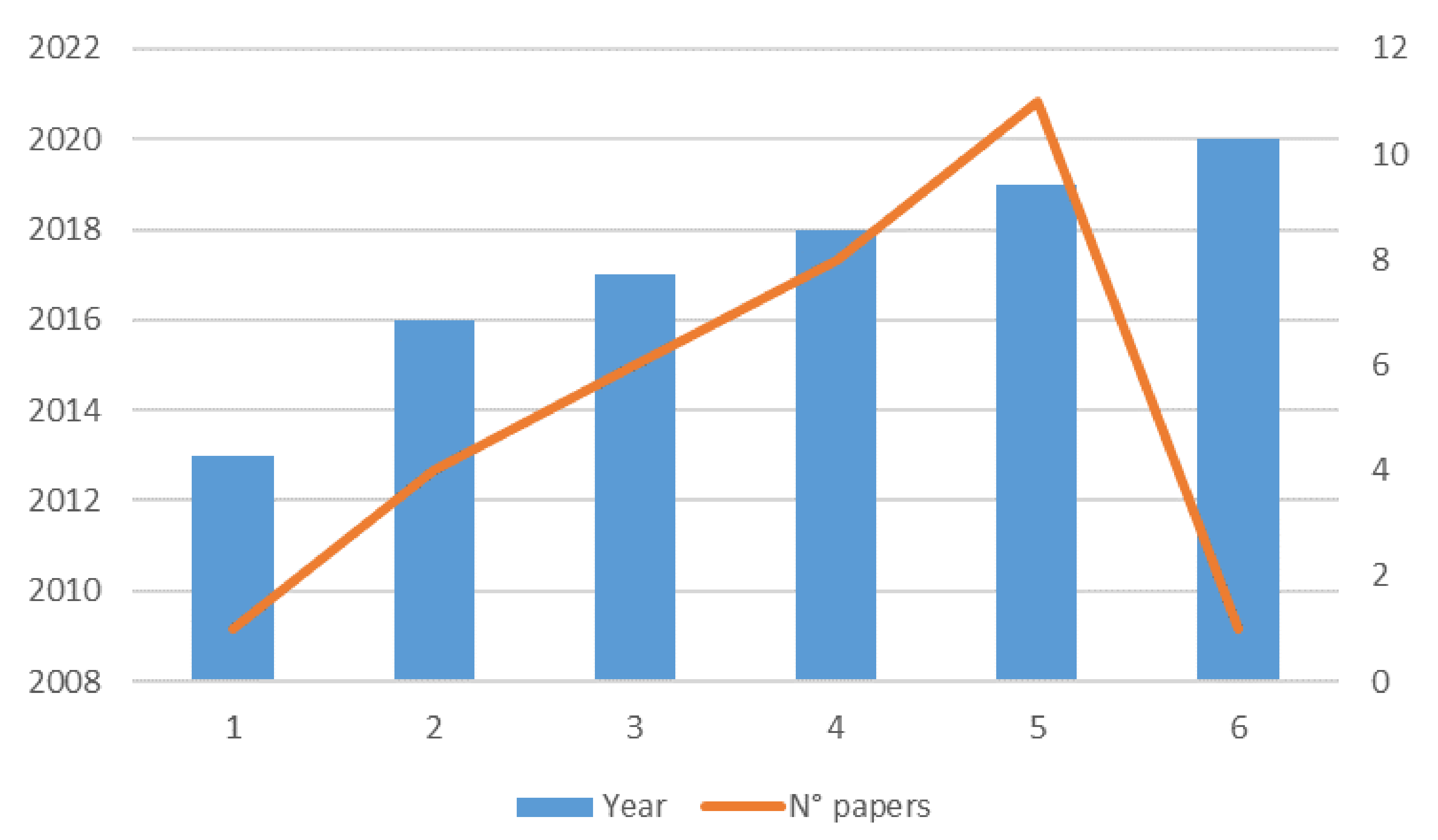

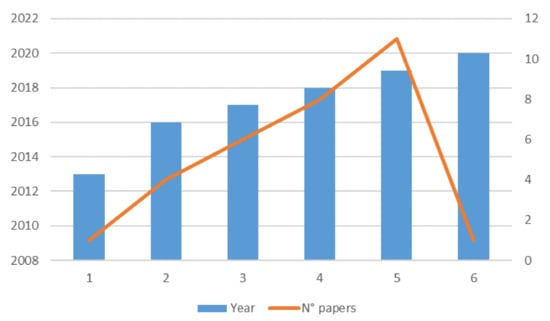

3.2. Publication by Years

The analysis of the sample compared to the years of publication shows that the research has grown year by year starting from 2013. This trend confirms the large interest around this topic after the I4.0 started. Figure 6 describes the above results.

Figure 6.

Distribution by year (source: Scopus).

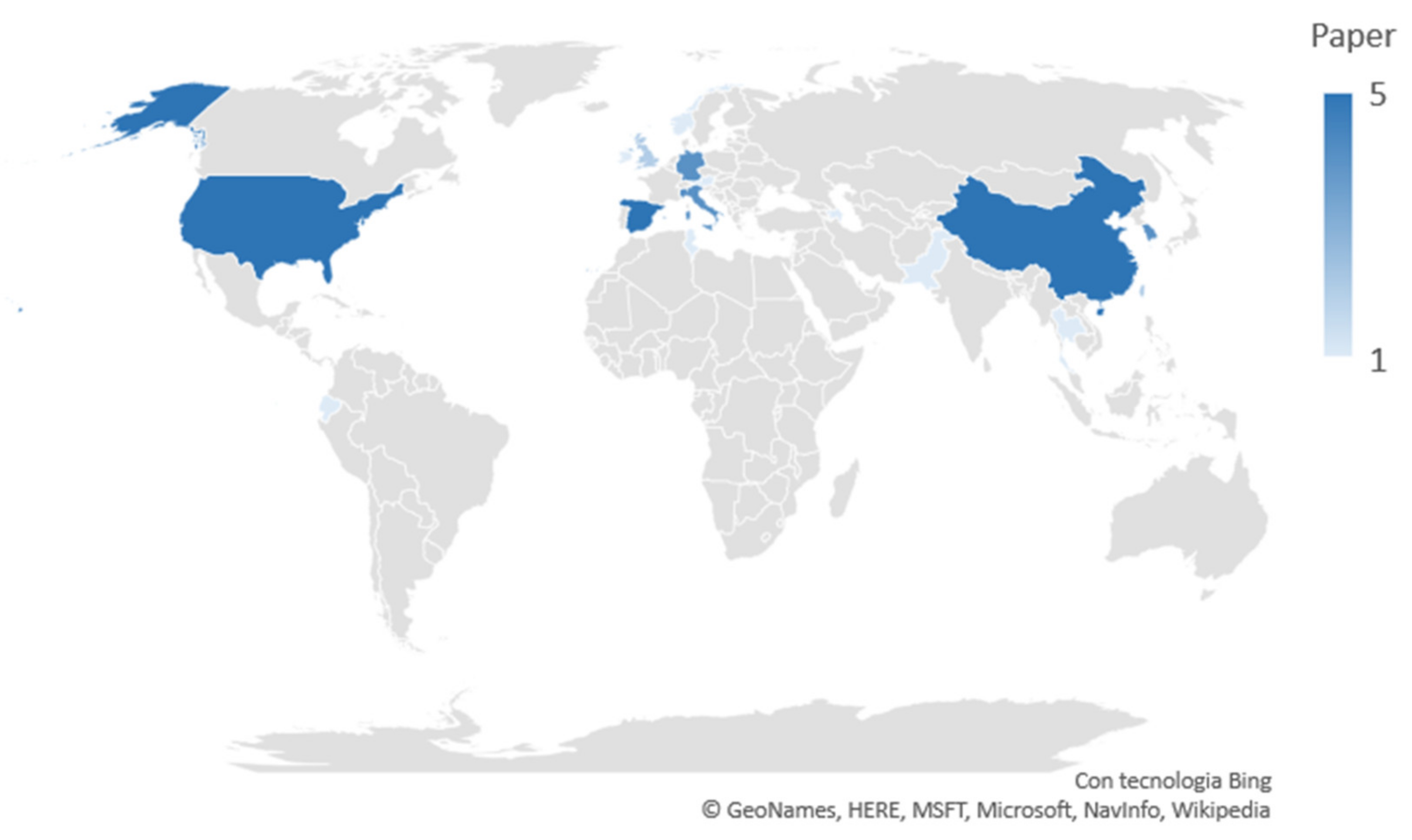

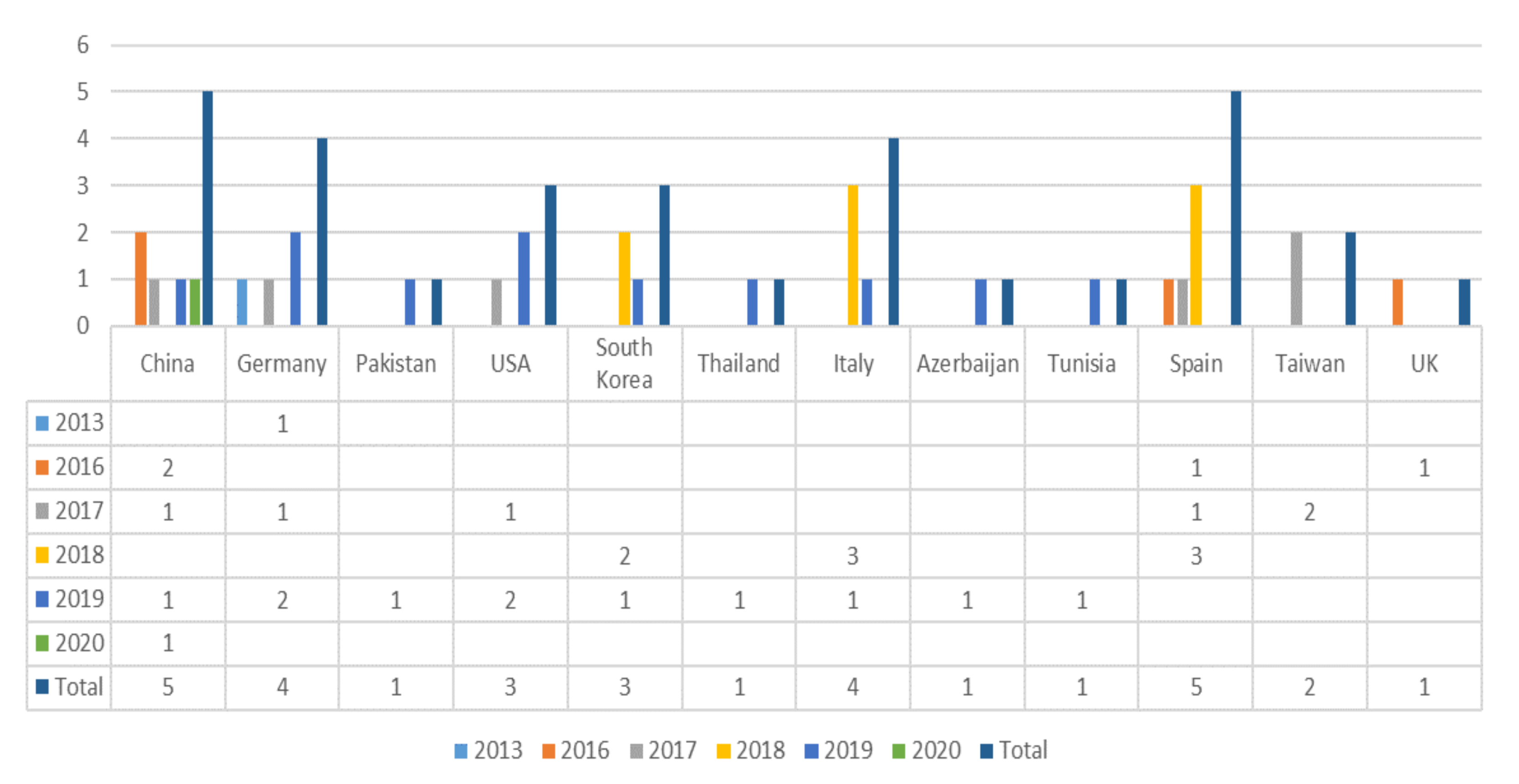

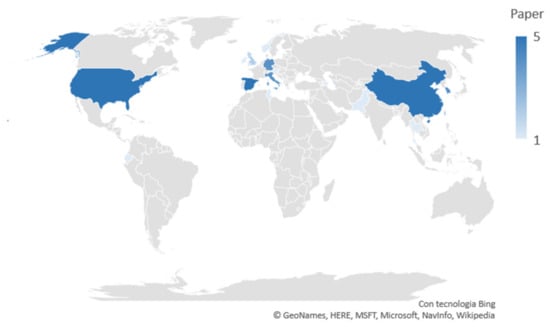

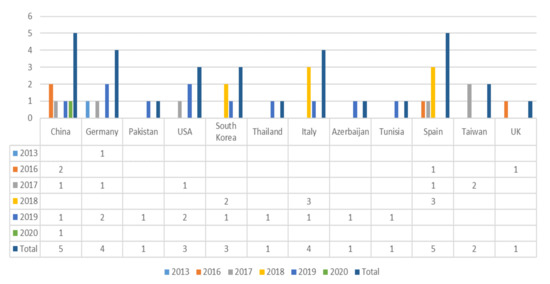

3.3. Country Analysis

Geographical distribution highlights some interesting observations. The first observation it that the most productive countries were China and Spain (Figure 7).

Figure 7.

Country distribution (source: Scopus).

A second observation was that 2019 was the year in which there were more documents published, as shown in Figure 8. The data are not surprising because it demonstrates the growing attention toward these issues.

Figure 8.

Geographic distribution of papers as a function of the publication year (source: Scopus).

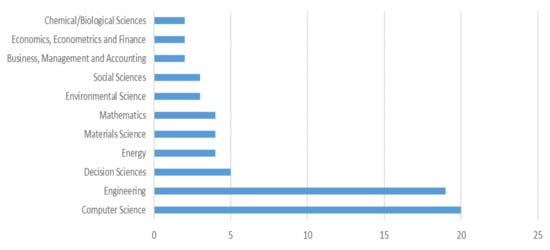

3.4. Subject Area

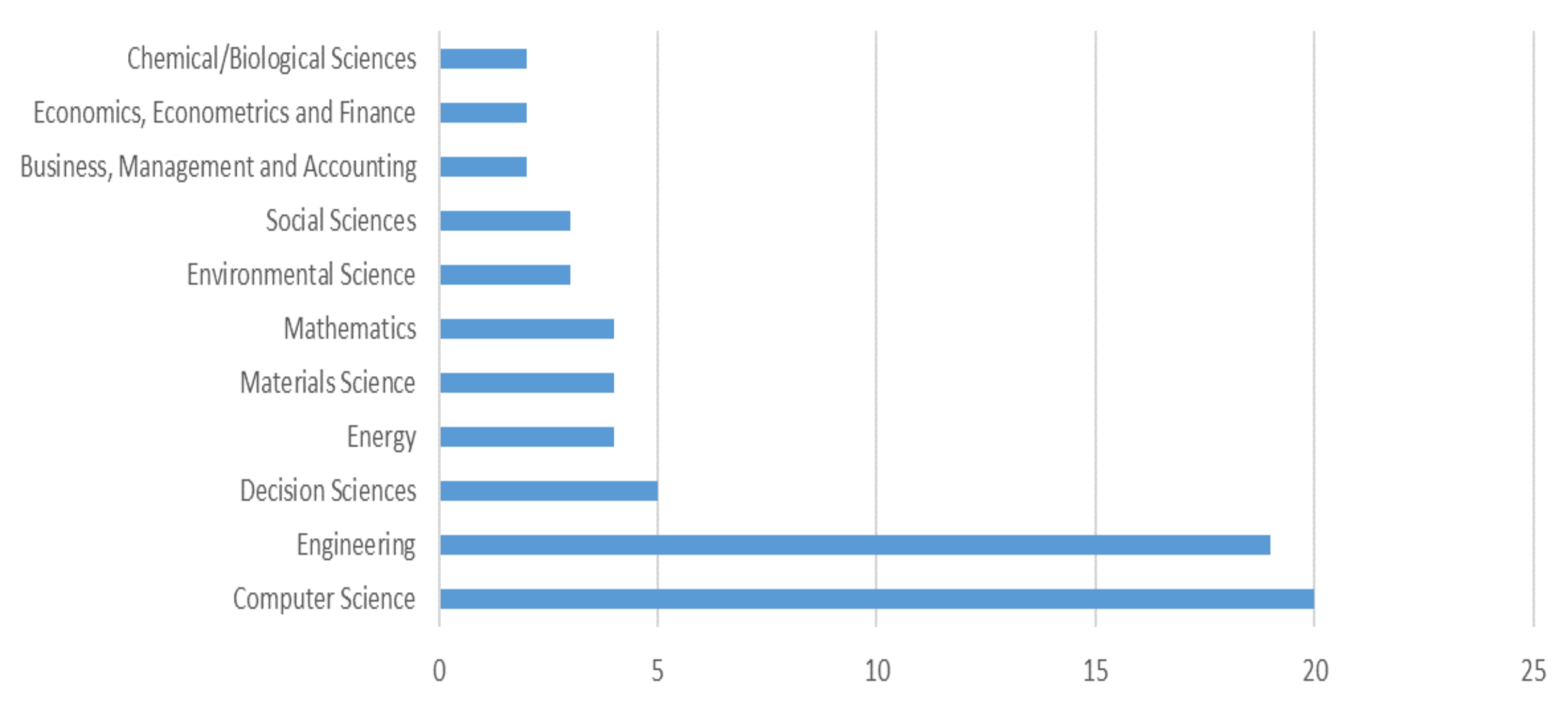

The 31 documents selected included 12 different subject areas and each paper considered the analysis of more than one research area. Figure 9 shows that the most significant areas were computer science and engineering with 29% and 28%, respectively. This means that these two subjects represent 57% of the total contribution. The other subject areas were: decision science (7%); energy, materials science and mathematics (all with 6%), environmental science and social sciences (both with 3%), followed by business, management and accounting, economics, econometrics and finance chemical/biological sciences (all with 3%).

Figure 9.

Publication by subject area (source: Scopus).

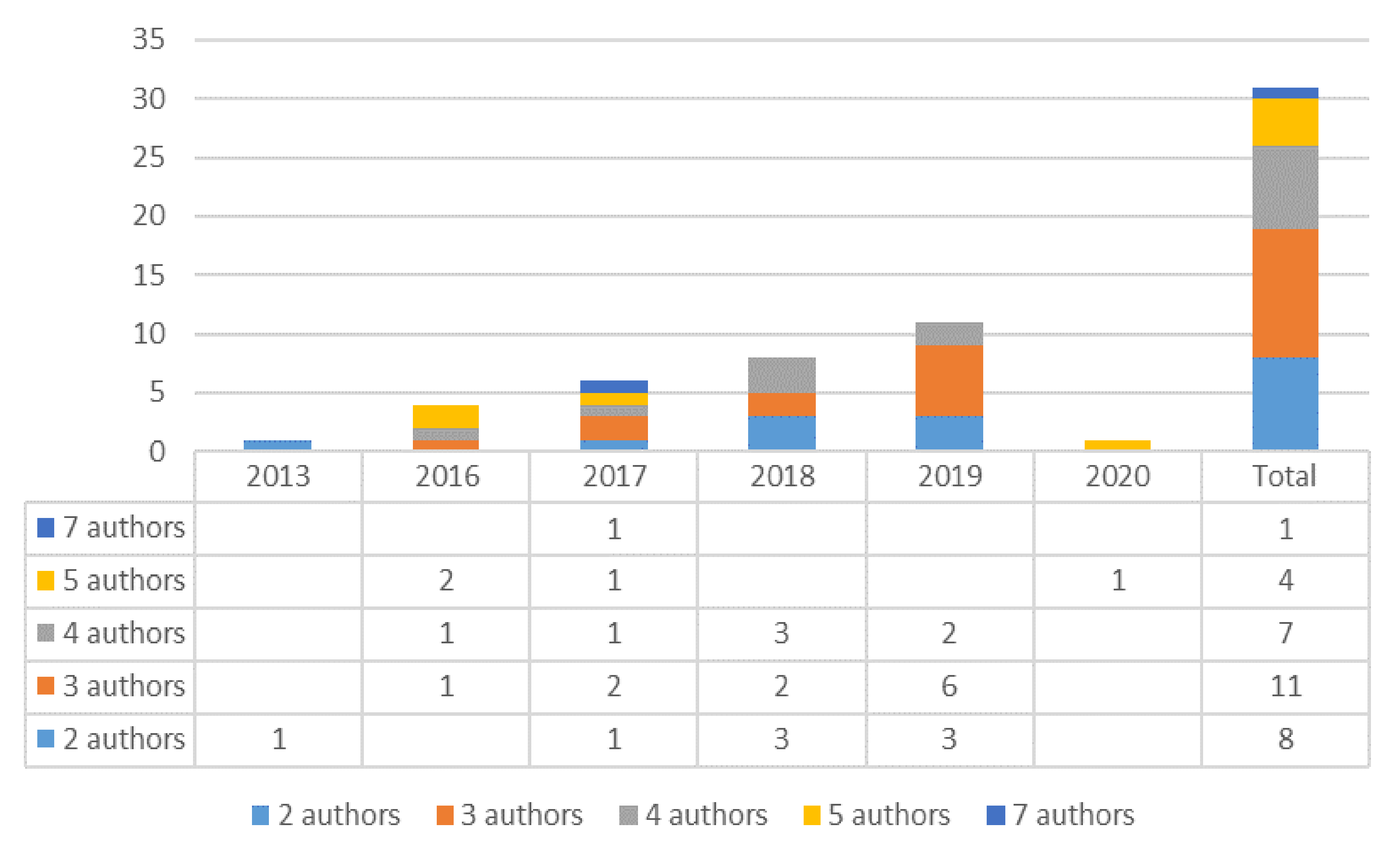

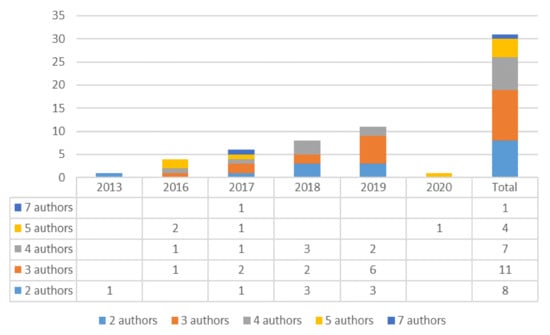

3.5. Most Collaborative Authors

Regarding the authors, a collaboration analysis was carried out. Figure 10 shows that most of the documents (11 documents; 35%) had three authors. Additionally, the second and third level of collaboration, where the authors were respectively two (eight documents; 26%) and four (seven documents; 23%), was quite sensible with eight and seven works, respectively.

Figure 10.

Most collaborative authors (source: Scopus).

3.6. Most Productive Authors

In this section, we analyzed the whole sample of authors. For the 31 papers, there were 100 authors and only four had two publications (13%). All the others only had one publication (87%). This fragmentation is due to the fact that the topics considered in this review are new and have only been particularly studied in the last two years (as already seen in the publication by years analysis). Thus, the number of authors interested in this kind of research has increased during the last period. It is interesting to note that, in general, the most productive authors had a significant number of citations and a good h-index. This means that they are very active in the academic community and in the specific topic analyzed. Table 2 shows the most productive authors as a function of their analyzed documents, their total number of publications, and their h-index.

Table 2.

The most productive authors (source: Scopus).

The analysis of the number of citations represents an important indication to verify the “resonance” of a document in the scientific community. Thus, an interesting point of view has emerged considering the most cited selected documents, as shown in Table 3. It is not surprising that the most quoted document concerns a practical evaluation of augmented reality in an Industry 4.0 [29]. The analysis also showed an interest in circular economy implementation [30].

Table 3.

The most cited documents (source: Scopus).

The most cited documents were analyzed considering the used keywords. As shown in Table 4, the three most used keywords were: (1) cyber physical systems; (2) IoT; and (3) industrial.

Table 4.

The most used Keywords (source SCOPUS).

4. Discussion

The aim of this section is to summarize the main findings of the research. Hence, only representative results from our research are presented. We decided to focus our discussion on conceptual, methodological, and application papers. Reviewer papers are not discussed in detail here since the current state of the main topic of the present research has been argued in the Introduction section.

4.1. Conceptual and Methodological Papers

Based on the contents and findings, the analysis highlighted the following considerations. Considering that an important prerequisite for smart manufacturing is cyber–physical integration, an interesting point of view has emerged from a study published by Chen et al. (2020) [31]. In their paper, the authors developed a conceptual framework for a smart factory integrating digital twin, big data, and edge-to-cloud service technology. Although the proposed CPS can be considered as a simple “set” of innovative technologies, in fact, it is an important support to the decision-making process that is useful in improving production processes, monitor quality, reduce costs, and monitor and provide environmental impact analysis. This means that a CPS represents a strategic tool to economic, social, and environmental aspects to achieve a circular economy. Another interesting issue was addressed by Chung et al. (2019) [32], who proposed Blockchain technology using the Fourier transform algorithm to optimize the manufacturing process and measure the state energy of work. It is clear that Blockchain is an innovative tool that can help to analyze a lot of data and retrace the entire manufacturing chain from an economic and environmental point of view. The analysis of the conceptual and methodological papers revealed that in the context of smart manufacturing, maturity and readiness models are often proposed to assess the adoption of digital technologies in SMEs such as the model conceptualized by Chonsawat and Sopadang (2019) [33]. These are potentially very useful tools since they could help to obtain an assessment of the strengths and weaknesses in the management of a company with a view to Industry 4.0. However, the models presented are often difficult to replicate and do not provide a really useful investigation tool for all management aspects within a company. Moreover, it is clear from the analysis that although there are several models, there is no single and recognized standard. Another interesting aspect that emerged from the survey concerns training. The academic and industrial community recognizes the importance of developing specific skills in the field of smart manufacturing. Generally, this is a proposed platform to help to customize learning through a modular approach such as MOOC (Massive Online Open Course), as described by Bruno and Antonelli (2018) [34]. Of course, these tools are fundamental for improving knowledge in all fields concerning smart manufacturing, ranging from digital technologies to integrated knowledge of economics and sustainability. A potential topic was also presented by Lee et al. (2018) [35], as they explained a conceptual framework based on a human–robot collaboration system to reach a global sustainable manufacturing from the environmental and social aspects. Previously, Lee et al. (2017) also proposed a systematic approach based on cyber–physical systems to optimize predictive production systems toward intelligent and sustainable production systems [36]. Finally, a prospective topic in the context of a circular economy for an intelligent efficiency of industrial water was proposed by Walsh et al. (2016) [37].

4.2. Application Papers

In general, the application papers presented real case studies that best represent the theoretical models and enrich the methodological description. For example, a physics simulation was proposed by Stocker et al. (2019) [38] to train the operators and avoid mistakes at multiple positions and measure the subsequent configuration efficiency. A case study in the field of industrial manufacturing was also presented. In this context, a physics simulation helped to compare various scenarios before implementation to reduce costs and achieve global sustainability within the company. Furthermore, the principle of the Internet of Things and its transfer to the industrial sector, in order to identify not only new managerial models, but to also optimize the efficiency of manufacturing systems, are being developed by several authors. In particular, Weber et. [39], proposed a multi-stage model in the context of industrial service based on IoT useful to generate added value in platform-based ecosystems. An interesting point of view, in the context of manufacturing systems, was presented by Malik and Khan [40], who proposed an optimized IoT based Job Shop Scheduler Monitoring System. The system aims to track the tasks being performed by the machines, enabling automatic detection of the completion time of a job and based on that, dynamic rescheduling. Meanwhile, Corbò et al. [41] applied IoT to develop a Smart Behavioral Filter (SBF) for the Programmable Logic Controllers with the aim to secure the PLC itself against logic attacks. Always in the manufacturing context, Um et al. [42] proposed an IoT standard to monitor an injection moding machine. The proposed system was based on Mobius, developed by the Korea Electronics Technology Institute (KETI). A different approach was analyzed by Arcidiacono and Pieroni [43] and by Fernandez-Carames and Fraga-Lamas [44]. In the first study, they proved the efficiency of the “Lean Six Sigma 4.0” in the context of a HealthCare environment. The second study showed how smart labels can provide identification, tracking, sensing, event detection, and interaction to human-centered Industry 4.0 applications. Emerging research topics include machine learning algorithms to identify technical defects in the manufacturing sector (such as to identify relationships that can be harnessed to preempt electrical defects at downline inspection stations) [45], genetic algorithms to predict customer needs [46], and robot actions using a multi-platform software application [47]. A very nice application was proposed by Zakhama et al. [48]. In particular, a SCARA robot’s system and software implementation were used to detect defects in the product. A compliance rate was calculated using an efficient algorithm. Nice applications based on a CPS were proposed by Jin et al. (2017) [49] and Lin et al. (2017) [50]. Respectively, the first was a framework of CPS as a 5C architecture including connection level, conversion level, cyber level, cognition level, and the second was a smart manufacturing platform based on CPS. Always on CPS, Astarloa et al. (2016) [51] proposed the application of the IEEE1588 protocol to new generation CPSs in order to achieve sub-microsecond synchronization. The analysis of the papers also highlighted the confirmed interest in technologies such as additive manufacturing as a tool to reduce the need for energy- and resource-intensive manufacturing processes [52].

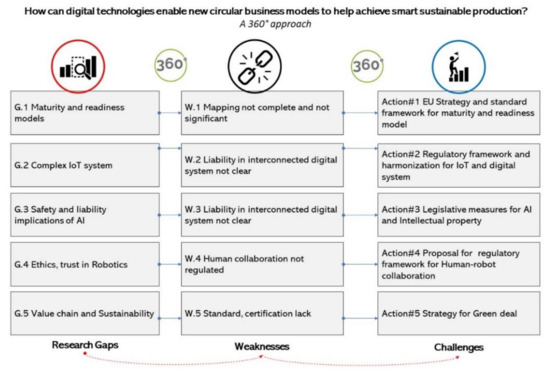

The analysis of selected papers highlighted some research gaps and weaknesses, as summarized in Table 5.

Table 5.

Research gaps and weaknesses.

5. Challenges and Limits

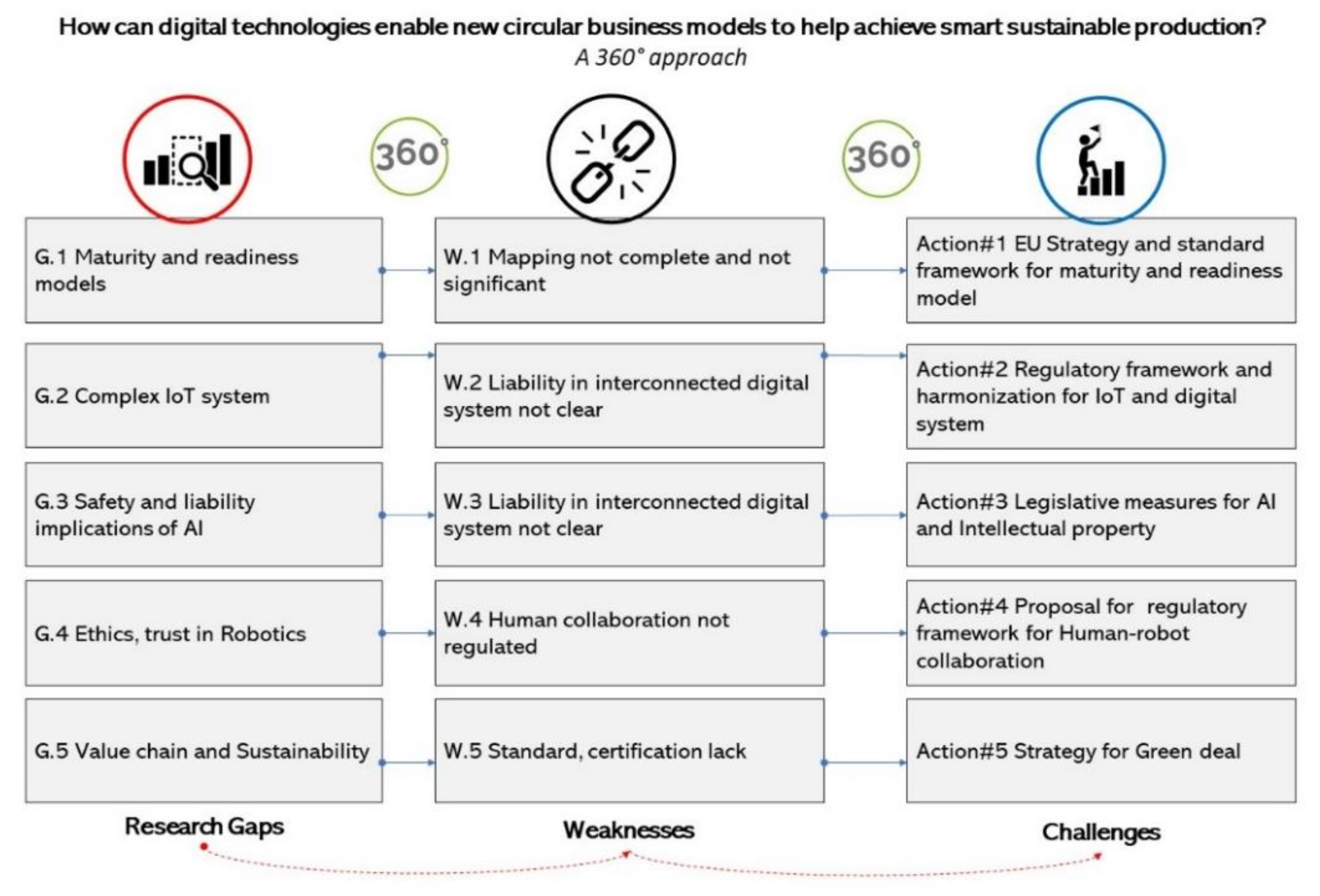

In the context of smart manufacturing, innovation embraces an important part of research and innovation issues. Furthermore, it is evident that Europe is going through an integration of the creation of a more circular economy and the digital revolution. It is also evident that digitally enabled solutions like digital platforms, smart devices, artificial intelligence, and IoT are already contributing to a circular economy. However, the literature analysis pointed out some research gaps and weaknesses on the IoT and some other topics. Based on the reviewed papers, we identified five research gaps: G.1 Maturity and readiness models; G.2 Complex IoT system; G.3 Safety and liability implications of AI; G.4 Ethics, trust in robotics; and G.5 Value chain and sustainability. For each of these categories, we identified five weaknesses and five challenges. Afterward, based on the review of the selected documents, we also identified possible actions to be implemented in the coming future. Figure 11 summarizes the gaps, weaknesses, and challenges that we identified.

Figure 11.

Gaps, weaknesses, and challenges.

Below is a report for each action that we identified, also taking into account some practical implications. Obviously, it is a guideline and we are aware that it is not exhaustive. However, it is the result of our research.

Action #1 Definition of EU Strategy and a standard framework for maturity and readiness model (G.1)

SLR highlighted that before investing in digital technologies, it is necessary to know the status quo in the company. In fact, identifying the level of digital maturity represents a starting point to define strategies. However, although several maturity models have been proposed in the literature to assist organizations, there is no structured and universal model [53,54]. This means that on one hand, it is possible to measure the maturity of an organization; on the other hand, since a single standard is missing, a comparison is not possible. In other words, a good model should allow one to answer the question “What is the digital maturity of a company?” and should be a standard. The challenge for the near future is to develop a self-diagnosis tool at the regulatory level (for example, ISO - International Organization for Standardization) to measure a maturity index. The final goal should be to evaluate maturity and digital potential.

Action #2 Regulatory framework and harmonization for IoT and digital system (G.2)

In this context, the SRL pointed out that the digital revolution implies that more digital data are being generated than ever before. This means that everyday physical objects are connected to each other through the so-called IoT, and so can be used in several contexts. Practically through IoT (tracking, monitoring, control, and optimization), it will be possible to implement a circular strategy for the efficient use of resources, or to reuse and recycle products or to increase the product lifetime. According to forecasts, by 2020, Wi-Fi connected devices will exceed 20 million. However, this could cause an exponential increase in the risks for user data, and therefore to their rights. The challenge is to contribute to a uniform application of the legislation on the protection of personal data within the IoT. It is of fundamental importance to identify the roles (owner, manager, authorized) of the various subjects operating in the IoT area in order to correctly apply the relevant legislation. Thus, an European analytical framework for measuring data flows should be pursued.

Action #3 Legislative measures for AI and Intellectual property (G.3)

According to the literature analysis, AI is destined to play an increasing role in the society of the third millennium, determining the progressive automation of the processes and functioning of an exponential number of sectors. However, one of the most discussed legal issues in relation to the diffusion and use of AI systems concerns the applicability to this area of the intellectual property law. In particular, the attribution of ownership of the rights that arise on the works is a crucial point. Thus, it seems that the future challenge is to define clear rules on who owns the property rights of the work created by AI that will allow the safe and reliable development of AI in Europe, with full respect to the values and rights of EU citizens. In other words, a collective and decisive EU agenda for AI is necessary to promote high ethical standards and to adopt principles and global standards.

Action #4 Proposal for regulatory framework for Human-robot collaboration (G.4)

In this context, SRL pointed out that digitalization and intelligent robotics are useful tools to optimize the value chain of an organization in the circular economy perspective and to ensure global sustainable manufacturing and mass customization. Examples are remanufacturing, recycling, and disassembly processes. Thus, the challenge is to promote the adoption of principles and global standards to ensure the safety of humans and to develop a comprehensive, systematic, and intelligent human–robot collaboration.

Action #5 Strategy for Green deal (G.5)

SLR highlighted that the challenge for the future is to develop advanced and sustainable materials, that are designed to meet the specific needs of societal and industry to benefit the widest community of users. These materials should be safe, sustainable, competitive within the circular economy, and respect regulatory standards. Furthermore, regulation, testing methodologies, and risk assessment standards must be improved to keep pace with innovation as well as conform to the circular economy. Thus, promoting a reference legislative framework to design, choose, and produce circular products should be a priority and it would be desirable to identify a “dashboard” containing standard Key Performance Indicators (KPIs) with the aim of constantly monitoring progress toward four thematic areas: sustainable production and consumption, waste management, secondary raw materials, and innovation. In this way, the circularity measure indicators in the criteria could be considered to access funding and incentives. In addition, it could be useful to develop homogeneous and harmonized data collection and processing tools such as The European Resource Efficiency Knowledge Center platform that provides information on improving resource efficiency.

6. Conclusions

6.1. Concluding Remarks

The present study represents a first investigation in the field of “digital manufacturing” and “sustainability” with a focus on circular economy. It is possible to draw some conclusions, according to some specific results discussed in the previous sections. In the context of manufacturing digitalization, smart manufacturing embraces an important part of the research and innovation issues indicated as priorities for the future. In particular, the digitalization of companies is strongly focusing on new technologies such as IoT and on more innovative business models. New business models are focused on reduction, collection, reuse, recovery, and recycling. If principles and best practices of smart manufacturing are fully implemented, companies will have the opportunity to maximize the synergies between digitalization and circular economy. In this way, it will possible to maximize reuse, reduce energy waste, save capital, re-manufacturing and recycling of products, components and materials in order to increase overall sustainability and profit. For example, Google is applying machine learning to improve their energy efficiency, and companies such as Bosch and Siemens are developing smart digital factories built on AI and machine learning, which can reduce energy consumption and waste during production.

6.2. Theoretical and Policy Implications

A circular economy, together with the development of new technologies, is bringing numerous benefits, especially in terms of economic, social, and environmental sustainability, and only in the European area will it be able to achieve a surprising impact that is estimated to be around € 1.8 trillion in benefits by 2030, with a relative increase in GDP of 11%. Thus, innovative and digital technologies are indeed a powerful enabler of the circular economy, but their implementation must be conducted within a “conscious” innovation path. It is necessary to think systemically, define a vision, and act. In fact, although there are cases of success in which the circular economy has effectively guaranteed an economic return in short times, generally, the recovery times of investments are still rather long, confirming the need for financial support through tax breaks and/or credits. The digitalization of industry can only succeed when innovation, sustainability, ethics, and society are understood as intertwining elements of one whole.

6.3. Limitations and Guidelines for Future Research

An obvious, but important point to remember is that a systematic review is subject to some limitations. It is possible to comment only on what is found. In addition, it is important to note that at present, only a small number of manuscripts have been published on the investigated topic. We are aware that it is not an exhaustive study. Therefore, the future development of the present research intends to systematically analyze the evolution of academic interest on these topics. Starting from the methodological approach outlined and structured in this first paper, the goal will be to update the survey in the next two years. Furthermore, the idea for future developments is to extend the work toward manufacturing process optimization/control, scheduling, and simulation of systems as well as supply chain management.

Author Contributions

All authors contributed equally to this work. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

This work was conducted under the framework of the Italian project “Linee Guida per I4.0—Campania”—funded by Regione Campania within POR FSE 2014-2020 Asse IV “Capacità istituzionale e amministrativa” objectives 18 (RA) 11.3 and 21 (RA) 11.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

Full list of analyzed papers.

Table A1.

Full list of analyzed papers.

| # | Authors | Year | Title | Journal/Proceedings | No. of Citations |

|---|---|---|---|---|---|

| 1 | Chen et al. | 2020 | The framework design of smart factory in discrete manufacturing industry based on cyber-physical system | International Journal of Computer Integrated Manufacturing | 0 |

| 2 | Stocker et al. | 2019 | Reinforcement learning–based design of orienting devices for vibratory bowl feeders | International Journal of Advanced Manufacturing Technology | 1 |

| 3 | Weber et al. | 2019 | Design and evaluation of an approach to generate cross-domain value scenarios in the context of the industrial internet of things: A capability-based approach | PICMET 2019-Portland International Conference on Management of Engineering and Technology: Technology Management in the World of Intelligent Systems, Proceedings | 0 |

| 4 | Malik and Khan | 2019 | IoT based job shop scheduler monitoring system | Proceedings-2019 IEEE International Congress on Cybermatics: 12th IEEE International Conference on Internet of Things, 15th IEEE International Conference on Green Computing and Communications, 12th IEEE International Conference on Cyber, Physical and Social Computing and 5th IEEE International Conference on Smart Data, iThings/GreenCom/CPSCom/SmartData 2019 | 0 |

| 5 | Chung et al. | 2019 | Blockchain Network Based Topic Mining Process for Cognitive Manufacturing | Wireless Personal Communications | 11 |

| 6 | Um et al. | 2019 | Industrial Device Monitoring and Control System based on oneM2M for Edge Computing | Proceedings of the 2018 IEEE Symposium Series on Computational Intelligence, SSCI 2018 | 3 |

| 7 | LaCasse et al. | 2019 | Operationalization of a Machine Learning and Fuzzy Inference-Based Defect Prediction Case Study in a Holonic Manufacturing System | Lecture Notes in Computer Science (including subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics) | 0 |

| 8 | Chonsawat and Sopadang | 2019 | The development of the maturity model to evaluate the smart SMEs 4.0 readiness | Proceedings of the International Conference on Industrial Engineering and Operations Management | 0 |

| 9 | Cimini et al. | 2019 | Industry 4.0 technologies impacts in the manufacturing and supply chain landscape: An overview | Studies in Computational Intelligence | 0 |

| 10 | Shang and You | 2019 | Data Analytics and Machine Learning for Smart Process Manufacturing: Recent Advances and Perspectives in the Big Data Era | Engineering | 0 |

| 11 | Ahadov et al. | 2019 | A summary of adapting Industry 4.0 vision into engineering education in Azerbaijan | IOP Conference Series: Materials Science and Engineering | 0 |

| 12 | Zakhama et al. | 2019 | Intelligent Selective Compliance Articulated Robot Arm robot with object recognition in a multi-agent manufacturing system | International Journal of Advanced Robotic Systems | 0 |

| 13 | Martín Gómez et al. | 2018 | Smart eco-industrial parks: A circular economy implementation based on industrial metabolism | Resources, Conservation and Recycling | 21 |

| 14 | Corbò et al. | 2018 | Smart Behavioral Filter for Industrial Internet of Things: A Security Extension for PLC | Mobile Networks and Applications | 0 |

| 15 | Bruno and Antonelli | 2018 | Ontology-based platform for sharing knowledge on industry 4.0 | IFIP Advances in Information and Communication Technology | 0 |

| 16 | Lee et al. | 2018 | A framework for process model based human-robot collaboration system using augmented reality | IFIP Advances in Information and Communication Technology | 0 |

| 17 | Arcidiacono and Pieroni | 2018 | The revolution Lean Six Sigma 4.0 | International Journal on Advanced Science, Engineering and Information Technology | 6 |

| 18 | Shim et al. | 2018 | Sustainable production scheduling in open innovation perspective under the fourth industrial revolution | Journal of Open Innovation: Technology, Market, and Complexity | 5 |

| 19 | Fernandez-Carames et al. | 2018 | A Review on Human-Centered IoT-Connected Smart Labels for the Industry 4.0 | IEEE Access | 23 |

| 20 | Blanco-Novoa et al. | 2018 | A Practical Evaluation of Commercial Industrial Augmented Reality Systems in an Industry 4.0 Shipyard | IEEE Access | 28 |

| 21 | Jin et al. | 2017 | CPS-enabled worry-free industrial applications | 2017 Prognostics and System Health Management Conference, PHM-Harbin 2017-Proceedings | 0 |

| 22 | Lin, Y.-C. et al. | 2017 | Development of Advanced Manufacturing Cloud of Things (AMCoT)-A Smart Manufacturing Platform | IEEE Robotics and Automation Letters | 27 |

| 23 | Lee et al. | 2017 | Cyber physical systems for predictive production systems | Production Engineering | 22 |

| 24 | Ramon et al. | 2017 | Development of a simple manufacturing process for all-inkjet printed organic thin film transistors and circuits | IEEE Journal on Emerging and Selected Topics in Circuits and Systems | 6 |

| 25 | Mueller et al. | 2017 | Challenges and Requirements for the Application of Industry 4.0: A Special Insight with the Usage of Cyber-Physical System | Chinese Journal of Mechanical Engineering (English Edition) | 14 |

| 26 | Hsiao and Huang | 2017 | Iterative learning control for trajectory tracking of robot manipulators | International Journal of Automation and Smart Technology | 6 |

| 27 | Saldivar et al. | 2016 | Identifying smart design attributes for Industry 4.0 customization using a clustering Genetic Algorithm | 2016 22nd International Conference on Automation and Computing, ICAC 2016: Tackling the New Challenges in Automation and Computing | 5 |

| 28 | Astarloa et al. | 2016 | FPGA based nodes for sub-microsecond synchronization of cyber-physical production systems on high availability ring networks | 2015 International Conference on ReConFigurable Computing and FPGAs, ReConFig 2015 | 1 |

| 29 | Walsh et al. | 2016 | An industrial water management value system framework development | Sustainable Production and Consumption | 11 |

| 30 | Fang et al. | 2016 | Closed Loop PMI Driven Dimensional Quality Lifecycle Management Approach for Smart Manufacturing System | Procedia CIRP | 4 |

| 31 | Kannengiesser and Müller | 2013 | Toward agent-based smart factories: A subject-oriented modeling approach | Proceedings-2013 IEEE/WIC/ACM International Joint Conference on Web Intelligence and Intelligent Agent Technology-Workshops, WI-IATW 2013 | 17 |

References

- Fang, F.Z.; Li, Z.; Arokiam, A.; Gorman, T. Closed Loop PMI Driven Dimensional Quality Lifecycle Management Approach for Smart Manufacturing System. Procedia CIRP 2016, 56, 614–619. [Google Scholar] [CrossRef]

- Mourtzis, D. Simulation in the design and operation of manufacturing systems: State of the art and new trends. Int. J. Prod. Res. 2019, 58, 1927–1949. [Google Scholar] [CrossRef]

- Shim, S.-O.; Park, K.; Choi, S. Sustainable production scheduling in open innovation perspective under the fourth industrial revolution. J. Open Innov. 2018, 4, 42. [Google Scholar] [CrossRef]

- Kannengiesser, U.; Müller, H. Towards agent-based smart factories: A subject-oriented modeling approach. In Proceedings of the 2013 IEEE/WIC/ACM International Joint Conference on Web Intelligence and Intelligent Agent Technology—Workshops (WI-IATW), Atlanta, GA, USA, 17–20 November 2013; pp. 83–86. [Google Scholar]

- Mueller, E.; Chen, X.-L.; Riedel, R. Challenges and Requirements for the Application of Industry 4.0: A Special Insight with the Usage of Cyber-Physical System. Chin. J. Mech. Eng. 2017, 30, 1050–1057. [Google Scholar] [CrossRef]

- Cui, Y.; Kara, S.; Chan, K.C. Manufacturing big data ecosystem: A systematic literature review. Robot. Comput. Integr. Manuf. 2020, 62, 101861. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Lona, L.R.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Jermsittiparsert, K.; Namdej, P.; Sriyakul, T. Impact of quality management techniques and system effectiveness on the green supply chain management practices. Int. J. Sup. Chain Manag. 2019, 8, 120–130. [Google Scholar]

- Chen, S.; Brahma, S.; Mackay, J.; Cao, C.; Aliakbarian, B. The role of smart packaging system in food supply chain. J. Food Sci. 2020, 85, 517–525. [Google Scholar] [CrossRef]

- Zheng, T.; Ardolino, M.; Bacchetti, A.; Perona, M. Enabling Technologies, Impacts and Challenges of “industry 4.0” in the Manufacturing Context: Some Insights from a Preliminary Literature Review.; Summer School “Francesco Turco”: Mount Pleasant, UT, USA, 2019; Volume 1, pp. 27–33. [Google Scholar]

- Prause, G.; Atari, S. On sustainable production networks for industry 4.0. Entrepreneurship Sustain. Issues 2017, 4, 421–431. [Google Scholar] [CrossRef]

- Climate Change and Land; Special Report; Intergovernmental Panel on Climate Change: Geneva, The Switzerland, 2020; ISBN 978-92-9169-154-8.

- MacArthur., E. Towards a Circular Economy, Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2012. [Google Scholar]

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring How Usage-Focused Business Models Enable Circular Economy through Digital Technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef]

- Zorpas, A.A. Strategy development in the framework of waste management. Sci. Total Environ. 2020, 716, 137088. [Google Scholar] [CrossRef] [PubMed]

- Report of the Secretary-General on the 2019 Climate Action Summit and the Way Forward in 2020. Available online: https://www.un.org/en/climatechange/assets/pdf/cas_report_11_dec.pdf (accessed on 22 March 2020).

- Cioffi, R.; Travaglioni, M.; Piscitelli, G.; Petrillo, A.; De Felice, F. Artificial intelligence and machine learning applications in smart production: Progress, trends, and directions. Sustainability 2020, 12, 492. [Google Scholar] [CrossRef]

- De Felice, F.; Petrillo, A.; Cooper, O. An integrated conceptual model to promote green policies. Int. J. Innov. Sustain. Dev. 2013, 7, 333–355. [Google Scholar] [CrossRef]

- Cimini, C.; Pezzotta, G.; Pinto, R.; Cavalieri, S. Industry 4.0 technologies impacts in the manufacturing and supply chain landscape: An overview. Studies Comp. Intel. 2019, 803, 109–120. [Google Scholar]

- Shang, C.; You, F. Data Analytics and Machine Learning for Smart Process Manufacturing: Recent Advances and Perspectives in the Big Data Era. Engineering 2019, 5, 1010–1016. [Google Scholar] [CrossRef]

- Ahadov, A.; Asgarov, E.S.; El-Thalji, I. A summary of adapting Industry 4.0 vision into engineering education in Azerbaijan. IOP Conf. Ser. Mater. Sci. Eng. 2019, 700, 012063. [Google Scholar] [CrossRef]

- Clarke, M.; Chalmers, I. Reflections on the history of systematic reviews. BMJ Evid.-Based Med. 2018, 23, 121–122. [Google Scholar] [CrossRef]

- Idrissi, N.; Zellou, A. A systematic literature review of sparsity issues in recommender systems. Soc. Netw. Anal. Min. 2020, 10, 15. [Google Scholar] [CrossRef]

- Pieper, D.; Mathes, T.; Eikermann, M. Impact of choice of quality appraisal tool for systematic reviews in overviews. J. Evid. Based Med. 2014, 7, 72–78. [Google Scholar] [CrossRef]

- Kitchenham, B. Procedures for Performing Systematic Reviews; Technical Report TR/SE-0401; Keele University: Newcastle, UK, 2004. [Google Scholar]

- Bilotta, G.S.; Milner, A.M.; Boyd, I. On the use of systematic reviews to inform environmental policies. Environ. Sci. Policy 2004, 42, 67–77. [Google Scholar] [CrossRef]

- Bearman, M.; Dawson, P. Qualitative synthesis and systematic review in health professions education. Med. Educ. 2013, 47, 252–260. [Google Scholar] [CrossRef] [PubMed]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. J. Clin. Epidemiol. 2009, 62, 1006–1012. [Google Scholar] [CrossRef]

- Blanco-Novoa, O.; Fernandez-Carames, T.M.; Fraga-Lamas, P.; Vilar-Montesinos, M.A. A Practical Evaluation of Commercial Industrial Augmented Reality Systems in an Industry 4.0 Shipyard. IEEE Access 2018, 6, 8201–8218. [Google Scholar] [CrossRef]

- Martín Gómez, A.M.; Aguayo González, F.; Marcos Bárcena, M. Smart eco-industrial parks: A circular economy implementation based on industrial metabolism. Res. Conser. Recycl. 2018, 135, 58–69. [Google Scholar] [CrossRef]

- Chen, G.; Wang, P.; Feng, B.; Li, Y.; Liu, D. The framework design of smart factory in discrete manufacturing industry based on cyber-physical system. Int. J. Comput. Integr. Manuf. 2020, 33, 79–101. [Google Scholar] [CrossRef]

- Chung, K.; Yoo, H.; Choe, D.; Jung, H. Blockchain Network Based Topic Mining Process for Cognitive Manufacturing. Wirel. Pers. Commun. 2019, 105, 583–597. [Google Scholar] [CrossRef]

- Chonsawat, N.; Sopadang, A. The development of the maturity model to evaluate the smart SMEs 4.0 readiness. In Proceedings of the International Conference on Industrial Engineering and Operations Management, JW Marriott Hotel Bangkok, Bangkok, Thailand, 5–7 March 2019; pp. 354–363. [Google Scholar]

- Bruno, G.; Antonelli, D. Ontology-based platform for sharing knowledge on industry 4.0. IFIP Adv. Inf. Commun. Technol. 2018, 540, 377–385. [Google Scholar]

- Lee, H.; Liau, Y.; Kim, S.; Ryu, K. A framework for process model based human-robot collaboration system using augmented reality. IFIP Adv. Inf. Commun. Technol. 2018, 536, 482–489. [Google Scholar]

- Lee, J.; Jin, C.; Bagheri, B. Cyber physical systems for predictive production systems. Prod. Eng. 2017, 11, 155–165. [Google Scholar] [CrossRef]

- Walsh, B.P.; Cusack, D.O.; O’Sullivan, D.T.J. An industrial water management value system framework development. Sustain. Prod. Consum. 2016, 5, 82–93. [Google Scholar] [CrossRef]

- Stocker, C.; Schmid, M.; Reinhart, G. Reinforcement learning–based design of orienting devices for vibratory bowl feeders. Int. J. Adv. Manuf. Technol. 2019, 105, 3631–3642. [Google Scholar] [CrossRef]

- Weber, P.; Hiller, S.; Lasi, H. Design and evaluation of an approach to generate cross-domain value scenarios in the context of the industrial internet of things: A capability-based approach. In Proceedings of the PICMET 2019 Portland International Conference on Management of Engineering and Technology: Technology Management in the World of Intelligent Systems, Portland, OR, USA, 25–29 August 2019. [Google Scholar]

- Malik, K.; Khan, S.A. Iiot based job shop scheduler monitoring system. In Proceedings of the 2019 IEEE International Congress on Cybermatics: 12th IEEE International Conference on Internet of Things, Atlanta, GA, USA, 14–17 July 2019. [Google Scholar]

- Corbò, G.; Foglietta, C.; Palazzo, C.; Panzieri, S. Smart Behavioural Filter for Industrial Internet of Things: A Security Extension for PLC. Mob. Netw. Appl. 2018, 23, 809–816. [Google Scholar] [CrossRef]

- Um, C.; Lee, J.; Jeong, J. Industrial Device Monitoring and Control System based on oneM2M for Edge Computing. In Proceedings of the 2018 IEEE Symposium Series on Computational Intelligence, SSCI 2018, Bangalore, India, 18–21 November 2018; pp. 1528–1533. [Google Scholar]

- Arcidiacono, G.; Pieroni, A. The revolution Lean Six Sigma 4.0. Int. J. Adv. Sci. Eng. Inf. Technol. 2018, 8, 141–149. [Google Scholar] [CrossRef]

- Fernandez-Carames, T.M.; Fraga-Lamas, P. A Review on Human-Centered IoT-Connected Smart Labels for the Industry 4.0. IEEE Access 2018, 6, 25939–25957. [Google Scholar] [CrossRef]

- LaCasse, P.M.; Otieno, W.; Maturana, F.P. Operationalization of a Machine Learning and Fuzzy Inference-Based Defect Prediction Case Study in a Holonic Manufacturing System. Lect. Notes Comput. Sci. 2019, 96–104. [Google Scholar]

- Saldivar, A.A.F.; Goh, C.; Li, Y.; Chen, Y.; Yu, H. dentifying smart design attributes for Industry 4.0 customization using a clustering Genetic Algorithm. In Proceedings of the 22nd International Conference on Automation and Computing, ICAC 2016: Tackling the New Challenges in Automation and Computing, Colchester, UK, 7–8 September 2016; pp. 408–414. [Google Scholar]

- Hsiao, T.; Huang, P.-H. Iterative Learning Control for Trajectory Tracking of Robot Manipulators. Int. J. Autom. Smart Technol. 2017, 7, 133–139. [Google Scholar] [CrossRef]

- Zakhama, A.; Charrabi, L.; Jelassi, K. Intelligent Selective Compliance Articulated Robot Arm robot with object recognition in a multi-agent manufacturing system. Int. J. Adv. Rob. Syst. 2019, 16, 16. [Google Scholar] [CrossRef]

- Jin, W.; Liu, Z.; Shi, Z.; Jin, C.; Lee, J. CPS-enabled worry-free industrial applications. In Proceedings of the Prognostics and System Health Management Conference, PHM-Harbin, Harbin, China, 9–12 July 2017. [Google Scholar]

- Lin, Y.-C.; Hung, M.-H.; Huang, H.-C.; Chen, C.-C.; Yang, H.-C.; Hsieh, Y.-S.; Cheng, F.-T. Development of Advanced Manufacturing Cloud of Things (AMCoT)-A Smart Manufacturing Platform. IEEE Rob. Autom. Lett. 2017, 2, 1809–1816. [Google Scholar] [CrossRef]

- Astarloa, A.; Moreira, N.; Bidarte, U.; Urbina, M.; Modrono, D. FPGA based nodes for sub-microsecond synchronization of cyber-physical production systems on high availability ring networks. In Proceedings of the 2015 International Conference on ReConFigurable Computing and FPGAs, ReConFig 2015, Mexico City, Mexico, 7–9 December 2015. [Google Scholar]

- Ramon, E.; Martinez-Domingo, C.; Alcalde-Aragones, A.; Carrabina, J. Development of a simple manufacturing process for all-inkjet printed organic thin film transistors and circuits. IEEE J. Emerg. Sel. Top. Circuits Syst. 2017, 7, 161–170. [Google Scholar] [CrossRef]

- Facchini, F.; Olésków-Szłapka, J.; Ranieri, L.; Urbinati, A. A maturity model for logistics 4.0: An empirical analysis and a roadmap for future research. Sustainability 2020, 12, 86. [Google Scholar] [CrossRef]

- Schumacher, A.; Schumacher, C.; Sihn, W. Industry 4.0 Operationalization Based on an Integrated Framework of Industrial Digitalization and Automation. Lect. Notes Mech. Eng. 2020, 301–310. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).