Comparison of Wear Performance of Austempered and Quench-Tempered Gray Cast Irons Enhanced by Laser Hardening Treatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. As-Received Gray Cast Iron

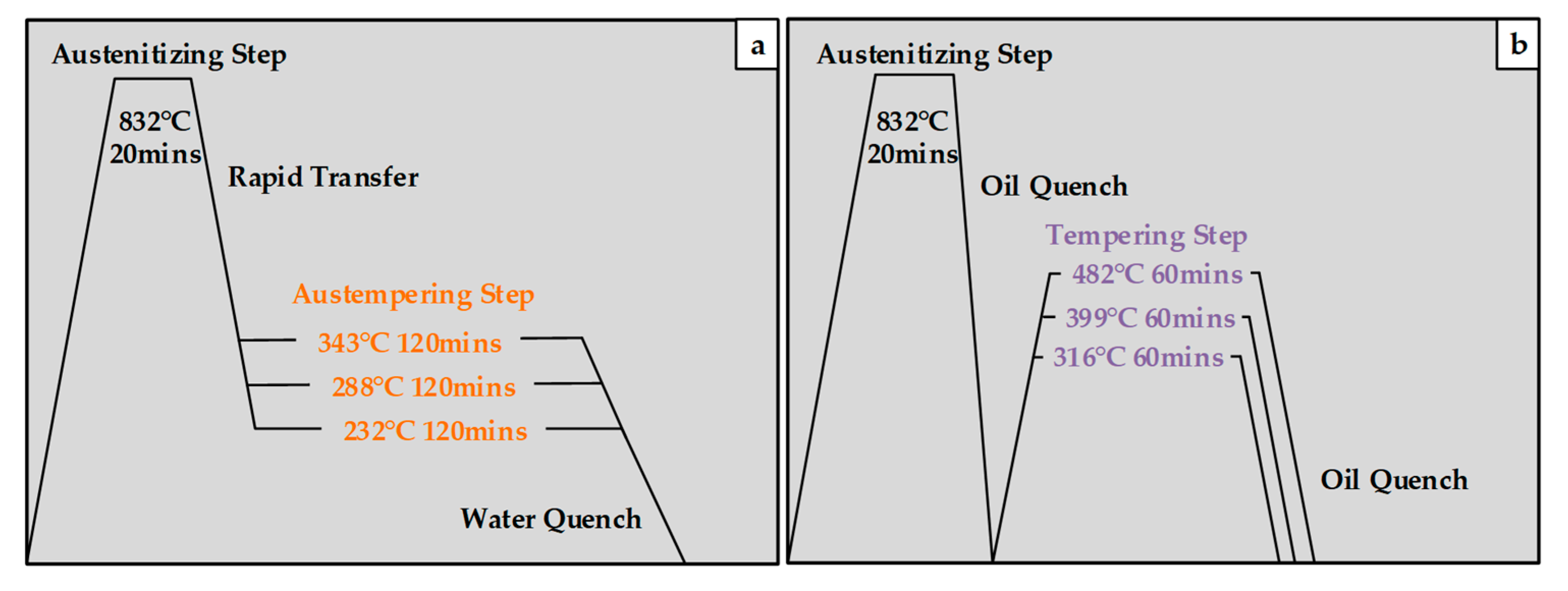

2.2. Heat Treatment Designs

2.2.1. Austempering Heat Treatment

2.2.2. Quench-Tempering Heat Treatment

2.3. Metallurgical Evaluation

2.4. Hardness Measurement

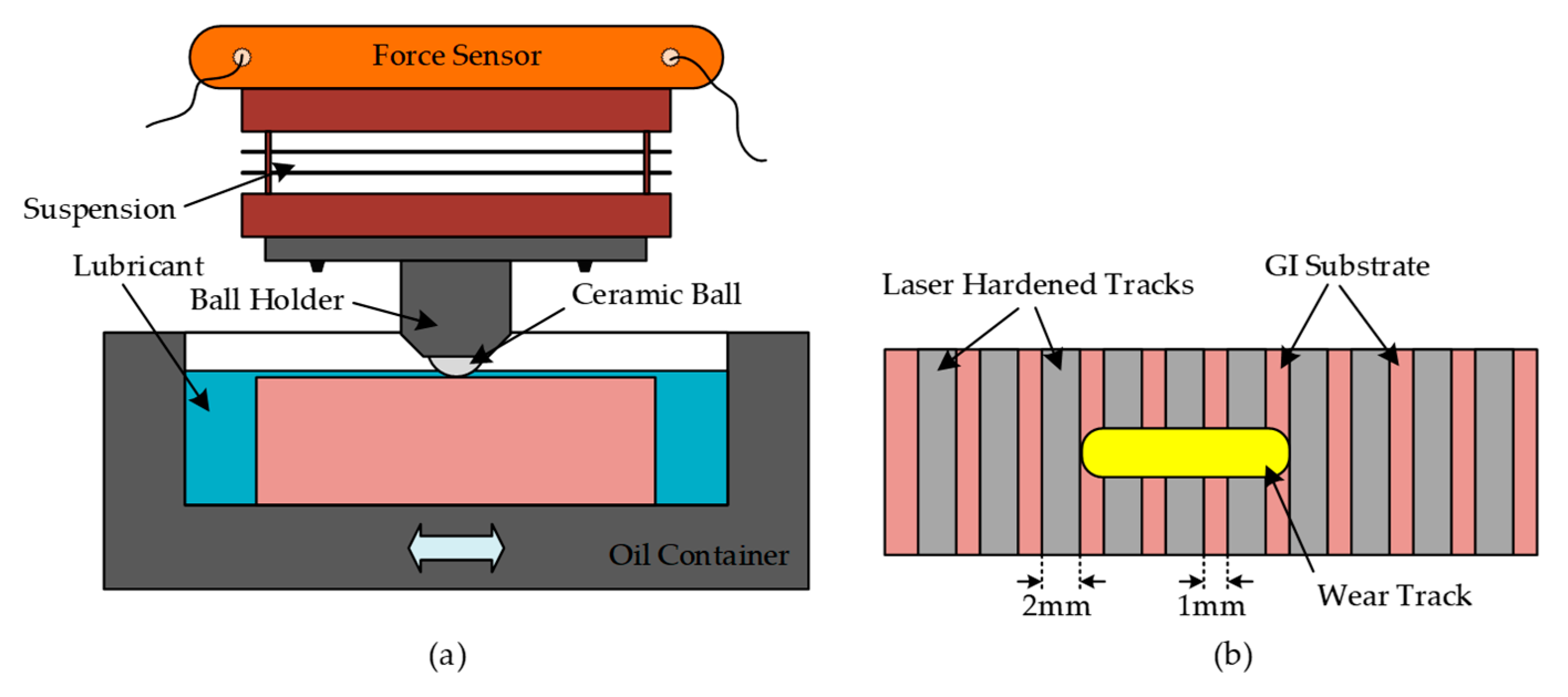

2.5. Ball-On-Flat Reciprocating Wear Tests

2.6. Laser Surface-Hardening Process

3. Results

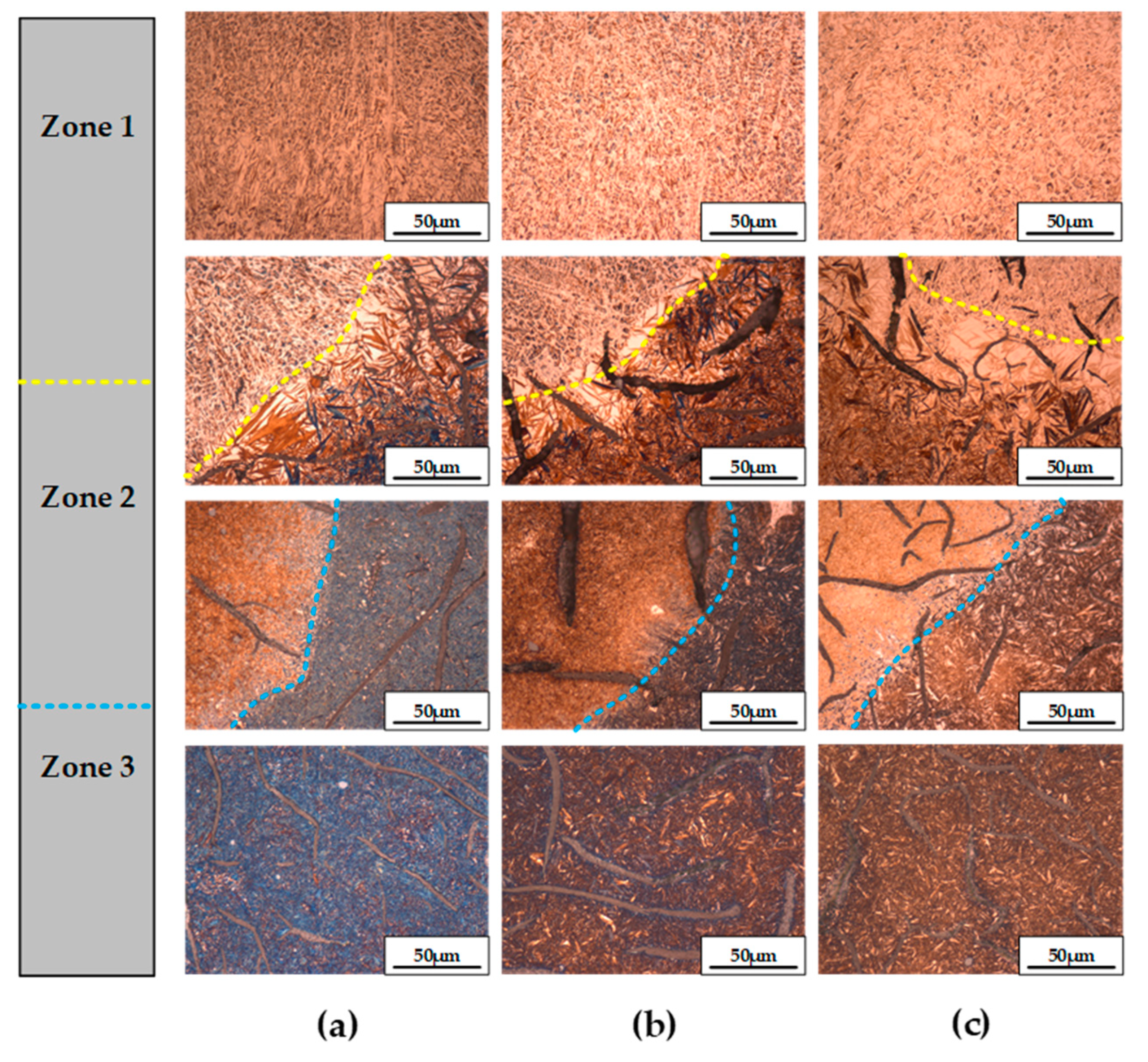

3.1. Microstructure

3.1.1. Laser-Hardened Austempered Gray Cast Iron (LHAGI)

3.1.2. Laser-Hardened Quench-Tempered Gray Cast Iron (LHQTGI)

3.2. Hardness

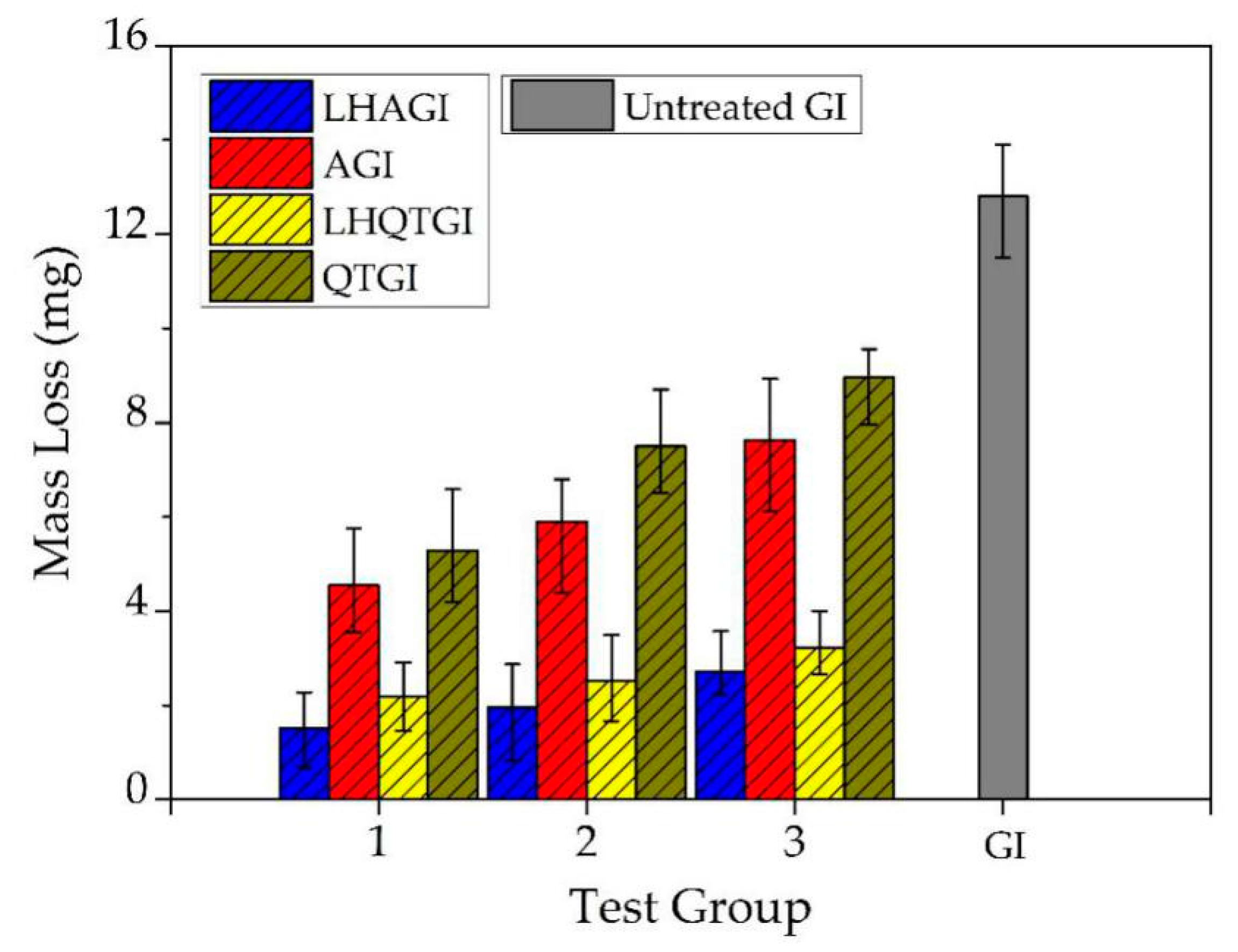

3.3. Wear Properties

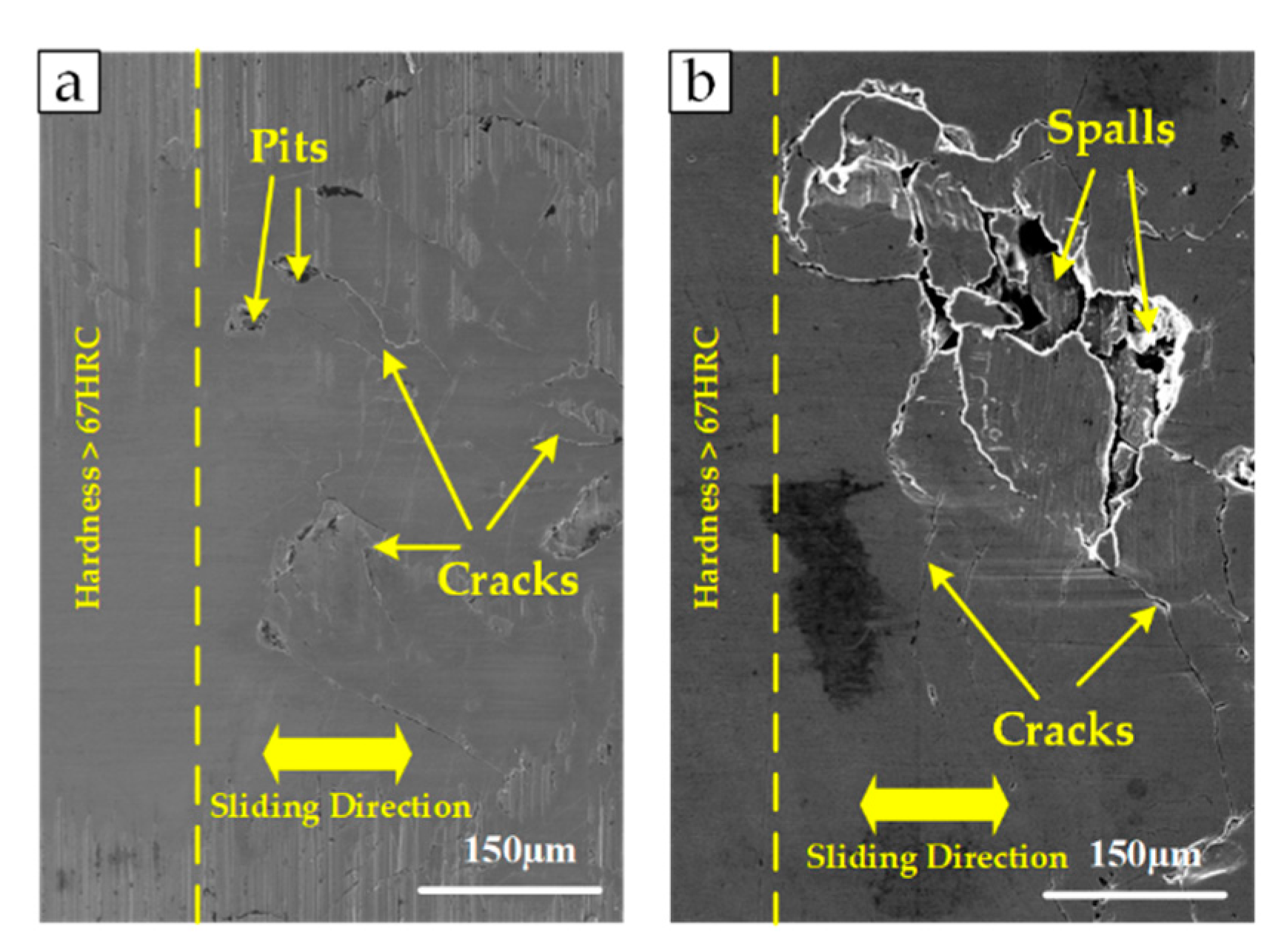

3.4. Worn Surfaces

4. Conclusions

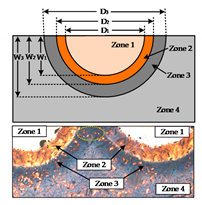

- Four regions were found under the laser-hardened surface of LHAGI specimens. Zone 1 was the laser-hardened region containing the ledeburite and had a hardness of approximately 67 HRC. Zone 2 was an upper heat-affected zone containing martensite with a hardness of approximately 67 HRC. Zone 4 was the substrate containing the acicular ferrite and stable austenite with high carbon content and had a hardness of 41–27 HRC with austempering temperatures from 232 to 399 °C. Due to the tempering effect in Zone 3, the hardness decreased accordingly. The acicular ferrite became thick with the increasing austempering temperature.

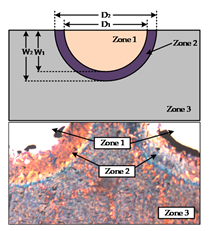

- Three regions were found under the laser-hardened surface of LHQTGI specimens. Zone 1 was the laser-hardened region containing the ledeburite and had a hardness of approximately 68 HRC. Zone 2 was the heat-affected zone containing the martensite and had a hardness of approximately 66 HRC. Zone 3 was the substrate containing the tempered martensite with a hardness ranging from 41 to 26 HRC with varying tempering temperatures from 316 to 482 °C.

- In reciprocating sliding wear tests, GI specimens without heat treatment had the lowest wear resistance due to the low surface hardness. The wear resistance was improved by applying the quench-tempering heat treatment and further improved by applying the austempering heat treatment. Both AGI and QTGI specimens had lower wear resistance when raising the austempering temperature or tempering temperature as a result of the reduction in hardness. After introducing the laser-hardening treatment, the wear performance of LHAGI and LHQTGI specimens was significantly enhanced because of the formation of high hardness ledeburitic and martensitic structures. The LHAGI specimens had higher wear resistance than the LHQTGI specimens. After analyzing the worn areas of the LHAGI and LHQTIGI specimens, it was found that cracks were the main wear mechanism.

- Overall, the use of LHQTGI to replace AGI in some GI parts can be considered since LHQTGI had higher wear resistance than that of AGI. However, the substitution of AGI by LHQTGI needs to be further studied in regard to the other details in manufacturing and production processes and the specific mechanical properties. In addition, the wear loss of AGI could be reduced significantly after receiving laser surface-hardening treatment. The findings obtained in the present research provide value in the future designs of GI engineering components.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Keller, J.; Fridrici, V.; Kapsa, P.; Vidaller, S.; Huard, J. Influence of chemical composition and microstructure of gray cast iron on wear of heavy duty diesel engines cylinder liners. Wear 2007, 263, 1158–1164. [Google Scholar] [CrossRef]

- Lombardi, A.; Ravindran, C.; Sediako, D.; Mackay, R. Determining the mechanisms of In-service cylinder distortion in aluminum engine blocks with cast-in gray iron liners. Met. Mater. Trans. A 2014, 45, 6291–6303. [Google Scholar] [CrossRef]

- Truhan, J.; Qu, J.; Blau, P. A rig test to measure friction and wear of heavy duty diesel engine piston rings and cylinder liners using realistic lubricants. Tribo. Int. 2005, 38, 211–218. [Google Scholar] [CrossRef]

- Chen, R.; Iwabuchi, A.; Shimizu, T. The effect of a T6 heat treatment on the fretting wear of a SiC particle-reinforced A356 aluminum alloy matrix composite. Wear 2000, 238, 110–119. [Google Scholar] [CrossRef]

- Fu, H.; Xiao, Q.; Fu, H. Heat treatment of multi-element low alloy wear-resistant steel. Mater. Sci. Eng. A 2005, 396, 206–212. [Google Scholar] [CrossRef]

- Wang, B.; Han, X.; Barber, G.; Pan, Y. Wear Behavior of Austempered and Quenched and Tempered Gray Cast Irons under Similar Hardness. Metal 2019, 9, 1329. [Google Scholar] [CrossRef] [Green Version]

- Hsu, C.; Shy, Y.; Yu, Y.; Lee, S. Effect of austempering heat treatment on fracture toughness of copper alloyed gray iron. Mater. Chem. Phys. 2000, 63, 75–81. [Google Scholar] [CrossRef]

- Balachandran, G.; Vadiraj, A.; Kamaraj, M.; Kazuya, E. Mechanical and wear behavior of alloyed gray cast iron in the quenched and tempered and austemepred conditions. Mater. Des. 2011, 32, 4042–4049. [Google Scholar] [CrossRef]

- Sarkar, T.; Bose, P.; Sutradhar, G. Mechanical and tribological characteristics of copper alloyed austempered gray cast iron (AGI). Mater. Today Proc. 2018, 5, 3664–3673. [Google Scholar] [CrossRef]

- Sarkar, T.; Sutradhar, G. Investigation on mechanical properties and wear behavior of Cu-alloyed austempered gray cast iron (AGI). Sadhana 2018, 43, 161. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Butler, D.; Wang, J.; Li, X.; Yui, A.; Zhou, L. Experimental investigation on grinding surface condition of 9Mn2V under different tempering processes. Adv. Mater. Res. 2012, 565, 88–93. [Google Scholar] [CrossRef]

- Wang, B.; Barber, G.C.; Sun, X.; Shaw, M.; Seaton, P. Characteristics of the transformation of retained austenite in tempered austempered ductile iron. J. Mater. Eng. Perf. 2017, 26, 2095–2101. [Google Scholar] [CrossRef]

- Khan, S.; Salam, L.; Ahmed, K. Lasering surface hardening of GCr15 bearing steel ring. Key Eng. Mater. 2010, 442, 130–136. [Google Scholar] [CrossRef]

- Tani, G.; Fortunato, A.; Ascari, A.; Campana, G. Laser surface hardening of martensite stainless steel hollow parts. Cirp. Annu. Manuf. Technol. 2010, 59, 207–210. [Google Scholar] [CrossRef]

- Oliveira, F.; Rossi, W.; Rossi, J. Laser modified thin layers in piston rings. Mater. Sci. Forum. 2012, 727–728, 1931–1937. [Google Scholar] [CrossRef]

- Zhan, J.; Yang, M. Investigation on the applications of YAG laser texturing technology to the cylinder wall of auto engine. Ind. Lubr. Tribol. 2014, 66, 387–392. [Google Scholar] [CrossRef] [Green Version]

- Joshi, S.; Choudhuri, D.; Mantri, S.; Banerjee, R.; Dahotre, N.; Banerjee, S. Rationalizing surface hardening of laser glazed grey cast iron via an integrated experimental and computational approach. Mater. Des. 2018, 156, 570–585. [Google Scholar] [CrossRef]

- Liu, A.; Previtali, B. Laser surface treatment of grey cast iron by high power diode laser. Phys. Procedia 2010, 5, 439–448. [Google Scholar] [CrossRef] [Green Version]

- Giorleo, L.; Liu, A.; Previtali, B. Apparent spot in circular laser hardening: Effect of process para. Int. J. Mater. 2010, 3, 1119–1122. [Google Scholar] [CrossRef]

- Su, W.; Zhou, T.; Zhang, P.; Zhou, H.; Li, H. Effect of distribution of striated laser hardening tracks on dry sliding wear resistance of biomimetic surface. Opt. Laser. Technol. 2018, 98, 281–290. [Google Scholar] [CrossRef]

- Selvan, J.; Subramanian, K.; Nath, A. Effect of laser surface hardening on En18(AISI 5135) steel. J. Mater. Proc. Technol. 1999, 91, 29–36. [Google Scholar] [CrossRef]

- Boccardo, A.; Dardati, P.; Celentano, D.; Godoy, L. Austempering heat treatment of ductile iron: Computational simulation and experimental validation. Finite. Elem. Anal. Des. 2017, 134, 82–91. [Google Scholar] [CrossRef]

- Cui, J.; Chen, L. Microstructure and mechanical properties of a wear-resistant alloyed ductile iron austempered at various temperatures. Met. Mater. Trans. A 2015, 46, 3627–3634. [Google Scholar] [CrossRef]

- Kim, Y.; Shin, H.; Park, H.; Lim, J. Investigation into mechanical properties of austempered ductile cast iron (ADI) in accordance with austempering temperature. Mater. Lett. 2008, 62, 357–360. [Google Scholar] [CrossRef]

- Nam, W.; Kim, D. Effects of alloying elements on microstructural evolution and mechanical properties of induction quenched-and-tempered steels. J. Mater. Sci. 2003, 38, 3611–3617. [Google Scholar] [CrossRef]

- Daber, S.; Rao, P. Formation of strain-induced martensite in austempered ductile iron. J. Mater. Sci. 2008, 43, 357–367. [Google Scholar] [CrossRef]

- Li, X.; Saal, P.; Gan, W.; Hoelzel, M.; Volk, W.; Petry, W.; Hofmann, M. Strain-induced martensitic transformation kinetic in austempered ductile iron (ADI). Met. Mater. Trans. A 2018, 49, 94–104. [Google Scholar] [CrossRef]

- Wang, B.; Barber, G.C.; Tao, C.; Han, X.; Sun, X. Tribological performance of austempered and tempered ductile iron. Met. Mater. Trans. B 2018, 49, 2261–2269. [Google Scholar] [CrossRef]

- Chandra, H.; Nukman; Sianturi, B. Analysis of fatigue life and crack propagation characterization of gray cast iron under normalizing process. J. Phys. 2019, 1198, 032006. [Google Scholar] [CrossRef]

- Marahleh, G.; Khede, A.; Al-Goussous, S. Fatigue crack propagation in SGI and CGI. J. Appl. Sci. 2005, 5, 1004–1011. [Google Scholar]

| Elements | Percentage (%) |

|---|---|

| Carbon, C | 3.53 |

| Silicon, Si | 2.71 |

| Copper, Cu | 0.94 |

| Manganese, Mn | 0.74 |

| Chromium, Cr | 0.12 |

| Phosphorous, P | 0.08 |

| Sulfur, S | 0.03 |

| Iron, Fe | Remainder |

| Frictional Pair | Ceramic Ball—GI Plate |

| Lubricant | PAO4 |

| Normal Load | 400 N |

| Frequency | 2 Hz |

| Displacement | 10 mm |

| Total Sliding Distance | 120 m |

| Wavelength | 1064 nm |

| Power Distribution | Gaussian-like Profile |

| Laser Power | 800W |

| Laser Spot Diameter | 2 mm |

| Scanning Speed | 2 mm/s |

| Frequency | 6 Hz |

| Pulse Time | 8 ms |

| Austempering Temperature | W1 (mm) | D1 (mm) | W2 (mm) | D2 (mm) | W3 (mm) | D3 (mm) | |

|---|---|---|---|---|---|---|---|

| 232 °C | 2.171 | 0.755 | 2.823 | 1.085 | 3.555 | 1.529 |  |

| 288 °C | 2.168 | 0.716 | 2.726 | 1.071 | 3.445 | 1.613 | |

| 343 °C | 2.187 | 0.745 | 2.851 | 1.058 | 3.483 | 1.575 |

| Tempering Temperature | W1 (mm) | D1 (mm) | W2 (mm) | D2 (mm) | |

|---|---|---|---|---|---|

| 316 °C | 2.237 | 0.751 | 3.022 | 1.118 |  |

| 399 °C | 2.216 | 0.735 | 3.062 | 1.089 | |

| 482 °C | 2.219 | 0.728 | 2.947 | 1.082 |

| Group 1 | Group 2 | Group 3 | ||||

|---|---|---|---|---|---|---|

| Austempering Temperature | 232 °C | 288 °C | 343 °C | |||

| Macro-Hardness (HRC) | AVE | SD | AVE | SD | AVE | SD |

| 41.6 | 0.6 | 37.5 | 0.3 | 27.7 | 0.5 | |

| Tempering Temperature | 316 °C | 399 °C | 482 °C | |||

| Macro-Hardness (HRC) | AVE | SD | AVE | SD | AVE | SD |

| 41.2 | 0.3 | 38.9 | 0.5 | 26.1 | 0.7 | |

| Group 1 | Group 2 | Group 3 | |||||

|---|---|---|---|---|---|---|---|

| Austempering Temperature | 232 °C | 288 °C | 343 °C | ||||

| Micro-Hardness Profile (HRC) | Zone 1 | AVE | SD | AVE | SD | AVE | SD |

| 67.5 | 0.4 | 67.8 | 0.5 | 68.2 | 0.2 | ||

| Zone 2 | AVE | SD | AVE | SD | AVE | SD | |

| 67.8 | 0.7 | 68.4 | 0.7 | 67.7 | 0.6 | ||

| Zone 3 | AVE | SD | AVE | SD | AVE | SD | |

| 38.3 | 0.4 | 33.5 | 0.4 | 24.6 | 0.5 | ||

| Tempering Temperature | 316 °C | 399 °C | 482 °C | ||||

| Micro-Hardness Profile (HRC) | Zone 1 | AVE | SD | AVE | SD | AVE | SD |

| 68.1 | 0.4 | 68.6 | 0.6 | 68.4 | 0.2 | ||

| Zone 2 | AVE | SD | AVE | SD | AVE | SD | |

| 66.5 | 0.6 | 66.2 | 0.3 | 66.7 | 0.8 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Barber, G.C.; Wang, R.; Pan, Y. Comparison of Wear Performance of Austempered and Quench-Tempered Gray Cast Irons Enhanced by Laser Hardening Treatment. Appl. Sci. 2020, 10, 3049. https://doi.org/10.3390/app10093049

Wang B, Barber GC, Wang R, Pan Y. Comparison of Wear Performance of Austempered and Quench-Tempered Gray Cast Irons Enhanced by Laser Hardening Treatment. Applied Sciences. 2020; 10(9):3049. https://doi.org/10.3390/app10093049

Chicago/Turabian StyleWang, Bingxu, Gary C. Barber, Rui Wang, and Yuming Pan. 2020. "Comparison of Wear Performance of Austempered and Quench-Tempered Gray Cast Irons Enhanced by Laser Hardening Treatment" Applied Sciences 10, no. 9: 3049. https://doi.org/10.3390/app10093049

APA StyleWang, B., Barber, G. C., Wang, R., & Pan, Y. (2020). Comparison of Wear Performance of Austempered and Quench-Tempered Gray Cast Irons Enhanced by Laser Hardening Treatment. Applied Sciences, 10(9), 3049. https://doi.org/10.3390/app10093049