Manufacturing Processes of Integral Blade Rotors for Turbomachinery, Processes and New Approaches

Abstract

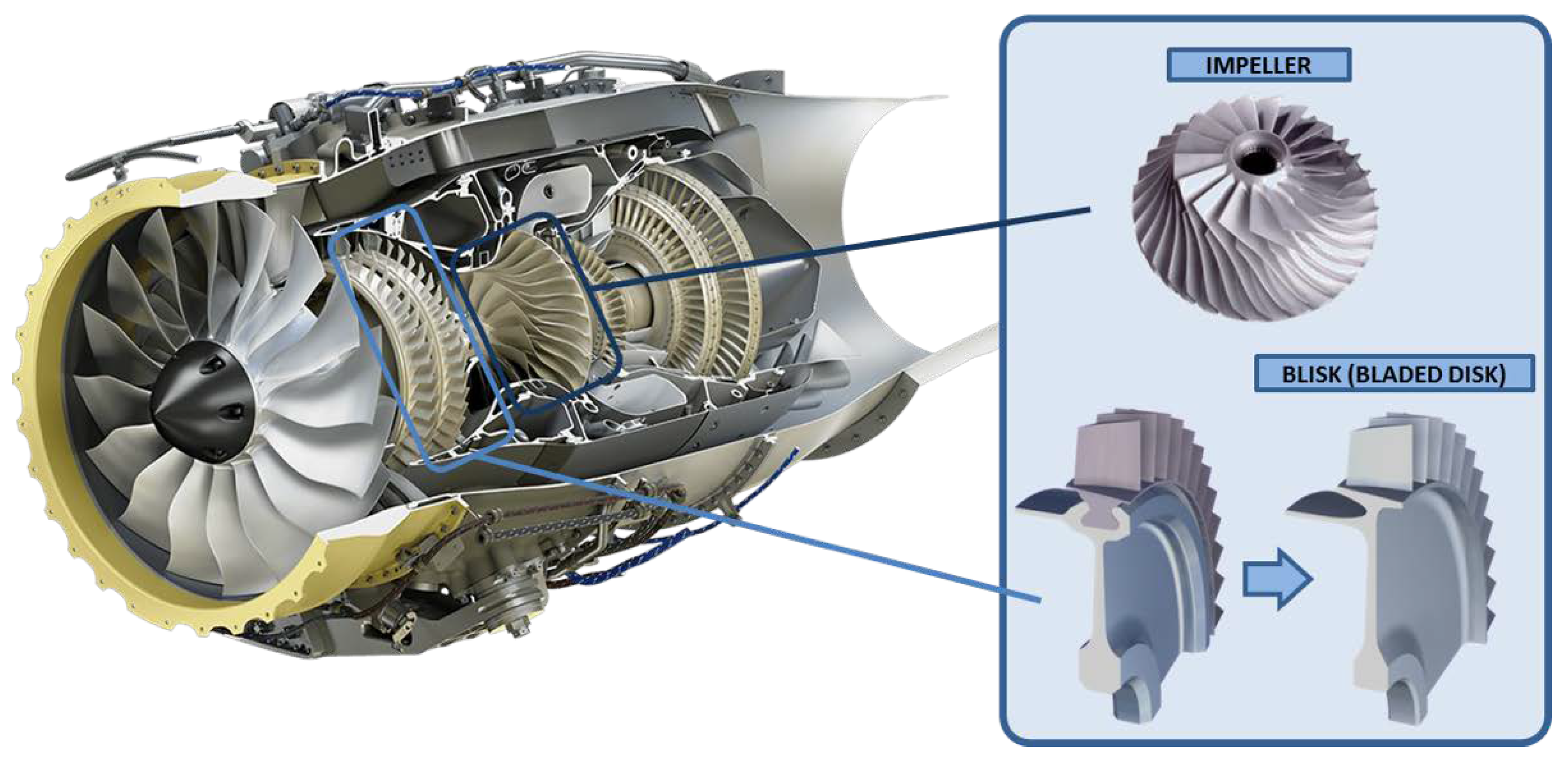

:1. Introduction

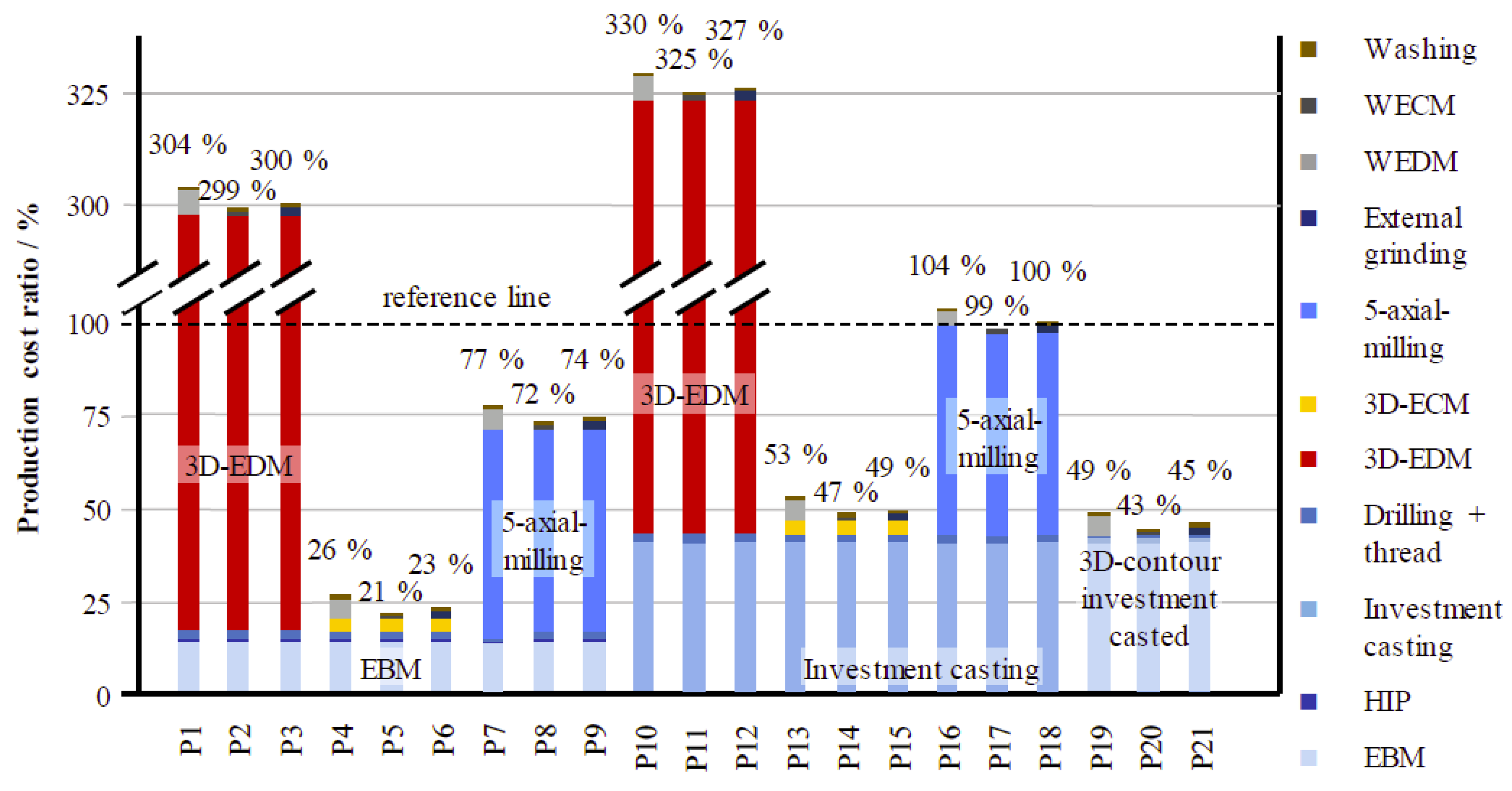

2. Monolithic Components: Manufacturing Processes

2.1. Casting

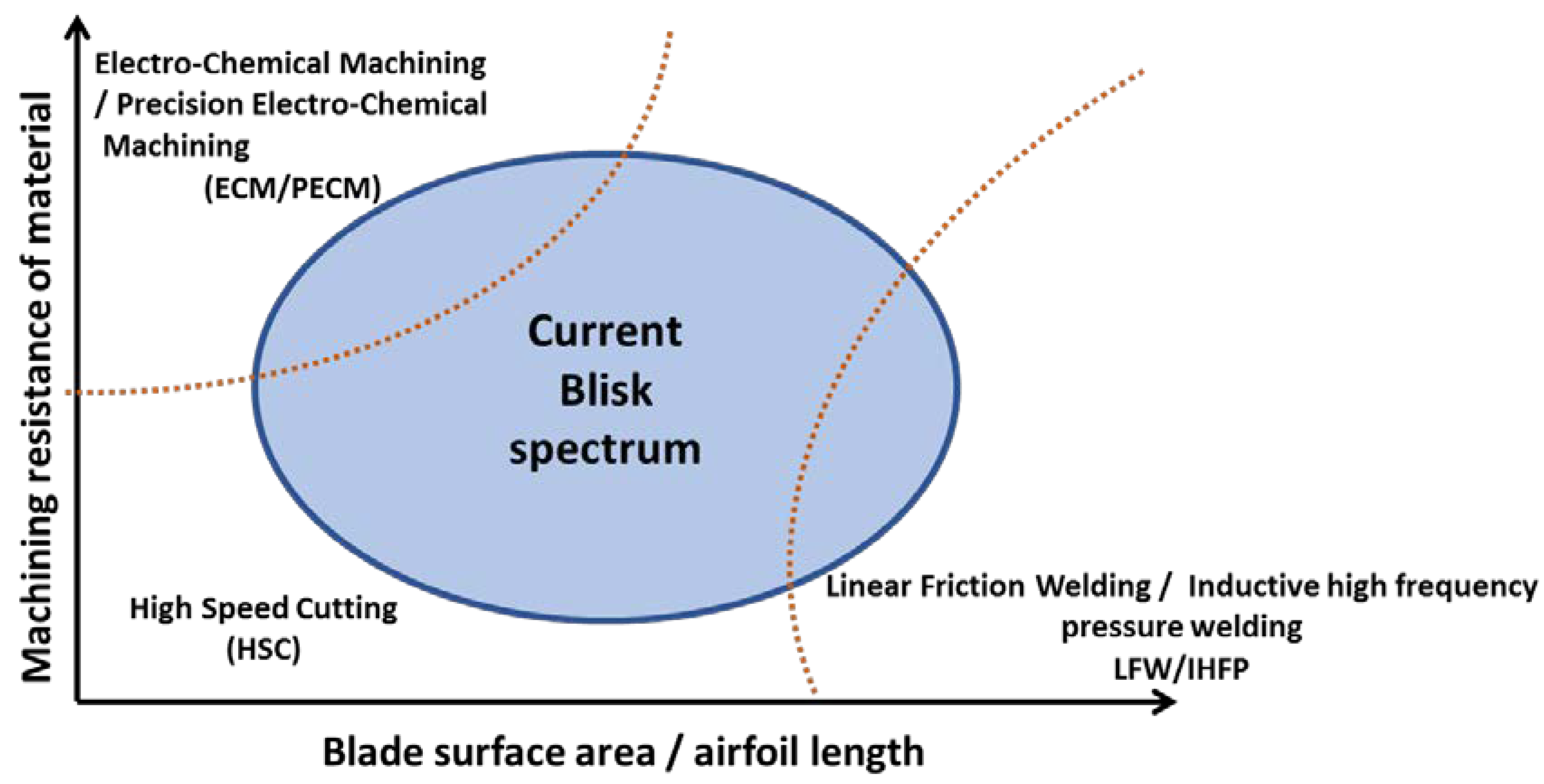

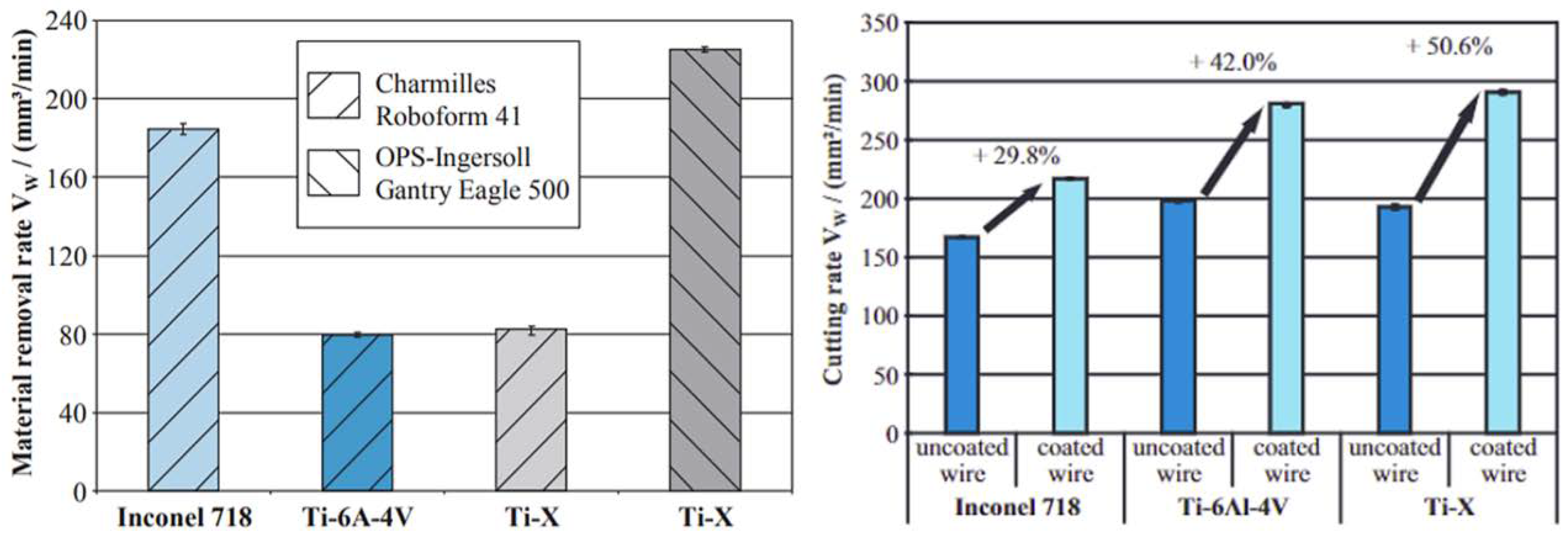

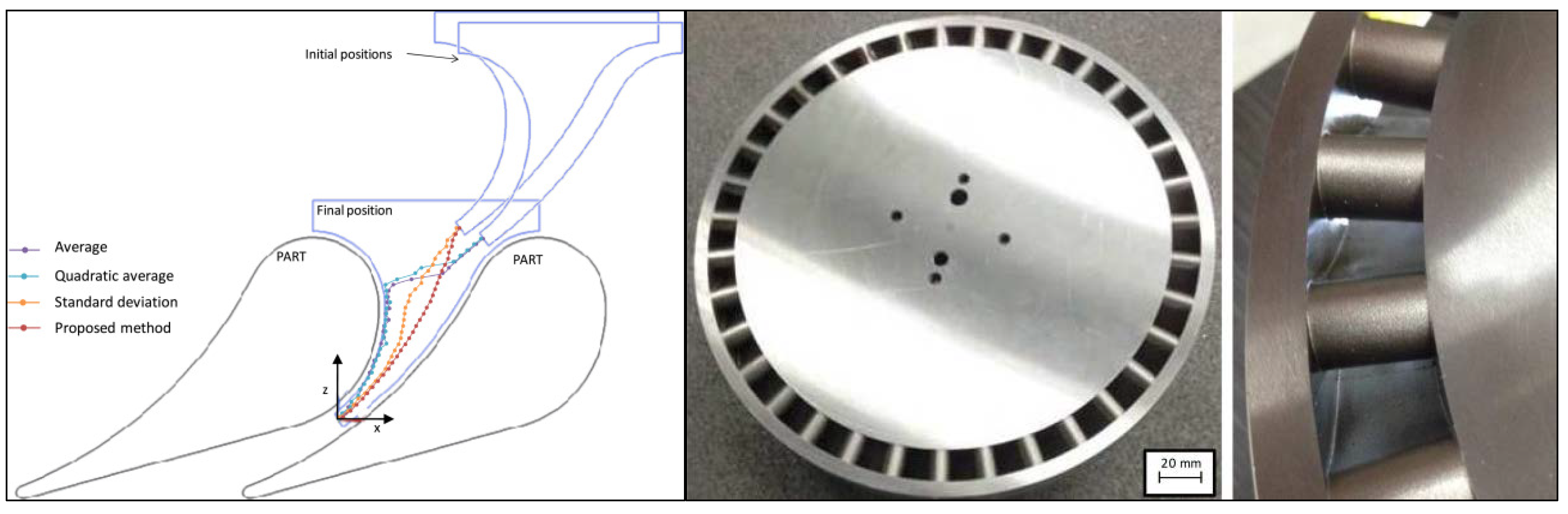

2.2. Electro Discharge Machining (EDM)

2.3. Electro Chemical Machining (ECM)/Precise Electro Chemical Machining (PECM)

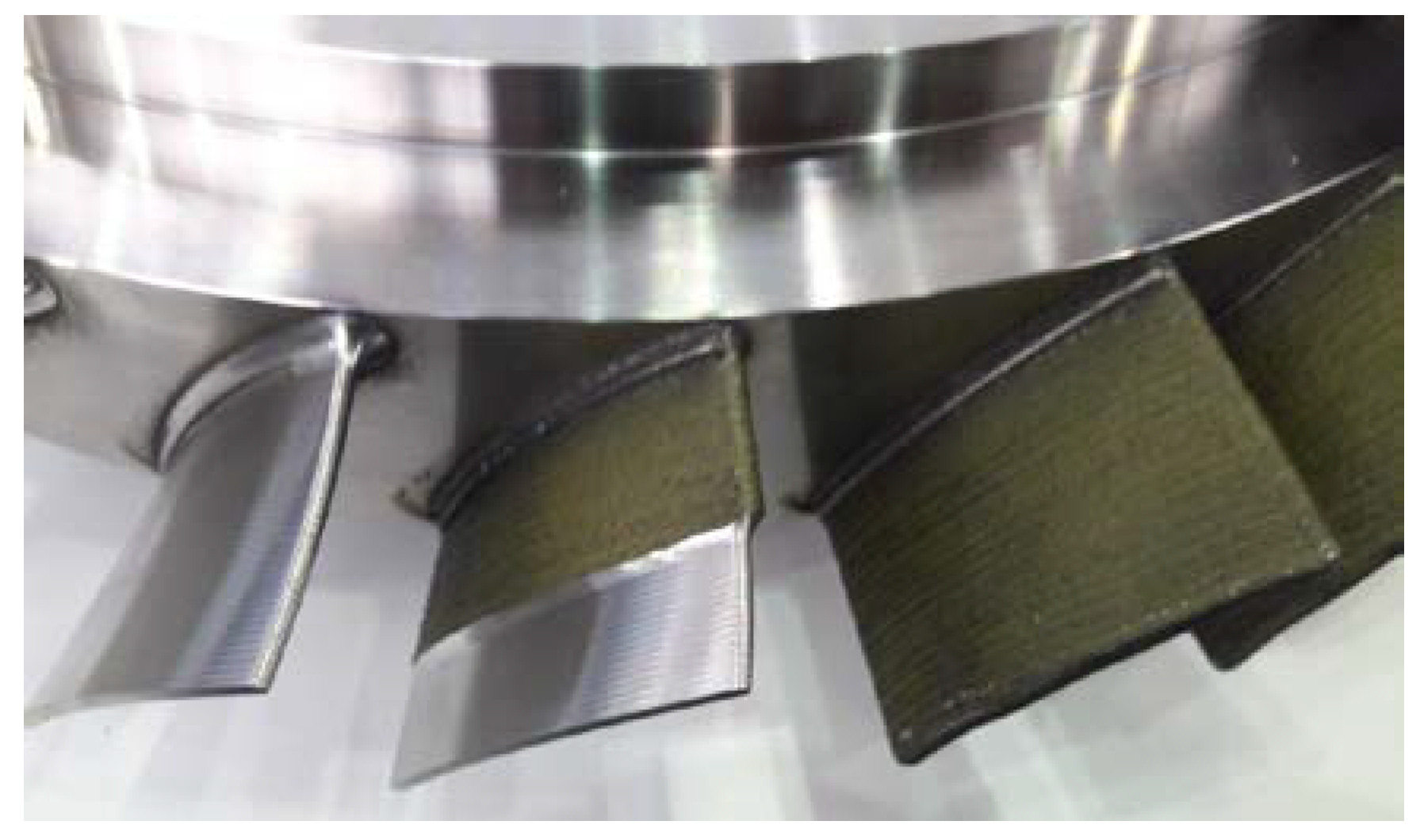

2.4. Additive Manufacturing (AM)

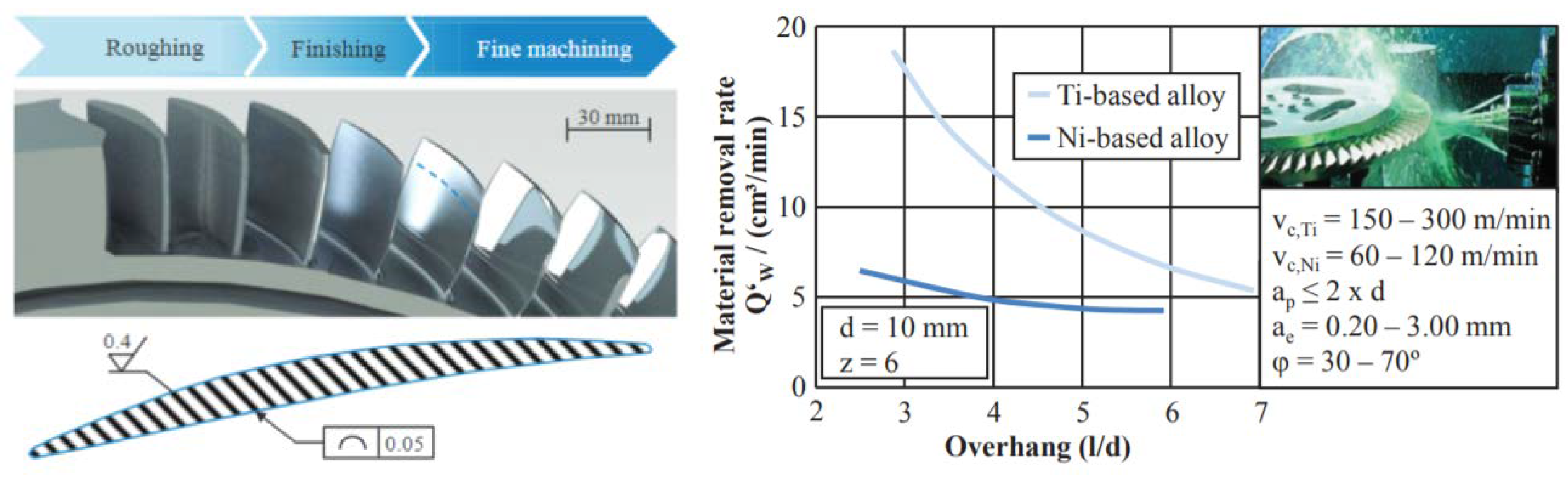

2.5. Conventional Machining Process: 5-Axis Milling

2.5.1. Cutting Tools and Tool Holders

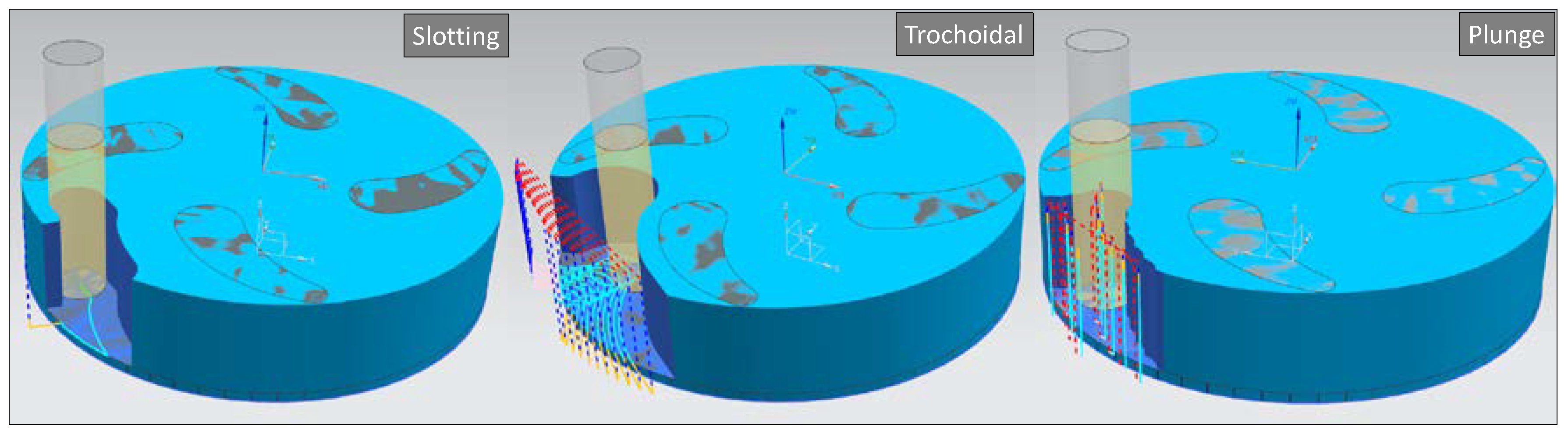

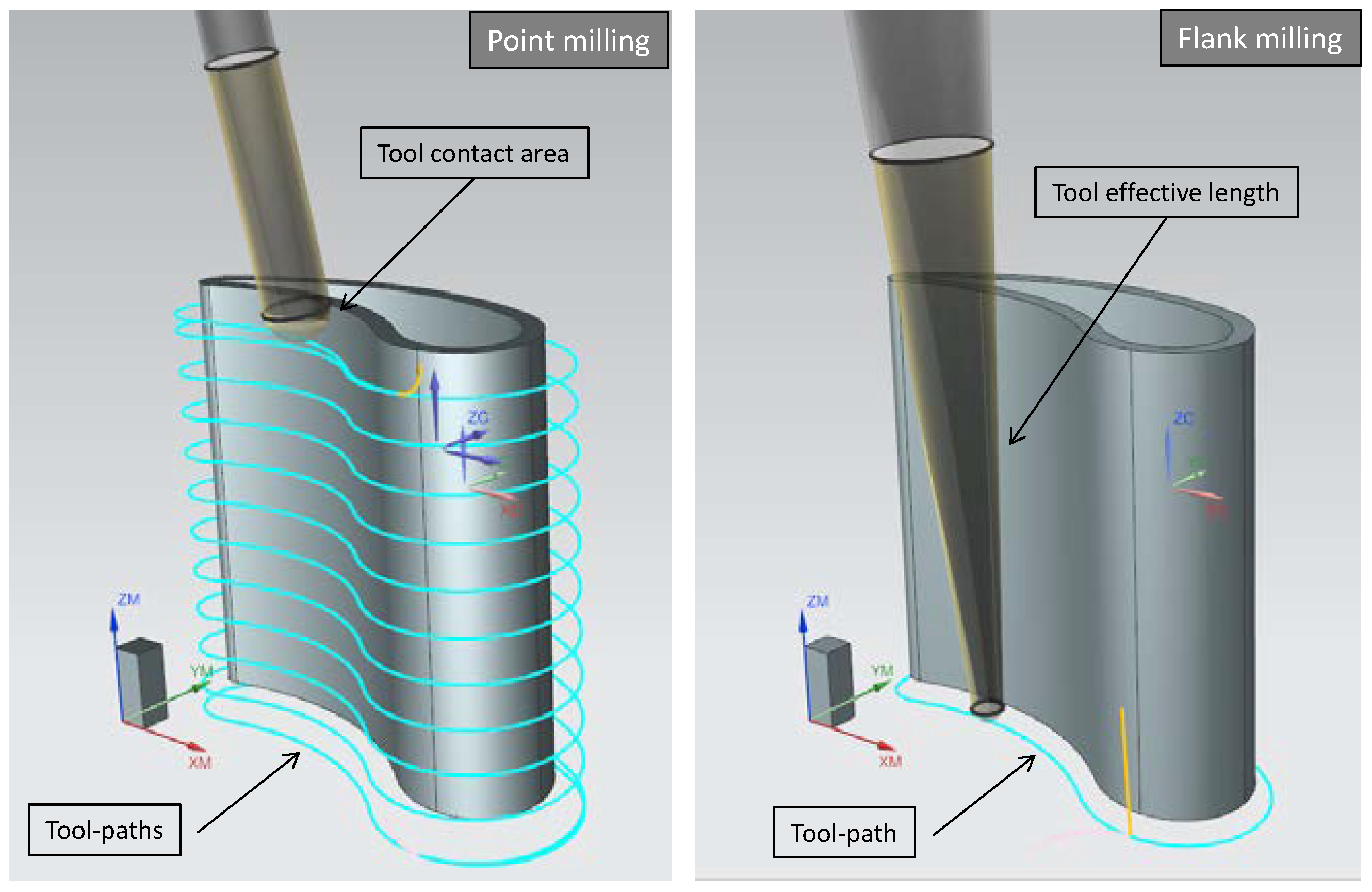

2.5.2. Manufacturing Strategies

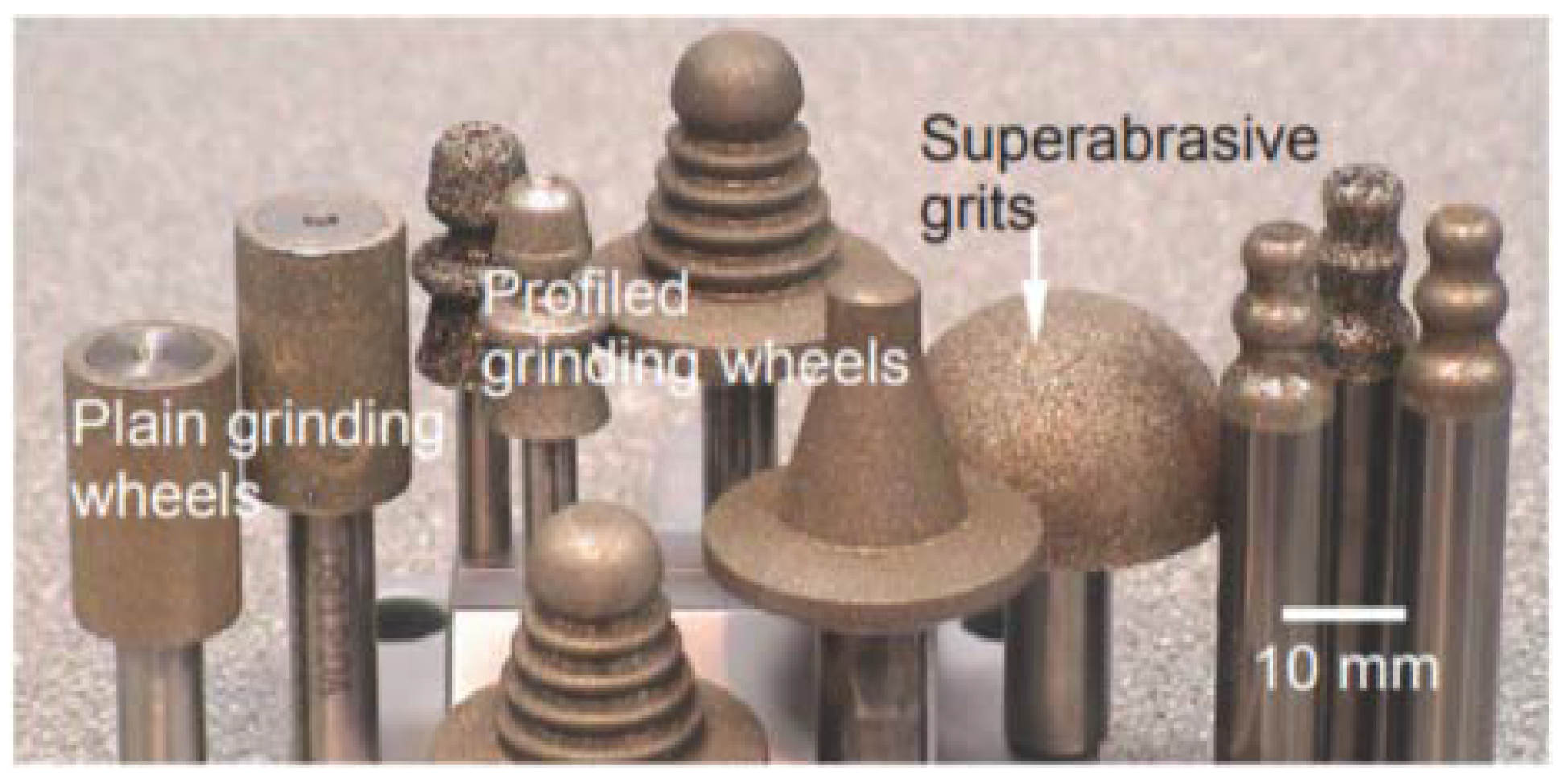

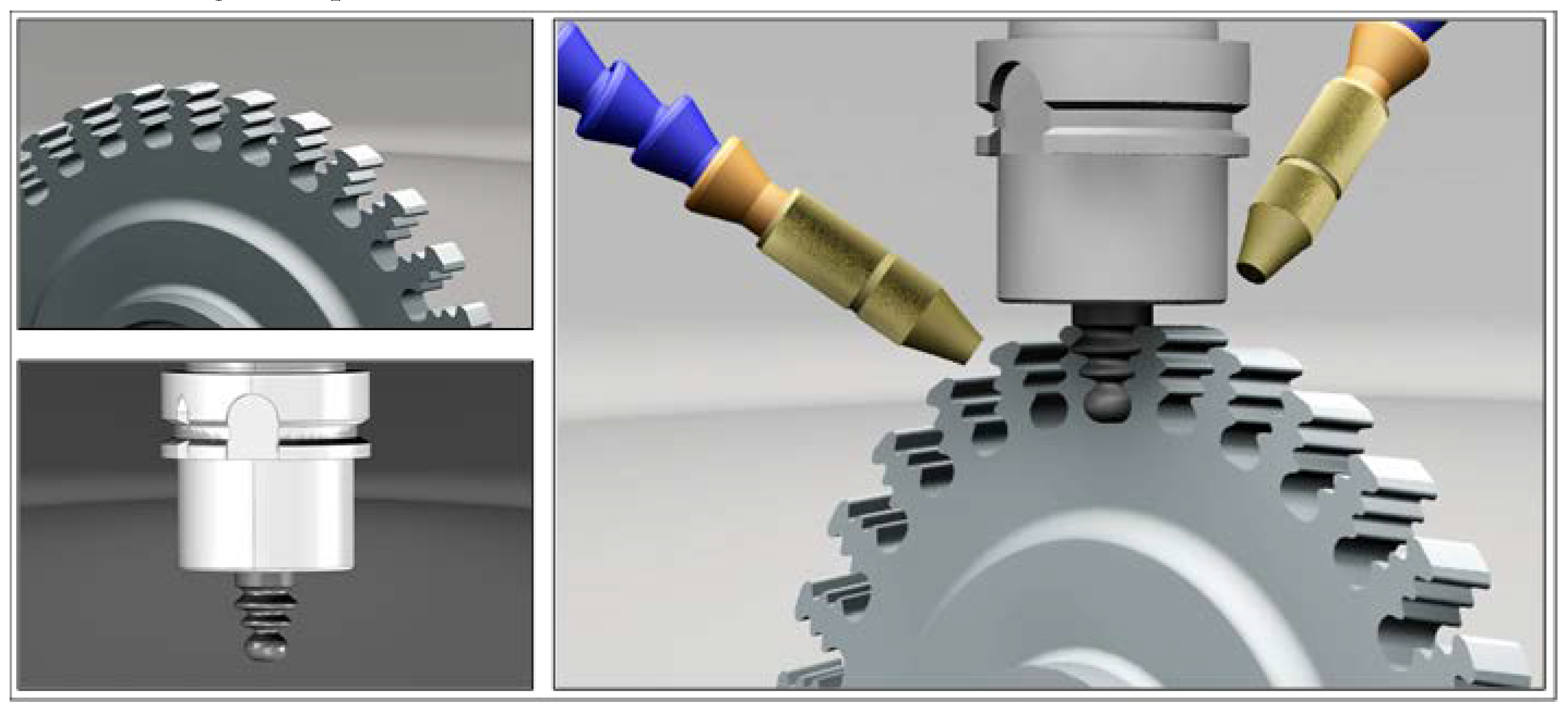

2.6. Super Abrasive Machining (SAM)

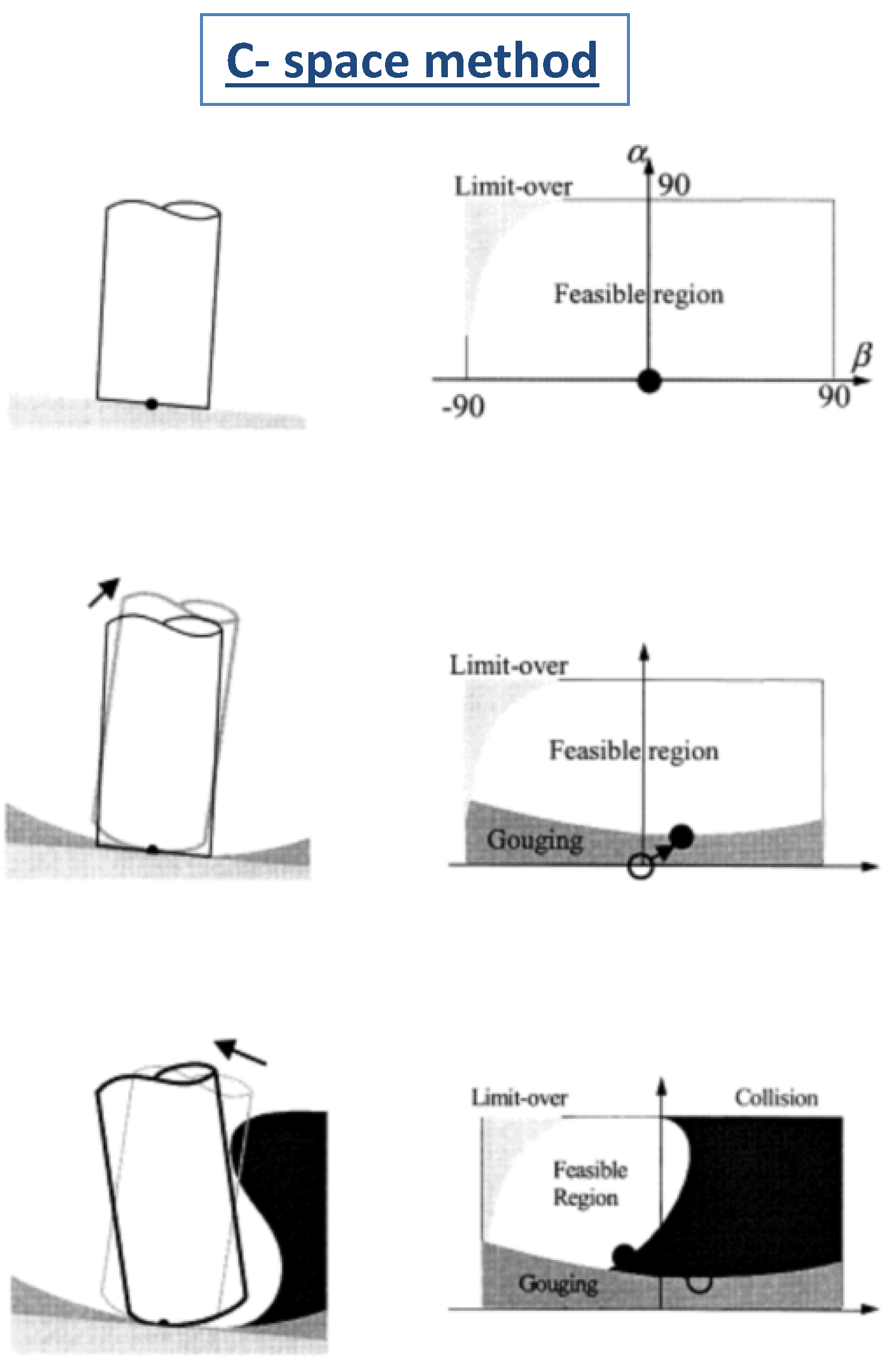

2.7. Algorithms to Optimise Manufacturing Processes

3. Summary and Conclusions

- -

- Complex design requirements and geometries: IBRs are classified as sculpted or free-form surfaces. For these geometries’ generation, different methods as B-Splines or NURBS are used. Therefore, additionally to the complexity of these geometries manufacturing, in some cases the accessibility for the tool along with the tough dimensional requirements are a handicap for manufacturers.

- -

- Difficult-to-cut materials: Present machining difficulties due to elevated cutting forces, high temperatures, limited cutting conditions and excessive tool wear.

- -

- High-cost production processes: Inside the IBRs manufacturing chain, many stages are presented such as, roughing, intermediate semifinishing, finishing and abrasive final operations in order to achieve desired tolerances. These stages imply higher machining times and tool wear.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Asociación Española de Empresas Tecnológicas de Defensa, Aeronáutica y Espacio (tedae). Retos del Sector Aeronáutico en España, Guía Estratégica 2015–2025. Available online: https://www.tedae.org/uploads/files/1461082425_retos-del-sector-aeronautico-en-espana-guia-estrategica-2015-2025-pdf.pdf (accessed on 1 February 2020).

- Bussmann, M.; Bayer, E. Blisk Production of the Future Technological and logistical aspects of future-oriented construction and manufacturing processes of integrally bladed rotors. In Proceedings of the 19th International Symposium on Airbreathing Engines, Montreal, QC, Canada, 7–11 September 2009; pp. 568–577. [Google Scholar]

- Artetxe, E.; González, H.; Calleja, A.; Fernández-Valdivielso, A.; Polvorosa, R.; Lamikiz, A.; López de Lacalle, L.N. Optimised methodology for aircraft engine IBRs five-axis machining process. Int. J. Mechatron. Manuf. Syst. 2016, 9, 385–401. [Google Scholar] [CrossRef]

- Klocke, F.; Schmitt, R.; Zeiss, M.; Heidemanns, L.; Kerkhoff, J.; Heinen, D.; Klink, A. Technological and Economical Assessment of Alternative Process Chains for Blisk Manufacture. [ed.] Procedia CIRP. In Proceedings of the 15th Machining Innovations Conference for Aerospace Industry, Hannover, Germany, 18–19 November 2015; pp. 67–72. [Google Scholar]

- Klocke, F.; Klink, A.; Veselovac, D.; Aspinwall, D.K.; Soo, S.L.; Schmidt, M.; Schilp, J.; Levy, G.; Kruth, J. Turbomachinery component manufacture by application of electrochemical, electro-physical and photonic processes. Cirp Ann. Manuf. Technol. 2014, 63, 703–726. [Google Scholar] [CrossRef]

- Rao, N. Materials for Gas Turbines-An Overview. In Advances in Gas Turbine Technology; In Tech: London, UK, 2011. [Google Scholar]

- Bußmann, M.; Kraus, J.; Bayer, E. An Integrated Cost-Effective Approach to Blisk Manufacturing. In Proceedings of the 17th Symposium on Air Breathing Engines, ISABE, Munich, Germany, 4–9 September 2005. [Google Scholar]

- Bußmann, M.; Bayer, E. Market-Oriented Blisk Manufacturing-A Challenge for Production Engineering. In Proceedings of the 1st European Air and Space Conference (CEAS 2007), Berlin, Germany, 10–13 September 2007. [Google Scholar]

- Kumar, B.R. A Review on Blisk Technology. Int. J. Innov. Res. Sci. 2013, 2–5, 1353–1358. [Google Scholar]

- Mateo, A. Blisk Fabrication by Linear Friction Welding; Advances in Gas Turbine Technology: London, UK, 2011. [Google Scholar]

- Snecma. Method for Producing a One-Piece Bladed Disc by Abrasive Water-Jet Cutting. Patent No. EP2257409B1, 8 October 2009. [Google Scholar]

- Leyens, C.; Hausmann, J.; Kumpfert, J. Continuous Fiber Reinforced Titanium Matrix Composites: Fabrication, Properties and Applications; WILEY-VCH Verlag GmbH & Co.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Bhattacharjee, A.; Saha, B.; Williams, J.C. Titanium Alloys: Part 2-Alloy Development, Properties and Applications. In Aerospace Materials and Material Technologies; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- de Monicault, J.M.; Guédou, J.G.; Soniak, F. Issues and Progresses in Manufacturing of Aero Titanium Parts. Safran Group, 24th ITA; TITANIUM Conference Proceedings; The International Titanium Association (ITA): Washington, DC, USA, 2008. [Google Scholar]

- Klink, A.; Hlavac, M.; Herrig, T.; Holsten, M. Technological and Economical Assessment of Alternative Process Chains for Turbocharger Impeller Manufacture. Procedia CIRP 2018, 77, 586–589. [Google Scholar] [CrossRef]

- Chevrolet. What is a Turbocharger and How does it Work? 2019. from Eagle ridge Chevrolet Buick GMC. Available online: https://www.eagleridgegm.com/what-is-a-turbocharger-and-how-does-it-work/ (accessed on 1 February 2020).

- ScottTech. How does a Centrifugal Pump Work? Available online: http://mahans.com/how-does-a-centrifugal-pump-work/ (accessed on 1 February 2020).

- Kruth, J.-P.; Stevens, L.; Froyen, L.; Lauwers, B. Study of the white layer of a surface machined by die-sinking electro-discharge machining. CIRP Ann. Manuf. Technol. 1995, 44, 169–172. [Google Scholar] [CrossRef]

- Aspinwall, D.K.; Soo, S.L.; Curtis, D.T.; Mantle, A.L. Profiled Superabrasive Grinding Wheels for the Machining of a Nickel Based Superalloy. Ann. CIRP 2017, 53, 335–338. [Google Scholar] [CrossRef]

- Klocke, F.; Zeis, M.; Klink, A. Technological and Economical Capabilities of Manufacturing Titanium- and Nickel-Based Alloys via Electrochemical Machining (ECM), Non-Conventional Processes, Erlangen: Esaform; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2012. [Google Scholar]

- Klocke, F.; Zeis, M.; Klink, A.; Veselovac, D. Technological and economical comparison of roughing strategies via milling, sinking-EDM, wire-EDM and ECM for titanium- and nickel-based blisks. CIRP J. Manuf. Sci. Technol. 2013, 6, 198–203. [Google Scholar] [CrossRef]

- Gang, L.I.; Zhao, W.-S.; Wang, Z.-L.; Wu, X. A special CAD/CAM software for electrodischarge machining of shrouded turbine blisk. J. Shanghai Univ. 2007, 11, 74–78. [Google Scholar]

- Yang, D.Y.; Cao, F.G.; Liu, J.Y.; Yang, L.G.; Zhang, K.; Zhu, Y.F. Overview on Five-Axis Precision EDM Techniques. Procedia CIRP 2013, 6, 192–198. [Google Scholar] [CrossRef] [Green Version]

- Ayesta, B.J.I. Optimum electrode path generation for EDM manufacturing of aerospace components. Robot. Comput. Manuf. 2016, 37, 273–281. [Google Scholar] [CrossRef]

- Kang, X.; Liang, W.; Yang, Y.; Zhao, W. Maximum free distance method for electrode feeding path planning in EDM machining of integral shrouded blisks. Precis. Eng. 2018, 51, 514–520. [Google Scholar] [CrossRef]

- Rajurkar, K.P.; Zhu, D.; McGeough, J.A.; Kozak, J.; De Silva, A. New Developments in Electro-Chemical Machining. CIRP Ann. Manuf. Technol. 1999, 48, 567–579. [Google Scholar] [CrossRef]

- Rajurkara, K.P.; Sundaraman, M.M.; Malshe, A.P. Review of Electrochemical and Electrodischarge Machining. The Seventeenth CIRP Conference on Electro Physical and Chemical Machining (ISEM). Procedia CIRP 2013, 6, 13–26. [Google Scholar]

- Chen, X.; Xu, Z.; Zhu, N.; Fang, Z.; Zhu, D. Experimental research on electrochemical machining of titanium alloy Ti60 for a blisk. Cin. J. Aeronaut. 2016, 29, 274–282. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Zhu, D.; Xu, Z.; Zhang, K.; Liu, J.; Qu, N.; Zhu, D. Improvement of trailing edge accuracy in blisk electrochemical machining by optimising the electric field with an extended cathode. J. Mater. Process. Technol. 2016, 231, 301–311. [Google Scholar] [CrossRef]

- Gibson, I.; David, R.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing. Johns. Matthey Technol. Rev. 2015, 59, 193–198. [Google Scholar]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Karlsson, J.; Norell, M.; Ackelid, U.; Engqvist, H.; Lausmaa, J. Surface oxidation behavior of Ti–6Al–4V manufactured by Electron Beam Melting (EBM®). J. Manuf. Process. 2014, 17, 120–126. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 1–23. [Google Scholar] [CrossRef]

- Cooke, A.L.; Soons, J.A. Variability in the Geometric Accuracy of Additively Manufactured, Test Parts. In Proceedings of the 21st Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 17–19 August 2010; pp. 1–12. [Google Scholar]

- The Boeing Company. Three Dimensional Printing of Parts. Patent No. 20150064299, 5 March 2015. [Google Scholar]

- Sander, P. First 3D Printed Hydraulic Manifold Successfully Flies on Airbus A380 Aircraft. Retrieved 19 March 2019, from 3D Printing Media Network. Available online: https://www.3dprintingmedia.network/first-3d-printed-hydraulic-manifold-successfully-flies-airbus-a380-aircraft/ (accessed on 1 February 2020).

- Toyserkani, E.K.A. Laser Cladding; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Aschenbruck, J.; Adamczuk, R.; Seume, J.R. Recent Progress in Turbine Blade and Compressor Blisk Regeneration. Procedia CIRP 2014, 22, 256–262. [Google Scholar] [CrossRef] [Green Version]

- Zelinski, P. Highlighting Hybrid Manufacturing. Available online: https://www.additivemanufacturing.media/articles/highlighting-hybrid-manufacturing, (accessed on 1 February 2020).

- Ruiz-Salas, J.; Gonzalez-Barrio, H.; Calleja-Ochoa, A.; Ukar-Arrien, E.; Lamikiz-Mentxaka, A. Turbo engine components repair methodology by laser material deposition. DYNA 2018, 93, 643–648. [Google Scholar] [CrossRef]

- Brown & Sharpe Manufacturing Company. Practical Treatise on Milling and Milling Machines; la Universidad de Wisconsin: Madison, WI, USA, 1935. [Google Scholar]

- Roberts, K.D. Eli Terry and the Connecticut Shelf Clock; Ken Roberts Publishing: Fitzwilliam, NH, USA, 1994. [Google Scholar]

- Woodbury, R.S. History of the Milling Machine; MIT Press: Cambridge, MA, USA, 1972. [Google Scholar]

- Noble, D.F. Forces of Production: A Social History of Industrial Automation; Knopf: New York, NY, USA, 1984. [Google Scholar]

- Sandvik Coromant. Workpiece Materials. Available online: https://www.sandvik.coromant.com/es-es/knowledge/materials/pages/workpiece-materials.aspx (accessed on 23 April 2019).

- GE International Inc. Spherical Cutter and Method for Machining a Curved Slot. Patent No. EP2540424A2, 2 January 2013. [Google Scholar]

- Emuge High Performance Tools. Circle Segment Cutters (5-axis Milling Tooling). Available online: https://www.emuge.com/products/end-mills/circle-segment-cutters (accessed on 20 March 2019).

- Calleja, A.; Bo, P.; González, H.; Barton, M.; López de Lacalle, L.N. Highly accurate 5-axis flank CNC machining with conical tools. Int. J. Adv. Manuf. Technol. 2018, 97, 1605–1615. [Google Scholar] [CrossRef] [Green Version]

- Polvorosa, R.; Suárez, A.; de Lacalle, L.N.L.; Cerrillo, I.; Wretland, A.; Veiga, F. Tool wear on nickel alloys with different coolant pressures: Comparison of Alloy 718 and Waspaloy. J. Manuf. Process. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Fernández-Valdivielso, A.; López de Lacalle, L.N.; Urbikain, G.; Rodriguez, A. Detecting the key geometrical features and grades of carbide inserts for the turning of nickel-based alloys concerning surface integrity. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 230, 3725–3742. [Google Scholar] [CrossRef]

- Suárez, A.; Veiga, F.; Polvorosa, R.; Artaza, T.; Holmberg, J.; Lopez de Lacalle, L.N.; Wretland, A. Surface integrity and fatigue of non-conventional machined Alloy 718. J. Manuf. Process. 2019, 48, 44–50. [Google Scholar]

- Fernández-Abia, A.I.; Barreiro, J.; de Lacalle, L.N.L.; Martínez-Pellitero, S. Behavior of austenitic stainless steels at high speed turning using specific force coefficients. Int. J. Adv. Manuf. Technol. 2012, 62, 505–515. [Google Scholar]

- Rodríguez-Barrero, S.; Fernández-Larrinoa, J.; Azkona, I.; López de Lacalle, L.N. Enhanced performance of nanostructured coatings for drilling by droplet elimination. Mater. Manuf. Process. 2015, 31, 593–602. [Google Scholar] [CrossRef]

- Morishige, K.; Takeuchi, Y. 5-Axis Control Rough Cutting of an Impeller with Efficiency and Accuracy. In Proceedings of the International Conference on Robotics and Automation, Albuquerque, NM, USA, 25 April 1997; pp. 1241–1246. [Google Scholar]

- Abele, E.; Hasenfratz, C.; Praetzas, C.; Stark, C.; Kannwischer, M.; Wichlas, N. Process design for rough machining of Ti6Al4V integral components. Procedia Manuf. 2017, 14, 118–127. [Google Scholar] [CrossRef]

- Pleta, A.; Niaki, F.A.; Mears, L. A comparative study on the cutting force coefficient identification between trochoidal and slot milling. Procedia Manuf. 2018, 26, 570–579. [Google Scholar] [CrossRef]

- Kappmeyer, G.; Hubig, C.; Hardy, M.; Witty, M.; Busch, M. Modern Machining of Advanced Aerospace Alloys-Enabler for Quality and Performance. Procedia CIRP 2012, 1, 28–43. [Google Scholar] [CrossRef]

- López de Lacalle, L.N.; Lamikiz, A.; Fernández de Larrinoa, J.; Azkona, I. Advanced Cutting Tools, Machining of Hard Materials; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Senatore, J.; Landon, Y.; Rubio, W. Analytical estimation of error in flank milling of ruled surfaces. Comput. Aided Des. 2008, 40, 595–603. [Google Scholar] [CrossRef]

- Ghadikolaei, A.D.; Mehrdad, V. Experimental study on the effect of finishing parameters on surface roughness in magneto-rheological abrasive flow finishing process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 229, 1517–1524. [Google Scholar] [CrossRef]

- Flaño, O.; Ayesta, I.; Izquierdo, B.; Sánchez, J.A.; Zhao, Y.; Kunieda, M. Improvement of EDM performance in high-aspect ratio slot machining using multi-holed electrodes. Precis. Eng. 2018, 51, 223–231. [Google Scholar]

- Petrilli, R. Super Abrasive Machining for PM, Metal-Powder.net; Elsevier Ltd.: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Caggiano, A.; Teti, R. CBN grinding performance improvement in aircraft engine components manufacture. Procedia CIRP 2009, 9, 109–114. [Google Scholar] [CrossRef]

- Sinha, M.K.; Madarkar, R.; Ghosh, S.; Rao, P.V. Application of eco-friendly nanofluids during grinding of Inconel 718 through small quantity lubrication. J. Clean. Prod. 2017, 141, 1359–1375. [Google Scholar] [CrossRef]

- Salmon, S.C. Creep-Feed Grinding. In Handbook of Modern Grinding Technology, Chapman and Hall Advanced Industrial Technology Series; Springer: Berlin/Heidelberg, Germany, 1986. [Google Scholar]

- United Technologies Corporation. Method of Machining between Contoured Surfaces with Cup Shaped Tool. Patent No. US2011/0189924 A1, 4 August 2011. [Google Scholar]

- González, H.; Calleja, A.; Pereira, O.; Ortega, N.; López de Lacalle, L.N.; Barton, M. Super Abrasive Machining of Integral Rotary Components Using Grinding Flank Tools. Metals 2018, 8, 24. [Google Scholar] [CrossRef]

- Curtis, D.T.; Soo, S.L.; Aspinwall, D.K.; Sage, C. Electrochemical superabrasive machining of a nickel-based aeroengine alloy using mounted grinding points. CIRP Ann. Manuf. Technol. 2009, 58, 173–176. [Google Scholar] [CrossRef]

- Wilk, W.; Tota, J. Modern technology of the turbine blades removal machining. In Proceedings of the 8 International Conference Advanced Manufacturing Operations, Kranevo, Bulgaria, 18–20 June 2008; pp. 347–355. [Google Scholar]

- González, H.; Pereira, O.; Fernández-Valdivielso, A.; López de Lacalle, L.N.; Calleja, A. Comparison of Flank Super Abrasive Machining vs. Flank Milling on Inconel® 718 Surfaces. Materials 2018, 11, 1638. [Google Scholar]

- Wu, C.Y. Arbitrary surface flank milling & flank SAM in the design and manufacturing of jet engine fan and compressor airfoils. In Proceedings of the ASME Turbo Expo 2012, Copenhagen, Denmark, 9 July 2012; pp. 1–10. [Google Scholar]

- United Technologies Corporation. Flank Auperabrasive Machining. Patent No. US7101263B2, 5 September 2006. [Google Scholar]

- United Technologies Corporation. Point Superabrasive Machining of Nickel Alloys. Patent No. US7144307B2, 5 December 2006. [Google Scholar]

- United Technologies Corporation. Slot Machining Mantel. Patent No. US7007382B2, 7 March 2006. [Google Scholar]

- Pratt & Whitney Canada Corp. Method of Machining Airfoils by Disc Tools. Patent No. US7303461B1, 4 December 2007. [Google Scholar]

- United Technologies Corporation. Superabrasive Tool. Patent No. US7789732B2, 7 Septiembre 2010. [Google Scholar]

- United Technologies Corporation. Machining Methods Using Superabrasive Tool. Patent No. US7896728B2, 1 March 2011. [Google Scholar]

- Fidia SpA, GE Avio SRL. Finishing Process for Making Blade Slots in a Rotor Disc. Patent No. EP2705926A1, 12 March 2014. [Google Scholar]

- Tang, T.C. Algorithms for collision detection and avoidance for five-axis NC machining: A state of the art review. Comput. Aided Des. 2014, 51, 1–17. [Google Scholar] [CrossRef]

- Chen, H.P.; Kuo, H.-H.; Tsay, D.-M. Removing tool marks of blade surfaces by smoothing five-axis point milling cutter paths. J. Mater. Process. Technol. 2009, 209–217, 5810–5817. [Google Scholar] [CrossRef]

- Tung, C.; Tso, P.-L. Tool Path Generation and Manufacturing Process for Blades of a Compressor Rotor. World Acad. Sci. Eng. Technol. 2011, 5, 154–159. [Google Scholar]

- Loney, G.C.; Ozsoy, T.M. NC machining of free form surfaces. Comput. Aided Des. 1987, 19, 85–90. [Google Scholar] [CrossRef]

- Han, Z.L.; Yang, D.C.H. Iso-phote based tool-path generation for machining free- form surfaces. J. Manuf. Sci. Eng. 1999, 121, 654–664. [Google Scholar] [CrossRef]

- Lin, R.S.; Koren, Y. Efficient tool-path planning for machining free-form surfaces. J. Eng. Ind. 1996, 118, 20–28. [Google Scholar] [CrossRef]

- Shokrollahi, N.; Shojaei, E. Experimental comparison of iso scallop, iso planar and iso parametric algorithms in machining sculptured surfaces. Indian J. Sci. Res. 2014, 1, 475–481. [Google Scholar]

- Choi, B.K.; Kim, D.H.; Jerard, R.N. C-space approach to tool-path generation for die and mould machining. Comput. Aided Des. 1997, 29, 657–669. [Google Scholar] [CrossRef]

- Morishige, K.; TKase, K.; Takeuchi, Y. Collision-free tool path generation using 2- dimensional C-space for 5-axis control machining. Int. J. Adv. Manuf. Technol. 1997, 13, 393–400. [Google Scholar] [CrossRef]

- Jun, C.-S.; Cha, K.; Lee, Y.-S. Optimizing tool orientations for 5-axis machining by configuration-space search method. Comput. Aided Des. 2003, 35, 549–566. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Ma, Y.; Jegadesh, G. Rolling-ball method and contour marching approach to identifying critical regions for complex surface machining. Comput. Ind. 2000, 41, 163–180. [Google Scholar] [CrossRef]

- Fan, H.Z.; Wang, W.; Xi, G. A novel five-axis rough machining method for efficient manufacturing of centrifugal impeller with free-form blades. Int. J. Adv. Manuf. Technol. 2013, 68, 1219–1229. [Google Scholar] [CrossRef]

- Heo, E.Y.; Kim, D.-W.; Jang, D.-K.; Chen, F.F. Efficient rough-cut plan for machining an impeller with a 5-axis NC machine. Int. J. Comput. Integr. Manuf. 2008, 21, 971–983. [Google Scholar] [CrossRef]

- Qi, R.; Liu, W.; Bian, H.; Li, L. Five-axis rough machining for impellers. Front. Mech. Eng. China 2009, 4, 71–76. [Google Scholar] [CrossRef] [Green Version]

- Lavernhe, S.; Tournier, C.; Lartingue, C. Optimization of 5-axis high-speed machining using a surface based approach. Comput. Aided Des. 2008, 40, 1015–1023. [Google Scholar] [CrossRef] [Green Version]

- Senatore, J.; Monies, F.; Ruio, W. 5-Axis Flank Milling of Sculptured Surfaces. In Machining of Complex Sculptured Surfaces; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Li, C.; Mann, S.; Bedi, S. Flank Millable Surfaces Generated via Polynomial Composition. Comput. Des. Appl. 2007, 4, 41–48. [Google Scholar] [CrossRef]

- Gong, H.; Wang, N. Optimize tool paths of flank milling with generic cutters based on approximation using the tool envelope surface. Comput. Aided Des. 2009, 41, 981–989. [Google Scholar] [CrossRef]

- Wu, C.Y. Arbitrary Surface Flank Milling of Fan, Compressor, and Impeller Blades. J. Eng. Gas Turbines Power 1995, 117, 534–539. [Google Scholar] [CrossRef]

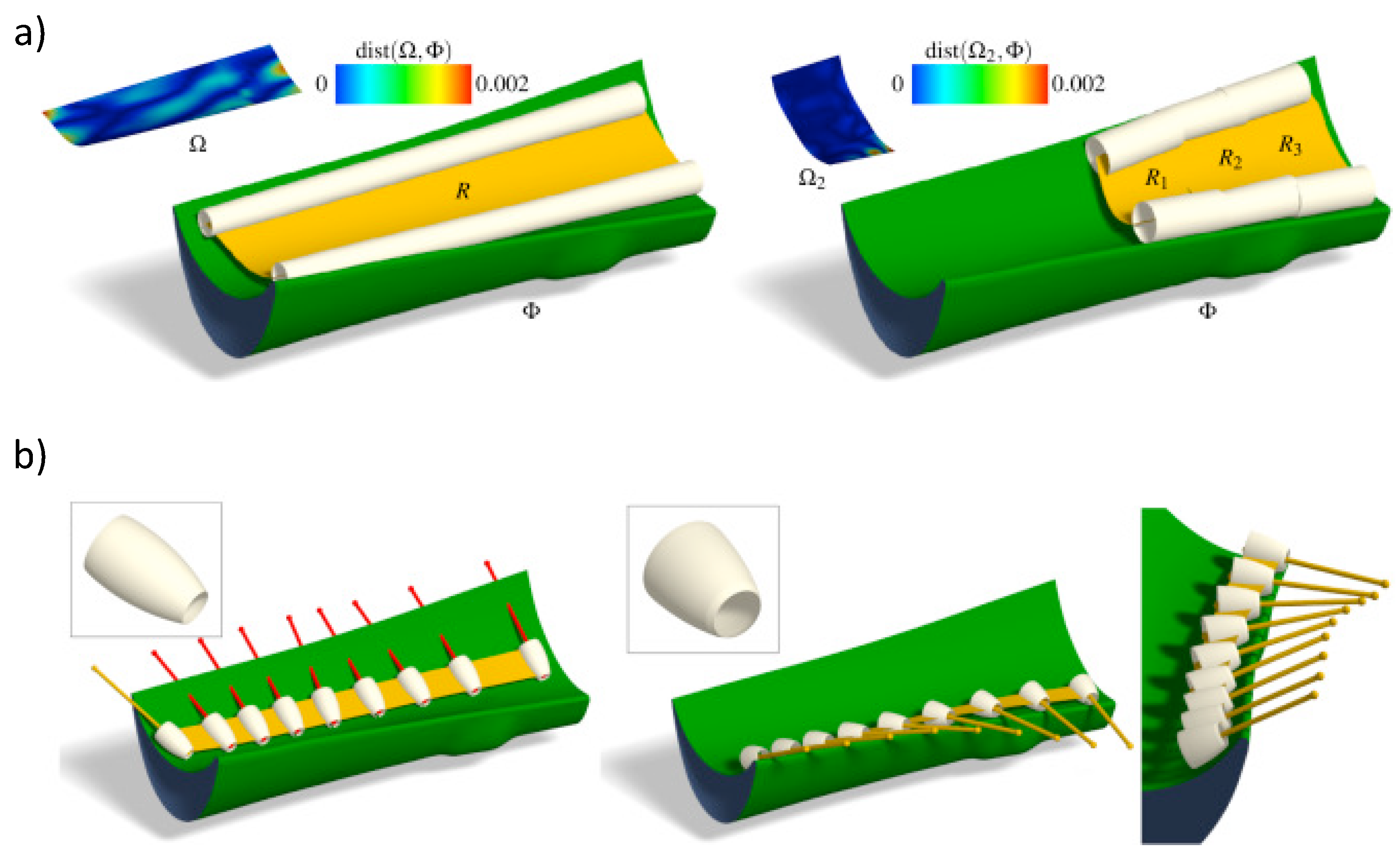

- Bo, P.; Barton, M.; Plakhotnik, D.; Pottmann, H. Towards efficient 5-axis flank CNC machining of free-form surfaces via fitting envelopes of surfaces of revolution. Comput. Aided Des. 2016, 79, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Bo, P.; Barton, M. On initialization of milling paths for 5-axis flank CNC machining of free-form surfaces with general milling tools. Comput. Aided Geom. Des. 2019, 71, 30–42. [Google Scholar] [CrossRef] [Green Version]

- Beranoagirre, A.; Olvera, D.; López de Lacalle, L.N. Milling of gamma titanium–aluminum alloys. Int. J. Adv. Manuf. Technol. 2011, 62, 83–88. [Google Scholar] [CrossRef]

- Radical Departures. Available online: https://www.radical-departures.net/articles/flexible-grinding-no-grinder-required/ (accessed on 14 August 2017).

| Patent Number & Title | Description | Figures |

|---|---|---|

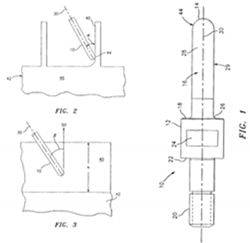

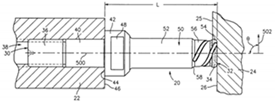

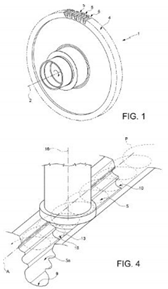

| US 7144307 Point abrasive maching of nickel alloys. UTC [73]. | This patent develops a superabrasive manufacturing process similar to point milling strategy for nickel-based alloys. The used tool consists in a specific tool coated with abrasive material. |  |

| US 7101263 Flank superabrasive machining. UTC [74]. | This patent develops a new superabrasive conical tool for using flank SAM on complex geometries as turbine blades. |  |

| US 7007382 Slot machining. UTC [75]. | This patent presents a methodology for initial slots in fir-trees in three different stages. (1) Slot base, (2) right lateral side and (3) left lateral side. |  |

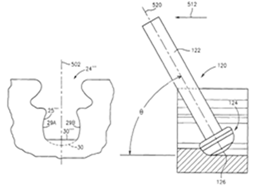

| US7303461B1 Method of machining airfoils by disc tools. Pratt and Whitney [76]. | This patent develops a grinding peripherical strategy to remove material on airfoils discs using multi-axis simultaneous motions. |  |

| US 7789732 Superabrasive tool. UTC [77]. | A special abrasive machining tool for point machining in different steps. The body is composed of a tool tip abrasive coating. |  |

| US 7896728 Machining methods using superabrasive tool. UTC [78]. | A tool for abrasive machining with a concave abrasive coated protuberance at the tip end and a radial span at least 20% of the protuberance radius. |  |

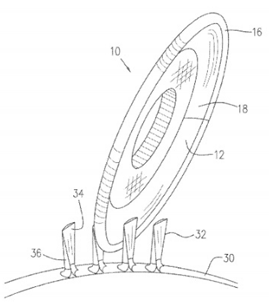

| EP 2705926 A1 Finishing process for making blade slots in a rotor disc. Fidia SpA & GE Avo SRL [79]. | This patent filed a finishing process for fir trees manufacturing using a grinding tool along trochoidal paths. |  |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

González-Barrio, H.; Calleja-Ochoa, A.; Lamikiz, A.; López de Lacalle, L.N. Manufacturing Processes of Integral Blade Rotors for Turbomachinery, Processes and New Approaches. Appl. Sci. 2020, 10, 3063. https://doi.org/10.3390/app10093063

González-Barrio H, Calleja-Ochoa A, Lamikiz A, López de Lacalle LN. Manufacturing Processes of Integral Blade Rotors for Turbomachinery, Processes and New Approaches. Applied Sciences. 2020; 10(9):3063. https://doi.org/10.3390/app10093063

Chicago/Turabian StyleGonzález-Barrio, Haizea, Amaia Calleja-Ochoa, A. Lamikiz, and L. N. López de Lacalle. 2020. "Manufacturing Processes of Integral Blade Rotors for Turbomachinery, Processes and New Approaches" Applied Sciences 10, no. 9: 3063. https://doi.org/10.3390/app10093063

APA StyleGonzález-Barrio, H., Calleja-Ochoa, A., Lamikiz, A., & López de Lacalle, L. N. (2020). Manufacturing Processes of Integral Blade Rotors for Turbomachinery, Processes and New Approaches. Applied Sciences, 10(9), 3063. https://doi.org/10.3390/app10093063