Strain Rate Dependencies and Competitive Effects of Dynamic Strength of Some Engineering Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Methods

3. Results

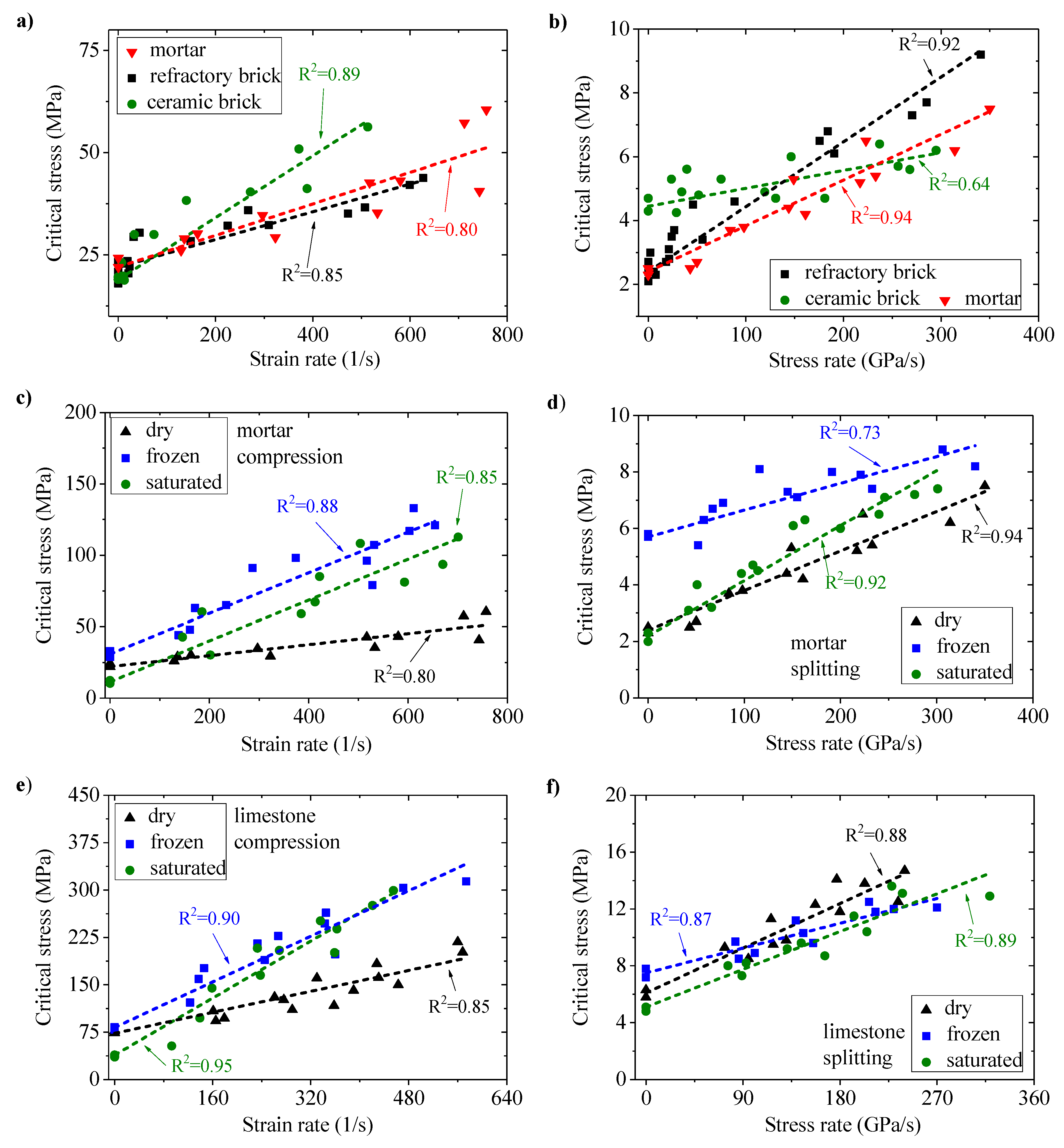

3.1. Comparison of Critical Stresses for Various Quasi-Brittle Materials

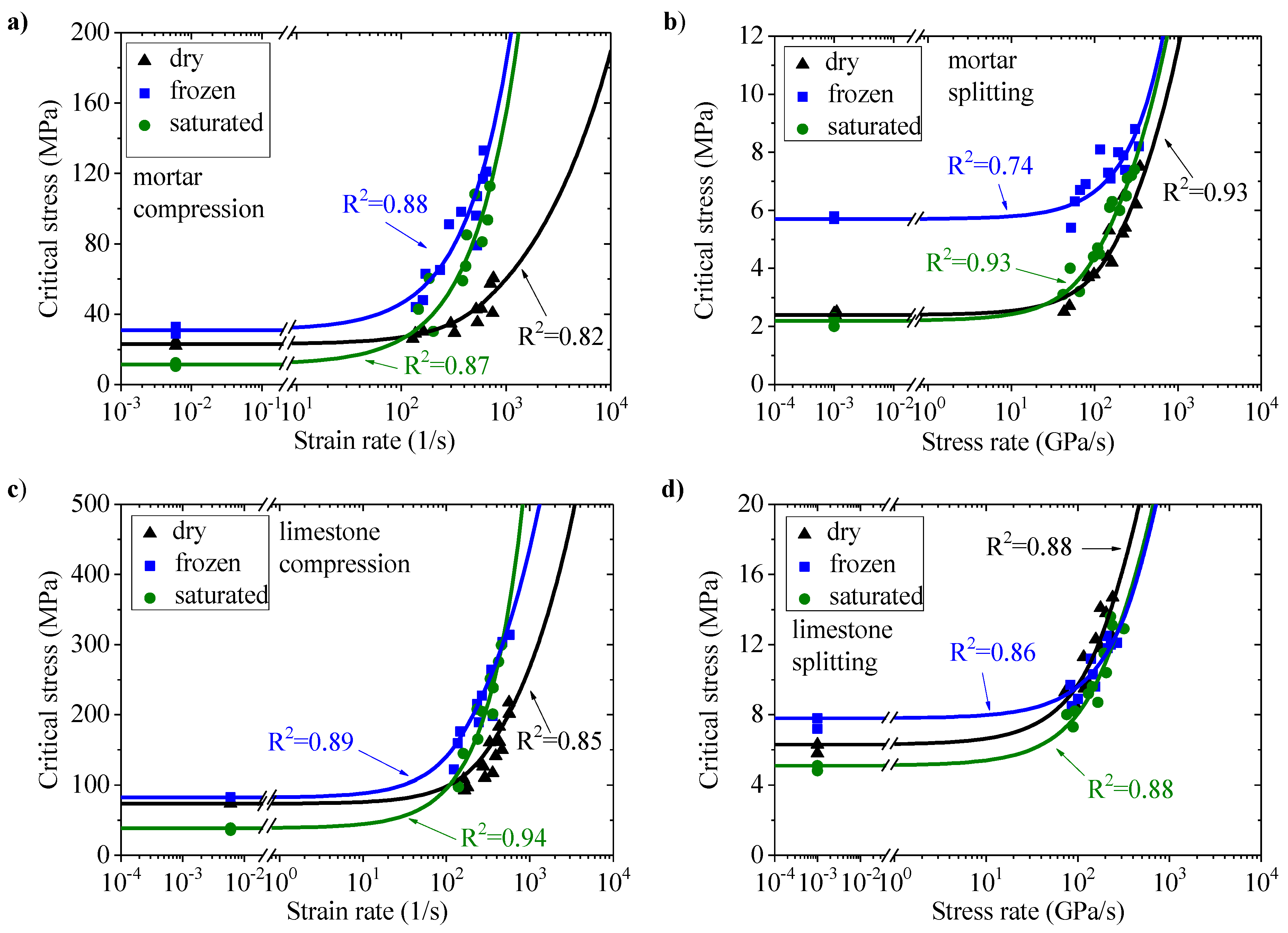

3.2. Comparison of Critical Stresses for Various States of Mortar and Limestone

3.3. Comparison of Critical Stresses for Metals with CG and UFG Structure

3.4. Comparison of Critical Stresses for Bitumen Binders for Asphalt Mixes

4. Discussion

4.1. Calculation of Critical Stress Dependencies on Strain and Loading Rates

4.2. A Possible Way to Predict the Competition of Strength Characteristics

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Meyers, M.A. Dynamic Behavior of Materials; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1994. [Google Scholar] [CrossRef]

- Zhang, Q.B.; Zhao, J. A review of dynamic experimental techniques and mechanical behaviour of rock materials. Rock Mech. Rock Eng. 2014, 47, 1411–1478. [Google Scholar] [CrossRef] [Green Version]

- Remington, B.A.; Allen, P.; Bringa, E.M.; Hawreliak, J.; Ho, D.; Lorenz, K.T.; Lorenzana, H.; McNaney, J.M.; Meyers, M.A.; Pollaine, S.W.; et al. Material dynamics under extreme conditions of pressure and strain rate. Mater. Sci. Technol. 2006, 22, 474–488. [Google Scholar] [CrossRef]

- Armstrong, R.W.; Walley, S.M. High strain rate properties of metals and alloys. Int. Mater. Rev. 2008, 53, 105–128. [Google Scholar] [CrossRef]

- Chen, W.; Lu, F.; Cheng, M. Tension and compression tests of two polymers under quasi-static and dynamic loading. Polym. Test. 2002, 21, 113–121. [Google Scholar] [CrossRef]

- Brara, A.; Klepaczko, J.R. Experimental characterization of concrete in dynamic tension. Mech. Mater. 2006, 38, 253–267. [Google Scholar] [CrossRef]

- Johnson, G.R.; Holmquist, T.J. Evaluation of cylinder-impact test data for constitutive model constants. J. Appl. Phys. 1988, 64, 3901–3910. [Google Scholar] [CrossRef]

- Siviour, C.R.; Jordan, J.L. High strain rate mechanics of polymers: A review. J. Dyn. Behav. Mater. 2016, 2, 15–32. [Google Scholar] [CrossRef] [Green Version]

- Arab, A.; Chen, P.; Guo, Y. Effects of microstructure on the dynamic properties of TA15 titanium alloy. Mech. Mater. 2019, 137, 103121. [Google Scholar] [CrossRef]

- Ramesh, K.T.; Hogan, J.D.; Kimberley, J.; Stickle, A. A review of mechanisms and models for dynamic failure, strength, and fragmentation. Planet. Space Sci. 2015, 107, 10–23. [Google Scholar] [CrossRef]

- Campbell, J.D.; Eleiche, A.M.; Tsao, M.C.C. Strength of metals and alloys at high strains and strain rates. In Fundamental Aspects of Structural Alloy Design; Jaffee, R.I., Wilcox, B.A., Eds.; Springer: Boston, MA, USA, 1977; pp. 545–563. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Forquin, P. Brittle materials at high-loading rates: An open area of research. Philos. Trans. R. Soc. A 2017, 375, 20160436. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yoo, D.-Y.; Banthia, N. Impact resistance of fiber-reinforced concrete—A review. Cement Concr. Compos. 2019, 104, 103389. [Google Scholar] [CrossRef]

- Klepaczko, J.R. Behavior of rock-like materials at high strain rates in compression. Int. J. Plast. 1990, 6, 415–432. [Google Scholar] [CrossRef]

- Abrosimov, S.A.; Bazhulin, A.P.; Voronov, V.V.; Krasyuk, I.K.; Pashinin, P.P.; Semenov, A.Y.; Stuchebryukhov, I.A.; Khishchenko, K.V. Study of mechanical properties of aluminum, AMg6M alloy, and polymethyl methacrylate at high strain rates under the action of picosecond laser radiation. Dokl. Phys. 2012, 57, 64–66. [Google Scholar] [CrossRef]

- Armstrong, R.W.; Li, Q. Dislocation mechanics of high-rate deformations. Metall. Mat. Trans. A 2015, 46, 4438–4453. [Google Scholar] [CrossRef]

- Armstrong, R. Size effects on material yield strength/deformation/fracturing properties. J. Mater. Res. 2019, 34, 2161–2176. [Google Scholar] [CrossRef]

- Petrov, Y.V.; Utkin, A.A. Dependence of the dynamic strength on loading rate. Sov. Mater. Sci. 1989, 25, 153–156. [Google Scholar] [CrossRef]

- Petrov, Y.V.; Morozov, N.F. On the modeling of fracture of brittle solids. J. Appl. Mech. 2008, 61, 710–712. [Google Scholar] [CrossRef]

- Gruzdkov, A.A.; Petrov, Y.V.; Smirnov, V.I. An invariant form of the dynamic criterion for yield of metals. Phys. Solid State 2002, 44, 2080–2082. [Google Scholar] [CrossRef]

- Petrov, Y.V.; Smirnov, I.V.; Utkin, A.A. Effects of strain-rate strength dependence in nanosecond load duration range. Mech. Solids 2010, 45, 476–484. [Google Scholar] [CrossRef]

- Kazarinov, N.A.; Bratov, V.A.; Petrov, Y.V. Simulation of dynamic crack propagation under quasi-static loading. Dokl. Phys. 2014, 59, 99–102. [Google Scholar] [CrossRef]

- Borodin, E.N.; Mayer, A.E.; Petrov, A.A.; Gruzdkov, Y.V. Maximum yield strength under quasi-static and high-rate plastic deformation of metals. Phys. Solid State 2014, 56, 2470–2479. [Google Scholar] [CrossRef]

- Runorm. Ceramic Brick and Stone. General Specifications. GOST 530-2012; Runorm: Moscow, Russia, 2017. [Google Scholar]

- Runorm. General-Purpose Fireclay and Semiacidic Refractory Articles. Specifications. GOST 390-2018; Runorm: Moscow, Russia, 2018. [Google Scholar]

- Runorm. Common Cements. Specifications. GOST 31108-2016; Runorm: Moscow, Russia, 2016. [Google Scholar]

- Russian Federation Gosstroy. Manufacturing and Usage of Solutions in Construction Industry. SP 82-101-98; Russian Federation Gosstroy: Moscow, Russia, 1998. [Google Scholar]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Smirnov, I.; Konstantinov, A. Influence of ultrafine-grained structure produced by equal-channel angular pressing on the dynamic response of pure copper. Procedia Struct. Integr. 2018, 13, 1336–1341. [Google Scholar] [CrossRef]

- Smirnov, I.V. Strength characteristics and fracture of ultrafine-grained titanium Grade 4 processed by equal channel cngular pressing—Conform. Tech. Phys. 2019, 64, 497–505. [Google Scholar] [CrossRef]

- Yildirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Presti, D.L. Recycled tyre rubber modified bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Kolsky, H. An investigation of the mechanical properties of materials at very high rates of loading. Proc. Phys. Soc. Sect. B 1949, 62, 676–700. [Google Scholar] [CrossRef]

- Hibbeler, R.C. Mechanics of Materials, 10th ed.; Pearson: London, UK, 2017. [Google Scholar]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications, 4th ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Lifshitz, J.M.; Leber, H. Data processing in the split Hopkinson pressure bar tests. Int. J. Impact Eng. 1994, 15, 723–733. [Google Scholar] [CrossRef]

- Bragov, A.M.; Lomunov, A.K. Methodological aspects of studying dynamic material properties using the Kolsky method. Int. J. Impact Eng. 1995, 16, 321–330. [Google Scholar] [CrossRef]

- Malinowski, J.Z.; Klepaczko, J.R. A unified analytic and numerical approach to specimen behaviour in the Split-Hopkinson pressure bar. Int. J. Mech. Sci. 1986, 28, 381–391. [Google Scholar] [CrossRef]

- Mishra, A.; Martin, M.; Thadhani, N.N.; Kad, B.K.; Kenik, E.A.; Meyers, M.A. High-strain-rate response of ultra-fine-grained copper. Acta Mater. 2008, 56, 2770–2783. [Google Scholar] [CrossRef]

- Petrov, Y.V. Incubation time criterion and the pulsed strength of continua: Fracture, cavitation, and electrical breakdown. Dokl. Phys. 2004, 49, 246–249. [Google Scholar] [CrossRef]

| Material | Ecomp (GPa) | ||||

|---|---|---|---|---|---|

| refractory brick | 2.9 (0.3) | 20.7 (2.6) | 2.4 (0.3) | 25 (5.0) | 46 (6.7) |

| ceramic brick | 3.6 (0.4) | 19.3 (0.7) | 4.5 (0.4) | 41 (8.7) | 14 (6.3) |

| mortar dry | 3.4 (0.6) | 23.0 (1.2) | 2.4 (0.2) | 22 (6.5) | 28 (4.9) |

| mortar saturated | 4.4 (0.5) | 11.4 (0.9) | 2.2 (0.2) | 65 (12.6) | 44 (5.4) |

| mortar frozen | 5.6 (0.5) | 30.9 (1.6) | 5.7 (0.4) | 58 (9.6) | 19 (6.0) |

| limestone dry | 7.2 (0.8) | 73.7 (4.0) | 6.3 (0.7) | 57 (12.8) | 68 (11.6) |

| limestone saturated | 10.7 (0.9) | 38.9 (2.4) | 5.1 (0.4) | 105 (16.4) | 59 (7.6) |

| limestone frozen | 15.5 (1.0) | 82.5 (3.5) | 7.8 (1.0) | 75 (18.0) | 36 (8.0) |

| Material | State | Ecomp (GPa) * | ||

|---|---|---|---|---|

| titanium | CG | 110 | 640 (28) | 1.07 (0.33) |

| titanium | UFG | 110 | 1014 (9) | 0.35 (0.14) |

| copper | CG | 128 | 258 (9) | 0.20 (0.04) |

| copper | UFG1 | 128 | 349 (3) | 0.04 (0.01) |

| copper | UFG2 | 128 | 365 (15) | 0.18 (0.05) |

| Material | Condition | E (GPa) | ||||

|---|---|---|---|---|---|---|

| PBB | C, R | 0.76 (0.07) | 2.6 * | - | 38 (0.9) | - |

| RBB | C, R | 0.70 (0.06) | 1.4 * | - | 29 (1.4) | - |

| BND | C, R | 0.65 (0.08) | 6 * | - | 28 (0.8) | - |

| PBB | S, M | - | - | 1.1 * | - | 75 (0.4) |

| RBB | S, M | - | - | 0.5 * | - | 102 (24.2) |

| BND | S, M | - | - | 0.8 * | - | 62 (5.1) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smirnov, I.; Konstantinov, A. Strain Rate Dependencies and Competitive Effects of Dynamic Strength of Some Engineering Materials. Appl. Sci. 2020, 10, 3293. https://doi.org/10.3390/app10093293

Smirnov I, Konstantinov A. Strain Rate Dependencies and Competitive Effects of Dynamic Strength of Some Engineering Materials. Applied Sciences. 2020; 10(9):3293. https://doi.org/10.3390/app10093293

Chicago/Turabian StyleSmirnov, Ivan, and Alexander Konstantinov. 2020. "Strain Rate Dependencies and Competitive Effects of Dynamic Strength of Some Engineering Materials" Applied Sciences 10, no. 9: 3293. https://doi.org/10.3390/app10093293