Residual Stress Relaxation of DRWDs in OSDs under Constant/Variable Amplitude Cyclic Loading

Abstract

:1. Introduction

2. Welding Residual Stress Distribution

2.1. Welding Residual Stress Measurement

2.2. Numerical Simulation

2.3. Welding Residual Stress Analysis

3. Analysis Model of the Residual Stress Relaxation Effects

3.1. Cyclic Plasticity Constitutive Model

3.1.1. Initial Yielding Condition of Materials

3.1.2. Plastic Flow Rule

3.1.3. Hardening Rule

3.2. A Coupled Stress Analysis Model That Considers the Welding Residual Stress and Mechanical Stress

- The Shell63 elastic shell element is used to establish the global model (GM) of steel box girders, including the top decks, ribs, bottom decks, and transverse diaphragm plates of the steel box girder system. The element size is 150 mm and the total number is 91,090. The length of the global model along the bridge is equal to five times the spacing of diaphragm plates and the width is 32.5 m; the length of the global model is 18.75 m. The thickness of the diaphragm plate is 14 mm.

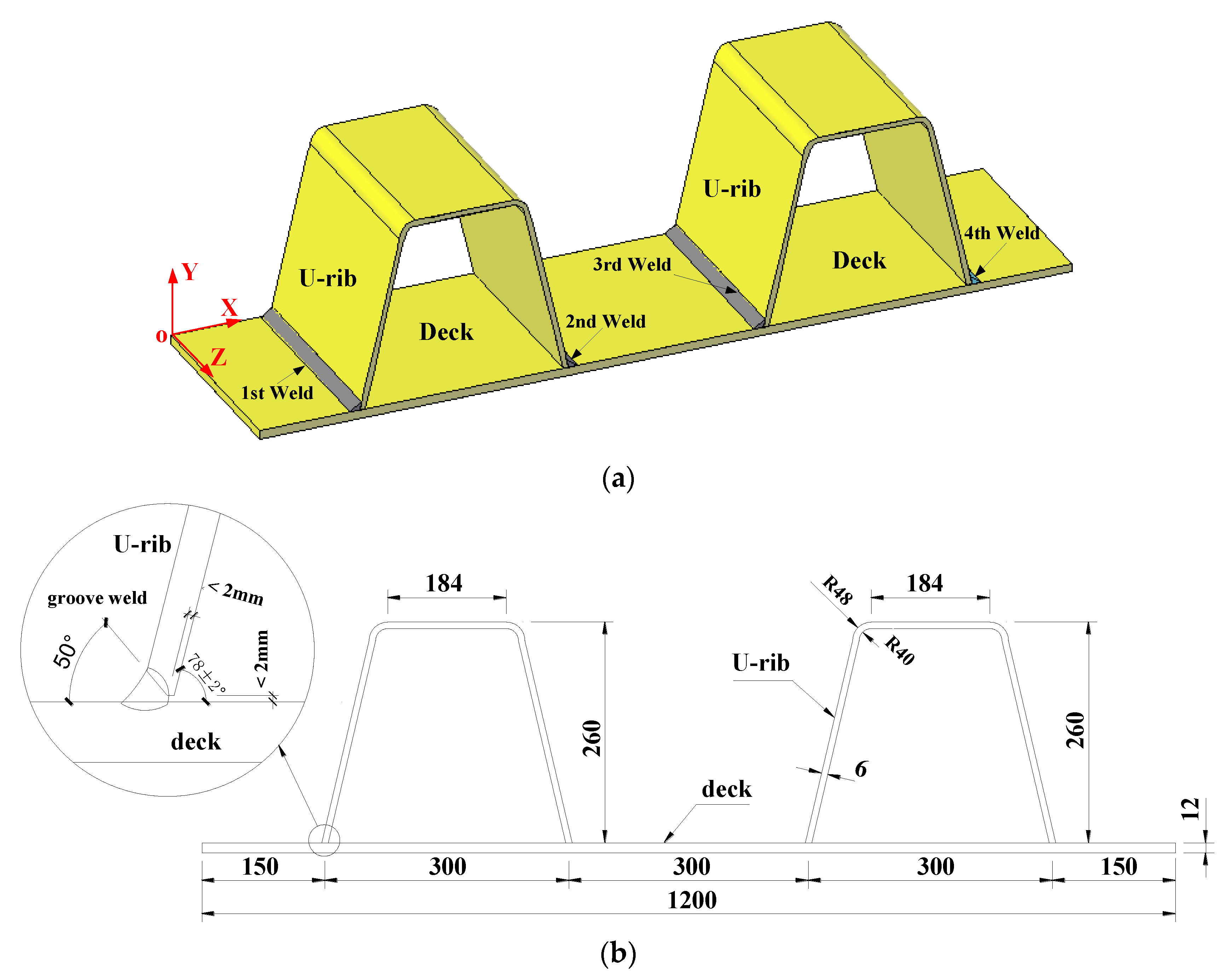

- The local fine model (LFM) of DRWDs is established with Jiangyin Yangtze River Highway Bridge as the engineering background. The eight-node solid element provided by ANSYS is used to perform a FEM simulation on the top decks, ribs, and weld structure in 1.5 U ribs. During the modeling process, the Solid70 elements and Solid185 elements are adopted for heat transfer analysis and mechanical analysis, respectively. The welding seam details are shown in Figure 1. The length of local fine model is 900 mm and the width is 300 mm.

- The multi-scale model of entire OSDs is modeled by embedding the LFM into the GM as shown in Figure 10a. In this model, the shell elements and solid elements are rigidly connected and the multipoint constraint algorithm is used in contact calculation. In contact connection area, the target element (Targe170) and contact element (Conta175) are defined as solid element (Solid185) surface and shell element (Shell63) nodes, respectively. All translational degrees of freedom (DOFs) are constrained at both ends of the multi-scale model of entire OSDs.

- The thermal structure coupling method is adopted to simulate the temperature field and stress field of welding process in the multi-scale model of entire OSDs. This process is the same as that in Section 2.2, so will not be repeated here. Then, the external fatigue loading is applied to the deck surface of the multi-scale model to obtain the true coupled stress time history of DRWDs. The blue distributed loads in Figure 10b are the external cyclic loads, which are applied on top of the welded joint in a 50 mm × 300 mm area, to simulate the effect of cyclic loading on the residual stress relaxation.

4. Residual Stress Relaxation of DRWDs by External Cyclic Loading

4.1. Welding Residual Stress Release of DRWDs under Constant Amplitude Cyclic Loading

4.1.1. Number of External Loading Cycles

4.1.2. Stress Amplitude of External Cyclic Loading

4.1.3. Stress Ratio of External Cyclic Loading

4.1.4. Release Formula of Welding Residual Stress under the Constant Amplitude Cyclic Loading

4.2. Welding Residual Stress Release of DRWDs under Variable Amplitude Cyclic Loading

5. Conclusions

- The stress relaxation condition of weld residual stress under the mechanical stress, which is induced by the external cyclic loading, depends on the sum of initial residual stress () and Mises structure stress () and exceeds the yield strength of the material (), rather than observing the stress variation of a certain uniaxial (longitudinal or transverse stress).

- Most of the welding residual stress release (about 95%) occurred in the first loading cycle under the constant amplitude cyclic loading. As the number of external loading cycles increased, the overall distribution trend of welding residual stress remained almost unchanged, and the stress decreased until it was stable after five cycles.

- The welding residual stress relaxation coefficient A decreases with the increase in stress amplitude (TSA), and decreases approximately linearly with the stress ratio (R); that is to say, the releasing amount of welding residual stress increases with the increase in stress amplitude (TSA) and increases approximately linearly with the increase in the stress ratio (R).

- The release behavior of residual stress is controlled by the maximum amplitude stress in the variable amplitude cyclic loading. Thus, the stress will not continue to be released if the DRWDs have the same or smaller amplitude loading after the residual stress is released.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hu, N.; Dai, G.L.; Yan, B. Recent development of design and construction of medium and long span high-speed railway bridges in China. Eng. Struct. 2014, 74, 233–241. [Google Scholar] [CrossRef]

- Song, Y.S.; Ding, Y.L.; Wang, G.X. Fatigue-life evaluation of a high-speed railway bridge with an orthotropic steel deck integrating multiple factors. Perform. J. Constr. Facil. 2016, 30, 04016036. [Google Scholar] [CrossRef]

- Ji, B.H.; Liu, R.; Chen, C. Evaluation on root-deck fatigue of orthotropic steel bridge deck. Constr. J. Steel. Res. 2013, 90, 174–183. [Google Scholar] [CrossRef]

- Gaul, R. A Long Life Pavement for Orthotropic Bridge Decks in China. Geotech. Spec. Publ. 2015, 196, 1–8. [Google Scholar]

- Ya, S.; Yamada, K. Fatigue evaluation of rib-to-deck welded joints of orthotropic steel bridge deck. J. Bridge Eng. 2015, 492–499. [Google Scholar] [CrossRef]

- Guo, T.; Frangopol, D.M.; Chen, Y.W. Fatigue reliability assessment of steel bridge details integrating weigh-in-motion data and probabilistic finite element analysis. Comp. Struct. 2012, 112–113, 245–257. [Google Scholar] [CrossRef]

- Liu, R.; Ji, B.; Wang, M.; Chen, C. Numerical evaluation of toe-deck fatigue in orthotropic steel bridge deck. Perform. J. Constr. Facil. 2015, 29, 04014180. [Google Scholar] [CrossRef]

- Xiao, Z.G.; Yamada, K. Stress analyses and fatigue evaluation of rib-to-deck joints in steel orthotropic decks. Int. J. Fatigue 2008, 30, 1387–1397. [Google Scholar] [CrossRef]

- Cheng, X.; Fisher, J.W.; Prask, H.J.; Gnäupel-Herold, T.; Yen, B.T.; Roy, S. Residual stress modification by post-weld treatment and its beneficial effect on fatigue strength of welded structures. Int. J. Fatigue 2003, 25, 1259–1269. [Google Scholar] [CrossRef]

- Cui, C.; Bu, Y.Z.; Bao, Y. Strain energy-based fatigue life evaluation of deck-to-rib welded joints in osd considering combined effects of stochastic traffic load and welded residual stress. J. Bridge Eng. 2017, 23, 04017127. [Google Scholar] [CrossRef]

- Xie, X.F.; Jiang, W.; Luo, Y.; Xu, S.; Gong, J.M.; Tu, S.T. A model to predict the relaxation of weld residual stress by cyclic load: Experimental and finite element modeling. Int. J. Fatigue 2017, 95, 293–301. [Google Scholar] [CrossRef]

- Farajian, M.; Nitschke, T.P.; Dilger, K. Mechanisms of residual stress relaxation and redistribution in welded high-strength steel specimens under mechanical loading. Weld. World 2010, 54, R366–R374. [Google Scholar] [CrossRef]

- Han, S.; Lee, T.; Shin, B. Residual stress relaxation of welded steel components under cyclic load. Steel Res. 2002, 73, 414–420. [Google Scholar] [CrossRef]

- Dattoma, V.; Giorgi, M.; Nobile, R. Numerical evaluation of residual stress relaxation by cycle load. J. Strain Anal. Eng. 2004, 39, 663–672. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, X.S.; Yan, Z.J. On the mechanism of residual stresses relaxation in welded joints under cyclic loading. Int. J. Fatigue 2017, 105, 43–59. [Google Scholar] [CrossRef]

- Zhang, Q.H.; Cui, C.; Bu, Y.Z.; Liu, Y.M.; Ye, H.W. Fatigue tests and fatigue assessment approaches for rib-to-diaphragm in steel orthotropic decks. Constr. J. Steel Res. 2015, 114, 110–118. [Google Scholar] [CrossRef]

- Cao, Y.B.; Ding, Y.L.; Song, Y.S.; Zhong, W. Fatigue Life Evaluation for Deck-Rib Welding Details of Orthotropic Steel Deck Integrating Mean Stress Effects. J. Bridge Eng. 2019, 24, 04018114. [Google Scholar] [CrossRef]

- Cui, C.; Zhang, Q.; Bao, Y.; Han, S.; Bu, Y. Residual Stress Relaxation at Innovative Both-side Welded Rib-to-deck Joints under Cyclic Loading. Constr. J. Steel Res. 2019, 156, 9–17. [Google Scholar] [CrossRef]

- Lee, C.H.; Chang, K.H.; Van Do, V.N. Finite element modeling of residual stress relaxation in steel butt welds under cyclic loading. Eng. Struct. 2015, 103, 63–71. [Google Scholar] [CrossRef]

- Hensel, J.; Nitschke-Pagel, T.; Dilger, K. Residual stress-based fatigue design of welded structures. Mater. Perform. Character. 2018, 7, 630–642. [Google Scholar] [CrossRef]

- Nelson, D.V.; McCrickerd, J.T. Residual-stress determination through combined use of holographic interferometry and blind-hole drilling. Exp. Mech. 1986, 26, 371–378. [Google Scholar] [CrossRef]

- Schajer, G.S. Measurement of non-uniform residual stresses using the hole-drilling method. Part II—Practical application of the integral method. J. Eng. Mater. Technol. 1988, 110, 344–349. [Google Scholar] [CrossRef]

- Teng, T.L.; Fung, C.P.; Chang, P.H.; Yang, C.W. Analysis of residual stresses and distortions in T-joint fillet welds. Int. J. Press. Vessels Pip. 2001, 78, 523–538. [Google Scholar] [CrossRef]

- Wang, W.; Yan, S.; Kodur, V. Temperature induced creep in low-alloy structural Q345 steel. Mater. J. Civ. Eng. 2016, 28, 1–6. [Google Scholar] [CrossRef]

- Yuan, G.; Shu, Q.; Huang, Z.; Li, Q. An experimental investigation of properties of Q345 steel pipe at elevated temperatures. Constr. J. Steel Res. 2016, 118, 41–48. [Google Scholar] [CrossRef] [Green Version]

- Timoshenko, S.P.; Goodier, J.N. The Theory of Elasticity; McGraw-Hill: New York, NY, USA, 1951. [Google Scholar]

- Chaboche, J.L. Time independent constitutive theories for cyclic plasticity. Int. Plast. J. 1986, 2, 149–188. [Google Scholar] [CrossRef]

- Van Do, V.N.; Lee, C.H.; Chang, K.H. High cycle fatigue analysis in presence of residual stresses by using a continuum damage mechanics model. Int. J. Fatigue 2015, 70, 51–62. [Google Scholar]

- Rousselier, G. On the plastic and viscoplastic constitutive equations-part I: Rules developed with internal variable concept. Press. J. Vessel. Technol. 1983, 105, 153–158. [Google Scholar]

- Chaboche, J.L. On some modifications of kinematic hardening to improve the description of ratchetting effects. Int. Plast. J. 1991, 7, 661–678. [Google Scholar] [CrossRef]

- Goldak, J.; Chakravarti, A.; Bibby, M. A new finite element model for welding heat sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

- Ucak, A.; Tsopelas, P. Accurate modeling of the cyclic response of structural components constructed of steel with yield plateau. Eng. Struct. 2012, 35, 272–280. [Google Scholar] [CrossRef]

- Chaboche, J.L.; Lesne, P.M. A non-linear continuous fatigue damage model. Fatigue Fract. Eng. Mater. Struct. 1988, 11, 1–17. [Google Scholar] [CrossRef]

- Tian, Q.; Zhuge, H.; Xie, X. Prediction of the Ultra-Low-Cycle Fatigue Damage of Q345qC Steel and its Weld Joint. Materials 2019, 12, 4014. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, J.B. Improvement of the Hysteretic Constitutive Model for Bridge Structural Steels and Its Application. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2016. (In Chinese). [Google Scholar]

- Yu, Y.; Wang, X.; Chen, Z. Evaluation on steel cyclic response to strength reducing heat treatment for seismic design application. Constr. Build. Mater. 2017, 140, 468–484. [Google Scholar] [CrossRef]

| Temperature /°C | Thermal Conductivity W/(m °C) | Density/ (kg m−3) | Specific Heat Capacity J/(kg °C) | Poisson’s Ratio | Linear Expansion Coefficient /10–5 °C | Elasticity Modulus /GPa | Yield Stress /MPa | Tangent Modulus /GPa |

|---|---|---|---|---|---|---|---|---|

| 20 | 50 | 7820 | 460 | 0.28 | 1.10 | 205 | 370 | 2.050 |

| 250 | 47 | 7700 | 480 | 0.29 | 1.22 | 187 | 280 | 1.870 |

| 500 | 40 | 7610 | 530 | 0.31 | 1.39 | 150 | 213 | 1.500 |

| 1000 | 30 | 7490 | 670 | 0.40 | 1.34 | 20 | 13 | 0.200 |

| 1500 | 35 | 7350 | 660 | 0.45 | 1.33 | 2 | 1 | 0.020 |

| 2000 | 45 | 7300 | 750 | 0.48 | 1.32 | 1.5 | 1 | 0.015 |

| 3000 | 50 | 7100 | 800 | 0.50 | 1.31 | 0.1 | 1 | 0.001 |

| No. | A | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mises 1 | TSA | LSA | Mises | Tran.2 | Long.3 | Mises | Tran. | Long. | Mises | |||

| 1 | 146.54 | 373.35 | 325.81 | 10.00 | 14.08 | 12.55 | 0.45 | 1.12 | 0.97 | 0.99 | 0.99 | 0.99 |

| 2 | 40.00 | 56.33 | 50.20 | 0.58 | 1.25 | 1.10 | 0.97 | 0.96 | 0.96 | |||

| 3 | 70.00 | 98.59 | 87.86 | 0.72 | 1.38 | 1.20 | 0.95 | 0.92 | 0.91 | |||

| 4 | 100.00 | 140.84 | 125.51 | 0.86 | 1.51 | 1.32 | 0.92 | 0.86 | 0.85 | |||

| 5 | 130.00 | 183.09 | 163.15 | 1.00 | 1.65 | 1.45 | 0.87 | 0.77 | 0.75 | |||

| Cases | |||||

|---|---|---|---|---|---|

| C1 | 130 | 40 | 40 | 40 | 40 |

| C2 | 40 | 130 | 40 | 40 | 40 |

| C3 | 40 | 40 | 130 | 40 | 40 |

| C4 | 40 | 40 | 40 | 130 | 40 |

| C5 | 40 | 40 | 40 | 40 | 130 |

| C6 | 32.5 | 65 | 65 | 65 | 65 |

| C7 | 65 | 65 | 65 | 65 | 65 |

| C8 | 97.5 | 65 | 65 | 65 | 65 |

| C9 | 130 | 65 | 65 | 65 | 65 |

| C10 | 130 | 100 | 65 | 65 | 65 |

| C11 | 130 | 65 | 100 | 65 | 65 |

| C12 | 65 | 130 | 100 | 65 | 65 |

| Cases | The Transverse Residual Stress (TRS) and Release Stress (RS) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| n = 1 | n = 2 | n = 3 | n = 4 | n = 5 | ||||||

| TRS | RS | TRS | RS | TRS | RS | TRS | RS | TRS | RS | |

| C1 | 131.99 | 14.78 | 131.89 | 0.15 | 131.89 | 0.00 | 131.89 | 0.00 | 131.89 | 0.00 |

| C2 | 143.59 | 3.03 | 131.99 | 11.75 | 131.90 | 0.10 | 131.90 | 0.00 | 131.90 | 0.00 |

| C3 | 143.59 | 3.03 | 143.43 | 0.09 | 131.99 | 11.66 | 131.89 | 0.02 | 131.89 | 0.00 |

| C4 | 143.59 | 3.03 | 143.43 | 0.09 | 143.43 | 0.00 | 131.87 | 11.54 | 131.82 | 0.12 |

| C5 | 143.59 | 3.03 | 143.43 | 0.09 | 143.43 | 0.00 | 143.43 | 0.00 | 132.09 | 11.79 |

| C6 | 144.00 | 2.69 | 141.60 | 2.41 | 141.50 | 0.09 | 141.50 | 0.00 | 141.50 | 0.00 |

| C7 | 141.60 | 5.02 | 141.34 | 0.21 | 141.34 | 0.00 | 141.34 | 0.00 | 141.34 | 0.00 |

| C8 | 137.59 | 9.12 | 137.49 | 0.12 | 137.49 | 0.00 | 137.49 | 0.00 | 137.49 | 0.00 |

| C9 | 131.99 | 14.78 | 131.88 | 0.17 | 131.88 | 0.00 | 131.88 | 0.00 | 131.88 | 0.00 |

| C10 | 131.99 | 14.78 | 131.84 | 0.19 | 131.84 | 0.00 | 131.84 | 0.00 | 131.84 | 0.00 |

| C11 | 131.99 | 14.78 | 131.86 | 0.15 | 131.86 | 0.00 | 131.86 | 0.00 | 131.86 | 0.00 |

| C12 | 141.60 | 5.02 | 131.99 | 9.76 | 131.85 | 0.20 | 131.85 | 0.00 | 131.85 | 0.00 |

| Cases | The Transverse Residual Stress (TRS) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| n = 1 | n = 2 | n = 3 | n = 4 | n = 5 | ||||||

| Ca | Si | Ca | Si | Ca | Si | Ca | Si | Ca | Si | |

| C1 | 131.99 | 132.54 | 131.89 | 132.39 | 131.89 | 132.39 | 131.89 | 132.39 | 131.89 | 132.39 |

| C2 | 143.59 | 144.29 | 131.99 | 132.54 | 131.90 | 132.44 | 131.90 | 132.44 | 131.90 | 132.44 |

| C3 | 143.59 | 144.29 | 143.43 | 144.19 | 131.99 | 132.54 | 131.89 | 132.52 | 131.89 | 132.52 |

| C4 | 143.59 | 144.29 | 143.43 | 144.19 | 143.43 | 144.19 | 131.87 | 132.65 | 131.82 | 132.53 |

| C5 | 143.59 | 144.29 | 143.43 | 144.19 | 143.43 | 144.19 | 143.43 | 144.19 | 132.09 | 132.40 |

| C6 | 144.00 | 144.63 | 141.60 | 142.22 | 141.50 | 142.13 | 141.50 | 142.13 | 141.50 | 142.13 |

| C7 | 141.60 | 142.30 | 141.34 | 142.09 | 141.34 | 142.09 | 141.34 | 142.09 | 141.34 | 142.09 |

| C8 | 137.59 | 138.20 | 137.49 | 138.08 | 137.49 | 138.08 | 137.49 | 138.08 | 137.49 | 138.08 |

| C9 | 131.99 | 132.54 | 131.88 | 132.36 | 131.88 | 132.36 | 131.88 | 132.36 | 131.88 | 132.36 |

| C10 | 131.99 | 132.54 | 131.84 | 132.35 | 131.84 | 132.35 | 131.84 | 132.35 | 131.84 | 132.35 |

| C11 | 131.99 | 132.54 | 131.86 | 132.38 | 131.86 | 132.38 | 131.86 | 132.38 | 131.86 | 132.38 |

| C12 | 141.60 | 142.30 | 131.99 | 132.54 | 131.85 | 132.34 | 131.85 | 132.34 | 131.85 | 132.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, W.; Ding, Y.; Song, Y.; Geng, F.; Wang, Z. Residual Stress Relaxation of DRWDs in OSDs under Constant/Variable Amplitude Cyclic Loading. Appl. Sci. 2021, 11, 253. https://doi.org/10.3390/app11010253

Zhong W, Ding Y, Song Y, Geng F, Wang Z. Residual Stress Relaxation of DRWDs in OSDs under Constant/Variable Amplitude Cyclic Loading. Applied Sciences. 2021; 11(1):253. https://doi.org/10.3390/app11010253

Chicago/Turabian StyleZhong, Wen, Youliang Ding, Yongsheng Song, Fangfang Geng, and Zhiwen Wang. 2021. "Residual Stress Relaxation of DRWDs in OSDs under Constant/Variable Amplitude Cyclic Loading" Applied Sciences 11, no. 1: 253. https://doi.org/10.3390/app11010253