Key Technology and Experimental Study of Unequal Pitches Meshing between Metal Worm and Plastic Helical Gears

Abstract

:1. Preface

2. Literature Review

- (1)

- The axial module of the worm is equal to the transverse module of the worm gear.

- (2)

- The pressure angle of the Worm and Worm gear is the same.

3. Meshing Theory of Steel Worm with Plastic Helical Gear

3.1. Coordinatesystem of Steel Worm Meshing Plastic Helical Gear

3.2. Helical Equation of Worm

3.3. The Meshing Equation of Steel Worm with Plastic Helical Gear

4. Research Method

5. Load Distribution Model

6. Finite Element Analysis (FEA) for Real Model

7. Experimental Verification

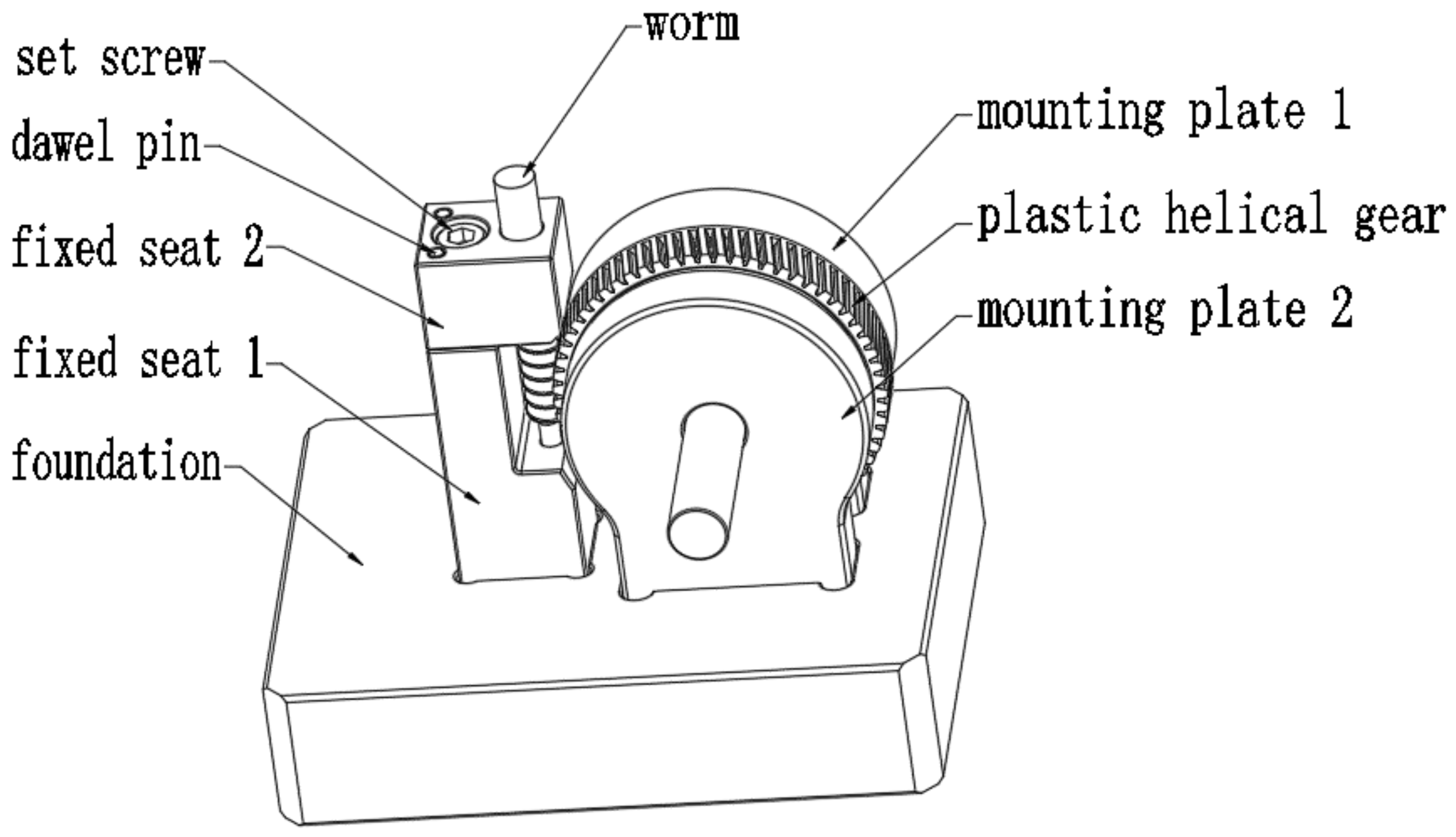

7.1. Introduction of Test Block and Test Machine

7.2. Parameter for Worm and Plastic Helical Gear

7.3. Test Method

7.4. Test Result

7.5. Test on Motor

8. Conclusions and Future Prospect

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Min, W.; Yong, W. Meshing transmission design of worm and helical gear in automobile micro-motor. Equip. Manuf. Technol. 2012, 11, 122–124. [Google Scholar]

- Deng, G.; Xu, F.; Liu, T. Experimental study on low noise for plastic helical gear and worm drive. Mech. Electr. Eng. Technol. 2010, 11, 122–123. [Google Scholar]

- Koide, T.; Takahama, K.I.; Miyachika, K.; Takahashi, H.; Namba, C. 405 Fatigue Life Prediction of Plastic Helical Wheel Meshed with Steel Worm. J. Mater. Metall. 2010, 2010, 105–106. [Google Scholar]

- Litvin, F.L.; Gonzalez-Perez, I.; Fuentes, A.; Vecchiato, D.; Sep, T.M. Generalized concept of meshing and contact of involute crossed helical gears and its application. Comput. Methods Appl. Mech. Eng. 2005, 194, 3710–3745. [Google Scholar] [CrossRef]

- Zhao, K.; Liu, H.; Lei, H.; Yu, X. Static simulation of worm helical gear based on ANSYS Workbench. J. Wuhan Polytechn. Univ. 2012, 31, 28–31. [Google Scholar]

- Du, K.; Du, X.; Zhou, Z. Contact ratio study of worm and helical gear transmission. Res. Dev. 2011, 8, 47–49. [Google Scholar]

- Zhang, L. Reflections on the design of engineering plastic Gear. J. Huaibei Vocat. Tech. Coll. 2009, 1, 45–46. [Google Scholar]

- Yun, Y.; Hu, H.; Ta, J. Changing rule of meshing force for plastic helical gear and steel worm. Mech. Drive 2018, 42, 27–32. [Google Scholar]

- Xu, H. Gear Manual; China Machine Press: Beijing, China, 2004. [Google Scholar]

- Chen, G.; Song, Z. Technology of Mechanical Manufacture; Beijing Institute of Technology Press: Beijing, China, 2007. [Google Scholar]

- Delrin100® Series Properties and Performance. Available online: https://www.dupont.com/knowledge/delrin-100-series.html (accessed on 5 May 2018).

- Chi, J.; Xiong, G. Dupont Technical Seminar. 2007. Available online: https://wenku.baidu.com/view/609b8bf9aef8941ea76e0598.html (accessed on 3 April 2018).

- Liu, H. Mechanics of Materials; Higher Education Press: Beijing, China, 1997. [Google Scholar]

- Liu, J.; Du, F. Gear modification and its application and analysis. J. Suzhou Inst. 2017, 105–108. [Google Scholar] [CrossRef]

- Li, L. Research on Meshing Performance of Plastic Worm Gear and Steel Worm. Available online: https://www.docin.com/p-1368083981.html 2007 (accessed on 20 July 2017).

- Hao, Y.; Yue, B. Meshing theory analysis of plastic helical gear and steel worm. Mech. Drive 2009, 33, 9–11. [Google Scholar]

- Peng, L.; Xue, H.; Wang, J. Study on gear modification and contact fatigue test. Mach. Tool Hydraul. 2017, 45, 7–10. [Google Scholar]

- Wang, C.; Yan, F.; Wang, F. Modification and noise reduction analysis of gear with high displacement. Tool Eng. 2017, 51, 71–75. [Google Scholar]

- Fan, Q.; Tang, J. Engineering Mechanics; Higher Education Press: Beijing, China, 2008. [Google Scholar]

- Heinz, P.B. Understanding right-angle gear backlash. Hydrocarb. Proc. 2017, 96, 17–18. [Google Scholar]

- Ren, J. Optimization Design and Finite Element Analysis of Gear Parameters Based on MATLAB; Jiangxi University of Science and Technology: Ganzhou, China, 2010. [Google Scholar]

- Li, C.; Liang, D.; Chen, B. Analysis and experimental study on meshing characteristics of plastic worm and copper helical gear. Mech. Drive 2017, 41, 58–62. [Google Scholar]

- Barton, P.M. Tragfaehigkeit von Schraubrad-Und Schneckengetrieben der Werkstoffpaarung Stahl/Kunststoff; Ruhr-Universitaet Bochum: Bochum, Germany, 2000. [Google Scholar]

| Strain (mm) | Stress (MPa) |

|---|---|

| 0.025 | 50 |

| 0.05 | 60 |

| 0.1 | 66 |

| 0.15 | 66.5 |

| Material | POM | S45C | |

|---|---|---|---|

| Physical Characteristics | |||

| Elastic modulus (MPA) | 3100 | 2.06 × 105 | |

| Poisson ratio | 0.35 | 0.3 | |

| M = 0.8 (Same Pitch) | M = 0.8 (Different Pitch) | M = 1.0 (Same Pitch) | M = 1.0 (Different Pitch) | ||||

|---|---|---|---|---|---|---|---|

| Torque (Nm) | Stress (MPa) | Torque (Nm) | Stress (MPa) | Torque (Nm) | Stress (MPa) | Torque (Nm) | Stress (MPa) |

| 1.05 | 28.53 | 1.05 | 22.83 | 1.05 | 15.51 | 1.05 | 13.75 |

| 1.90 | 35.98 | 1.90 | 29.70 | 1.9 | 20.52 | 1.9 | 18.10 |

| 2.9 | 38.26 | 2.90 | 31.62 | 2.9 | 24.12 | 2.9 | 22.43 |

| 3.9 | 41.45 | 3.90 | 34.68 | 3.9 | 30.81 | 3.9 | 28.13 |

| 5 | 45.75 | 5 | 38.92 | 5 | 34.42 | 5 | 32.11 |

| Normal Pitch | Pressure Angle | Helical/Lead Angle | Number of Teeth | Outside Meter | Root Meter | |

|---|---|---|---|---|---|---|

| Equal pitch worm | 2.513 | 12° | 5.93° | 1 | 9 | 4.3 |

| smaller pitch worm | 2.469 | 12° | 5.93° | 1 | 9 | 4.3 |

| plastic helical gear | 2.513 | 12° | 5.93° | 72 | 60.75 | 56.25 |

| Equal pitch worm | 3.142 | 12° | 9.16° | 1 | 7.9 | 4.36 |

| smaller pitch worm | 3.094 | 12° | 9.16° | 1 | 7.9 | 4.36 |

| plastic helical gear | 3.142 | 12° | 9.16° | 63 | 65.35 | 61.9 |

| No. of Helical Gear | Equal Pitch Worm & Plastic Helical Gear | Unequal Pitch Worm & Helical Gear | ||

|---|---|---|---|---|

| Max Breakage Force (Kgf) | Max Breakage Force (Kgf) | |||

| M = 0.8 | M = 1.0 | M = 0.8 | M = 1.0 | |

| No. 1 | 436.36 | 364.21 | 564.99 | 413.85 |

| No. 2 | 430.42 | 352.11 | 568.95 | 420.92 |

| No. 3 | 488.31 | 361.32 | 559.15 | 415.33 |

| No. 4 | 493.26 | 365.65 | 565.19 | 427.62 |

| No. 5 | 444.18 | 341.59 | 560.24 | 411.23 |

| No. 6 | 456.74 | 355.19 | 542.31 | 413.56 |

| No. 7 | 455.95 | 349.53 | 551.23 | 409.23 |

| No. 8 | 460.4 | 355.61 | 538.92 | 407.56 |

| No. 9 | 465.15 | 354.69 | 546.38 | 418.96 |

| No. 10 | 451.89 | 343.58 | 549.21 | 421.55 |

| Average | 447.36 | 362.53 | 554.66 | 415.98 |

| No. of Motor | Equal Pitch Worm & Plastic Helical Gear for Gearbox | Unequal Pitch Worm & Plastic Helical Gear for Gearbox | ||

|---|---|---|---|---|

| Max Breakage Torque (Nm) | Max Breakage Torque (Nm) | |||

| M = 0.8 | M = 1 | M = 0.8 | M = 1 | |

| No. 1 | 58.20 | 73.50 | 65.20 | 79.50 |

| No. 2 | 58.50 | 77.20 | 64.30 | 82.30 |

| No. 3 | 57.30 | 77.50 | 60.70 | 81.40 |

| No. 4 | 58.20 | 74.30 | 64.30 | 78.60 |

| No. 5 | 56.20 | 72.50 | 66.40 | 78.80 |

| No. 6 | 56.50 | 76.80 | 66.20 | 81.30 |

| No. 7 | 56.10 | 73.60 | 65.40 | 80.50 |

| No. 8 | 58.20 | 76.20 | 65.10 | 82.10 |

| No. 9 | 57.60 | 75.10 | 64.80 | 78.20 |

| No. 10 | 57.10 | 74.50 | 65.30 | 75.30 |

| Average | 57.39 | 75.12 | 64.77 | 79.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Z.; Ren, J.; Feng, Z.; Li, J. Key Technology and Experimental Study of Unequal Pitches Meshing between Metal Worm and Plastic Helical Gears. Appl. Sci. 2021, 11, 333. https://doi.org/10.3390/app11010333

Shi Z, Ren J, Feng Z, Li J. Key Technology and Experimental Study of Unequal Pitches Meshing between Metal Worm and Plastic Helical Gears. Applied Sciences. 2021; 11(1):333. https://doi.org/10.3390/app11010333

Chicago/Turabian StyleShi, Zhaoyao, Jihua Ren, Zhipeng Feng, and Jing Li. 2021. "Key Technology and Experimental Study of Unequal Pitches Meshing between Metal Worm and Plastic Helical Gears" Applied Sciences 11, no. 1: 333. https://doi.org/10.3390/app11010333