A New Circuit Design of AC/DC Converter for T8 LED Tube

Abstract

:1. Introduction

2. The Proposed LED Converter for a T8 LED Tube

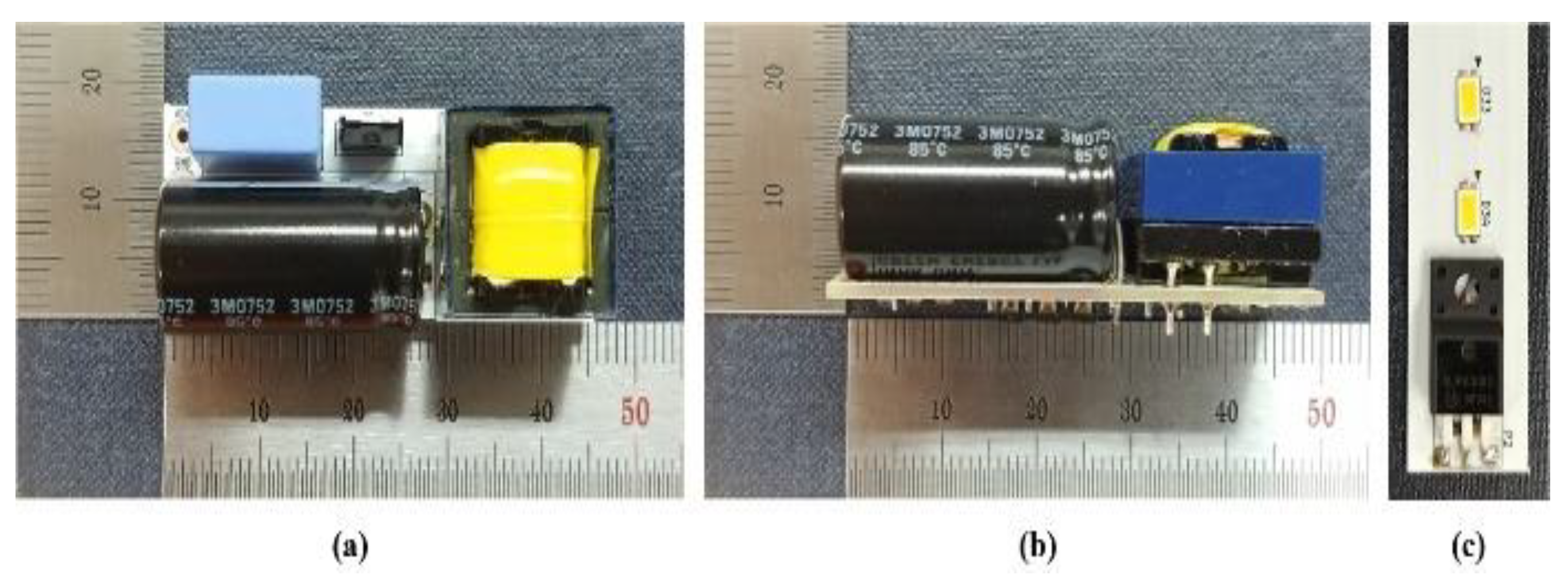

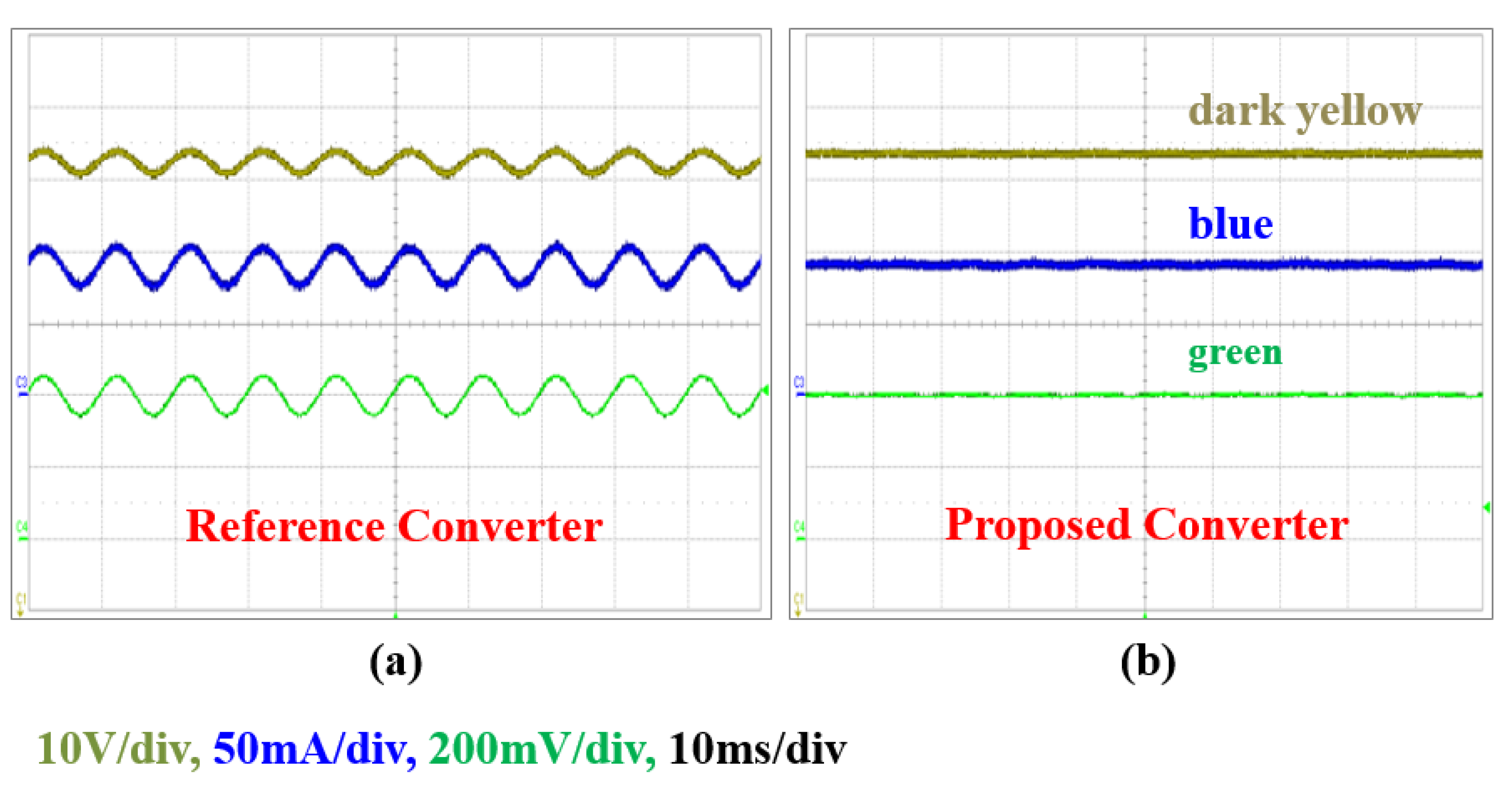

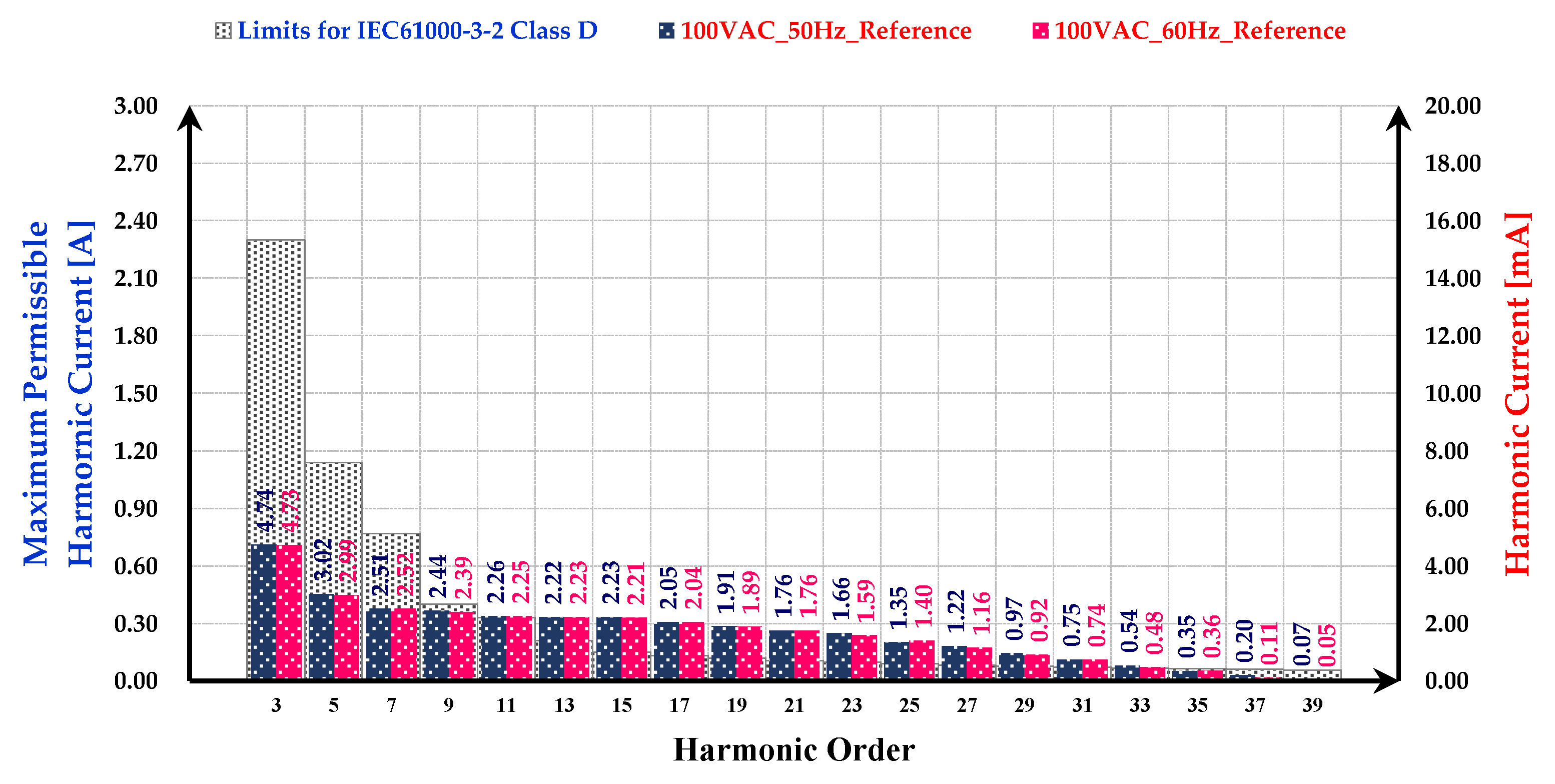

2.1. Power Stage

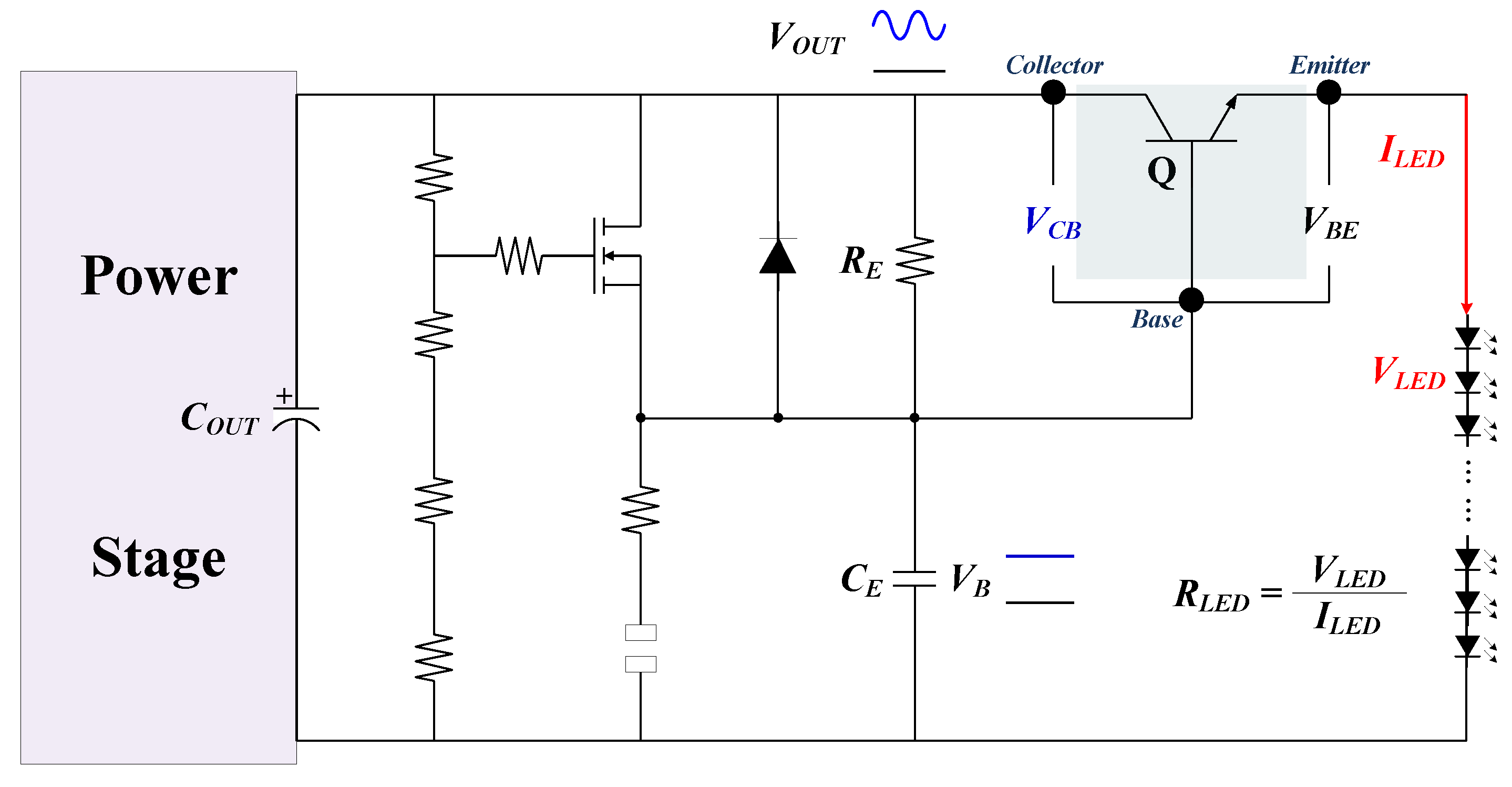

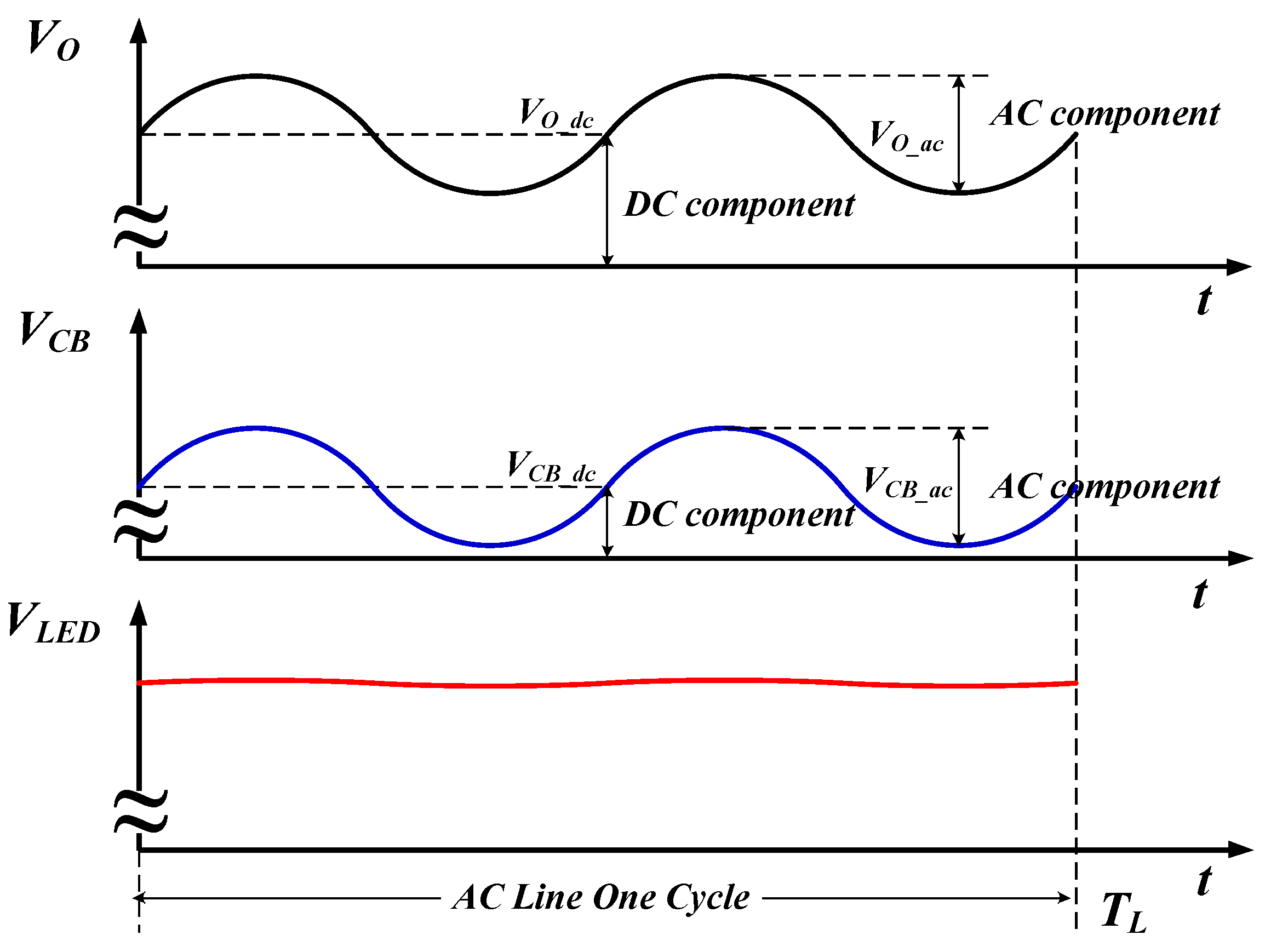

2.2. Ripple Free Stage

3. Design Parameters

3.1. Determining the Inductance: L

3.2. Determining the Output Capacitance:

3.3. Determining the Power Device: S, D

3.4. Determining the Output Ripple Eliminator: , , Q

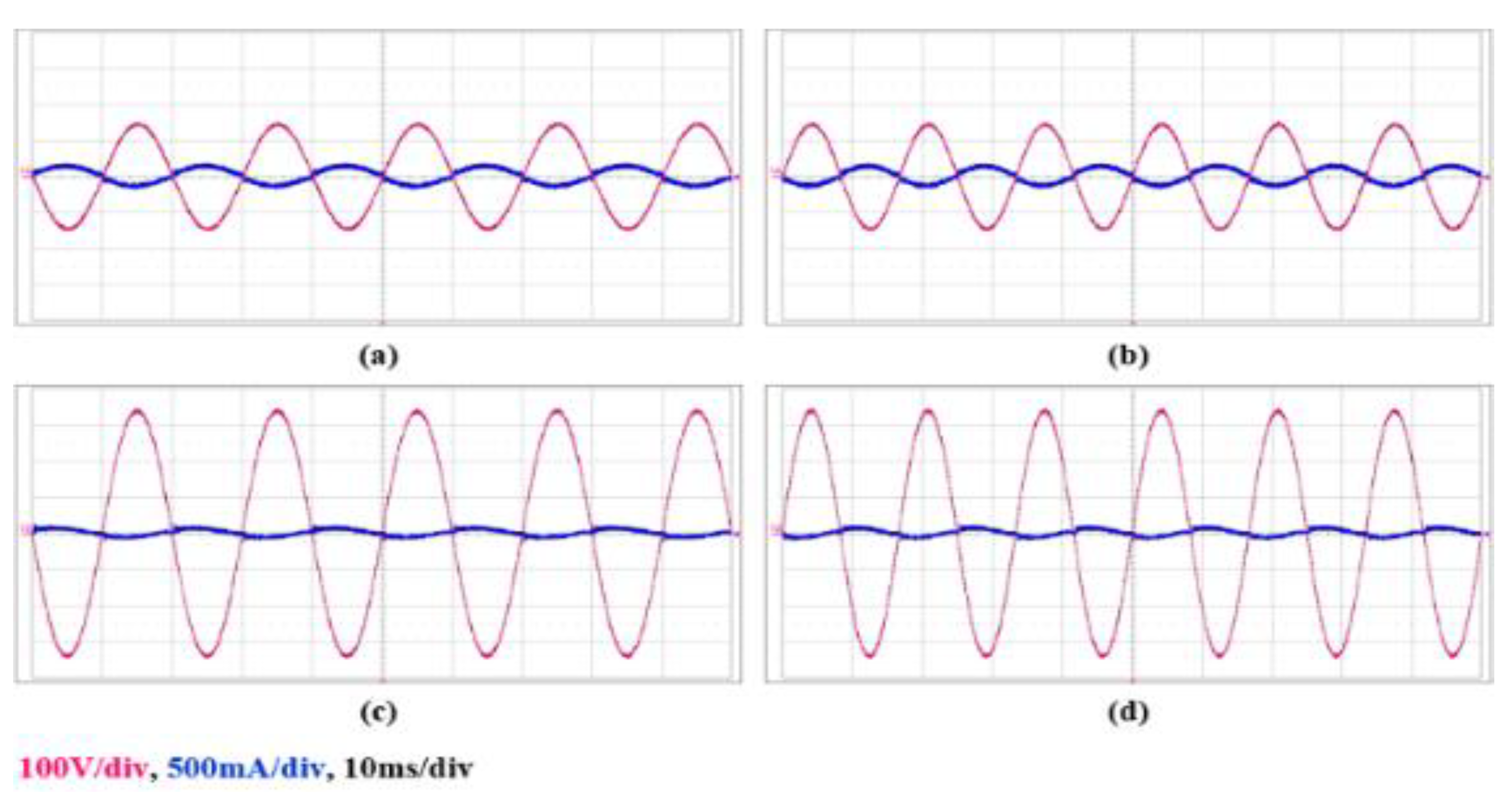

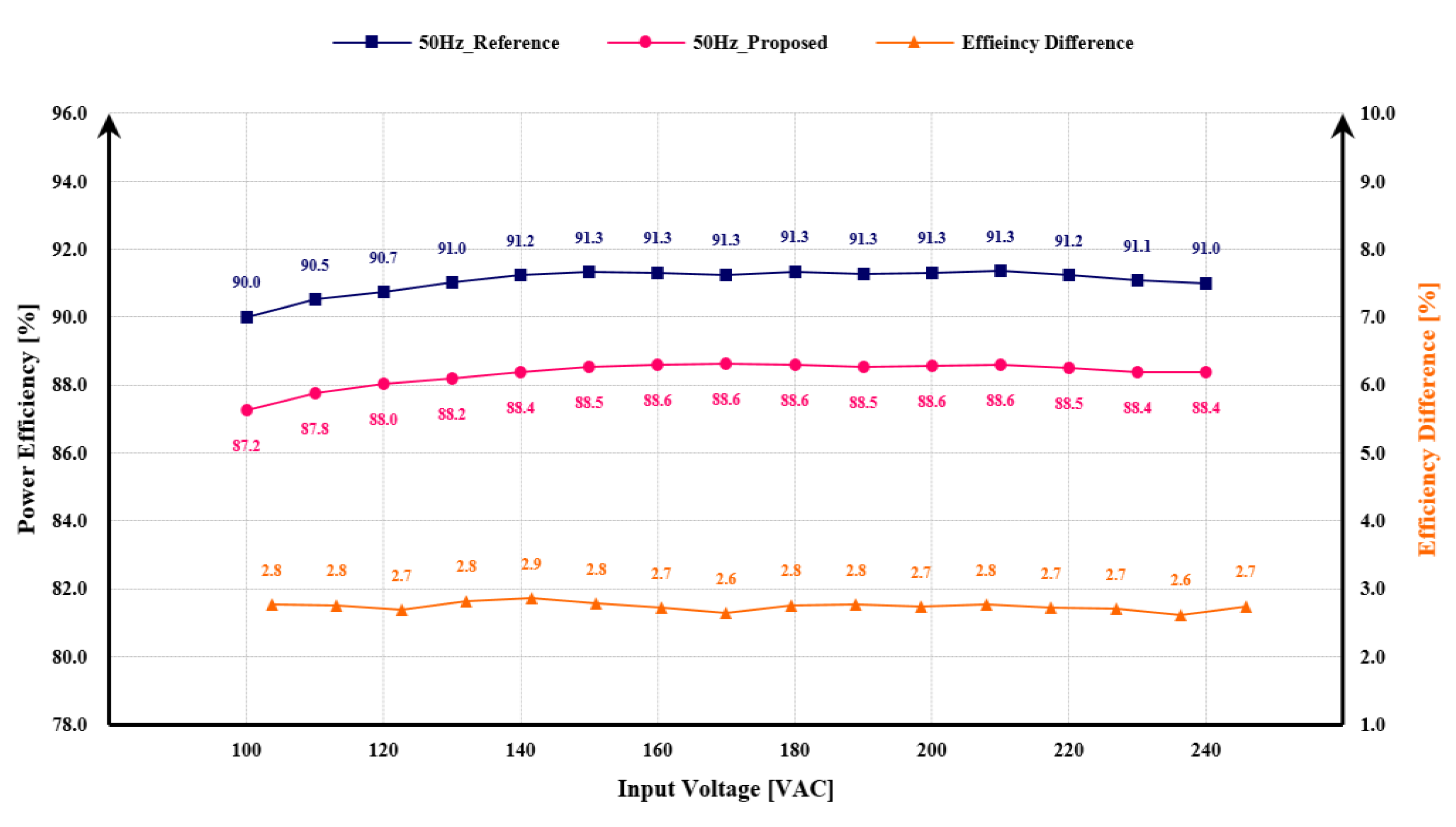

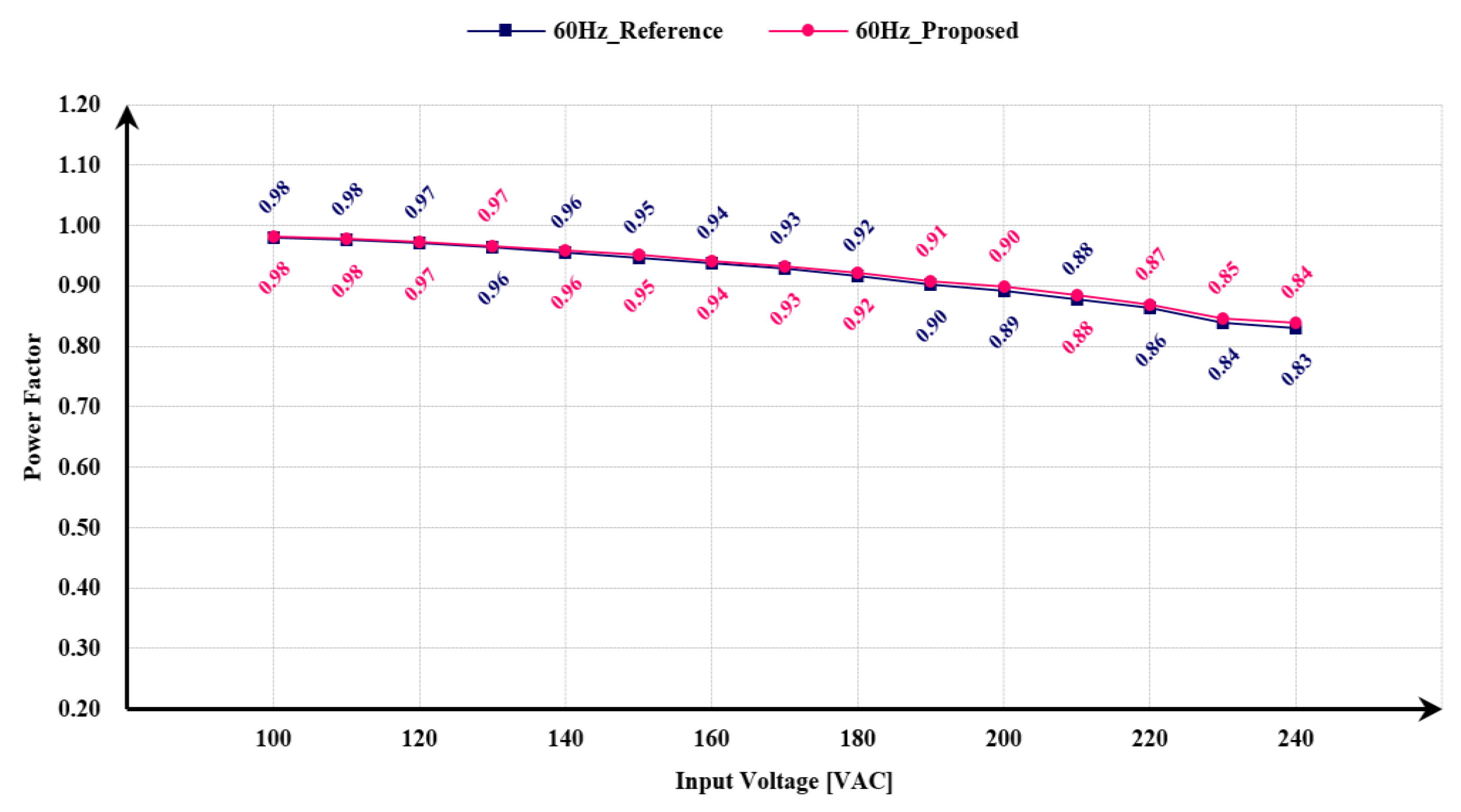

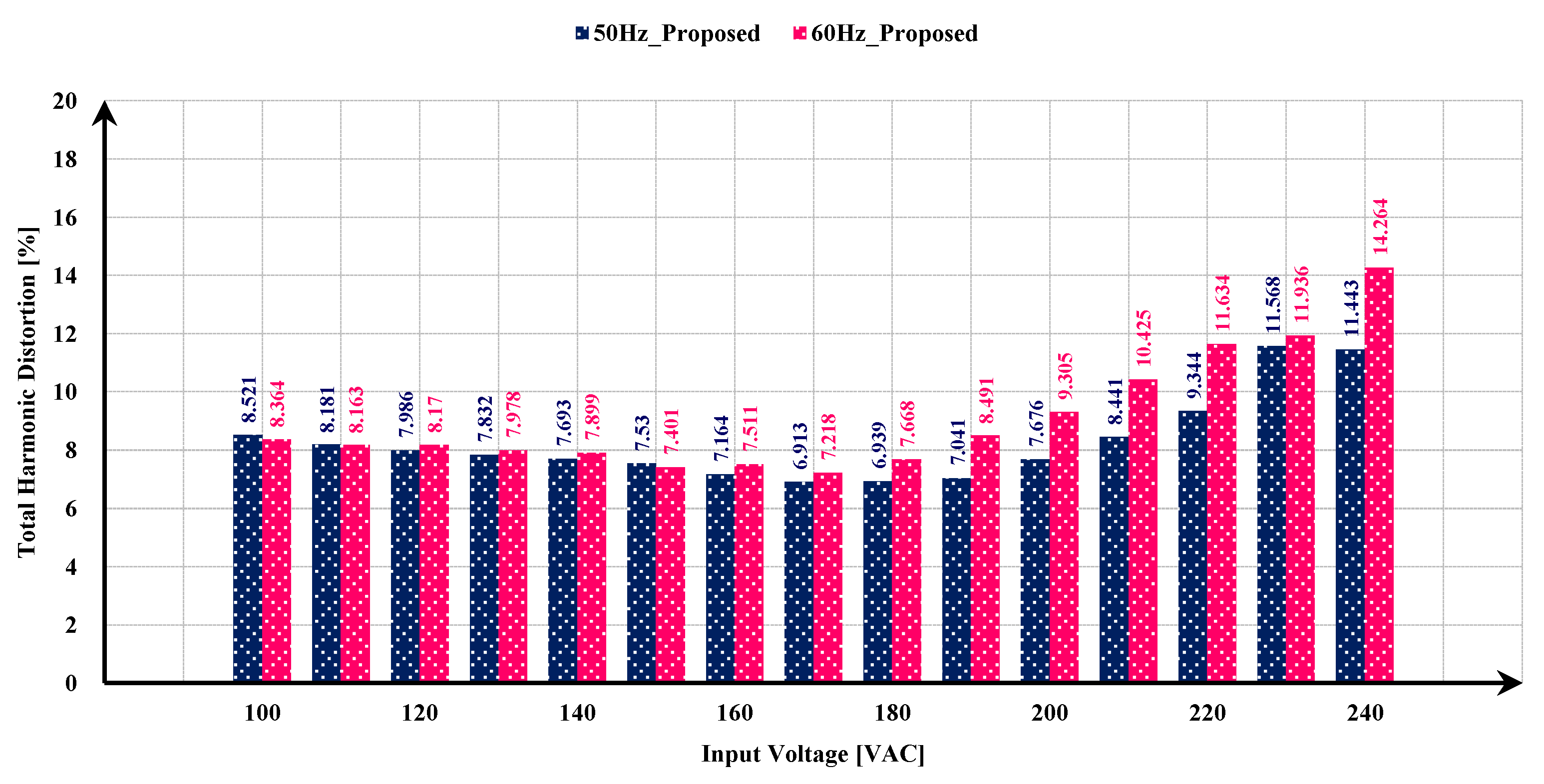

4. Experimental Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Weir, B. Driving the 21st century’s lights. IEEE Spectrum 2012, 49, 42–47. [Google Scholar] [CrossRef]

- Tsao, J.Y. Solid-state lighting: Lamps, chips, and materials for tomorrow. IEEE Circuits Devices Mag. 2004, 20, 28–37. [Google Scholar] [CrossRef]

- Lamar, D.G.; Arias, M.; Rodriguez, A.; Fernandez, A.; Hernando, M.M.; Sebastian, J. Design-oriented analysis and performance evaluation of a low-cost high-brightness LED driver based on flyback power factor corrector. IEEE Trans. Ind. Electron. 2012, 60, 2614–2626. [Google Scholar] [CrossRef]

- Wang, Y.; Alonso, J.M.; Ruan, X. A Review of LED Drivers and Related Technologies. IEEE Trans. Ind. Electron. 2017, 64, 5754–5765. [Google Scholar] [CrossRef]

- Kim, S.H.; Lee, S. A New High-Performance LED Converter With Separation of the AC and DC Driving Parts for a T8 LED Tube. IEEE Access 2019, 7, 61433–61441. [Google Scholar] [CrossRef]

- Peretto, L.; Pivello, E.; Tinarelli, R.; Emanuel, A.E. Theoretical analysis of the physiologic mechanism of luminous variation in eye-brain system. IEEE Trans. Instrum. Meas. 2007, 56, 164–170. [Google Scholar] [CrossRef]

- Wilkins, A.; Veitch, J. A Review of the Literature on Light Flicker: Ergonomics, Biological Attributes, Potential Health Effects, and Methods in Which Some LED Lighting May Introduce Flicker; IEEE Std: Piscataway, NJ, USA, 2008; pp. 1–26. [Google Scholar]

- Wilkins, A.; Veitch, J.; Lehman, B. LED lighting flicker and potential health concerns: IEEE standard PAR1789 update. In Proceedings of the 2010 IEEE Energy Conversion Congress and Exposition, Atlanta, GA, USA, 12–16 September 2010; pp. 171–178. [Google Scholar]

- IEEE Standards Association. IEEE Standards Association. IEEE Recommended Practices for Modulating Current in High-Brightness LEDs for Mitigating Health Risks to Viewers; IEEE Std.; Piscataway, NJ, USA, 2015; pp. 1–80. [Google Scholar]

- Trujillo, C.; Henao, G.; Castro, J.; Narvaez, A. Design and development of a LED Driver prototype with a Single-Stage PFC and low current harmonic distortion. IEEE Latin Am. Trans. 2017, 15, 1368–1375. [Google Scholar]

- Mark, R.S. The IESNA, Lightging Handbook-Reference and Application (vol. 1); IESNA: New York, NY, USA, 2000. [Google Scholar]

- Fang, P.; Liu, Y. Energy channeling LED driver technology to achieve flicker-free operation with true single stage power factor correction. IEEE Trans. Power Electron. 2016, 32, 3892–3907. [Google Scholar] [CrossRef]

- Reddy, U.R.; Narasimharaju, B.L. Single-stage electrolytic capacitor less non-inverting buck-boost PFC based AC–DC ripple free LED driver. IET Power Electron. 2017, 10, 38–46. [Google Scholar] [CrossRef]

- Ahn, H.; Hong, S.; Kwon, O. A Highly Accurate Current LED Lamp Driver With Removal of Low-Frequency Flicker Using Average Current Control Method. IEEE Trans. Power Electron. 2017, 33, 8741–8753. [Google Scholar] [CrossRef]

- Pereira, G.G.; Costa, M.A.D.; Alonso, J.M.; De Melo, M.F.; Barriquello, C.H. LED driver based on input current shaper without electrolytic capacitor. IEEE Trans. Ind. Electron. 2017, 64, 4520–4529. [Google Scholar] [CrossRef]

- Fang, P.; Liu, Y.; Sen, P.C. A Flicker-Free Single-Stage Offline LED Driver With High Power Factor. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 654–665. [Google Scholar] [CrossRef]

- Fang, P.; Sheng, B.; Webb, S.; Zhang, Y.; Liu, Y.-F. LED Driver Achieves Electrolytic Capacitor-Less and Flicker-Free Operation with an Energy Buffer Unit. IEEE Trans. Power Electron. 2019, 34, 6777–6793. [Google Scholar] [CrossRef]

- Fang, P.; Webb, S.; Chen, Y.; Liu, Y.-F.; Sen, P.C.; Sam, W. A Multiplexing Ripple Cancellation LED Driver with True Single-Stage Power Conversion and Flicker-free Operation. IEEE Trans. Power Electron. 2019, 34, 10105–10120. [Google Scholar] [CrossRef]

- International Electrotechnical Commission. IEC 60061-1: Lamp Caps and Holders Together with Gauges for the Control of Interchangeability and Safety—PART 1: LAMP CAPS; IEC: Geneva, Switzerland, 2005. [Google Scholar]

- Wang, Y.; Zhang, S.; Alonso, J.M.; Liu, X.; Xu, D. A single-Stage LED Driver With High-Performance Primary-Side-Regulated Characteristic. IEEE Trans. Circuits Syst. II Express Briefs 2018, 65, 76–80. [Google Scholar] [CrossRef]

- Lei, C. Single Stage Primary Side Regulation PFC Controller for LED Driver; Application note AN1115 for Diodes Incorporated: Plano, TX, USA, 2015. [Google Scholar]

- Adragna, C. Design Equations of High-Power-Factor Flyback Converters Based on the L6561; Application note AN1059 for STMicroelectronics: Geneva, Switzerland, 2003. [Google Scholar]

- Diodes Incorporated. Single Stage Primary Side Regulation PFC Controller for LED Driver. AP1682E Datasheet; Diodes Incorporated: Plano, TX, USA, 2014. [Google Scholar]

- Roy, R.V. Minimizing Light Flicker in LED Lighting Applications; Application note AN022 for Richtek Technology: Hsinchu, Taiwan, 2014. [Google Scholar]

- Malik, N.R. Transistor Amplifiers. In Electronic Circuits; Prentice Hall, International: London, UK, 1995; pp. 474–572. [Google Scholar]

- Seoul Semiconductor. Specification SSC-STW8Q14BE. SSC-STW8Q14BE Technical Datasheet; Seoul Semiconductor: Gyeonggi-do, Korea, 2012. [Google Scholar]

- On Semiconductor. Complementary Power Darlingtons. MJF6388 Datasheet; On Semiconductor: Pheonix, AZ, USA, 2014. [Google Scholar]

- International Electrotechnical Commission. Electromagnetic Compatibility, Part 3, Section 2. Limits for Harmonic Current Emissions (Equipment Input Current ≤ 16 A Per Phase), IEC Standard 61000-3-2; IEC: Geneva, Switzerland, 2005. [Google Scholar]

- EPSMA Technical Committee. PFC Harmonic Current Emissions—Guide to EN61000-3-2:2014; EPSMA: Little Haseley, Oxfordshire, UK, 2018. [Google Scholar]

| 10 W LED Converter | ||||

|---|---|---|---|---|

| Item | MIN | TYP | MAX | |

| Input Voltage (VAC) | 100 | 90 | 100 | - |

| 240 | - | 240 | 264 | |

| Input Current (mA) | 34.1 (@90 VAC) | - | 122.2 (@264 VAC) | |

| Input Frequency (Hz) | 50 | - | 60 | |

| Input Power (W) | 9.0 | 10.0 | 11.0 | |

| Output Voltage (V) | 102 | 106 | 112 | |

| Output Current (mA) | 81.8 | 87.0 | 92.2 | |

| AC Driving Circuit | Fuse | 250 V, 1 A |

| Line Filter | TOROIDAL, 31 uH, 4 A | |

| X-capacitor | 275 VAC, 100 nF | |

| Bridge Diode | VRRM = 1000 V, IO = 1 A | |

| Film Capacitor | 600 V, 100 nF | |

| PCB | CEM-3, 1T, 0.5 oz, Single Layer | |

| DC Driving Circuit | Film Capacitor | 630 V, 100 nF |

| Inductor | EE1616, 1.38 mH | |

| Electrolytic Capacitor | 400 V, 22 uF, 105 °C | |

| FET | VDSS = 800 V, ID = 2.5A, RDS(ON) < 4.5 Ω | |

| Diode | VRRM = 1000 V, IO = 1 A | |

| PCB | FR-4, 1T, 0.5 oz, Double Layer | |

| Darlington Transistor | NPN, VCE 100 V, IC = 10 A |

| Input | Reference | Proposed | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Light Output (mV) | Percent Flicker (%) | Light Output (mV) | Percent Flicker (%) | ||||||

| VAC | Hz | MAX | AVG | MIN | MAX | AVG | MIN | ||

| 100 | 50 | 450 | 393 | 336 | 14.5 | 401 | 393 | 385 | 2.0 |

| 60 | 443 | 394 | 345 | 12.5 | 402 | 395 | 388 | 1.8 | |

| 240 | 50 | 451 | 394 | 337 | 14.5 | 401 | 393 | 385 | 2.0 |

| 60 | 443 | 394 | 345 | 12.4 | 400 | 393 | 386 | 1.8 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Jung, H. A New Circuit Design of AC/DC Converter for T8 LED Tube. Appl. Sci. 2021, 11, 421. https://doi.org/10.3390/app11010421

Kim S, Jung H. A New Circuit Design of AC/DC Converter for T8 LED Tube. Applied Sciences. 2021; 11(1):421. https://doi.org/10.3390/app11010421

Chicago/Turabian StyleKim, Sunghwan, and Haiyoung Jung. 2021. "A New Circuit Design of AC/DC Converter for T8 LED Tube" Applied Sciences 11, no. 1: 421. https://doi.org/10.3390/app11010421