Methodology for Complex Efficiency Evaluation of Machinery Safety Measures in a Production Organization

Abstract

:1. Introduction

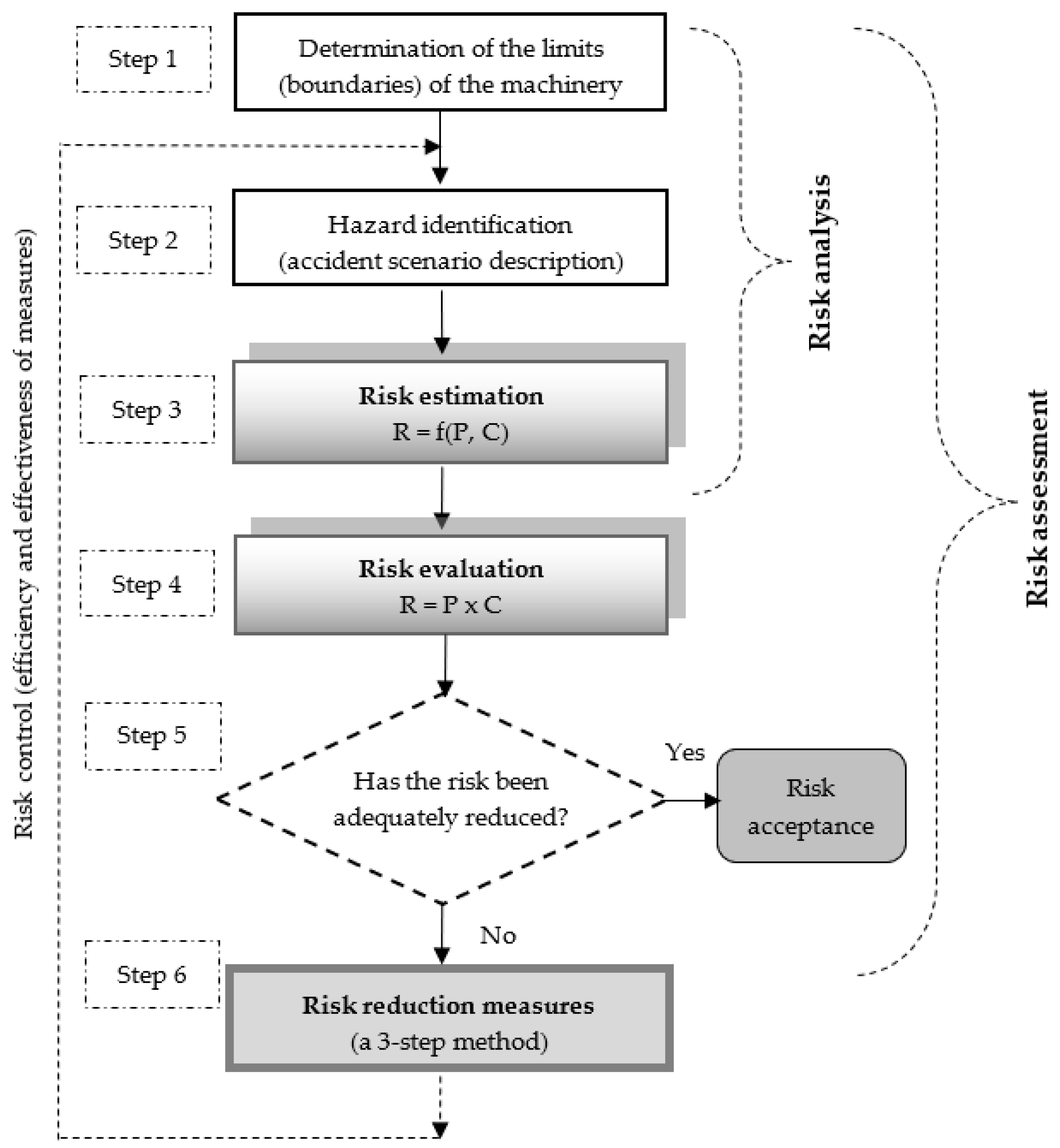

2. Machinery Risk Assessment Methodology

2.1. Basic Principles in Risk Assessment Procedure

2.2. Risk Assessment Methods

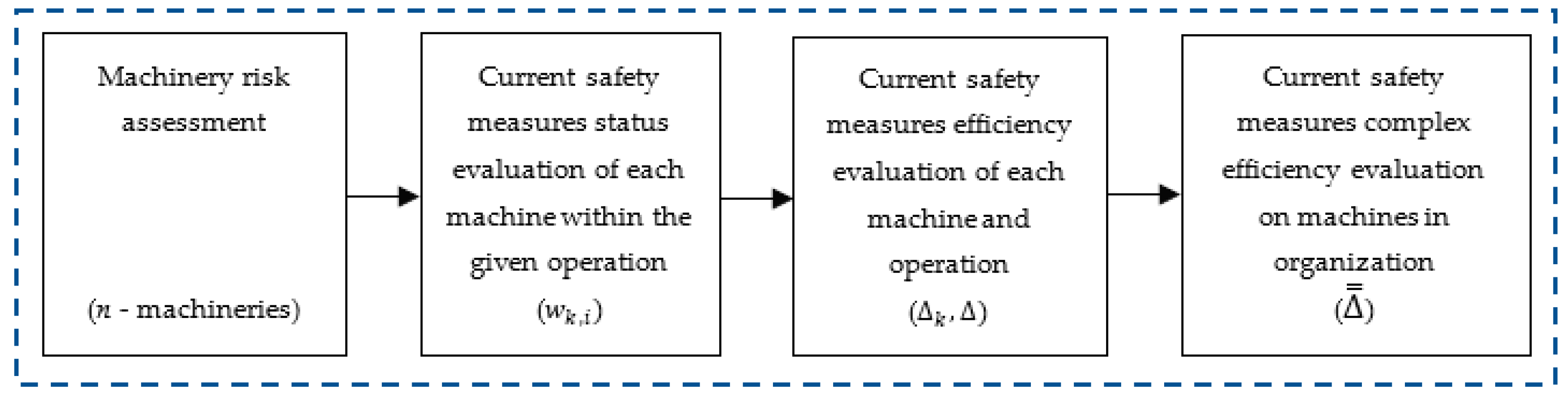

3. Analytical Methodology for the Evaluation of Machinery Safety

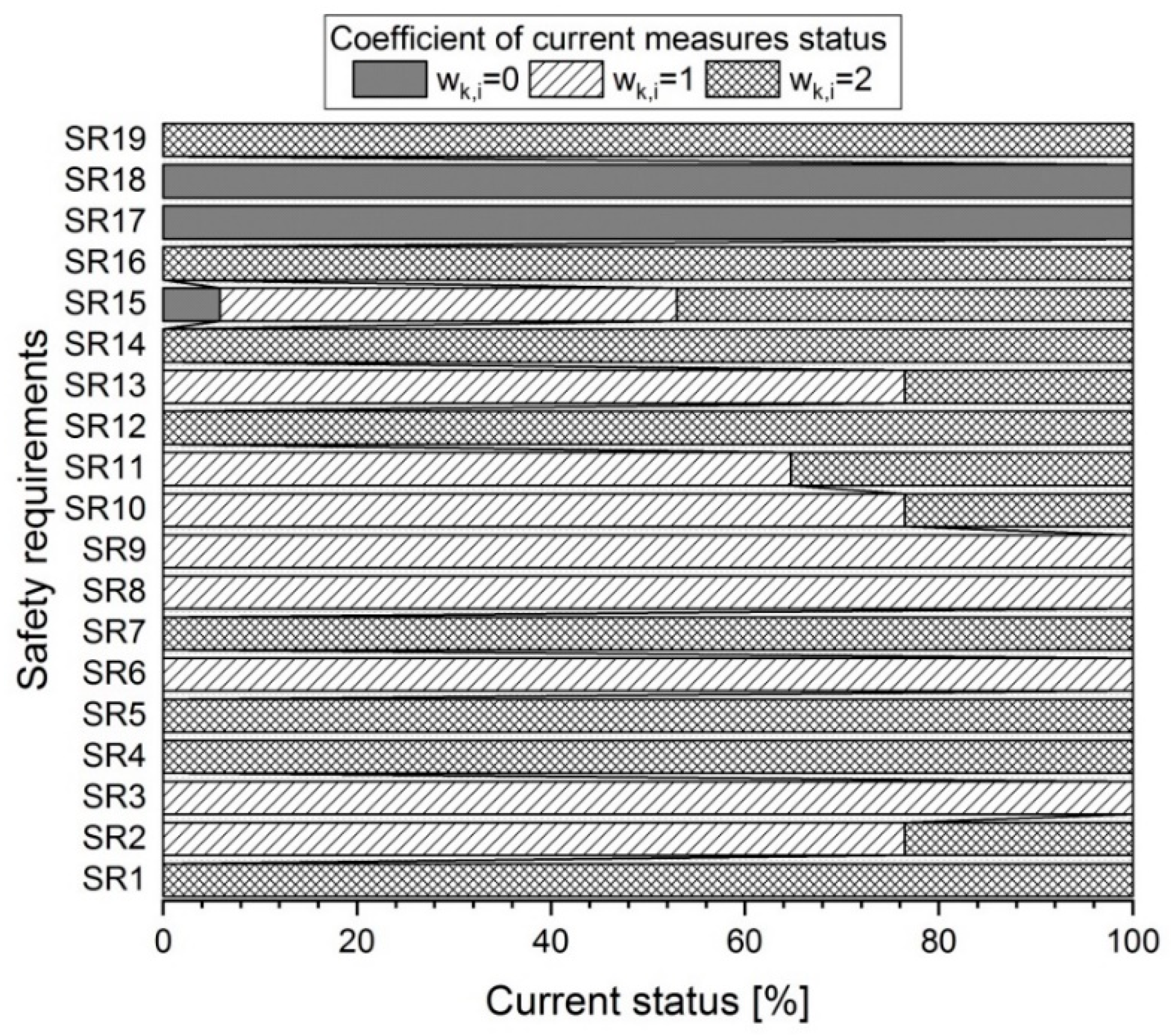

3.1. Evaluation of the Status of Current Measures

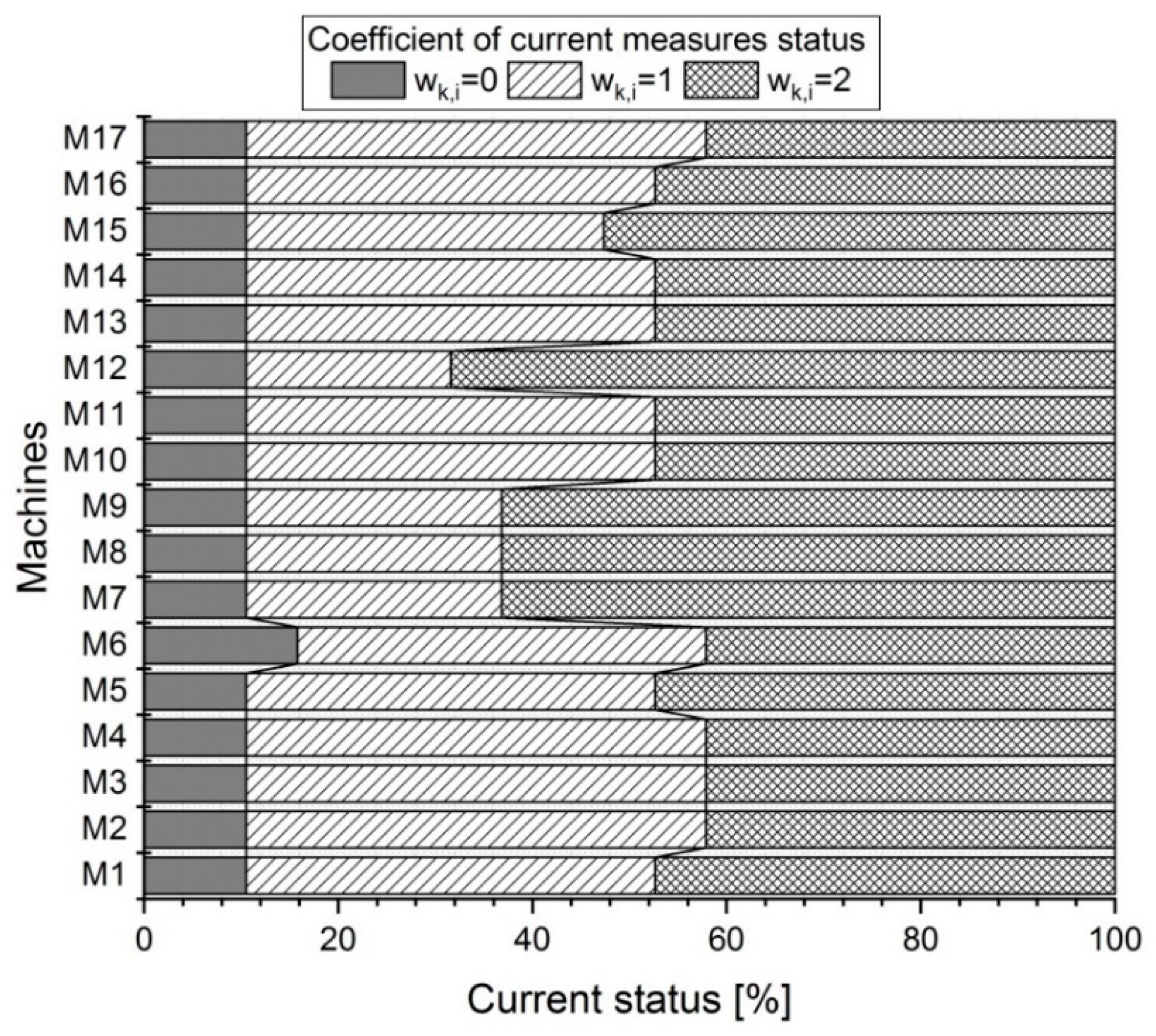

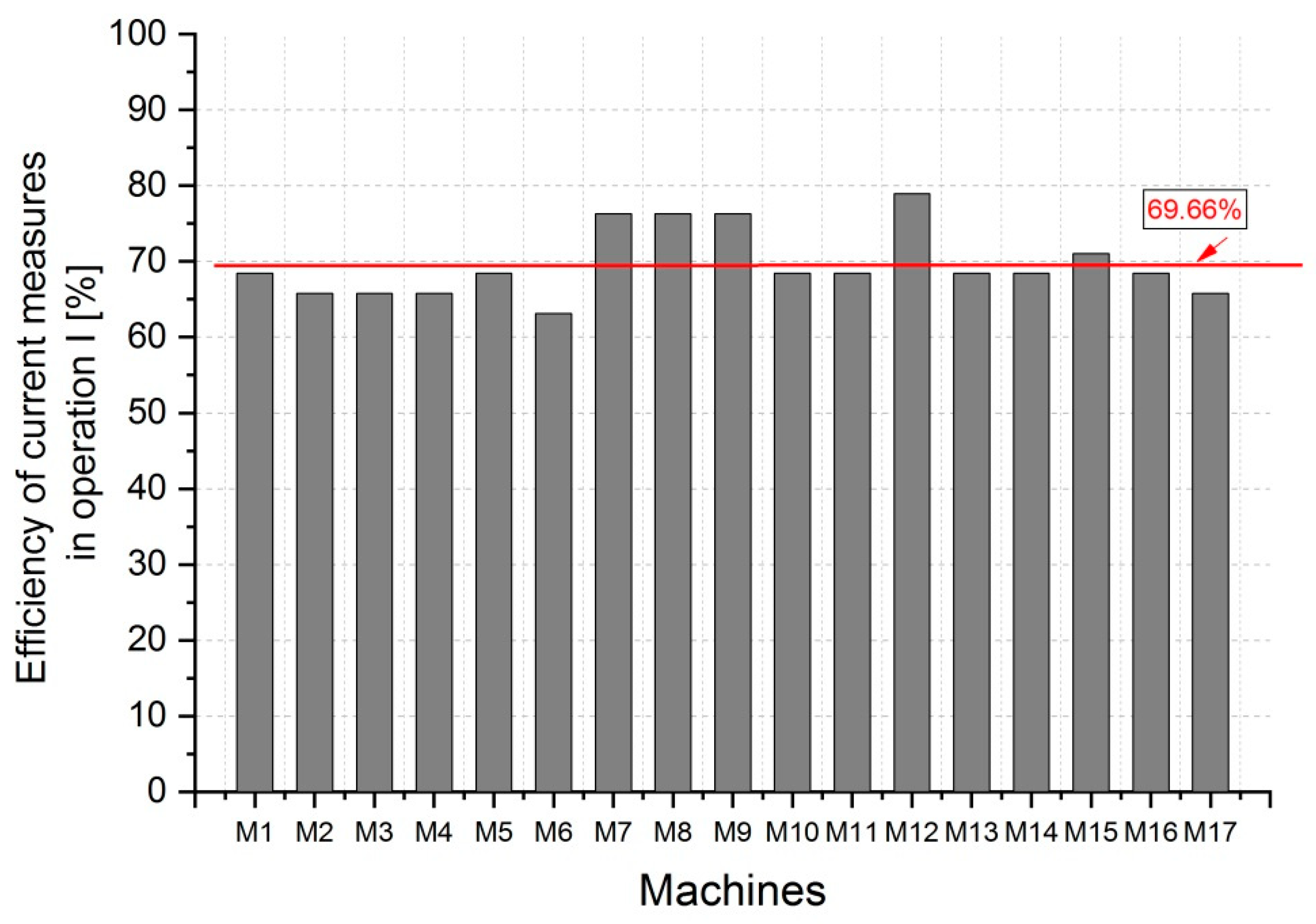

3.2. Evaluation of Current Measures Status in Operations or Organizations

- if , then the level of safety measures efficiency in a given operation is low;

- if then the level of safety measures efficiency in a given operation is negligible;

- if , then the level of safety measures efficiency in a given operation is middle;

- if then the level of safety measures efficiency in a given operation is high;

- if , then the level of safety measures efficiency in a given operation is very high.

4. Results

- risk assessment of each machine based on the unified methodology in accordance with ISO 12100 (risk matrix—specific methodology of the organization),

- status evaluation of already established (current) safety measures for each machine according to the determined safety requirements (SR1—SR19) by means of the coefficient of current measures status,

- evaluation of the efficiency level of such measures (with regard to the outcomes from risk assessment) for each machine and for each operation,

- evaluation of complex efficiency level of introduced protection/safety measures for the whole organization.

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| n. | Machinery Safety Requirements (SR) |

| SR1 | Safeguards or protective devices are a part of the machine which will prevent the operator´s contact with hazards and access thereto—e.g., above, under, around or through. |

| SR2 | Guards are fixed to their place on the machine by a system, the removal thereof is required by a tool, preventing from arbitrary manipulation. Safety systems remain connected to guards or machine also after the removal of guards. |

| SR3 | The construction of safety guards and protective devices is from sufficiently solid material which meets common operation conditions. |

| SR4 | Safeguards or protective devices do not mean any new hazard or do not create conditions limiting machine functionality. |

| SR5 | It is not possible to easily defunction or deactivate the guard or protective device. |

| SR6 | Safeguards or protective devices enables a safe installation and/or replacement of tools and safe greasing and maintenance of a machine by access limitation. |

| SR7 | The existing guard or protective device are sufficiently resistant to prevent from parts flying away (e.g., material, part of a machine during malfunction). |

| SR8 | Safeguards or protective devices are not an obstacle into a view into operation area. |

| SR9 | Special hand tools enable additional protection of employees when placing or removing material from hazardous area. Tools enable simple manipulation with material and eliminate operator´s need of a hand placing into hazardous zone. |

| SR10 | Protective device is located in the adequate distance from the hazardous area so that the operator has no access to hazardous parts of the machine throughout common operation or unusual activity. |

| SR11 | Protective devices ensure prevention (elimination or minimization) of operator or other workers touch probability with the machine or its hazardous moving parts. |

| SR12 | The machinery, its part is designed in the way so that fire origination in case of the machine´s overheating and/or explosion triggered by gases, liquids, dust or other substances are prevented. |

| SR13 | Machinery parts, around which persons move are designed in the way which prevents slipping, tripping or fall. |

| SR14 | Moving parts of machinery are covered such as e.g., chains, gear boxes, belts, shafts, etc. |

| SR15 | Machinery is equipped with one or several pieces of equipment for emergency stopping, which enable averting of proximate or imminent hazard. Alarm devices and symbols are placed on the machine. |

| SR16 | Safety machinery devices cannot be replaced by other devices, e.g., barrier, safety lock throughout the machine operation. |

| SR17 | Machinery is equipped with the means for all energy sources disconnection, and they are marked and lockable, in order to prevent harm of person in case of their repeated connection. |

| SR18 | When performing maintenance of the machine, additional protective measures of securing or blocking (Lockout, Tagout—LOTO devices) are applied. |

| SR19 | There are machine operating instructions in official language of the Commonwealth countries comprehensible for the operator. The operator has attended training, is informed about the content of the operating instructions manual and the residual risks. The operator uses personal protective equipment (PPE) for the activities assigned to them. |

References

- Harris, J.R.; Current, R.S. Machine Safety, New & Updated Consensus Standards. Prof. Saf. 2012, 57, 50–57. [Google Scholar]

- Jocelyn, S.; Chinniah, Y.; Ouali, M.-S.; Yacout, S. Application of logical analysis of data to machinery-related accident prevention based on scarce data. Reliab. Eng. Syst. Saf. 2017, 159, 223–236. [Google Scholar] [CrossRef]

- Task Report, No.20402 of the Plan of Main Tasks of the National Labor Inspectorate for 2020 Analysis of Occupational Accidents, Diseases Related to Processing and Serious Industrial Accidents in Organizations within the Scope of Labor Inspection September 2019. Available online: https://www.ip.gov.sk/wp-content/uploads/2020/04/Spr%C3%A1va-P%C3%9A-za-rok-2019.pdf (accessed on 10 October 2020).

- Bluff, E. Safety in machinery design and construction: Performance for substantive safety outcomes. Saf. Sci. 2014, 66, 27–35. [Google Scholar] [CrossRef]

- Dźwiarek, M.; Latała, A. Analysis of occupational accidents: Prevention through the use of additional technical safety measures for machinery. Int. J. Occup. Saf. Ergon. 2016, 22, 186–192. [Google Scholar] [CrossRef] [Green Version]

- Chinniah, Y. Analysis and prevention of serious and fatal accidents related to moving parts of machinery. Saf. Sci. 2015, 75, 163–173. [Google Scholar] [CrossRef]

- Wachter, J.K.; Yorio, P.L. A system of safety management practices and worker engagement for reducing and preventing accidents: An empirical and theoretical investigation. Accid. Anal. Prev. 2014, 68, 117–130. [Google Scholar] [CrossRef] [Green Version]

- Newnam, S.; Oxley, J. A program in safety management for the occupational driver: Conceptual development and implementation case study. Saf. Sci. 2016, 84, 238–244. [Google Scholar] [CrossRef]

- Tuncel, S.; Lotlikar, H.; Salem, S.; Daraiseh, N. Effectiveness of behaviour based safety interventions to reduce accidents and injuries in workplaces: Critical appraisal and meta-analysis. Theor. Issues Ergon. Sci. 2006, 7, 191–209. [Google Scholar] [CrossRef]

- Skowron-Grabowska, B.; Sobociński, M.D. Behaviour Based Safety (BBS)—Advantages and Criticism. Prod. Eng. Arch. 2018, 20, 12–15. [Google Scholar] [CrossRef] [Green Version]

- Towards Vision Zero A Guide for Business Leaders Towards a Safer and Healthier Workplace. Available online: www.wshi.gov.sg (accessed on 21 September 2019).

- Council Directive. Directive 89/391/EEC of the Council Directive of 12 June 1989 on the Introduction of Measures to Encourage Improvements in the Safety and Health of Workers at Work OHSI. Directive 89/391/EEC; Council Directive: Brussels, Belgium, 1989. [Google Scholar]

- European Parliament and of the Council. Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on Machinery, and Amending Directive 95/16/EC (Recast); European Parliament and of the Council: Brussels, Belgium, 2006. [Google Scholar]

- Galvez, N.; Marsot, J.; Martin, P.; Siadat, A.; Etienne, A. EZID: A new approach to hazard identification during the design process by analysing energy transfers. Saf. Sci. 2017, 95, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Gardner, D.; Carlopio, J.; Fonteyn, P.N.; Cross, J.A. Mechanical Equipment Injuries in Small Manufacturing Businesses. Knowledge, Behavioral, and Management Issues. Int. J. Occup. Saf. Ergon. 1999, 5, 59–71. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bluff, E. Safety in machinery design and construction: Knowledge and performance. Saf. Sci. 2015, 74, 59–69. [Google Scholar] [CrossRef]

- Choudhry, R.M.; Lingard, H.; Blismas, N. Designing for Safety: Perspectives from European Union, United Kingdom, Australia and United States Pertaining to Safety and Health in Construction. Available online: https://www.irbnet.de/daten/iconda/CIB20214.pdf (accessed on 17 May 2020).

- Cordero, C.A.; Muñoz Sanz, J.L.; Wiña, P.L. Measurement of machinery safety level in the European market: A real case based on market surveillance data. Saf. Sci. 2009, 47, 1351–1358. [Google Scholar] [CrossRef]

- Standard ISO 12100. Safety of Machinery—General Principles for Design—Risk Assessment and Risk Reduction; ISO: Geneva, Switzerland, 2010. [Google Scholar]

- Standard ISO 13949-1. Safety of Machinery—Safety-Related Parts of Control Systems—Part 1: General Principles for Design; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Gauthiera, F.; Chinniahb, Y.; Burlet-Vienneyc, D.; Aucourtb, B.; Larouche, S. Risk assessment in safety of machinery: Impact of construction flaws in risk estimation parameters. Saf. Sci. 2018, 109, 421–453. [Google Scholar] [CrossRef]

- Pačaiová, H.; Nagyová, A.; Kotianová, Z.; Bernatík, A. Risk Assessment Methodology in SME. Acta Mech. Slovaka 2013, 17, 30–35. [Google Scholar] [CrossRef]

- Etherton, J.; Taubitz, M.; Raafat, H.M.N.; Rusell, J.; Roudebush, C. Machinety Risk Assessment for Risk Reduction. Hum. Ecol. Risk Assess. Int. J. 2010, 7, 1787–1799. [Google Scholar] [CrossRef]

- Gauthier, F.; Lambert, S.; Chinniah, Y. Experimental Analysis of 31 Risk Estimation Tools Applied to Safety of Machinery. Int. J. Occup. Saf. Ergon. 2012, 18, 245–265. [Google Scholar] [CrossRef]

- Sinay, J.; Brestovic, T.; Markovic, J.; Glatz, J.; Gorzas, M.; Vargova, M. Analysis of the Risks of Hydrogen Leakage from Hydrogen-Powered Cars and Their Possible Impact on Automotive Market Share Increase. Appl. Sci. 2020, 10, 4292. [Google Scholar] [CrossRef]

- Comparea, M.; Zioa, E.; Moronie, E.; Portinarif, G.; Zaninif, T. Development of a methodology for systematic analysis of risk reduction by protective measures in tyre production machinery. Saf. Sci. 2018, 110, 13–28. [Google Scholar] [CrossRef] [Green Version]

- Pacaiova, H.; Sinay, J.; Nagyova, A. Development of GRAM—A risk measurement tool using risk based thinking principles. Measurement 2017, 100, 288–296. [Google Scholar] [CrossRef]

- Zhang, P.; Qin, G.; Wang, Y. Optimal Maintenance Decision Method for Urban Gas Pipelines Based on as Low as Reasonably Practicable Principle. Sustainability 2019, 11, 153. [Google Scholar] [CrossRef] [Green Version]

- Rasheed, S.; Wang, C.; Lucena, B. Risk Leveling in Program Environments—A Structured Approach for Program Risk Management. Sustainability 2015, 7, 5896–5919. [Google Scholar] [CrossRef] [Green Version]

- Jones-Lee, M.; Aven, T. ALARP—What does it really mean? Reliab. Eng. Syst. Saf. 2011, 96, 877–882. [Google Scholar] [CrossRef]

- Aljaroudi, A.; Khan, F.; Akinturk, A.; Haddara, M.; Thodi, P. Risk assessment of offshore crude oil pipeline failure. J. Loss Prev. Process Ind. 2015, 37, 101–109. [Google Scholar] [CrossRef]

- Oravec, M.; Vargova, S.; Rusnak, O.; Kotianova, Z. Intermediate ceiling board—Risk element of road tunnels. In Proceedings of the International Scientific Conference on Fire Protection, Safety and Security, Zvolen, Slovakia, 3–5 May 2017; Masaryka, T.G., Ed.; Technicka Univerzita vo Zvolene: Zvolen, Slovakia, 2017; pp. 177–188. [Google Scholar]

- Ehlers, S.G.; Field, W.E. Injury/Fatality-Causing Incidents Involving the Rearward Movement of Agricultural Machinery: Types, Causes, and Preventive Measures. Safety 2016, 3, 8. [Google Scholar] [CrossRef] [Green Version]

- Ambrisko, L.; Marasova, D.; Knapcikova, L.; Saderova, J.; Cehlar, M.; Khouri, S. Mechanical properties and chemical composition of rubber gaskets. Przem. Chem. 2020, 99, 598–601. [Google Scholar] [CrossRef]

- Neslušan, M.; Minárik, P.; Grenčík, J.; Trojan, K.; Zgútová, K. Non-destructive evaluation of the railway wheel surface damage after long-term operation via Barkhausen noise technique. Wear 2019, 420, 195–206. [Google Scholar] [CrossRef]

- Stejskal, T.; Dovica, M.; Svetlik, J.; Demec, P. Experimental assessment of the static stiffness of machine parts and structures by changing the magnitude of the hysteresis as a function of loading. Open Eng. 2019, 9, 655–659. [Google Scholar] [CrossRef]

- Burlet-Vienney, D.; Chinniah, Y.; Bahloul, A.; Roberge, B. Design and application of a 5 step risk assessment tool for confined space entries. Saf. Sci. 2015, 80, 144–155. [Google Scholar] [CrossRef]

- Standard ISO/TR 14121-2. Safety of Machinery—Risk Assessment—Part 2: Practical Guidance and Examples of Methods; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- Torres-Ruiz, A.; Ravindran, A.R. Multiple criteria framework for the sustainability risk assessment of a supplier portfolio. J. Clean. Prod. 2018, 172, 4478–4493. [Google Scholar] [CrossRef]

- Lindhout, P.; Reniers, G. Risk validation by the regulator in Seveso companies: Assessing the unknown. J. Loss Prev. Process Ind. 2017, 49, 78–83. [Google Scholar] [CrossRef]

- Jocelyn, S.; Chinniah, Y.; Ouali, M.S. Contribution of dynamic experience feedback to the quantitative estimation of risks for preventing accidents: A proposed methodology for machinery safety. Saf. Sci. 2016, 88, 64–75. [Google Scholar] [CrossRef]

- Kumar, S.; Tauseef, S.M. Analysis of Various Lockout Tagout (LOTO) Devices used in Industrial Safety. Int. J. Eng. Technol. 2018, 7, 1329–1335. [Google Scholar] [CrossRef]

- Standard BS 14100. Control of Hazardous Energy on Machinery; Specification: London, UK, 2020. [Google Scholar]

- Pacaiova, H.; Glatz, J.; Kacvinsky, S. Positive and negative aspect in application of maintenance management philosophy. J. Appl. Eng. Sci. 2012, 10, 99–105. [Google Scholar] [CrossRef] [Green Version]

- Blecha, P.; Durakbasa, N.; Holub, M. Digitized Production—Its Potentials and Hazards. In Proceedings of the International Symposium for Production Research, 1st ed.; Durakbasa, N., Gencyilmaz, M., Eds.; Springer: Charm, Switzerland, 2018; pp. 402–411. ISBN 978-3-319-92266-9. [Google Scholar]

- Kamenicky, L.; Markulik, S. How to transform the requirements into the management system? In Proceedings of the 15th International Multidisciplinary Scientific GeoConference SGEM 2015, Albena, Bulgaria, 18–24 June 2015; SGEM2015 Conference Proceedings. Volume 2, pp. 689–694, ISBN 978-619-7105-40-7. [Google Scholar] [CrossRef]

- Standard ISO/TR 22100-4. Safety of Machinery—Relationship with ISO 12100—Part 4: Guidance to Machinery Manufacturers for Consideration of Related IT-Security (Cyber Security) Aspects; ISO: Geneva, Switzerland, 2018. [Google Scholar]

- Nagyova, A.; Kotianova, Z.; Glatz, J.; Sinay, J. Human Failures on Production Line as a Source of Risk of Non-conformity Occurrence. In Advances in Safety Management and Human Performance; Arezes, P., Boring, R., Eds.; AHFE; Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2020; Volume 1204. [Google Scholar] [CrossRef]

- Slezak, A.; Bajdur, W.A.; Batko, K.M.; Scurek, R. Simulation of S-Entropy Production during the Transport of Non-Electrolyte Solutions in the Double-Membrane System. Entropy 2020, 22, 463. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Estimation of Probability (P) and Consequence (C), and Risk. (Step 3, Figure 1) | Consequence (C) | ||||

| Level of C | 1—minor | 2—serious | 3—severe | ||

| Description | Almost accident, or injury with the sick leave duration max. 3 days | Sick leave more than 3 days | Severe occupational injury | ||

| Probability (P) | Risk evaluation (Step 4, Figure 1) | ||||

| Level of P | Description | R = P × C | |||

| 1—low | The harm after exposure to a hazard is almost impossible. | R(1) | R(2) | R(3) | |

| 2—medium | The harm after exposure to a hazard is almost possible. | R(2) | R(4) | R(6) | |

| 3—high | The harm after exposure to a hazard is almost certain. | R(3) | R(6) | R(9) | |

| Acceptable risk assessment (Risk category) (Step 5, Figure 1) | Taking measures to reduce risk (Step 6, Figure 1) | ||||

| R(1); R(2) | Negligible | No measures for risk level reduction are necessary. | |||

| R(3); R(4) | Acceptable (ALARP) | It is suitable to accept and/or increase the efficiency of measures to reduce the risk level, by reducing the P level or C level. | |||

| R(6); R(9) | Inacceptable | It is inevitable to immediately take and increase the efficiency of measures to reduce the risk level, by reducing the P level and/or C level. | |||

| Explanation | |

|---|---|

| Measures for the fulfillment of the i-th requirement on the k-th machine are not introduced. | |

| Measures for the fulfillment of the i-th requirement on the k-th machine are introduced but not followed. | |

| Measures for the fulfillment of the i-th requirement on the k-th machine are introduced and fully followed. |

| Type of Hazard | Machinery A003: Risk Assessment | Risk Reduction | → | SafetyRequirements | |||||||

| n. | Hazardous Situation | Potential Consequence | P | C | R | Level of Risk | Protective Measures (Recommended) | VERIFICATION OF CURRENT SAFETY MEASURES | i = 1–19 | ||

| Mechanical | M1 | acceleration, deceleration (working regime, equipment) | impact, crushing, being thrown | 4 | 3 | 12 | H | safety devices (emergency stop, safeguard, LOTO), following SWP, PPE | SR1 | 2 | |

| M2 | moving elements of a machine | drawing in or trapping, crushing | 3 | 3 | 9 | H | SR2 | 1 | |||

| Mn | … | SR3 | 1 | ||||||||

| Electrical | E1 | contact with live parts | burns, death | 3 | 5 | 15 | STOP | safety devices (emergency stop, LOTO, safeguard, covering live parts), following WP, PPE, regular maintenance-revisions, training | SR4 | 2 | |

| E2 | arc flash | burns, death | 4 | 5 | 20 | STOP | safety devices (emergency stop, LOTO, safeguard), maintain safe distance, following SWP, PPE, regular maintenance-revisions, training | SR5 | 2 | ||

| En | …. | SR6 | 1 | ||||||||

| Thermal | T1 | burns | 3 | 3 | 9 | H | safety devices (emergency stop, safeguard, LOTO), following SWP, PPE | SR7 | 2 | ||

| Tn | … | SR8 | 1 | ||||||||

| Noise | N1 | moving elements (mutual interaction) | discomfort, tiredness | 3 | 3 | 9 | H | following SWP, using PPE | SR9 | 1 | |

| Nn | … | SR10 | 1 | ||||||||

| Radiation | R1 | high-frequency electromagnetic radiation | burns, headache | 3 | 4 | 12 | H | following SWP, using PPE, status check, and regular maintenance | SR11 | 1 | |

| Rn | … | SR12 | 2 | ||||||||

| Material/substance | S1 | gas (during bag welding) | fire, explosion | 3 | 4 | 12 | H | following SWP, using PPE, exhaustion | SR13 | 1 | |

| Sn | … | SR14 | 2 | ||||||||

| Ergonomic | Eg1 | position at work (operator, maintenance worker) | musculoskeletal disorder, discomfort | 3 | 3 | 9 | H | following SWP and work pauses, construction solution | SR15 | 2 | |

| Egn | … | SR16 | 2 | ||||||||

| Environmental impact | En1 | low or high environment temperature | tiredness, stress | 3 | 3 | 9 | H | following SWP, suitable work climate | SR17 | 0 | |

| En2 | electromagnetic disruption | tiredness, stress | 3 | 3 | 9 | H | construction solution, line placement | SR18 | 0 | ||

| En3 | … | SR19 | 2 | ||||||||

| [%] = 76.32 (High) | |||||||||||

| Operation | Number | Average | Max | Min | Range | Stand. Deviation | 95% Confidence Interval |

|---|---|---|---|---|---|---|---|

| I | 17 | 69.66 | 78.95 | 63.16 | 15.79 | 4.57 | (67.24, 72.02) |

| II | 20 | 75.66 | 78.95 | 47.37 | 31.58 | 6.77 | (72.49, 78.83) |

| III | 23 | 53.89 | 81.58 | 52.63 | 28.95 | 6.03 | (51.28, 56.50) |

| Complex efficiency of organization | 60 | 65.61 | 81.58 | 47.37 | 34.21 | 11.25 | (48.66, 68.52) |

| Safety Requirements SR/Current Status [%] | ||||||||||

| SR1 | SR2 | SR3 | SR4 | SR5 | SR6 | SR7 | SR8 | SRS9 | SR10 | |

| 0 | 0.0 | 0.0 | 0.0 | 1.6 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0 |

| 1 | 32.0 | 68.0 | 61.7 | 36.7 | 70.0 | 100 | 1.7 | 100 | 100 | 60.0 |

| 2 | 68.0 | 32.0 | 38.3 | 61.7 | 30.0 | 0.0 | 98.3 | 0.0 | 0.0 | 40.0 |

| SR11 | SR12 | SR13 | SR14 | SR15 | SR16 | SR17 | SR18 | SR19 | ||

| 0 | 0.0 | 0.0 | 0.0 | 1.7 | 1.7 | 0.0 | 100 | 100 | 0.0 | |

| 1 | 56.7 | 38.3 | 58.3 | 0.0 | 73.3 | 36.7 | 0.0 | 0.0 | 38.3 | |

| 2 | 43.7 | 61.7 | 41.7 | 98.3 | 25.0 | 63.3 | 0.0 | 0.0 | 61.7 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pačaiová, H.; Andrejiová, M.; Balažiková, M.; Tomašková, M.; Gazda, T.; Chomová, K.; Hijj, J.; Salaj, L. Methodology for Complex Efficiency Evaluation of Machinery Safety Measures in a Production Organization. Appl. Sci. 2021, 11, 453. https://doi.org/10.3390/app11010453

Pačaiová H, Andrejiová M, Balažiková M, Tomašková M, Gazda T, Chomová K, Hijj J, Salaj L. Methodology for Complex Efficiency Evaluation of Machinery Safety Measures in a Production Organization. Applied Sciences. 2021; 11(1):453. https://doi.org/10.3390/app11010453

Chicago/Turabian StylePačaiová, Hana, Miriam Andrejiová, Michaela Balažiková, Marianna Tomašková, Tomáš Gazda, Katarína Chomová, Ján Hijj, and Lukáš Salaj. 2021. "Methodology for Complex Efficiency Evaluation of Machinery Safety Measures in a Production Organization" Applied Sciences 11, no. 1: 453. https://doi.org/10.3390/app11010453

APA StylePačaiová, H., Andrejiová, M., Balažiková, M., Tomašková, M., Gazda, T., Chomová, K., Hijj, J., & Salaj, L. (2021). Methodology for Complex Efficiency Evaluation of Machinery Safety Measures in a Production Organization. Applied Sciences, 11(1), 453. https://doi.org/10.3390/app11010453