Effects of Velocity and Permeability on Tracer Dispersion in Porous Media

Abstract

1. Introduction

2. Materials and Method

2.1. Tracer Evaluation

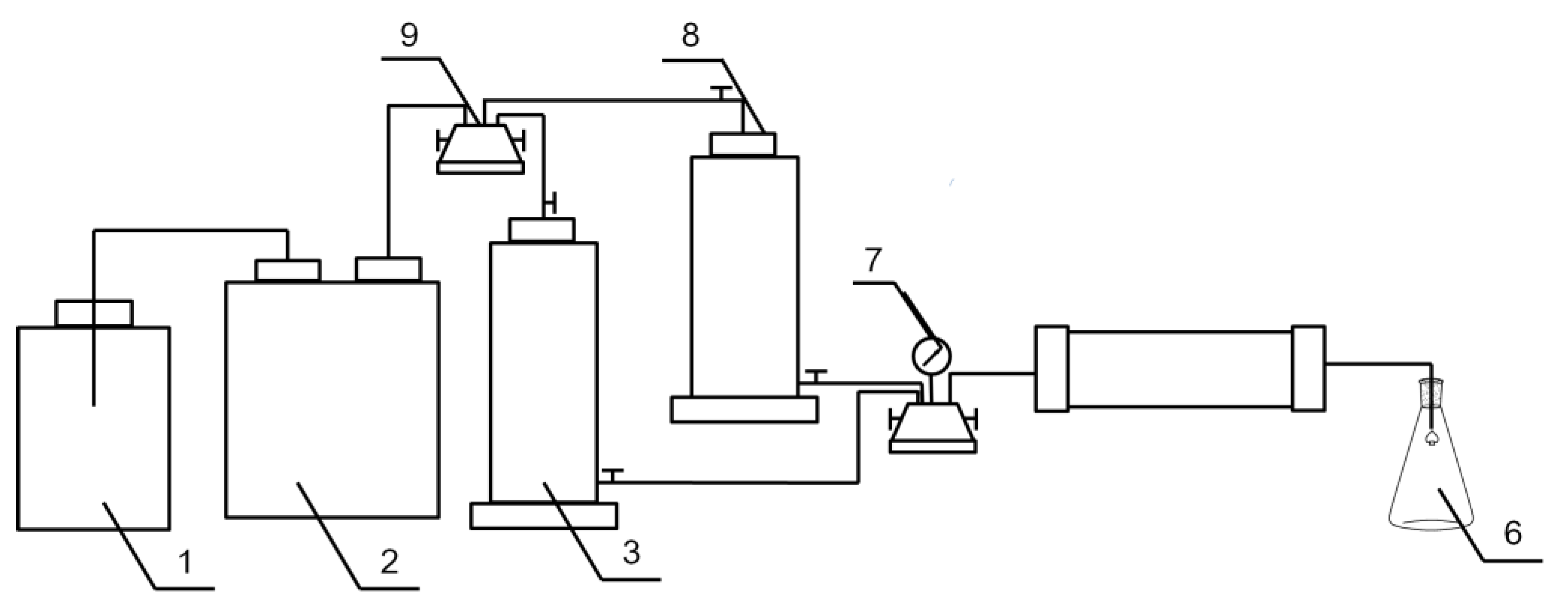

2.2. Experimental Setup and Procedure

3. Experimental Results and Discussion

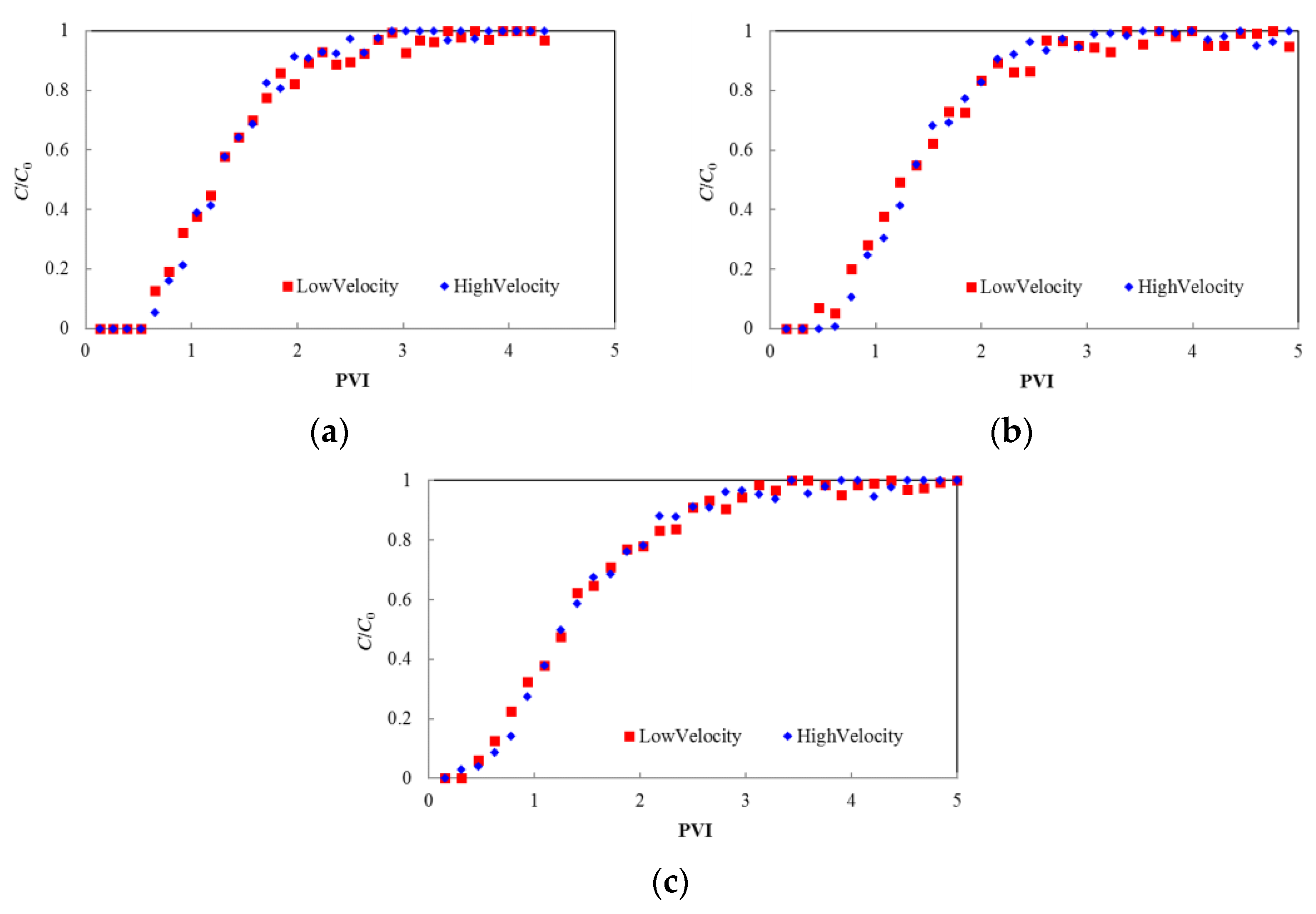

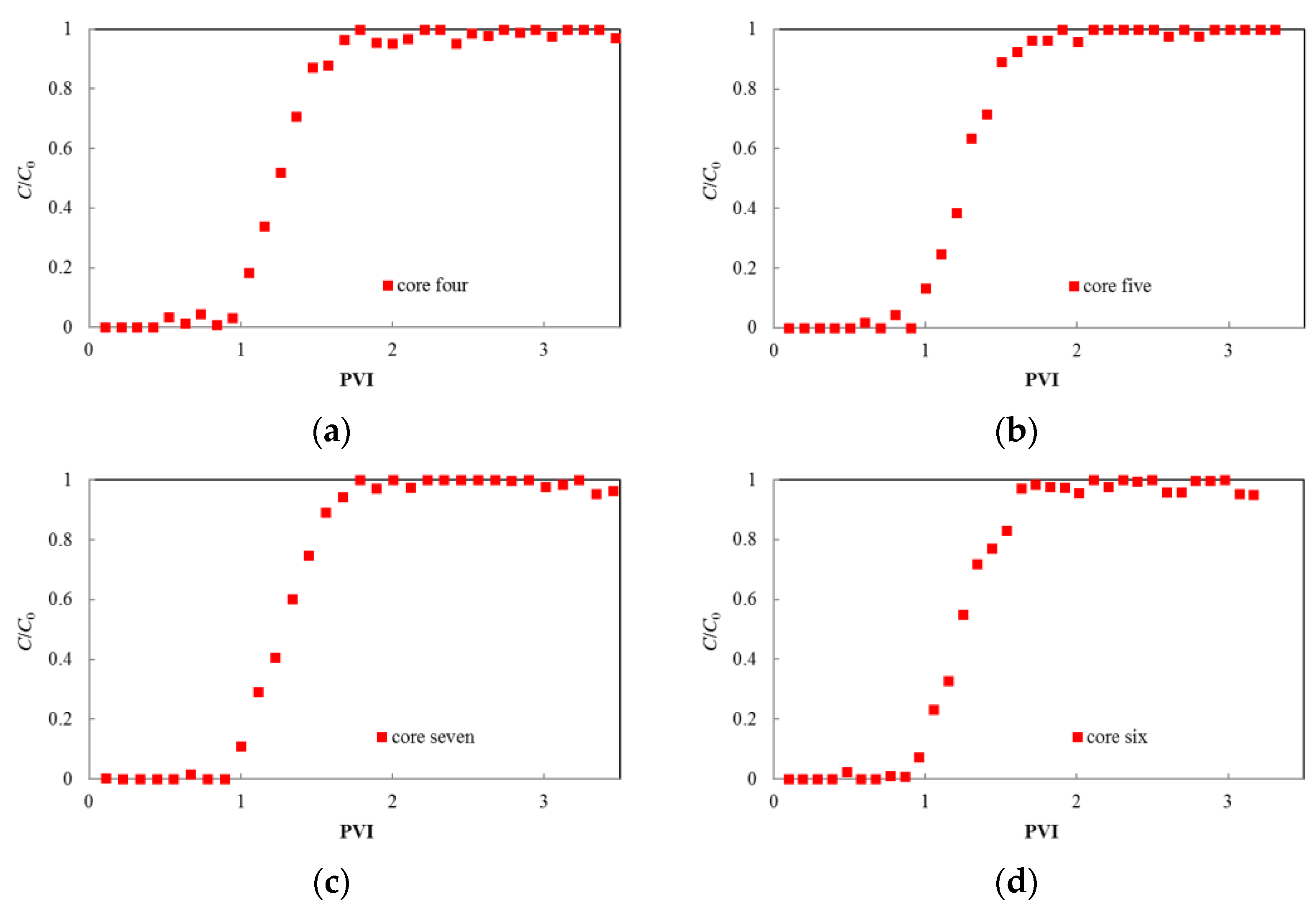

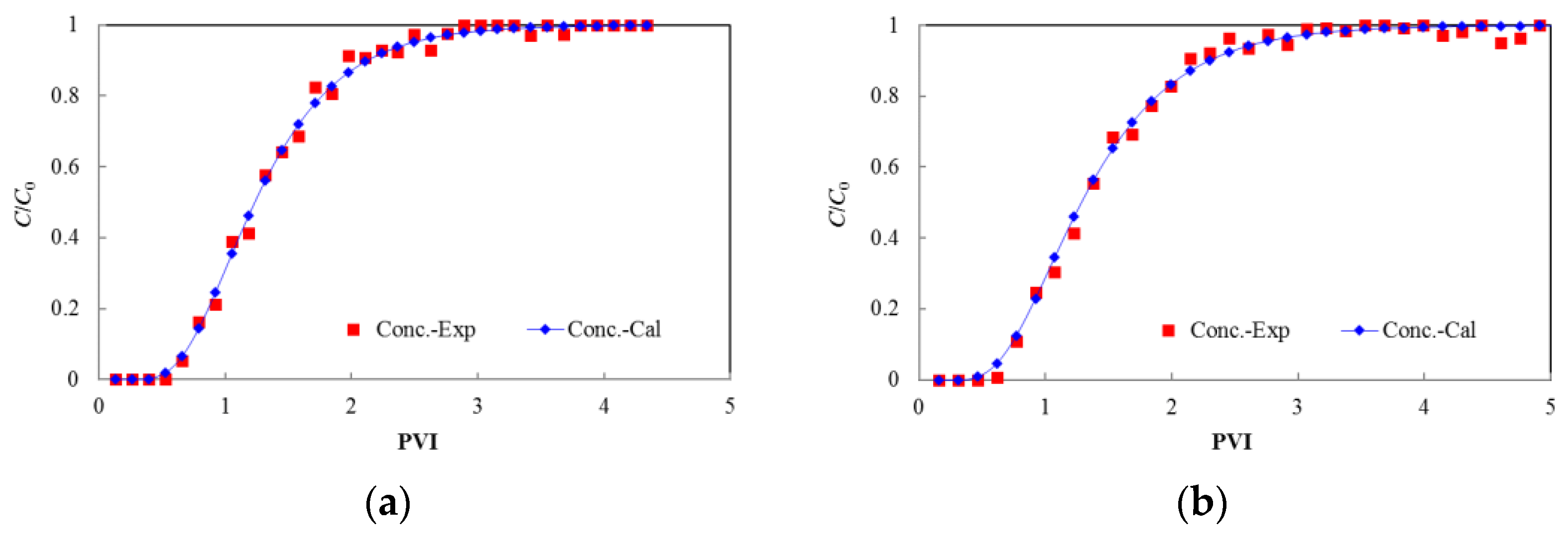

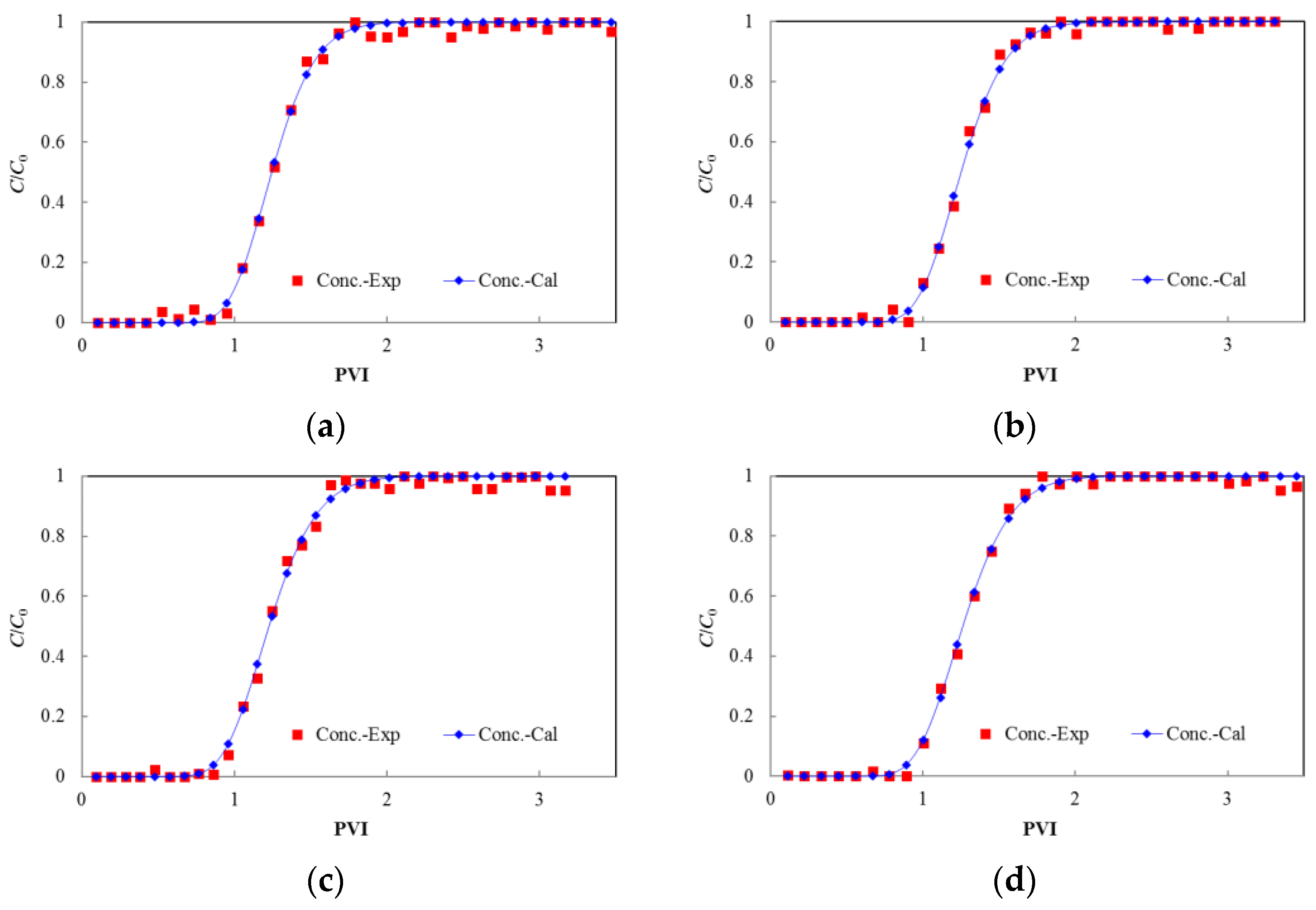

3.1. Experimental Results

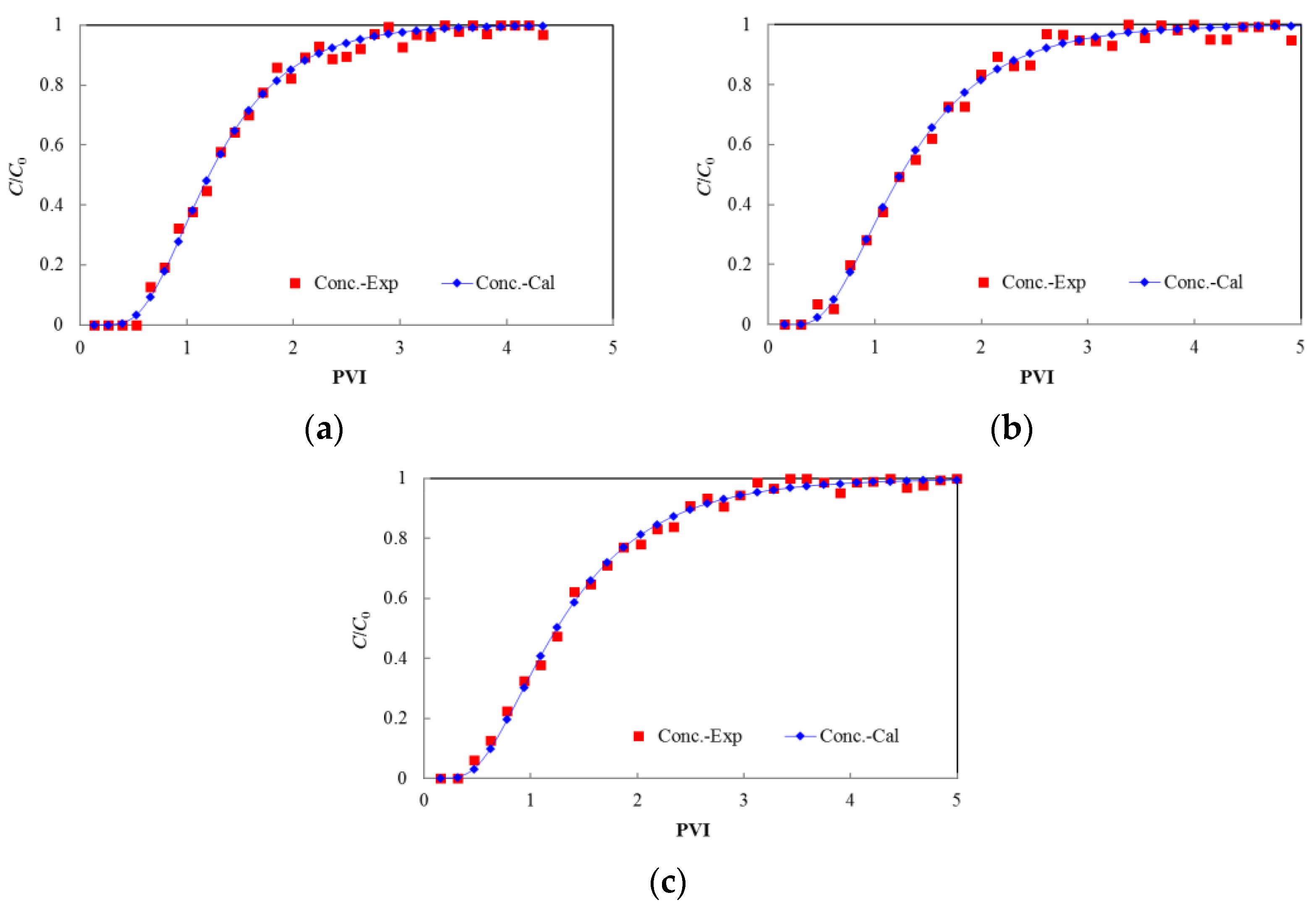

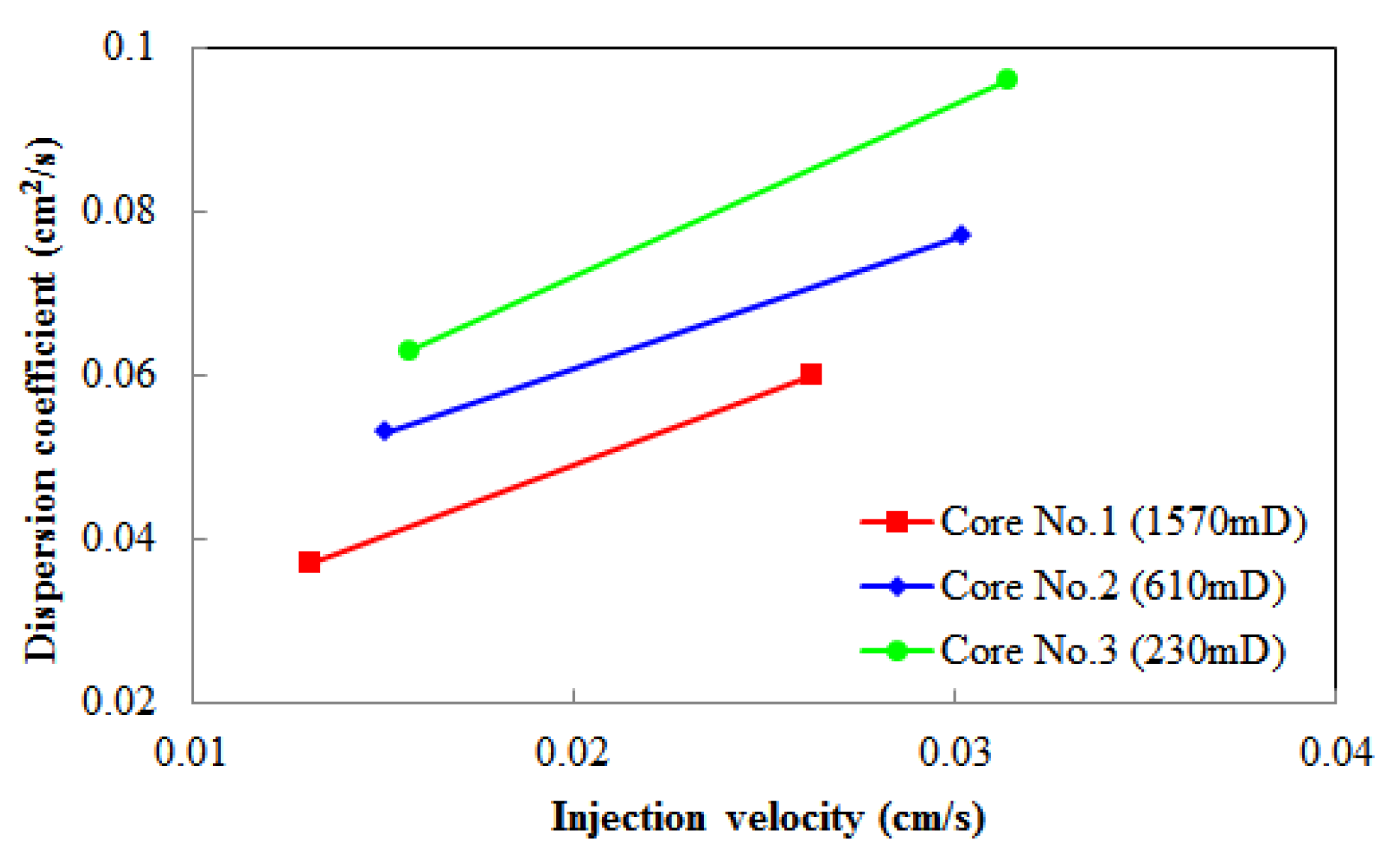

3.2. Results Analysis

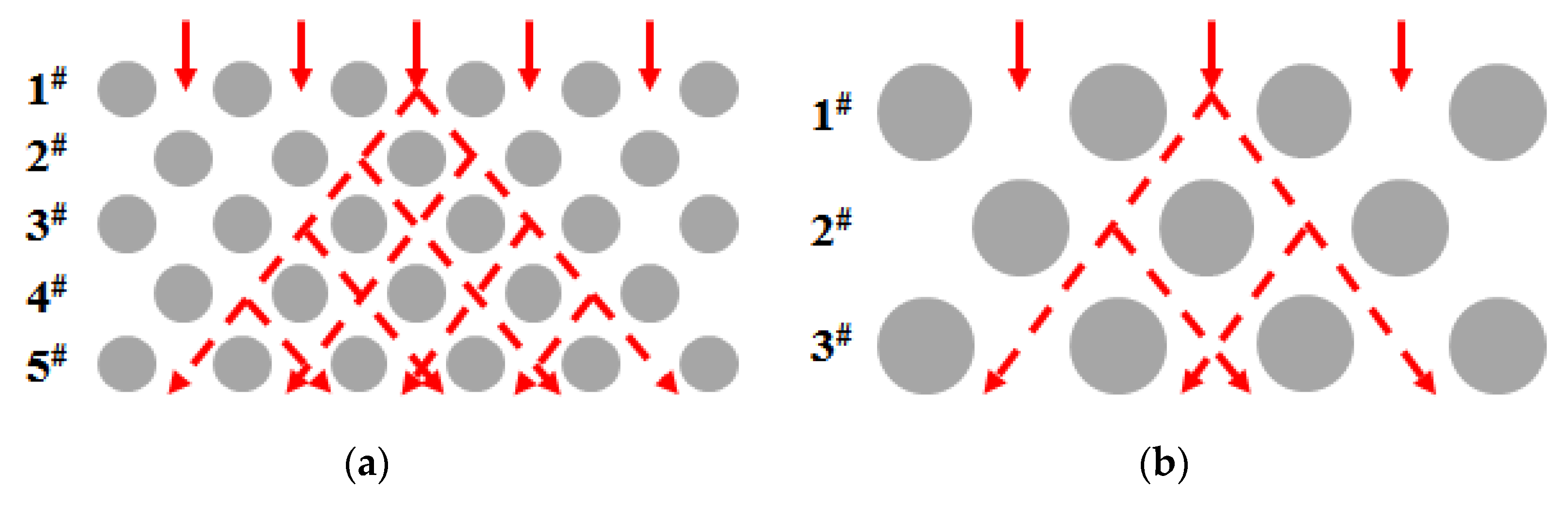

3.3. Discussion

3.3.1. Equations of Dispersion Coefficient in Cores

3.3.2. Mechanisms of the Relations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| C | tracer concentration in aqueous solution (mg/L) |

| C0 | tracer concentration in injected solution (mg/L) |

| D | dispersion coefficient (cm2/s) |

| DL | longitudinal dispersion coefficient (cm2/s) |

| DN | dispersion coefficients of the natural cores (cm2/s) |

| DA | dispersion coefficients of the sand-filled cores (cm2/s) |

| u | tracer interstitial velocity (cm/s) |

| α | adjustable parameter in dispersion relationship |

| β | exponential parameter in dispersion relationship |

| x | flow distance (cm) |

| t | time (s) |

| t’ | modified time |

| K | core permeability (mD) |

| Φf | flow porosity |

| Φ | porosity |

| ρr | rock density (g/cm3) |

| So | oil saturation |

| Swc | bound water saturation |

| a | Langmuir isothermal adsorption coefficient |

| s | Laplace variable |

Appendix A. Mathematical Model and Analytical Solution of Tracer Flow in Porous Media

References

- Serres-Piole, C.; Preud’homme, H.; Moradi-Tehrani, N.; Allanic, C.; Jullia, H.; Lobinski, R. Water tracers in oilfield applications: Guidelines. J. Pet. Sci. Eng. 2012, 98–99, 22–39. [Google Scholar] [CrossRef]

- Cao, V.; Schaffer, M.; Taherdangkoo, R.; Licha, T. Solute Reactive Tracers for Hydrogeological Applications: A Short Review and Future Prospects. Water 2020, 12, 653. [Google Scholar] [CrossRef]

- Liu, T.J.; Liu, W.X.; Diwu, P.X.; Hu, G.X.; Xu, T.; Li, Y.Q.; You, Z.J.; Qiao, R.W.; Wang, J. Modeling Tracer Flow Characteristics in Different Types of Pores: Visualization and Mathematical Modelling. Comp. Model. Eng. Sci. 2020, 123, 1205–1222. [Google Scholar] [CrossRef]

- Kamali, F.; Hussain, F. Field-scale simulation of CO2 enhanced oil recovery and storage through SWAG injection using laboratory estimated relative permeabilities. J. Pet. Sci. Eng. 2017, 156, 396–407. [Google Scholar] [CrossRef]

- Hussain, F.; Cinar, Y.; Bedrikovetsky, P. Comparison of Methods for Drainage Relative Permeability Estimation from Displacement Tests; SPE Improved Oil Recovery Symposium: Tulsa, OK, USA, 2010. [Google Scholar]

- Zou, S.; Hussain, F.; Arns, J.; Guo, Z.; Arns, C.H. Computation of relative permeability from in-situ imaged fluid distributions at the pore scale. SPE J. 2018, 23, 737–749. [Google Scholar] [CrossRef]

- Liu, T.J.; Jiang, B.Y.; Liu, R.; Zhang, X.H.; Xie, X.Q. Reservoir characteristics of chromatographic effect of tracer flow in porous medium. J. Chongqing Univ. 2013, 36, 58–63. [Google Scholar]

- Tatomir, A.; McDermott, C.; Bensabat, J.; Class, H.; Edlmann, K.; Taherdangkoo, R.; Sauter, M. Conceptual model development using a generic Features, Events, and Processes (FEP) database for assessing the potential impact of hydraulic fracturing on groundwater aquifers. Adv. Geosci. 2018, 45, 185–192. [Google Scholar] [CrossRef]

- Xu, J.P.; Wang, L.Z.; Zhu, K.Q. Concentration distribution and variation in a polymer-flooding reservoir. J. Tsinghua Univ. 2002, 04, 455–457. [Google Scholar]

- Fan, Y.; Liu, C.Q. Two-dimensional Transport of solute in porous media and its numerical solution. Acta Petrolei Sinica. 1988, 1, 75–85. [Google Scholar]

- Liu, T.J.; Diwu, P.X.; Liu, R.; Jiang, L.W.; Jiang, B.Y. Fast Algorithm of Numerical Solutions for Strong Nonlinear Partial Differential Equations. Adv. Mech. Eng. 2014, 6, 1–5. [Google Scholar] [CrossRef]

- Zhang, P.Y. Penetration Migration of Suspended Particles in Porous Media: Pore Structure and Particle Scale Effects. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2016. [Google Scholar]

- Yang, J.Z. Experimental study indoor of diffusion coefficient of dispersion coefficient. Geotech. Investig. Survey 1985, 1, 55–59. [Google Scholar]

- Ma, X.Y.; Kang, X.B.; Wang, Z.M.; Wang, X.; Shi, X.D. Cl- Transport in Saturated Soils under Different Pore Conditions. Res. Explor. Lab. 2018, 37, 30–33+67. [Google Scholar]

- Huang, K.L. Research on the Scale Effect of Hydrodynamic Dispersion in Porous Media-Current Status and Prospect. Hydrogeol. Eng. Geo. 1991, 03, 25–26+31. [Google Scholar]

- Zou, L.Z.; Pan, J.; Yang, C.B.; Zhang, H.Y. Present situation on the study of scale effect of hydraulic parameter in aquifer. J. Changchun Univ. Earth Sci. 1994, 1, 66–69. [Google Scholar]

- Wang, F. A Study on the Hydrodynamic Diffusion and Scale Effect of Loose Rock Mass Pore Media. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2015. [Google Scholar]

- Xu, Y.L. Experimental Study of Contaminant Transport and the Velocity Dependence of Dispersion in Porous Media. Master’s Thesis, Hefei University Technology, Hefei, China, 2017. [Google Scholar]

- Rao, D.Y.; Bai, B. Study on the factors affecting dispersity of porous media by SPH simulation in solute transport. J. Hydraul. Eng. 2019, 50, 824–834. [Google Scholar]

- Witt, K.J.; Brauns, J. Permeability allisotropy due to particle shape. J. Waterw. 1983, 109, 1181–1187. [Google Scholar]

- Shinohara, K.; Oida, M.; Golman, B. Effect of particle shape on angle of internal friction by triaxle compression test. Powder Technol. 2000, 107, 131–136. [Google Scholar] [CrossRef]

- Delgado, J.M.P.Q. A critical review of dispersion in packed beds. Heat Mass Transf. 2006, 42, 279–310. [Google Scholar] [CrossRef]

- Rouse, P.C.; Fannin, R.J.; Shuttle, D.A. Influence of roundness on the void ratio and strength of uniform sand. Geotechnique 2008, 58, 227–231. [Google Scholar] [CrossRef]

- Van der Meer, A.P.; Blanchard, C.M.R.J.P.; Wesselingh, J.A. Mixing of particles in liquid fluidized beds. Chem. Eng. Res. Des. 1984, 62, 214–222. [Google Scholar]

- Galvin, K.P.; Swann, R.; Ramirez, W.F. Segregation and Dispersion of a Binary System of Particles in a Fluidized Bed. AICHE J. 2006, 52, 3401–3410. [Google Scholar] [CrossRef]

- Zhao, G.J. Markov Process Describes Dispersion Phenomena in Porous Medium. Master’s Thesis, Northeast Petrology University, Daqing, China, 2007. [Google Scholar]

- Hua, F. Experimental Study of Dispersion Coefficient and Scale Effect in Single Horizontal Fracture. Master’s Thesis, Hefei University Technology, Hefei, China, 2010. [Google Scholar]

- Qi, T.; Li, M. Study of the relationship between dispersion coefficients and permeability by percolation network model. Chin. J. Hydrodyn. 2017, 32, 477–483. [Google Scholar]

- Khan, M.S.; Mitra, S.; Ghatage, S.V.; Doroodchi, E.; Joshi, J.B.; Evans, G.M. Segregation and dispersion studies in binary solid-liquid fluidised beds: A theoretical and computational study. Powder Technol. 2017, 314, 400–411. [Google Scholar] [CrossRef]

- Khan, M.S.; Evans, G.M.; Nguyen, A.V.; Mitra, S. Analysis of particle dispersion coefficient in solid-liquid fluidised beds. Powder Technol. 2020, 365, 60–73. [Google Scholar] [CrossRef]

- Taylor, G.I. Dispersion of soluble matter in solvent flowing slowly through a tube. Proc. R. Soc. 1953, 219, 186–203. [Google Scholar]

- Home, R.N.; Rodriguez, F. Dispersion in tracer flow in fractured geothermal systems. Geophys. Res. Lett. 1983, 10, 289–292. [Google Scholar]

- Simpson, E.S. Velocity and the Longitudinal Dispersion Coefficient in Flow through Porous Media; Dewiest: San Diego, CA, USA, 1969; pp. 109–200. [Google Scholar]

- Ebach, E.A.; White, R.R. Mixing of fluids flowing through beds of packed solids. Am. Inst. Chem. Eng. 1958, 4, 161–169. [Google Scholar] [CrossRef]

- Sahimi, M.; Hughes, B.D.; Scfiven, L.E.; Davis, H.T. Dispersion in flow through porous media-One phase flow. Chem. Eng. Sci. 1986, 41, 2103–2122. [Google Scholar] [CrossRef]

- Pugliese, L.; Poulsen, T.G. Estimating solute dispersion coefficients in porous media at low pore water velocities. Soil Sci. 2014, 179, 175–181. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, D.J.; Kumar, N. Analytical solutions to one-dimensional advection–diffusion equation with variable coefficients in semi-infinite media. J. Hydrol. 2009, 118, 539–549. [Google Scholar] [CrossRef]

- Kumar, D.J.; Kumar, A.; Kumar, A.; Yadav, R.R. Analytical solutions for temporally and spatially dependent solute dispersion of pulse type input concentration in one-dimensional semi-infinite media. J. Hydro-Environ. Res. 2009, 2, 254–263. [Google Scholar]

| Researchers | Research Method | Findings |

|---|---|---|

| Van der Meer et al. [24] | Single solid phase for dimensionless fractional liquid volume fraction distributed between 0.5 and 0.9, 0.002 < u < 0.3 m/s | Dispersion coefficient is a sole function of liquid superficial velocity D = 0.25uβ, exponential parameter β was fixed at 2.2 |

| Taylor et al. [31,32,33] | Experiments on two glass spheres of different particle sizes in a one-dimensional vertical soil column | The dispersion coefficient varies linearly with the interstitial velocity, i.e., D = αu |

| Galvin et al. [25] | Theoretical derivation and fluidization experiments verification in a Perspex tube, 50 mm in diameter | The dispersion coefficient varies linearly with the interstitial velocity—i.e., D = αdu/φ—adjustable parameter α was fixed at 0.7 |

| Ebach and White [34] | Experiment in a packed bed | β is negatively correlated with the flow rate |

| Sahimi et al. [35] | Experiment in a two-dimensional porous medium | The longitudinal dispersion coefficient DL does not vary linearly with water velocity |

| Pugliese and Poulsen [36] | Measuring the dispersion coefficient in a series of porous media with different grain sizes and shapes | The closer the particle is to a spherical shape, the more significant the nonlinear relationship between the dispersion coefficient and the velocity of water flow is—that is, β approaches 1.0 as the particle curvature increases |

| Kumar et al. [37,38] | Mathematical model on solute transport and dispersion in soil | In a certain range, the dynamic dispersion coefficient is linearly related to the square of the soil pore water velocity and the dispersion coefficient is positively related to the coefficient of variation of the velocity |

| Khan et al. [30] | Mathematical model and numerical model (CFD-DEM) | Dispersion coefficient incorporating the mean free path of collision and interstitial fluid velocity as the characteristic velocity of collision |

| Test Item | Test Results |

|---|---|

| Background concentration of SCN− in formation water | 0 mg/L |

| Compatibility test | No precipitation and lost concentration of 1% and 2% for days 3 and 10 in formation water, respectively |

| Static adsorption test | Adsorption ratio of 2.2% |

| Core No. | Factor | Porosity (%) | Length (cm) | Permeability (mD) | Flow Rate (cm3/s) | Superficial Velocity (cm/s) | Dispersion Coefficient (cm2/s) |

|---|---|---|---|---|---|---|---|

| 1 | Low velocity | 0.31 | 24 | 1570 | 0.02 | 0.0131 | 0.037 |

| High velocity | 0.31 | 24 | 1570 | 0.04 | 0.0263 | 0.060 | |

| 2 | Low velocity | 0.27 | 23.6 | 610 | 0.02 | 0.0151 | 0.053 |

| High velocity | 0.27 | 23.6 | 610 | 0.04 | 0.0302 | 0.077 | |

| 3 | Low velocity | 0.26 | 24.1 | 230 | 0.02 | 0.0157 | 0.063 |

| High velocity | 0.26 | 24.1 | 230 | 0.04 | 0.0314 | 0.096 |

| Core No. | Porosity (%) | Length (cm) | Permeability (mD) | Flow Rate (cm3/s) | Superficial Velocity (cm/s) | Dispersion Coefficient (cm2/s) |

|---|---|---|---|---|---|---|

| 4 | 0.372 | 25 | 621 | 0.02 | 0.011 | 0.004 |

| 5 | 0.366 | 25 | 650 | 0.03 | 0.017 | 0.007 |

| 6 | 0.382 | 25 | 699 | 0.05 | 0.027 | 0.013 |

| 7 | 0.351 | 25 | 574 | 0.08 | 0.046 | 0.023 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Liu, T.; Li, Y.; Li, Y.; You, Z.; Zuo, M.; Diwu, P.; Wang, R.; Zhang, X.; Liang, J. Effects of Velocity and Permeability on Tracer Dispersion in Porous Media. Appl. Sci. 2021, 11, 4411. https://doi.org/10.3390/app11104411

Yang Y, Liu T, Li Y, Li Y, You Z, Zuo M, Diwu P, Wang R, Zhang X, Liang J. Effects of Velocity and Permeability on Tracer Dispersion in Porous Media. Applied Sciences. 2021; 11(10):4411. https://doi.org/10.3390/app11104411

Chicago/Turabian StyleYang, Yulong, Tongjing Liu, Yanyue Li, Yuqi Li, Zhenjiang You, Mengting Zuo, Pengxiang Diwu, Rui Wang, Xing Zhang, and Jinhui Liang. 2021. "Effects of Velocity and Permeability on Tracer Dispersion in Porous Media" Applied Sciences 11, no. 10: 4411. https://doi.org/10.3390/app11104411

APA StyleYang, Y., Liu, T., Li, Y., Li, Y., You, Z., Zuo, M., Diwu, P., Wang, R., Zhang, X., & Liang, J. (2021). Effects of Velocity and Permeability on Tracer Dispersion in Porous Media. Applied Sciences, 11(10), 4411. https://doi.org/10.3390/app11104411