Approaching Nuclear Safety Culture in Fission and Fusion Technology

Abstract

:Featured Application

Abstract

1. Introduction

- The management’s commitment to give priority to the safety principles in their decisions;

- The individual responsibility to report with full transparency;

- A questioning attitude (understanding the purposes and knowing the limits of procedures);

- A rigorous and cautious approach for each person—duty of alert exercised;

- The know-how and competences proved by training, accreditation and qualification;

- The person’s motivation for setting goals, recognitions and penalties.

2. Nuclear Safety Culture in Fission

2.1. Czech Republic Nuclear Power Plants and Research Reactors

2.2. NSC in Fission: The Czech Republic Implementation

- A—positive manifestation of safety culture;

- B—expected condition;

- C—non-compliance with the healthy safety culture attribute;

- D—denying of the healthy safety culture attribute.

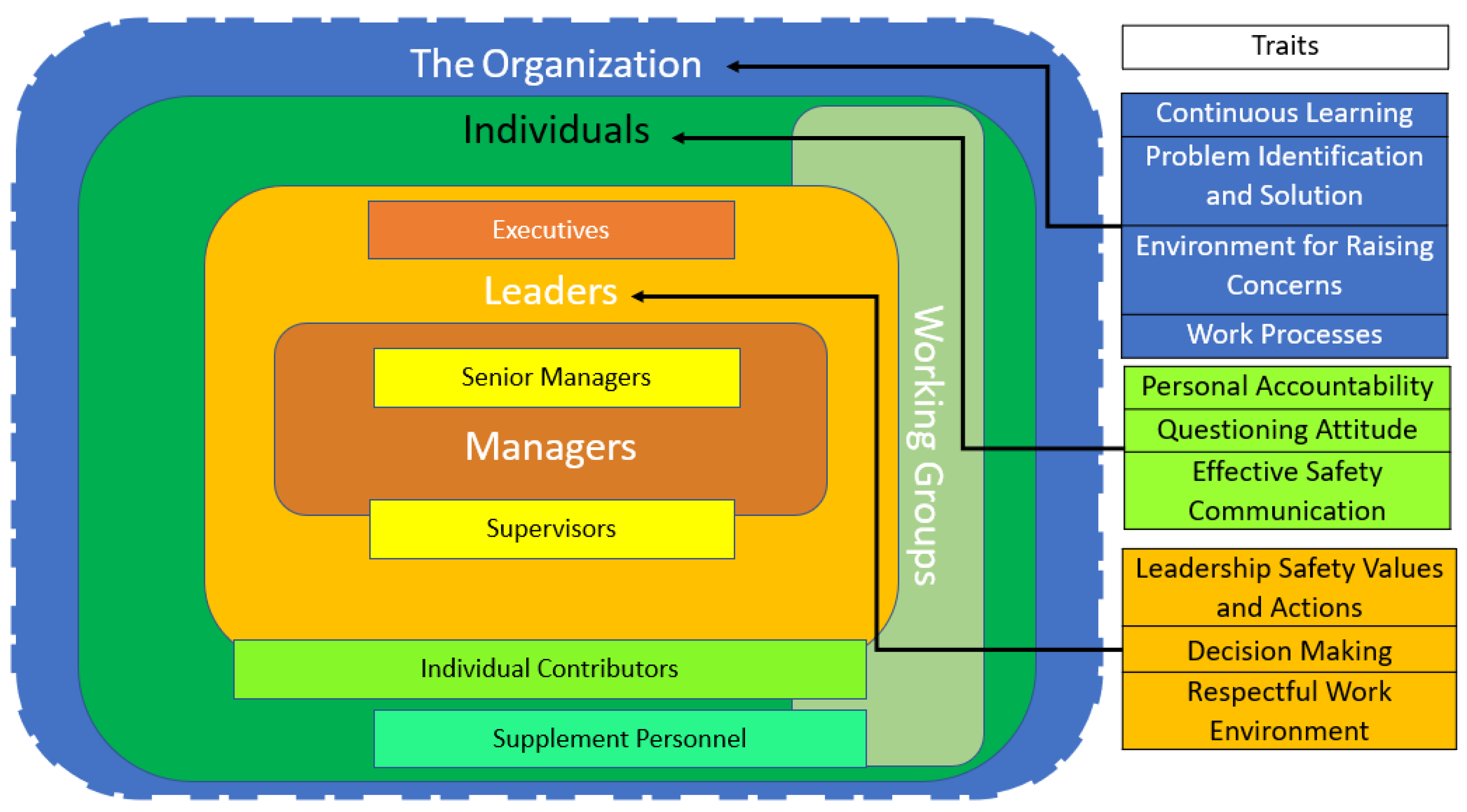

- “Leadership Safety Values and Actions”—whether leaders demonstrate their commitment to safety in decision making and behavior;

- “Problem Identification and Resolution”—whether issues, which can potentially impact safety, are promptly identified, evaluated, addressed and corrected commensurate with their safety significance;

- “Personal Accountability”—whether all individuals take personal responsibility for safety;

- “Work Processes”—whether the process of planning and controlling work activities is implemented to maintain safety;

- “Continuous Learning”—whether emerging opportunities to learn about ensuring safety are sought out and taken;

- “Environment for Raising Concerns”—whether a healthy environment exists for personnel feel free to raise safety concerns without fear;

- “Effective Safety Communication”—whether communication maintains a focus on safety;

- “Respectful Work Environment”—whether the organization trusts and respects individuals;

- “Questioning Attitude”—whether individuals avoid complacency and continuously reconsider existing conditions and activities in order to identify discrepancies;

- “Decision making”—whether decisions that support or affect nuclear safety are systematic, rigorous and thorough.

- -

- Satisfaction with the favorable assessment for both NPPs, even on an international basis, e.g., in the framework of a number of reports and conclusions from missions carried out by IAEA or WANO;

- -

- Prevailing emphasis placed on technical aspects of the operation, at the expense of the interest of the personnel leading and the management and cooperation between particular organizational units, with little emphasis placed by top management on enforcement of appropriate behavior;

- -

- non-conceptual efforts to reduce costs also had an influence [51].

3. Nuclear Safety Culture in Fusion

3.1. ITER Project in the French Nuclear Context

3.2. NSC in Fusion: The ITER Implementation

- -

- Implementing a robust Nuclear Safety Culture (NSC) through staff and organizations involved in the life cycle of the ITER project;

- -

- Implementing safety requirements on Protection Important Components (PICs);

- -

- Identifying the Protection Important Activities (PIAs) related to PICs defined in the contract requirements;

- -

- Implementing a robust surveillance/Technical Control (TC) of PIAs and Protection Important Systems, Structures and Components.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ASDEX | Axially Symmetric Divertor Experiment |

| ASN | Autorité de Sûreté Nucléaire (in French) or Nuclear Safety Authority |

| CEA | Commissariat à l’énergie atomique et aux énergies alternatives (in French) or French Alternative Energies and Atomic Energy Commission |

| DiD | Defense in Depth |

| EC | European Commission |

| EU | European Union |

| HLW | High-Level Waste |

| IAEA | International Atomic Energy Agency |

| ICF | Inertial Confinement Fusion |

| INB | Installation Nucléaire de Base (in French) or basic nuclear installation |

| IO | ITER Organization |

| ITER | International Thermonuclear Experimental Reactor |

| JET | Joint European Torus |

| LLW | Low-Level Waste |

| MCF | Magnetic Confinement Fusion |

| MLW | Medium-Level Waste |

| NPPs | Nuclear Power Plants |

| NS | Nuclear Safety |

| NSC | Nuclear Safety Culture |

| PIA | Protection Important Activity |

| PIC | Protection Important Component |

| PSR | Preliminary Safety Report (or in French, RPrS, Rapport Préliminaire de Sûreté) |

| SMR | Small Modular Reactors |

| TC | Technical Check |

| UN | United Nations |

| US | United States |

| VLLW | Very Low-Level Waste |

| VV | Vacuum Vessel |

References

- European Atomic Energy Community, Food and Agriculture Organization Of The United Nations, International Atomic Energy Agency, International Labour Organization, International Maritime Organization, OECD Nuclear Energy Agency, Pan American Health Organization, United Nations Environment Programme, World Health Organization. Fundamental Safety Principles; IAEA Safety Standards Series No. SF-1; IAEA: Vienna, Austria, 2006. [Google Scholar]

- International Nuclear Safety Advisory Group. Safety Culture; INSAG-4; IAEA: Vienna, Austria, 1991. [Google Scholar]

- International Nuclear Safety Advisory Group. Key Practical Issues in Strengthening Safety Culture; INSAG-15; IAEA: Vienna, Austria, 2002. [Google Scholar]

- WANO. Traits of Healthy Nuclear Safety Culture—WANO Principle. PL 2013-01. 2013. Available online: https://www.wano.info/getmedia/49f169b0-a385-4cd2-a7d8-2f64b64cd8d2/WANO-PL-2013-1-Pocketbook-English.pdf.aspx (accessed on 19 April 2021).

- INPO. Traits of a Healthy Nuclear Safety Culture. Rev.1, INPO 12-012. 2013. Available online: https://www.nrc.gov/docs/ML1303/ML13031A707.pdf (accessed on 19 April 2021).

- Herb, J.; Raeder, J.; Weller, A.; Wolf, R.; Boccaccini, L.V.; Carloni, D.; Jin, X.Z.; Stieglitz, R.; Pistner, C. Review of the Safety Concept for Fusion Reactor Concepts and Transferability of the Nuclear Fission Regulation to Potential Fusion Power Plants. GRS Report 389. 2016. Available online: http://www.grs.de/sites/default/files/pdf/grs-389_1.pdf (accessed on 19 April 2021).

- Mainardi, E. Impieghi Dell’Energia Nucleare; Delfino Editore: Sassari, Italy, 2008. [Google Scholar]

- Lukacs, M.; Williams, L.G. Nuclear safety issues for fusion power plants. Fusion Eng. Des. 2020, 150, 111377. [Google Scholar] [CrossRef]

- ITER Website. Available online: https://www.iter.org/ (accessed on 28 December 2020).

- EC Website. Available online: https://ec.europa.eu/energy/en/topics/nuclear-energy (accessed on 28 December 2020).

- IAEA. Safety Culture; Safety Series No. 75-INSAG-4; IAEA: Vienna, Austria, 1991; Available online: https://www-pub.iaea.org/MTCD/publications/PDF/Pub882_web.pdf (accessed on 19 April 2021).

- IAEA. TMI Accident Report. Available online: https://inis.iaea.org/collection/NCLCollectionStore/_Public/13/677/13677904.pdf (accessed on 19 April 2021).

- IAEA. Chernobyl Accident Report. Available online: https://www-pub.iaea.org/MTCD/publications/PDF/Pub913e_web.pdf (accessed on 19 April 2021).

- IAEA. The Fukushima Daiichi Accident. Vienna. 2015. Available online: https://www.iaea.org/publications/10962/the-fukushima-daiichi-accident (accessed on 19 April 2021).

- International Atomic Energy Agency. IAEA Safety Glossary: 2018 Edition. Vienna. 2019. Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/PUB1830_web.pdf (accessed on 19 April 2021).

- ITER. Available online: https://www.iter.org/ (accessed on 19 April 2021).

- CEZ-ETE. Available online: https://www.cez.cz/en/energy-generation/nuclear-power-plants/temelin (accessed on 19 April 2021).

- CEZ-EDU. Available online: https://www.cez.cz/en/energy-generation/industrial-tourism/dukovany-power-plant-information-centre (accessed on 19 April 2021).

- Státní Energetická Koncepce Míří do Meziresortního Připomínkového Řízení. Available online: https://www.mpo.cz/dokument106059.html (accessed on 19 April 2021).

- Státní Energetická Koncepce České Republiky. Available online: https://www.mpo.cz/dokument158059.html (accessed on 19 April 2021).

- LVR15. Available online: http://cvrez.cz/vyzkumna-infrastruktura/vyzkumny-reaktor-lvr-15/ (accessed on 19 April 2021).

- LR-0. Available online: http://cvrez.cz/en/infrastructure/research-reactor-lr-0/ (accessed on 19 April 2021).

- SUSEN. Available online: http://susen2020.cz/ (accessed on 19 April 2021).

- Training Reactor. Available online: http://www.reaktor-vr1.cz/en/ (accessed on 19 April 2021).

- VR2. Available online: http://www.reaktor-vr1.cz/en/about-us/vr-2 (accessed on 19 April 2021).

- Institute of Plasma Physics of the CAS. Available online: http://www.ipp.cas.cz/vedecka_struktura_ufp/tokamak/tokamak_compass/ (accessed on 19 April 2021).

- COMPASS. Available online: http://www.ipp.cas.cz/vyzkum/Projekty/COMPASS_U.html (accessed on 19 April 2021).

- IBRS. Available online: https://www.protext.cz/english/press-release.php?id=19194 (accessed on 19 April 2021).

- UJV. Available online: https://www.ujv.cz/cs/o-spolecnosti/historie (accessed on 19 April 2021).

- WENRA. WENRA Handbook on Reactor Safety Part 2: WENRA Statements and Safety Reference Levels. Version 2 December 2014. Available online: http://www.wenra.org/media/filer_public/2015/01/06/wenra_handbook_part_2_-_wenra_statements_and_safety_reference_levels.pdf (accessed on 19 April 2021).

- ETSON. Technical Report Comparison of Rules-Making and Practices Concerning Safety Culture Oversight. ETSON/ 2020-001, November 2020. Available online: http://www.etson.eu/sites/default/files/publications/reports/EG7_safety_culture_oversight.pdf (accessed on 19 April 2021).

- TACR. Available online: https://www.tacr.cz/ (accessed on 19 April 2021).

- GACR. Available online: https://gacr.cz/ (accessed on 19 April 2021).

- Act 18/1997 as amended, on Peaceful Utilisation of Nuclear Energy and Ionising Radiation (the Atomic Act) and on Amendments and Alterations to Some Acts. In Sbírka Zákonů České Republiky; 24 January 1997; Ministry of the Interior: Prague, Czech Republic, 1997.

- IAEA. Safety Report Series No.1: Examples of Safety Culture Practices. Vienna. 1997. Available online: https://www.iaea.org/publications/5134/examples-of-safety-culture-practices (accessed on 19 April 2021).

- IAEA. Safety Report Series No.1: Developing Safety Culture in Nuclear Activities—Practical Suggestions to Assist Progress. Vienna. 1998. Available online: https://www.iaea.org/publications/5144/developing-safety-culture-in-nuclear-activities-practical-suggestions-to-assist-progress (accessed on 19 April 2021).

- IAEA. IAEA-TECDOC-1329 Safety Culture in Nuclear Installations: Guidance for Use in the Enhancement of Safety Culture. Vienna. 2002. Available online: https://www.iaea.org/publications/6721/safety-culture-in-nuclear-installations-guidance-for-use-in-the-enhancement-of-safety-culture (accessed on 19 April 2021).

- WENRA Safety Reference Levels for Existing Reactors, Update in Relation to Lessons Learned from Tepco Fukushima Dai-Ichi Accident”, 24th September 2014; WENRA: 20134, European Union. Available online: https://www2.nsr.go.jp/data/000242775.pdf (accessed on 19 April 2021).

- Act 263/2016 as amended by Act No. 183/2017 Coll., Atomic Act. In Sbírka Zákonů České Republiky; 14 July 2016; Ministry of The Interior: Prague, Czech Republic, 2016.

- Decree 408/2016 Coll., on management system requirements. In Sbírka Zákonů České Republiky; 6 December 2016; Ministry of The Interior: Prague, Czech Republic, 2016.

- Decree 21/2017 Coll., on Assuring Nuclear Safety of a Nuclear Installation. In Sbírka Zákonů České Republiky; 23 January 2017; Ministry of The Interior: Prague, Czech Republic, 2017.

- Decree 162/2017 Coll., on safety assessment requirements under the Atomic Act. In Sbírka Zákonů České Republiky; 25 May 2017; Ministry of the Interior: Prague, Czech Republic, 2017.

- BN-JB-1.1 (Rev. 0.1) Systém řízení. 2020. Available online: https://www.sujb.cz/dokumenty-apublikace/publikace-sujb (accessed on 19 April 2021).

- BN-JB-1.6 (Rev. 0.0) Kultura Bezpečnosti. 2021. Available online: https://www.sujb.cz/fileadmin/sujb/docs/dokumenty/publikace/BN-JB-1-6_Kultura_bezpecnosti.pdf (accessed on 19 April 2021).

- United States Nuclear Regulatory Commission. NUREG—2165 Safety Culture Common Language; Office of Nuclear Reactor Regulation: Washington, DC, USA, 2014.

- GRS. Leitfaden für die Erfassung und Beurteilung Wesentlicher Merkmale der Sicherheitskultur Deutscher Kernkraftwerke durch die Genehmigungs und Aufsichtsbehörden; October 2015; GRS: Köln, Germany, 2015. [Google Scholar]

- Jae, M.; Han, K. Development of a New Methodology for Evaluating Nuclear Safety Culture; 10th August 2015; Hanyang University: Seoul, Korea, 2015. [Google Scholar]

- State Ofiice for Nuclear Safety, B-VDS038(2)_INS_HOD_JB_2.01, Sběr A Hodnocení Dat K Vyhodnocení Úrovně Kultury Bezpečnosti Na Jaderných Zařízeních, 1 March 2020.

- IAEA. A Harmonized Safety Culture Model. IAEA Working Document, Revision 5th May 2020. Available online: https://www.iaea.org/sites/default/files/20/05/harmonization_05_05_2020-final_002.pdf (accessed on 19 April 2021).

- Státní Úřad pro Jadernou Bezpečnost, Zpráva o Výsledcích Činnosti Sújb při Výkonu Státního Dozoru nad Jadernou Bezpečností Jaderných Zařízení a Radiační Ochranou za Rok 2015, Část I, Praha. 2016. Available online: https://www.sujb.cz/dokumenty-a-publikace/vyrocni-zpravy (accessed on 19 April 2021).

- State Office for Nuclear Safety, the Czech Republic National Report under the Convention on Nuclear Safety Prague, April 2016. Available online: https://www.sujb.cz/en/reports (accessed on 19 April 2021).

- Order Dated 7 February 2012 Relating to the General Technical Regulations Applicable to Basic Nuclear Installations. 2012. Available online: http://www.french-nuclear-safety.fr/References/Regulations/Order-of-7-February-2012 (accessed on 19 April 2021).

- Council Directive 2009/71/EURATOM Establishing a Community Framework for the Nuclear Safety of Nuclear Installations, 25 June 2009. Available online: https://ec.europa.eu/energy/sites/default/files/documents/15._it_2nd_2020_report_a-nsd.pdf (accessed on 14 May 2021).

- Council Directive 2014/87/EURATOM Amending Directive 2009/71/ EURATOM Establishing a Community Framework for the Nuclear Safety of Nuclear Installations, 8 July 2014. Available online: https://eur-lex.europa.eu/legal-content/EN/NIM/?uri=celex:32014L0087 (accessed on 14 May 2021).

- Joint European Torus (JET). Available online: https://www.euro-fusion.org/devices/jet/ (accessed on 19 April 2021).

- Axially Symmetric Divertor Experiment (ASDEX). Available online: https://www.ipp.mpg.de/16195/asdex (accessed on 19 April 2021).

- Tokar, M.Z. An assessment for the erosion rate of DEMO first wall. Nucl. Fusion 2018, 58, 16016. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lomonaco, G.; Mainardi, E.; Marková, T.; Mazzini, G. Approaching Nuclear Safety Culture in Fission and Fusion Technology. Appl. Sci. 2021, 11, 4511. https://doi.org/10.3390/app11104511

Lomonaco G, Mainardi E, Marková T, Mazzini G. Approaching Nuclear Safety Culture in Fission and Fusion Technology. Applied Sciences. 2021; 11(10):4511. https://doi.org/10.3390/app11104511

Chicago/Turabian StyleLomonaco, Guglielmo, Enrico Mainardi, Tereza Marková, and Guido Mazzini. 2021. "Approaching Nuclear Safety Culture in Fission and Fusion Technology" Applied Sciences 11, no. 10: 4511. https://doi.org/10.3390/app11104511

APA StyleLomonaco, G., Mainardi, E., Marková, T., & Mazzini, G. (2021). Approaching Nuclear Safety Culture in Fission and Fusion Technology. Applied Sciences, 11(10), 4511. https://doi.org/10.3390/app11104511