Anisotropic Thermal Conductivity of Nickel-Based Superalloy CM247LC Fabricated via Selective Laser Melting

Abstract

:1. Introduction

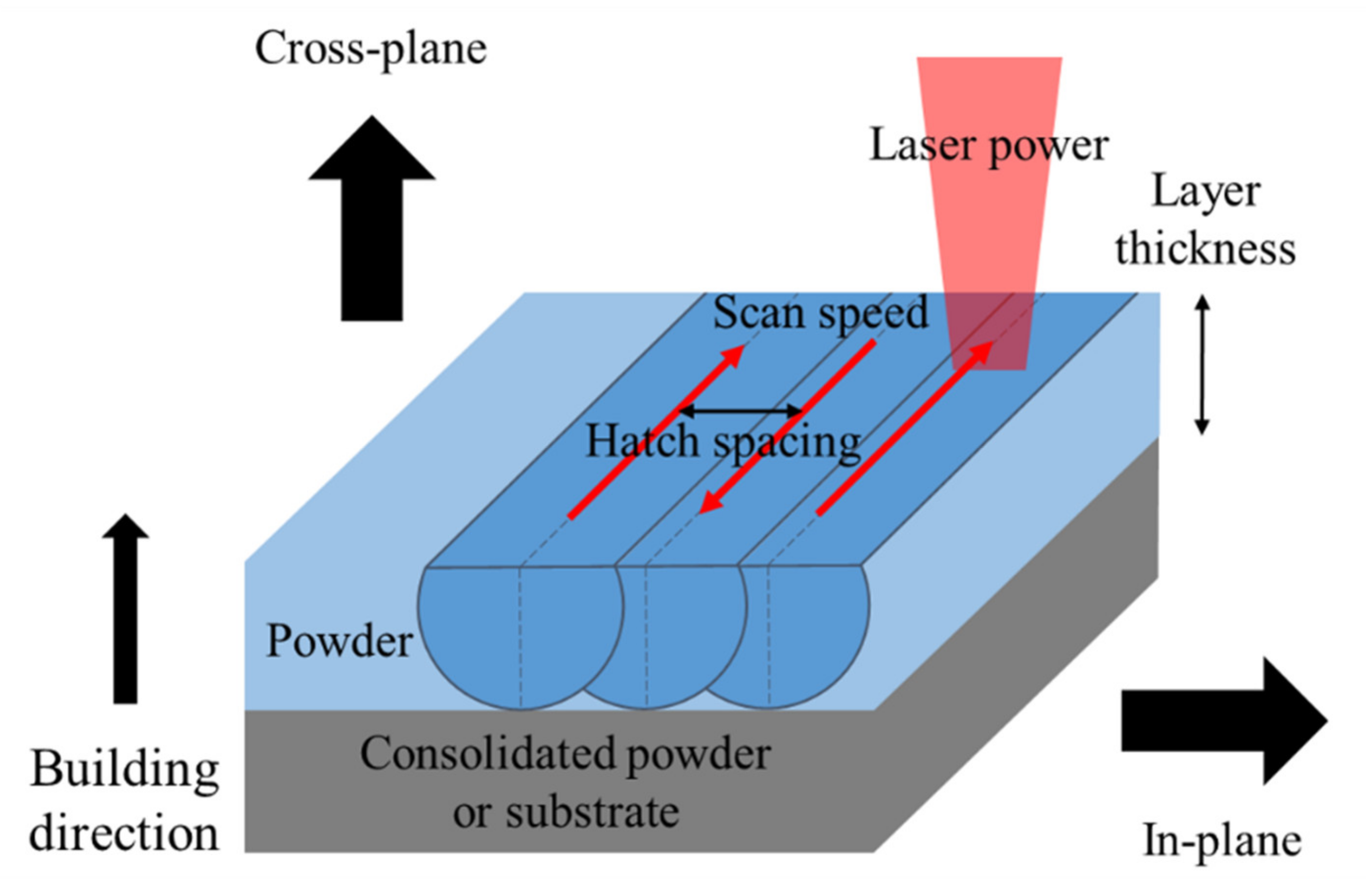

2. Experimental Procedure

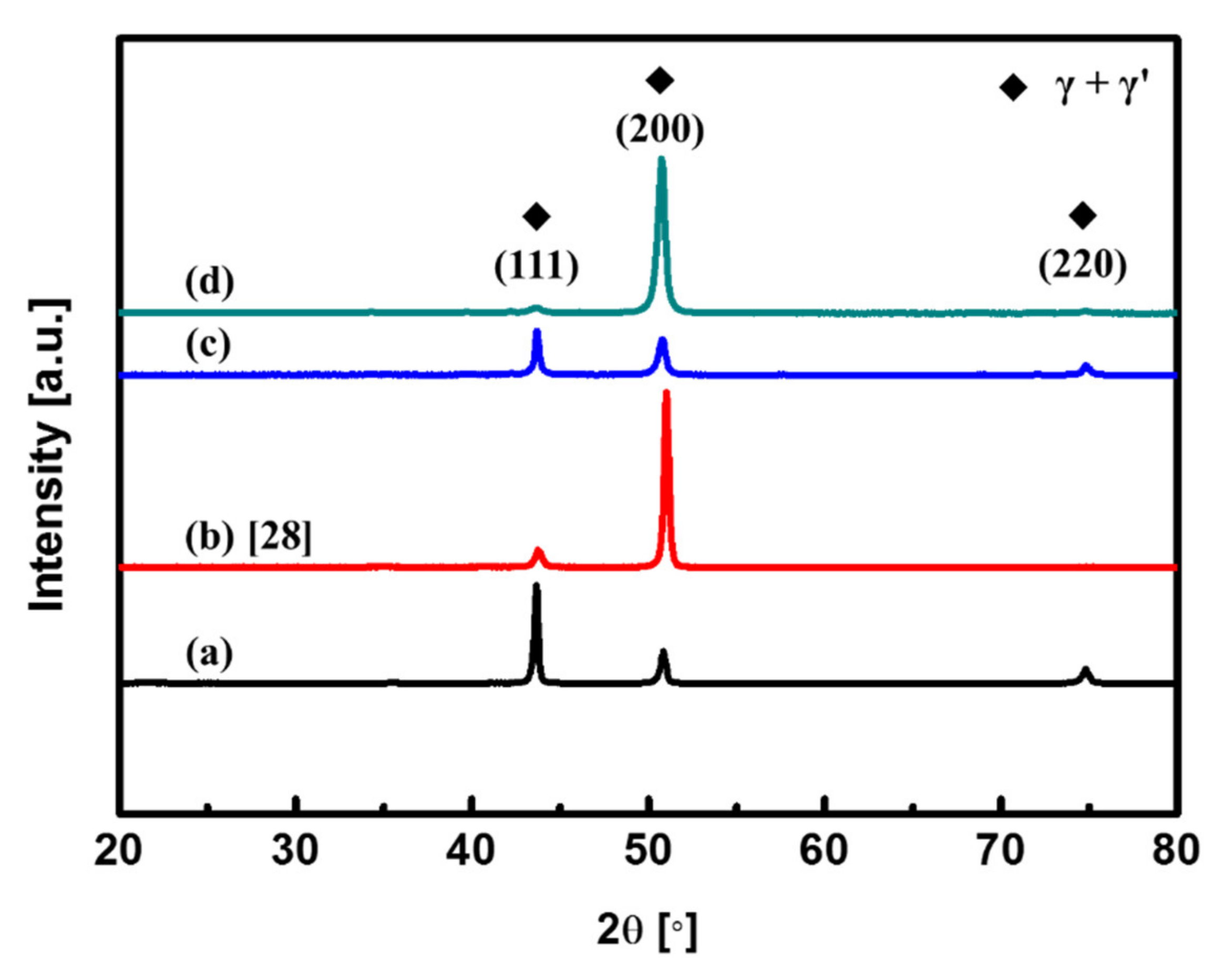

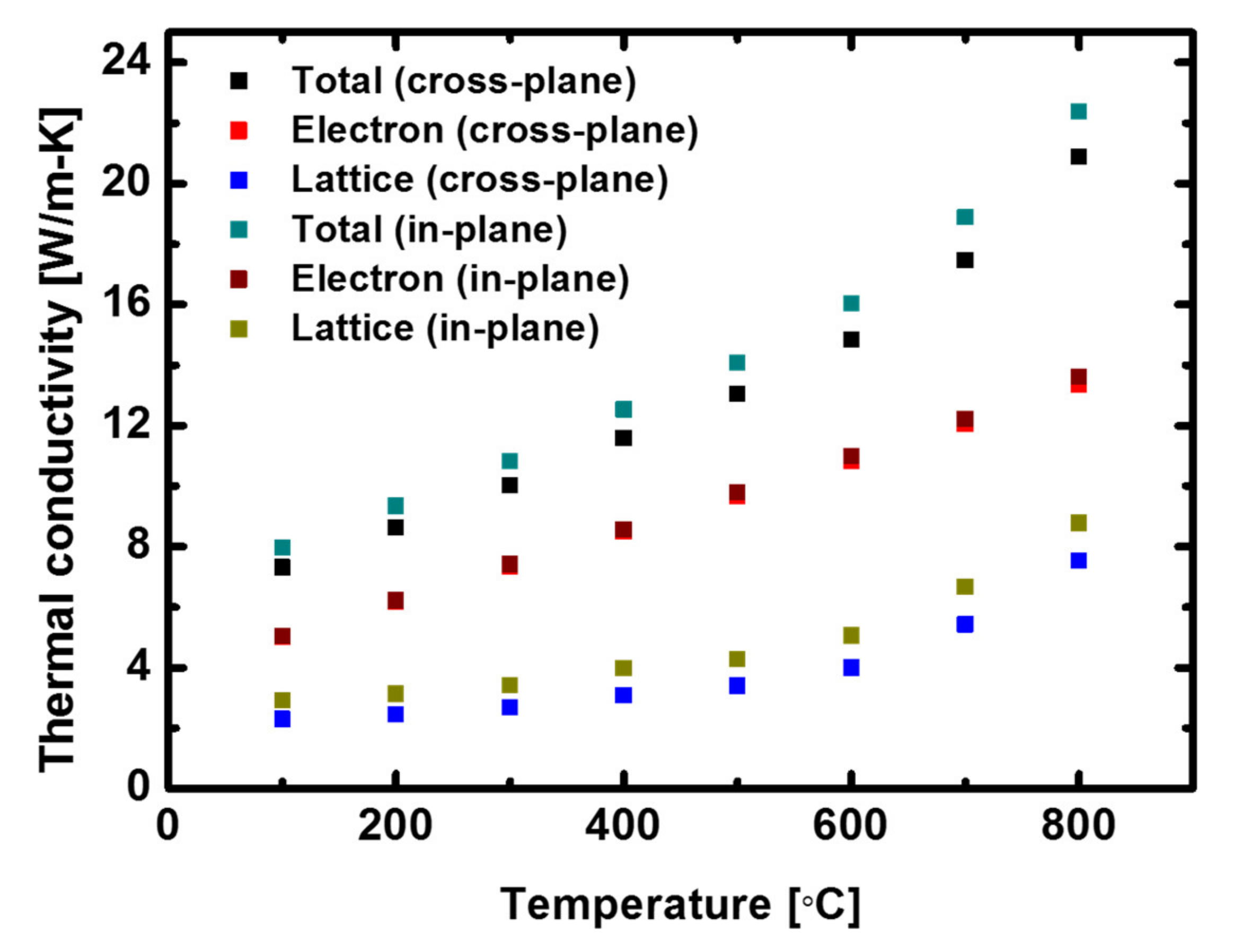

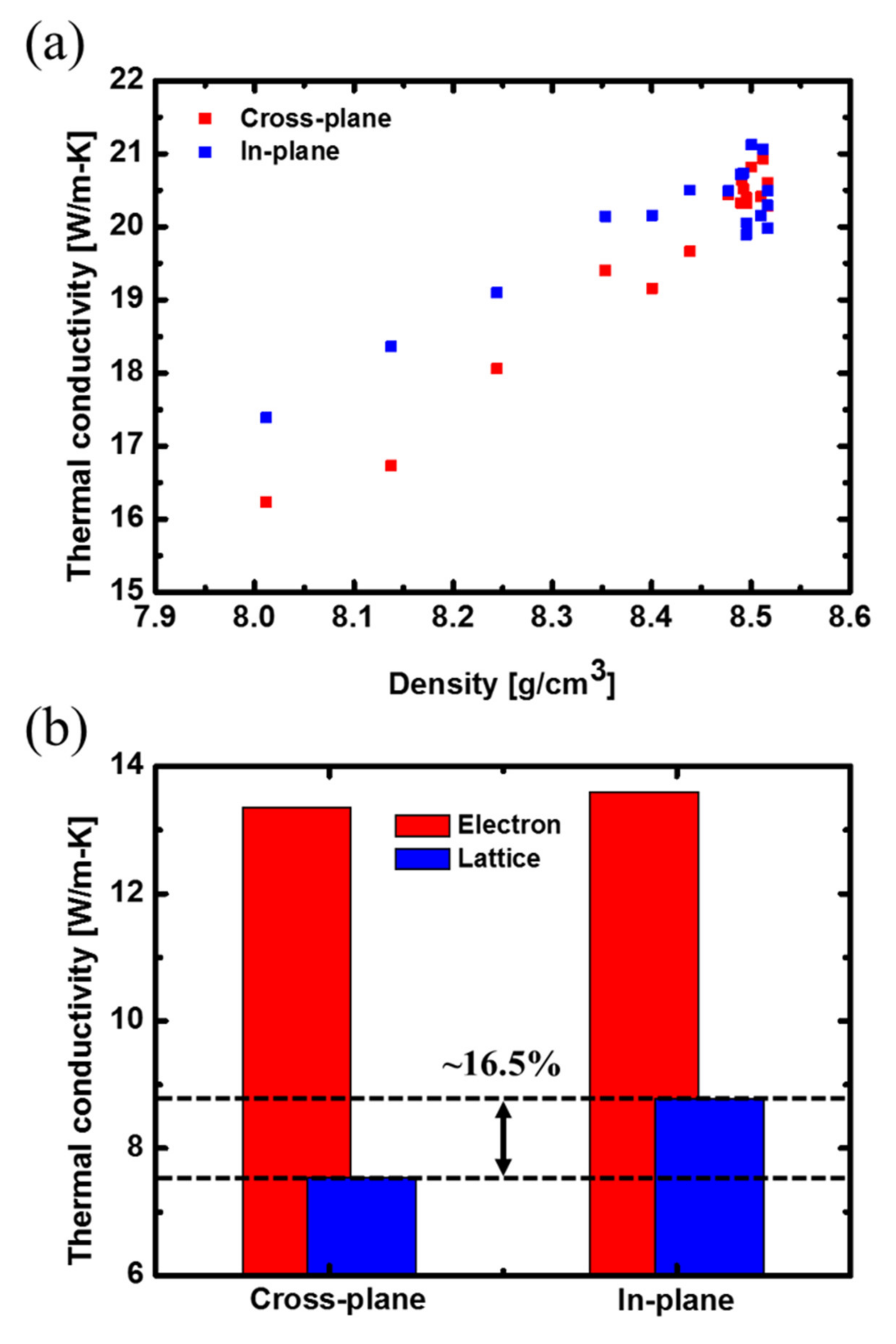

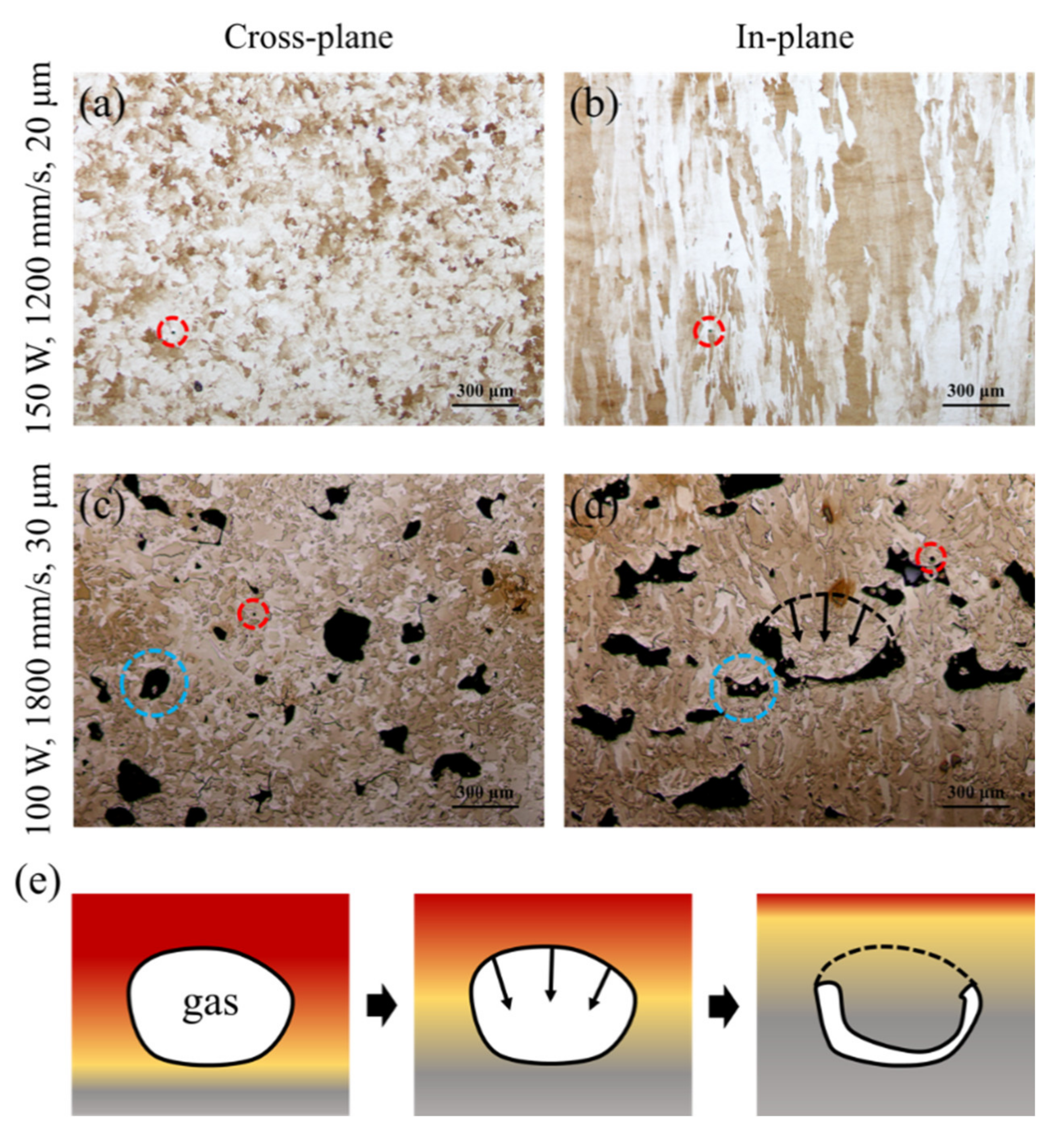

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rahman, M.M.; Ibrahim, T.K.; Abdalla, A.N. Thermodynamic performance analysis of gas-turbine power-plant. Int. J. Phys. Sci. 2011, 6, 3539–3550. [Google Scholar]

- Chumsty, N.; Heyes, A. Jet Propulsion, 3rd ed.; Cambridge University Press: New York, NY, USA, 2003. [Google Scholar]

- Reed, R.C. The Superalloys: Fundamentals and Applications, 1st ed.; Cambridge University Press: New York, NY, USA, 2008. [Google Scholar]

- Wee, S.; Do, J.; Kim, K.; Lee, C.; Seok, C.; Choi, B.-G.; Choi, Y.; Kim, W. Review on mechanical thermal properties of superalloys and thermal barrier coating used in gas turbines. Appl. Sci. 2020, 10, 5476. [Google Scholar] [CrossRef]

- Yao, Y.; Zhang, J.-Z.; Tan, X.-M. Numerical study of film cooling from converging slot-hole on a gas turbine suction side. Int. Commun. Heat Mass Transf. 2014, 52, 61–72. [Google Scholar] [CrossRef]

- Fang, X.; Qu, N.; Li, H.; Zhu, D. Enhancement of insulation coating durability in electrochemical drilling. Int. J. Adv. Manuf. Technol. 2013, 68, 2005–2013. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Z.; Zhu, Y.; Zhu, D. Machining of a film-cooling hole in a single-crystal superalloy by high-speed electrochemical discharge drilling. Chin. J. Aeronaut. 2016, 29, 560–570. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Xu, Z.; Zhu, D.; Qu, N.; Zhu, Y. Drilling of film cooling holes by a EDM/ECM in situ combined process using internal and side flushing of tubular electrode. Int. J. Adv. Manuf. Technol. 2016, 83, 505–517. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Sotov, A.V.; Agapovichev, A.V.; Smelov, V.G.; Kokareva, V.V.; Dmitrieva, M.O.; Melnikov, A.A.; Golanov, S.P.; Anurov, Y.M. Investigation of the IN-738 superalloy microstructure and mechanical properties for the manufacturing of gas turbine engine nozzle guide vane by selective laser melting. Int. J. Adv. Manuf. Technol. 2020, 107, 2525–2535. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Thivillon, L.; Bertrand, P.; Smurov, I. Strategy of manufacturing components with designed internal structure by selective laser melting of metallic powder. Appl. Surf. Sci. 2007, 254, 980–983. [Google Scholar] [CrossRef]

- Liu, S.Y.; Li, H.Q.; Qin, C.X.; Zong, R.; Fang, X.Y. The effect of energy density on texture and mechanical anisotropy in selective laser melted Inconel 718. Mater. Des. 2020, 191, 108642. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.-D.; Nazé, L.; Sennour, M. Microstructural and mechanical approaches of the selective laser melting process applied to a nickel-base superalloy. Mater. Sci. Eng. A 2012, 534, 446–451. [Google Scholar] [CrossRef]

- Joguet, D.; Danlos, Y.; Bolot, R.; Montavon, G.; Coddet, C. Modeling and measurement of the effective young modulus of porous biomedical materials manufactured via SLM. Key Eng. Mater. 2014, 606, 125–128. [Google Scholar] [CrossRef]

- Alkahari, M.R.; Furumoto, T.; Ueda, T.; Hosokawa, A.; Tanaka, R.; Abdul Aziz, M.S. Thermal conductivity of metal powder and consolidated material fabricated via selective laser melting. Key Eng. Mater. 2012, 244–249. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Zeng, X.; Yang, Z.; Wu, H. Effect of crystallographic texture on thermal anisotropy of selective laser melted Cu-2.4 Ni-0.7 Si alloy. J. Alloys. Compd. 2018, 743, 258–261. [Google Scholar] [CrossRef]

- Strumza, E.; Yeheskel, O.; Hayun, S. The effect of texture on the anisotropy of thermophysical properties of additively manufactured AlSi10Mg. Additive Manuf. 2019, 29, 100762. [Google Scholar] [CrossRef]

- Kim, M.-S. Effects of processing parameters of selective laser melting process on thermal conductivity of AlSi10Mg alloy. Materials 2021, 14, 2410. [Google Scholar] [CrossRef]

- Zieliñska, M.; Yavorska, M.; Porêba, M.; Sieniawski, J. Thermal properties of cast nickel based superalloys. Arch. Mater. Sci. Eng. 2010, 44, 35–38. [Google Scholar]

- Terada, Y.; Ohkubo, K.; Miura, S.; Sanchez, J.M.; Mohri, T. Thermal conductivity and thermal expansion of Ir3X (X= Ti, Zr, Hf, V, Nb, Ta) compounds for high-temperature applications. Mater. Chem. Phys. 2003, 80, 385–390. [Google Scholar] [CrossRef]

- Przeliorz, R.; Piątkowski, J. Thermophysical properties of nickel-based cast superalloys. Metalurgija 2015, 54, 543–546. [Google Scholar]

- Ormerod, J.; Taylor, R.; Edwards, R. Thermal diffusivity of cast irons. Met. Technol. 1978, 5, 109–113. [Google Scholar] [CrossRef]

- Brooks, R.; Day, A.; Mills, K.; Quested, P. Physical property measurements for the mathematical modeling of fluid flow in solidification processes. Int. J. Thermophys. 1997, 18, 471–480. [Google Scholar] [CrossRef]

- Matsushita, T.; Fecht, H.-J.; Wunderlich, R.K.; Egry, I.; Seetharaman, S. Studies of the thermophysical properties of commercial CMSX-4 alloy. J. Chem. Eng. Date 2009, 54, 2584–2592. [Google Scholar] [CrossRef]

- Harris, K.; Erickson, G.L.; Schwer, R.E. MAR M 247 derivations—CM 247 LC DS alloy, CMSX single crystal alloys, properties and performance. Superalloys 1984, 1984, 221–230. [Google Scholar]

- Ali, H.; Ghadbeigi, H.; Mumtaz, K. Effect of scanning strategies on residual stress and mechanical properties of selective laser melted Ti6Al4V. Mater. Sci. Eng A 2018, 712, 175–187. [Google Scholar] [CrossRef]

- Spierings, A.B.; Schneider, M.; Eggenberger, R. Comparison of density measurement techniques for additive manufactured metallic parts. Rapid Prototyp. J. 2011, 17, 380–386. [Google Scholar] [CrossRef]

- Kim, K.; Kim, W. Thermophysical properties of nickel-based superalloy CM247LC. Trans. Korean Soc. Mech. Eng. B 2020, 44, 619–625. [Google Scholar] [CrossRef]

- Divya, V.D.; Muñoz-Moreno, R.; Messé, O.M.D.M.; Barnard, J.S.; Baker, S.; Illston, T.; Stone, H.J. Microstructure of selective laser melted CM247LC nickel-based superalloy and its evolution through heat treatment. Mater. Charact. 2016, 114, 62–74. [Google Scholar] [CrossRef] [Green Version]

- Kurzynowski, T.; Stopyra, W.; Gruber, K.; Ziółkowski, G.; Kuźnicka, B.; Chlebus, E. Effect of scanning and support strategies on relative density of SLM-ed H13 steel in relation to specimen size. Materials 2019, 12, 239. [Google Scholar] [CrossRef] [Green Version]

- Gu, H.; Gong, H.; Pal, D.; Rafi, K.; Starr, T.; Stucker, B. Influences of energy density on porosity and microstructure of selective laser melted 17-4PH stainless steel. In Proceedings of the 2013 Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2013. [Google Scholar]

- Sallica-Leva, E.; Jardini, A.L.; Fogagnolo, J.B. Microstructure and mechanical behavior of porous Ti–6Al–4V parts obtained by selective laser melting. J. Mech. Behav. Biomed. Mater. 2013, 26, 98–108. [Google Scholar] [CrossRef]

- Koh, J.C.Y.; Fortini, A. Thermal Conductivity And Electrical Resistivity of Porous Material; NASA: Washington, DC, USA, 1971. [Google Scholar]

- Kruth, J.-P.; Froyen, L.; Van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Ronneberg, T.; Davies, C.M.; Hooper, P.A. Revealing relationships between porosity, microstructure and mechanical properties of laser powder bed fusion 316L stainless steel through heat treatment. Mater. Des. 2020, 189, 108481. [Google Scholar] [CrossRef]

- Dong, S.; Zhang, X.; Ma, F.; Jiang, J.; Yang, W.; Lin, Z. Research on metallurgical bonding of selective laser melted AlSi10Mg alloy. Mater. Res. Express 2020, 7, 025801. [Google Scholar] [CrossRef]

- Sola, A.; Nouri, A. Microstructural porosity in additive manufacturing: The formation and detection of pores in metal parts fabricated by powder bed fusion. J. Adv. Manuf. Process. 2019, 1, e10021. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.; Koo, J.; Park, E.; Kim, N.; Kim, W. Anisotropic Thermal Conductivity of Nickel-Based Superalloy CM247LC Fabricated via Selective Laser Melting. Appl. Sci. 2021, 11, 4843. https://doi.org/10.3390/app11114843

Kim K, Koo J, Park E, Kim N, Kim W. Anisotropic Thermal Conductivity of Nickel-Based Superalloy CM247LC Fabricated via Selective Laser Melting. Applied Sciences. 2021; 11(11):4843. https://doi.org/10.3390/app11114843

Chicago/Turabian StyleKim, Kyomin, Jageon Koo, Eunju Park, Namhun Kim, and Woochul Kim. 2021. "Anisotropic Thermal Conductivity of Nickel-Based Superalloy CM247LC Fabricated via Selective Laser Melting" Applied Sciences 11, no. 11: 4843. https://doi.org/10.3390/app11114843

APA StyleKim, K., Koo, J., Park, E., Kim, N., & Kim, W. (2021). Anisotropic Thermal Conductivity of Nickel-Based Superalloy CM247LC Fabricated via Selective Laser Melting. Applied Sciences, 11(11), 4843. https://doi.org/10.3390/app11114843