Experimental Investigation and Artificial Neural Network Based Prediction of Bond Strength in Self-Compacting Geopolymer Concrete Reinforced with Basalt FRP Bars

Abstract

1. Introduction

2. Experimental Investigation

2.1. Test Program

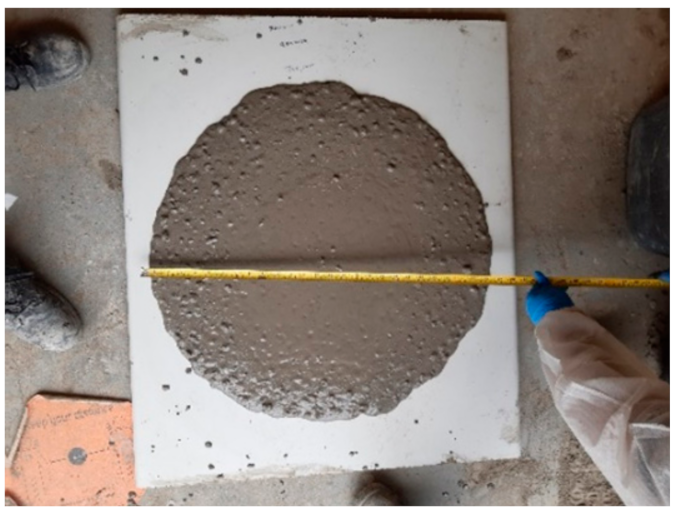

2.2. Materials

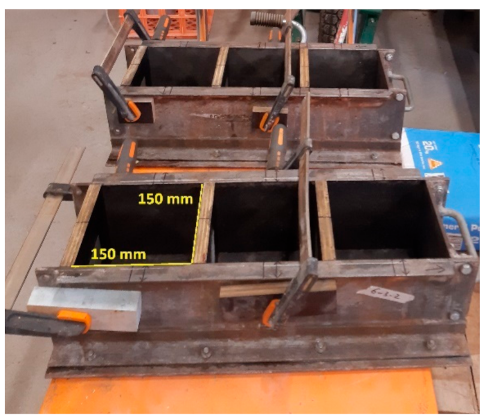

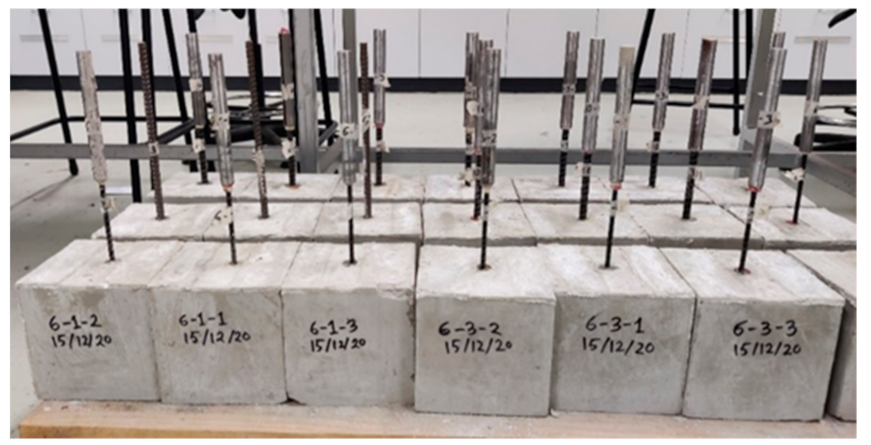

2.3. Pull-Out Specimen Preparation

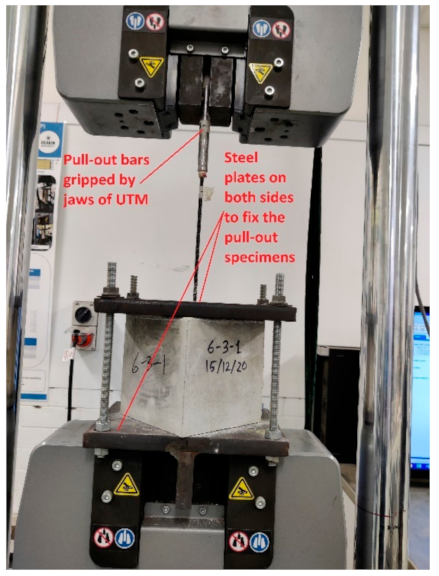

2.4. Pull-Out Test Set-Up

3. Test Results and Discussion

3.1. Bond Strength

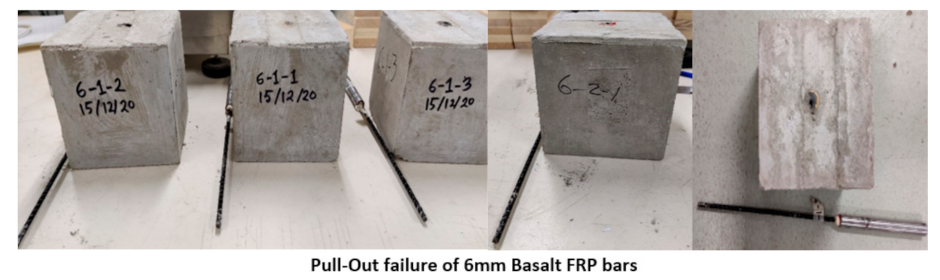

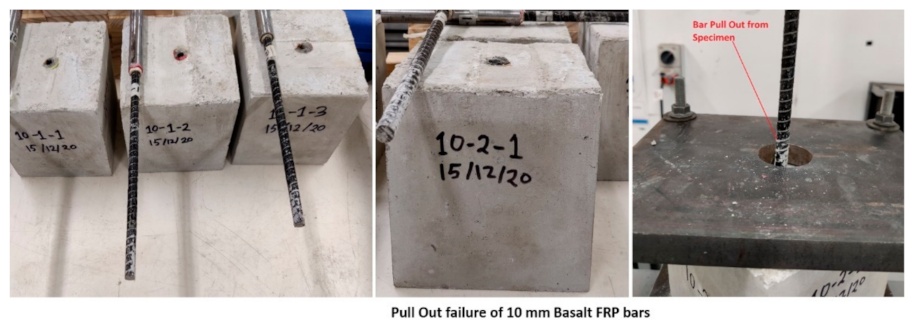

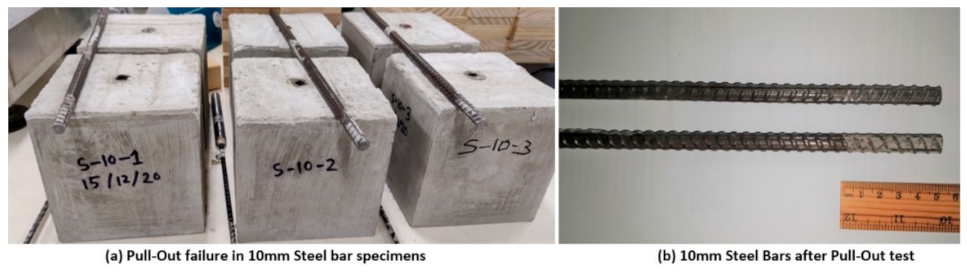

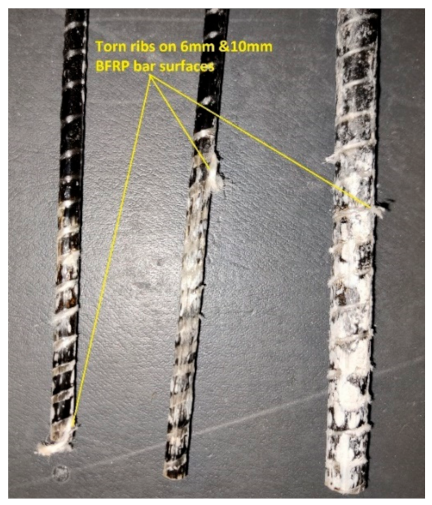

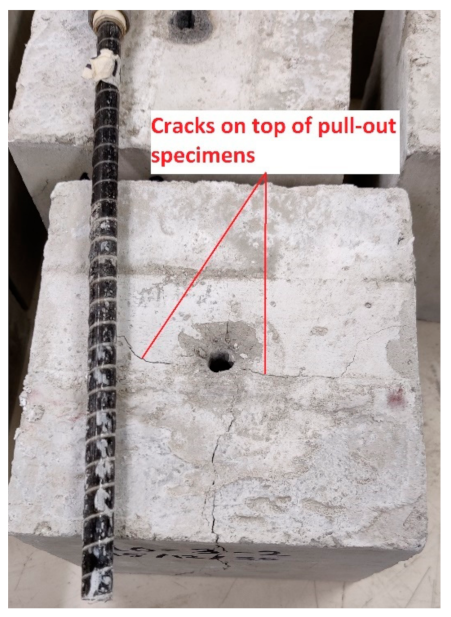

3.2. Failure Mode

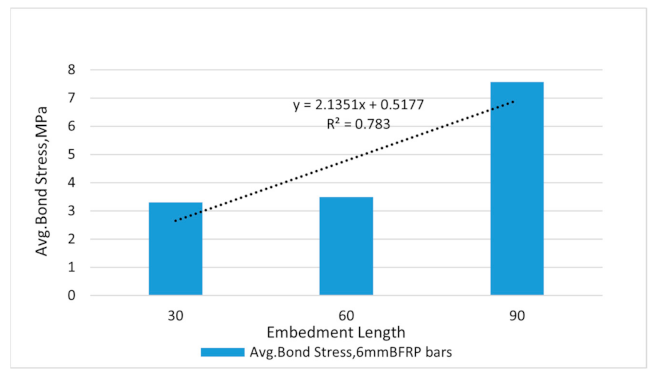

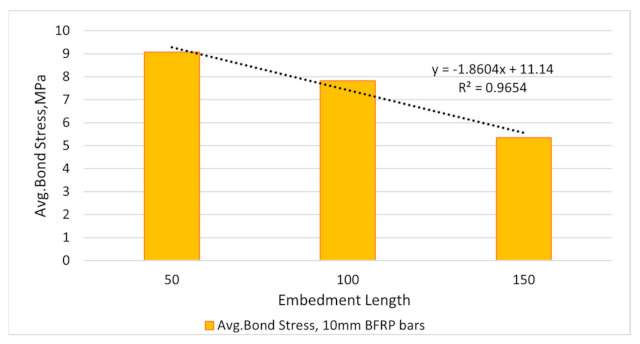

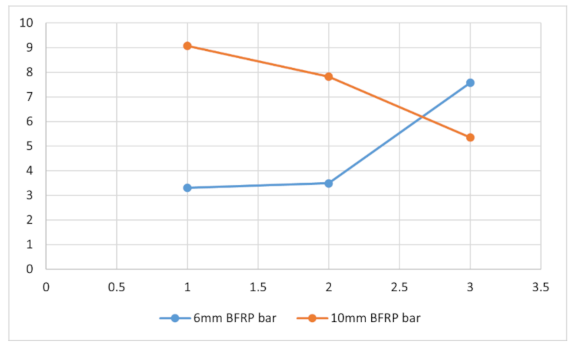

3.3. Effect of Bar Diameter and Embedment Length

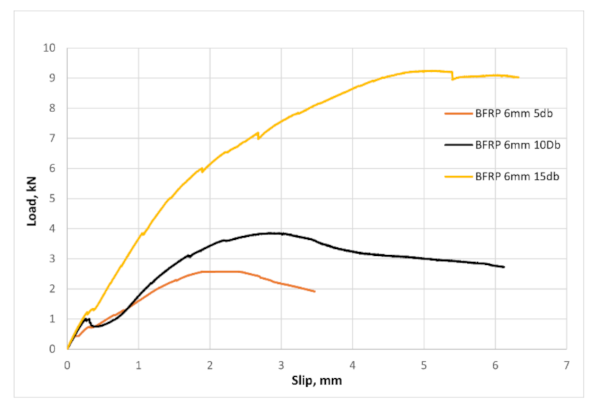

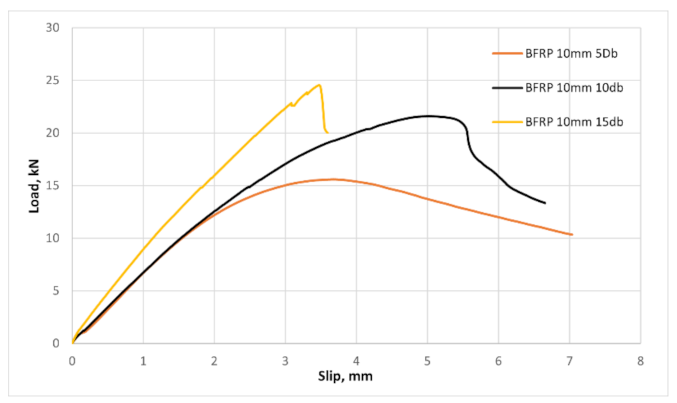

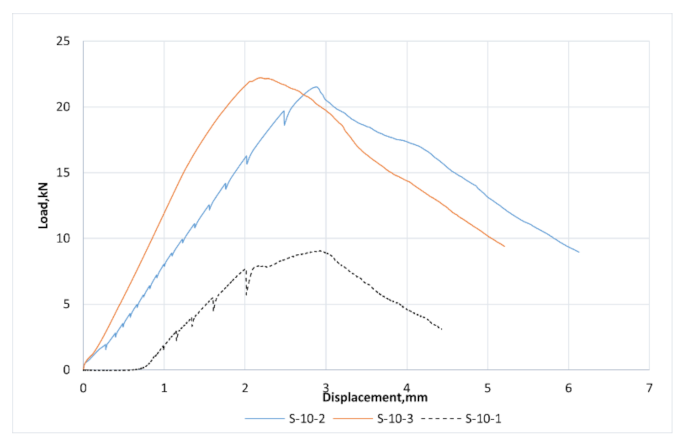

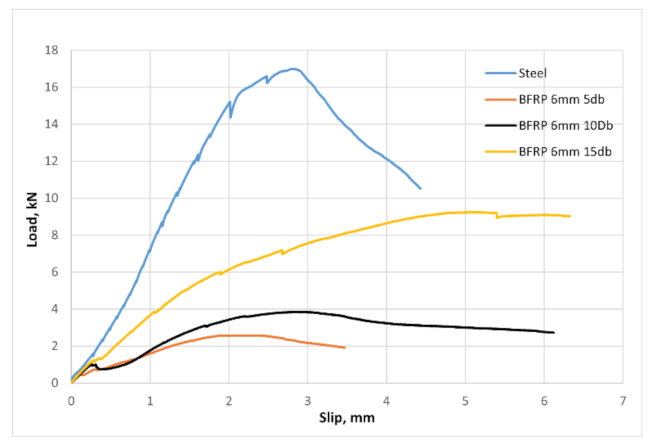

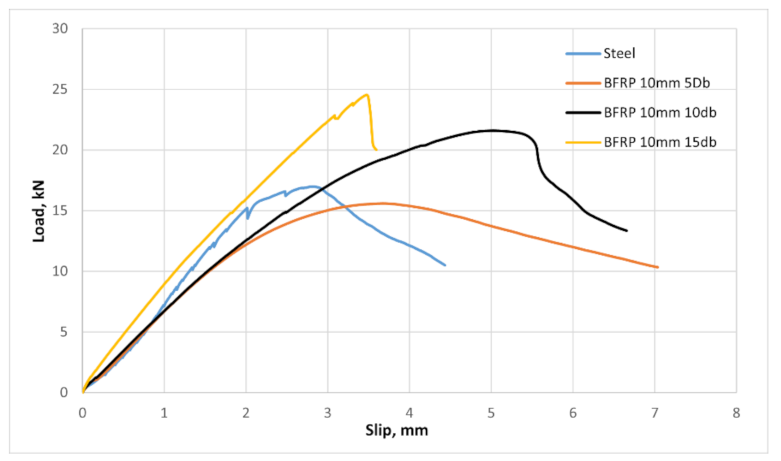

3.4. Load–Slip Relationship

4. Theoretical Investigation of Bond Behaviour

4.1. Bond Strength Prediction Using an Artificial Neural Network (ANN)

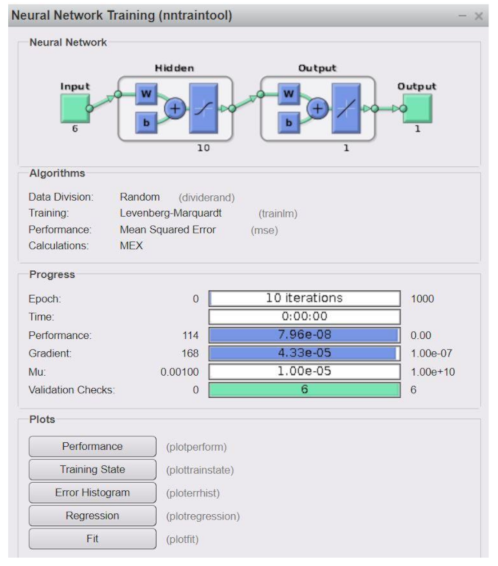

4.1.1. ANN Model Development

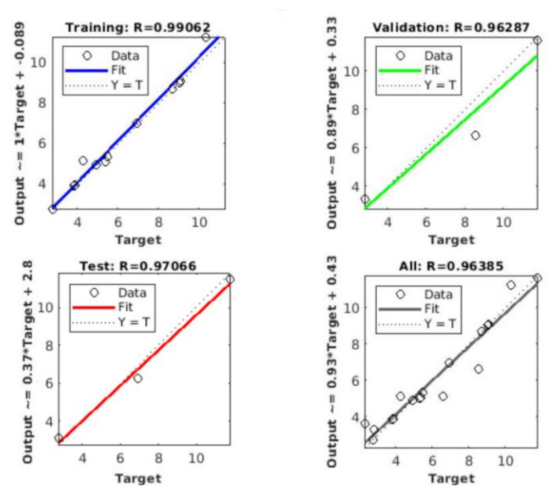

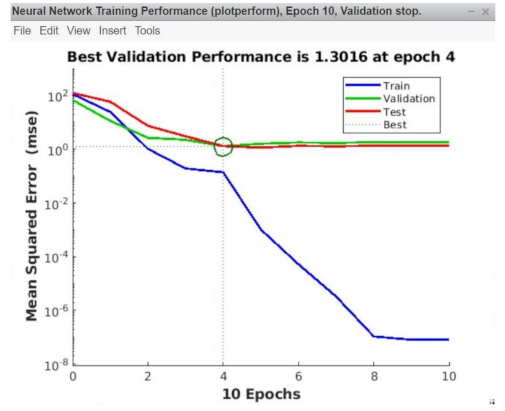

4.1.2. ANN Model Training and Analysis

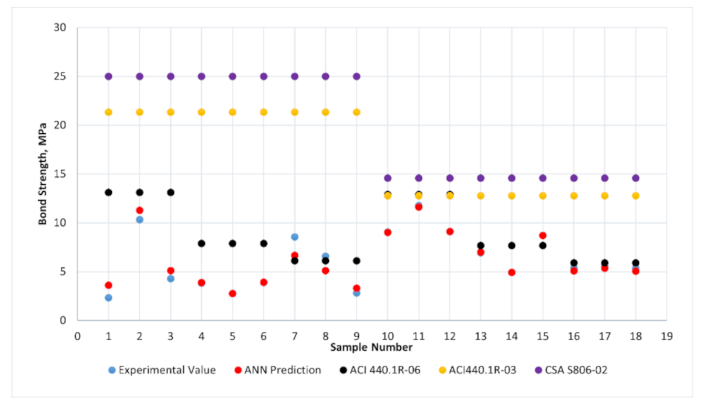

4.1.3. ANN Comparison with Other Prediction Models

5. Conclusions

- The average bond strength offered by 10-mm steel-reinforced SCGC is higher than that of 6-mm and 10-mm BFRP bars; however, all of the BFRP-reinforced specimens gave similar bond performance for traditional, ordinary Portland cement concrete.

- The 10-mm-diameter BFRP bars performed well when the embedment length was kept at 5 db, and when the embedment length was increased, the bond strength was found to decrease for 10-mm BFRP bars.

- When comparing the performance of basalt bars with steel bars, we noted that the pull-out specimens reinforced with steel were able to take maximum stresses (around 500 MPa); however, for the basalt, since the tensile stress was almost 1100 MPa, the basalt bars pulled out before the peak was reached.

- Even though the ANN model is a non-traditional approach, it proved to provide realistic prediction in the case of the newly developed composite (SCGC–BFRP) compared to the existing theoretical and analytical models, such as ACI and CSA, which overpredicted the bond strength.

- The ANN model gave good prediction of bond strength, with the lowest MSE values, and R2 values of 0.99 for test, 0.97 for validation and 0.96 for training for all types of basalt FRP specimens. Future works on this topic would enhance the database to give more accurate predictions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rolland, A.; Quiertant, M.; Khadour, A.; Chataigner, S.; Benzarti, K.; Argoul, P. Experimental investigations on the bond behavior between concrete and FRP reinforcing bars. Constr. Build. Mater. 2018, 173, 136–148. [Google Scholar] [CrossRef]

- Dong, Z.; Wu, G.; Xu, B.; Wang, X.; Taerwe, L. Bond durability of BFRP bars embedded in concrete under seawater conditions and the long-term bond strength prediction. Mater. Des. 2016, 92, 552–562. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhou, N.; Zhou, L.; Zhang, H.; Li, H.; Zhou, Y. Experimental and theoretical study of bond behaviour between FRP bar and high-volume fly ash-self-compacting concrete. Mater. Struct. 2021, 54, 1–17. [Google Scholar] [CrossRef]

- Alkhraisha, H.; Mhanna, H.; Tello, N.; Abed, F. Serviceability and flexural behavior of concrete beams reinforced with basalt fiber-reinforced polymer (BFRP) Bars Exposed to Harsh Conditions. Polymers 2020, 12, 2110. [Google Scholar] [CrossRef] [PubMed]

- El Mesalami, N.; Abed, F.; El Refai, A. Concrete columns reinforced with GFRP and BFRP bars under concentric and eccentric loads: Experimental testing and analytical investigation. J. Compos. Constr. 2021, 25, 04021003. [Google Scholar] [CrossRef]

- Kashani, A.; Ngo, T.D.; Mendis, P. The effects of precursors on rheology and self-compactness of geopolymer concrete. Mag. Concr. Res. 2019, 71, 557–566. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Rahman, S.K.; Al-Ameri, R. A newly developed self-compacting geopolymer concrete under ambient condition. Constr. Build. Mater. 2021, 267, 121822. [Google Scholar] [CrossRef]

- Desnerck, P.; de Schutter, G.; Taerwe, L. Bond behaviour of reinforcing bars in self-compacting concrete: Experimental de-termination by using beam tests. Mater. Struct. Constr. 2010, 43, 53–62. [Google Scholar] [CrossRef]

- Boel, V.; Helincks, P.; Desnerck, P.; De Schutter, G. Bond Behaviour and shear capacity of self-compacting concrete. In Design, Production and Placement of Self-Consolidating Concrete; Springer: Dordrecht, The Netherlands, 2010; pp. 343–353. [Google Scholar]

- Tighiouart, B.; Benmokrane, B.; Gao, D. Investigation of bond in concrete member with fibre reinforced polymer (FRP) bars. Constr. Build. Mater. 1998, 12, 453–462. [Google Scholar] [CrossRef]

- FIB. FRP Reinforcement in RC Structures; Technical Report, Bulletin No. 40; FIB: Lausanne, Switzerland, 2007. [Google Scholar]

- High, C.; Seliem, H.M.; El-Safty, A.; Rizkalla, S.H. Use of basalt fibers for concrete structures. Constr. Build. Mater. 2015, 96, 37–46. [Google Scholar] [CrossRef]

- Elgabbas, F.; Vincent, P.; Ahmed, E.A.; Benmokrane, B. Experimental testing of basalt-fiber-reinforced polymer bars in concrete beams. Compos. Part B Eng. 2016, 91, 205–218. [Google Scholar] [CrossRef]

- Ahmed, A.; Guo, S.; Zhang, Z.; Shi, C.; Zhu, D. A review on durability of fiber reinforced polymer (FRP) bars reinforced seawater sea sand concrete. Constr. Build. Mater. 2020, 256, 119484. [Google Scholar] [CrossRef]

- Michaud, D.; Fam, A. Development length of small-diameter basalt FRP bars in normal- and high-strength concrete. J. Compos. Constr. 2021, 25, 04020086. [Google Scholar] [CrossRef]

- Ceroni, F.; Cosenza, E.; Gaetano, M.; Pecce, M.R. Durability issues of FRP rebars in reinforced concrete members. Cem. Concr. Compos. 2006, 28, 857–868. [Google Scholar] [CrossRef]

- Cosenza, E.; Manfredi, G.; Realfonzo, R. Behavior and modeling of bond of FRP rebars to concrete. J. Compos. Constr. 1997, 1, 40–51. [Google Scholar] [CrossRef]

- Nanni, A.; Faza, S. Design and construction of concrete reinforced with FRP bars: An emerging technology. Concr. Int. 2002, 24, 53–58. [Google Scholar]

- Mesbah, H.-A.; Benzaid, R.; Benmokrane, B. Evaluation of bond strength of FRP reinforcing rods in concrete and FE modelling. Int. J. Civ. Eng. Constr. Sci. 2017, 4, 21–41. [Google Scholar]

- Khayat, K.H.; Desnerck, P. Bond properties of self-compacting concrete. In Mechanical Properties of Self-Compacting Concrete; State-of-the-Art Report of RILEM Technical Committee 228-MPS; Springer: Cham, Switzerland, 2014; pp. 95–139. [Google Scholar]

- ACI Committee. Guide Test Methods for Fiber-Reinforced Polymer (FRP) Composites for Reinforcing or Strengthening Concrete and Masonry Structures; ACI 440.3R-04; ACI: Farmington Hills, MI, USA, 2012. [Google Scholar]

- RILEM. RILEM Technical Recommendations for the Testing and Use of Construction Materials; RILEM: Paris, France, 1994. [Google Scholar]

- Shoaib Hussain, A.; Al-Ameri, R. Bond Strength and Anchorage Length of BFRP in Concrete; Deakin University: Geelong, Australia, 2019. [Google Scholar]

- Domone, P.L.; Chai, H.W. Design and testing of self-compacting concrete. In Production Methods and Workability of Concrete; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Chopra, D.; Siddique, R. Kunal Strength, permeability and microstructure of self-compacting concrete containing rice husk ash. Biosyst. Eng. 2015, 130, 72–80. [Google Scholar] [CrossRef]

- CSA. Design and Construction of Building Components with Fibre-Reinforced Polymers; CSA: Toronto, ON, USA, 2002. [Google Scholar]

- Wang, L.; Song, Z.; Yi, J.; Li, J.; Fu, F.; Qian, K. Experimental studies on bond performance of BFRP bars reinforced coral aggregate concrete. Int. J. Concr. Struct. Mater. 2019, 13, 1–10. [Google Scholar] [CrossRef]

- Nguyen, H.-A.; Chang, T.-P.; Shih, J.-Y. Engineering properties and bonding behavior of self-compacting concrete made with no-cement binder. J. Mater. Civ. Eng. 2018, 30, 04017294. [Google Scholar] [CrossRef]

- Castel, A.; Foster, S.J. Bond strength between blended slag and Class F fly ash geopolymer concrete with steel reinforcement. Cem. Concr. Res. 2015, 72, 48–53. [Google Scholar] [CrossRef]

- Liu, H.; Yang, J.; Wang, X. Bond behavior between BFRP bar and recycled aggregate concrete reinforced with basalt fiber. Constr. Build. Mater. 2017, 135, 477–483. [Google Scholar] [CrossRef]

- Trabacchin, G.; Ayala, D.D.; Stegemann, J.; Zhang, M. Bond behaviour of basalt FRP bars in geopolymer concrete bond behaviour of basalt FRP bars in geopolymer concrete. In Proceedings of the 1st International Conference in Low-Carbon Cement & Concrete Technology, London, UK, 24–26 June 2019; pp. 1–4. [Google Scholar]

- El Refai, A.; Ammar, M.-A.; Masmoudi, R. Bond performance of basalt fiber-reinforced polymer bars to concrete. J. Compos. Constr. 2015, 19, 04014050. [Google Scholar] [CrossRef]

- Shen, D.; Li, C.; Feng, Z.; Wen, C.; Ojha, B. Influence of strain rate on bond behavior of concrete members reinforced with basalt fiber-reinforced polymer rebars. Constr. Build. Mater. 2019, 228, 116755. [Google Scholar] [CrossRef]

- Solyom, S.; Balázs, G.L. Bond of FRP bars with different surface characteristics. Constr. Build. Mater. 2020, 264, 119839. [Google Scholar] [CrossRef]

- Muñoz, M.B. Study of Bond Behaviour between FRP Reinforcement and Concrete. Ph.D. Thesis, Universitat de Girona, Girona, Spain, 2010. [Google Scholar]

- Vincent, P.; Ahmed, E.; Benmokrane, B. Characterization of basalt fiber-reinforced polymer (BFRP) reinforcing bars for concrete structures. In Proceedings of the 3rd Specialty Conference on Material Engineering & Applied Mechanics, Canadian Society of Civil Engineers, Montreal, QC, Canada, 29 May–1 June 2013. [Google Scholar]

- Liu, X.; Wang, X.; Xie, K.; Wu, Z.; Li, F. Bond behavior of basalt fiber-reinforced polymer bars embedded in concrete under mono-tensile and cyclic loads. Int. J. Concr. Struct. Mater. 2020, 14, 1–15. [Google Scholar] [CrossRef]

- Dong, Z.; Wu, G.; Zhao, X.-L.; Wang, Z.-K. A refined prediction method for the long-term performance of BFRP bars serviced in field environments. Constr. Build. Mater. 2017, 155, 1072–1080. [Google Scholar] [CrossRef]

- Baena, M.; Torres, L.; Turon, A.; Barris, C. Experimental study of bond behaviour between concrete and FRP bars using a pull-out test. Compos. Part B Eng. 2009, 40, 784–797. [Google Scholar] [CrossRef]

- Maranan, G.; Manalo, A.; Karunasena, K.; Benmokrane, B. Bond stress-slip behavior: Case of GFRP bars in geopolymer concrete. J. Mater. Civ. Eng. 2015, 27, 04014116. [Google Scholar] [CrossRef]

- Bi, Q.; Wang, H. Bond strength of BFRP bars to basalt fiber reinforced high-strength concrete. In Advances in FRP Composites in Civil Engineering, Proceedings of the 5th International Conference on FRP Composites in Civil Engineering, CICE, Beijing, China, 27–29 September 2010; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Seis, M.; Beycioǧlu, A. Bond performance of basalt fiber-reinforced polymer bars in conventional Portland cement concrete: A relative comparison with steel rebar using the hinged beam approach. Sci. Eng. Compos. Mater. 2017, 24, 909–918. [Google Scholar] [CrossRef]

- Golafshani, E.M.; Rahai, A.; Sebt, M.H. Bond behavior of steel and GFRP bars in self-compacting concrete. Constr. Build. Mater. 2014, 61, 230–240. [Google Scholar] [CrossRef]

- Achillides, Z.; Pilakoutas, K. Bond behavior of fiber reinforced polymer bars under direct pullout conditions. J. Compos. Constr. 2004, 8, 173–181. [Google Scholar] [CrossRef]

- Elgabbas, F.; Ahmed, E.A.; Benmokrane, B. Physical and mechanical characteristics of new basalt-FRP bars for reinforcing concrete structures. Constr. Build. Mater. 2015, 95, 623–635. [Google Scholar] [CrossRef]

- Tepfers, R.; De Lorenzis, L. Bond of FRP reinforcement in concrete—A challenge. Mech. Compos. Mater. 2003, 39, 315–328. [Google Scholar] [CrossRef]

- Cosenza, E.; Manfredi, G.; Realfonzo, R. Development length of FRP straight rebars. Compos. Part B Eng. 2002, 33, 493–504. [Google Scholar] [CrossRef]

- Wambeke, B.W.; Shield, C.K. Development length of glass fiber-reinforced polymer bars in concrete. ACI Struct. J. 2006, 103, 11. [Google Scholar]

- Hong, L.; Chen, Y.D.; Li, T.D.; Gao, P.; Sun, L.Z. Microstructure and bonding behavior of fiber-mortar interface in fiber-reinforced concrete. Constr. Build. Mater. 2020, 232, 117235. [Google Scholar] [CrossRef]

- Hong, L.; Li, T.; Chen, Y.; Gao, P.; Sun, L. Characteristics of interfacial shear bonding between basalt fiber and Mortar Matrix. Materials 2020, 13, 5037. [Google Scholar] [CrossRef] [PubMed]

- Mousavi, S.; Dehestani, M. Bond strength and development length of glass fiber-reinforced polymer bar in unconfined self-consolidating concrete. J. Reinf. Plast. Compos. 2016, 35, 924–941. [Google Scholar] [CrossRef]

- Nurwidayati, R.; Ekaputri, J.J.; Triwulan; Suprobo, P. Effect of embedment length on bond strength of geopolymer concrete. In AIP Conference Proceedings; AIP Publishing: College Park, MD, USA, 2020. [Google Scholar]

- Hamad, J.A.R.; Johari, M.A.M.; Haddad, R.H. Mechanical properties and bond characteristics of different fiber re-inforced polymer rebars at elevated temperatures. Constr. Build. Mater. 2017, 142, 521–535. [Google Scholar] [CrossRef]

- Looney, T.J.; Arezoumandi, M.; Volz, J.S.; Myers, J.J. An experimental study on bond strength of reinforcing steel in self-consolidating concrete. Int. J. Concr. Struct. Mater. 2012, 6, 187–197. [Google Scholar] [CrossRef]

- Saleh, N.; Ashour, A.; Lam, D.; Sheehan, T. Experimental investigation of bond behaviour of two common GFRP bar types in high—Strength concrete. Constr. Build. Mater. 2019, 201, 610–622. [Google Scholar] [CrossRef]

- Islam, S.; Afefy, H.M.; Sennah, K.; Azimi, H. Bond characteristics of straight- and headed-end, ribbed-surface, GFRP bars embedded in high-strength concrete. Constr. Build. Mater. 2015, 83, 283–298. [Google Scholar] [CrossRef]

- Maranan, G.B.; Manalo, A.C.; Karunasena, W.; Benmokrane, B. Pullout behaviour of GFRP bars with anchor head in geo-polymer concrete. Compos. Struct. 2015, 132, 1113–1121. [Google Scholar] [CrossRef]

- ACI (American Concrete Institute). Guide for the Design and Construction of Structural Concrete Reinforced with Fiber-Reinforced Polymer (FRP) Bars; ACI 440.1R-15; ACI: Farmington Hills, MI, USA, 2015. [Google Scholar]

- ACI (American Concrete Institute). Guide for the Design and Construction of Concrete Reinforced with FRP Bars; ACI 440.1R-03; ACI: Farmington Hills, MI, USA, 2003. [Google Scholar]

- Haddad, R.; Haddad, M. Predicting fiber-reinforced polymer-concrete bond strength using artificial neural networks: A comparative analysis study. Struct. Concr. 2021, 22, 38–49. [Google Scholar] [CrossRef]

- He, Z.; Tian, G.-W. Probabilistic evaluation of the design development length of a GFRP rod pull-out from concrete. Eng. Struct. 2011, 33, 2943–2952. [Google Scholar] [CrossRef]

- Acciai, A.; D’Ambrisi, A.; De Stefano, M.; Feo, L.; Focacci, F.; Nudo, R. Experimental response of FRP reinforced members without transverse reinforcement: Failure modes and design issues. Compos. Part B Eng. 2016, 89, 397–407. [Google Scholar] [CrossRef]

- Gao, J.; Koopialipoor, M.; Armaghani, D.J.; Ghabussi, A.; Baharom, S.; Morasaei, A.; Shariati, A.; Khorami, M.; Zhou, J. Evaluating the bond strength of FRP in concrete samples using machine learning methods. Smart Struct. Syst. 2020, 26, 403–418. [Google Scholar]

- Dahou, Z.; Sbartaï, Z.M.; Castel, A.; Ghomari, F. Artificial neural network model for steel–concrete bond prediction. Eng. Struct. 2009, 31, 1724–1733. [Google Scholar] [CrossRef]

- Makni, M.; Daoud, A.; Karray, M.A.; Lorrain, M. Artificial neural network for the prediction of the steel-concrete bond behaviour. Eur. J. Environ. Civ. Eng. 2014, 18, 862–881. [Google Scholar] [CrossRef]

- Golafshani, E.M.; Rahai, A.; Sebt, M.H. Artificial neural network and genetic programming for predicting the bond strength of GFRP bars in concrete. Mater. Struct. 2014, 48, 1581–1602. [Google Scholar] [CrossRef]

- Su, M.; Zhong, Q.; Peng, H.; Li, S. Selected machine learning approaches for predicting the interfacial bond strength between FRPs and concrete. Constr. Build. Mater. 2021, 270, 121456. [Google Scholar] [CrossRef]

- George, U.A.; Elvis, M.M. Modelling of the mechanical properties of concrete with cement ratio partially replaced by aluminium waste and sawdust ash using artificial neural network. SN Appl. Sci. 2019, 1, 1514. [Google Scholar] [CrossRef]

- Bashir, R.; Ashour, A. Neural network modelling for shear strength of concrete members reinforced with FRP bars. Compos. Part B Eng. 2012, 43, 3198–3207. [Google Scholar] [CrossRef]

- Alnedawi, A.; Al-Ameri, R.; Nepal, K.P. Neural network-based model for prediction of permanent deformation of unbound granular materials. J. Rock Mech. Geotech. Eng. 2019, 11, 1231–1242. [Google Scholar] [CrossRef]

- Sancak, E. Prediction of bond strength of lightweight concretes by using artificial neural networks. Sci. Res. Essays 2009, 30, 256–266. [Google Scholar]

- Abdalla, J.A.; Hawileh, R.; Altamimi, A.K. Prediction of FRP-concrete ultimate bond strength using Artificial Neural Network. In Proceedings of the 4th International Conference on Modeling, Simulation and Applied Optimization (ICMSAO), Kuala Lumpur, Malaysia, 19–21 April 2011; pp. 1–4. [Google Scholar]

- Asteris, P.; Kolovos, K.; Douvika, M.; Roinos, K. Prediction of self-compacting concrete strength using artificial neural networks. Eur. J. Environ. Civ. Eng. 2016, 20, s102–s122. [Google Scholar] [CrossRef]

- Ceroni, F.; Bonati, A.; Galimberti, V.; Occhiuzzi, A. Effects of Environmental Conditioning on the Bond Behavior of FRP and FRCM Systems Applied to Concrete Elements. J. Eng. Mech. 2018, 144, 04017144. [Google Scholar] [CrossRef]

- De Domenico, D.; Urso, S.; Borsellino, C.; Spinella, N.; Recupero, A. Bond behavior and ultimate capacity of notched concrete beams with externally-bonded FRP and PBO-FRCM systems under different environmental conditions. Constr. Build. Mater. 2020, 265, 121208. [Google Scholar] [CrossRef]

| Bar Type | Nominal Diameter (mm) | Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|

| BFRP | 6 | 1000 | ≥55 |

| BFRP | 10 | 1260 | ≥55 |

| Steel | 10 | 620 | 200 |

| Mix Proportion (Kg/m3) [2] | |

|---|---|

| Fly Ash | 480 |

| Slag | 360 |

| Micro Fly Ash | 120 |

| Sodium Metasilicate (Anhy.) Alkali Activator | 96 |

| Fine Aggregates | 763 |

| Coarse Aggregates | 677 |

| Properties of Fresh SCGC | |

| Slump Flow (mm) | 670 |

| T500 (sec) | 4.10 |

| Properties of Hardened SCGC | |

| Compressive Strength, at 28th Day (MPa) | 40 |

| Indirect Tensile Strength, at 28th Day (MPa) | 3 |

| Modulus of Elasticity, at 28th Day (GPa) | 15 |

| Sl. No | Specimen No. | Bar Diameter db (mm) | Embedment Length in Terms of Bar Diameter | Embedment Length (mm) |

|---|---|---|---|---|

| 1 | 6-1-1 | 6 | 5 db | 30 |

| 2 | 6-1-2 | 6 | 5 db | 30 |

| 3 | 6-1-3 | 6 | 5 db | 30 |

| 4 | 6-2-1 | 6 | 10 db | 60 |

| 5 | 6-2-2 | 6 | 10 db | 60 |

| 6 | 6-2-3 | 6 | 10 db | 60 |

| 7 | 6-3-1 | 6 | 15 db | 90 |

| 8 | 6-3-2 | 6 | 15 db | 90 |

| 9 | 6-3-3 | 6 | 15 db | 90 |

| 10 | 10-1-1 | 10 | 5 db | 50 |

| 11 | 10-1-2 | 10 | 5 db | 50 |

| 12 | 10-1-3 | 10 | 5 db | 50 |

| 13 | 10-2-1 | 10 | 10 db | 100 |

| 14 | 10-2-2 | 10 | 10 db | 100 |

| 15 | 10-2-3 | 10 | 10 db | 100 |

| 16 | 10-3-1 | 10 | 15 db | 150 |

| 17 | 10-3-2 | 10 | 15 db | 150 |

| 18 | 10-3-3 | 10 | 15 db | 150 |

| 19 | S-10-1 | 10 | 5 db | 50 |

| 20 | S-10-2 | 10 | 5 db | 50 |

| 21 | S-10-3 | 10 | 5 db | 50 |

| Sl.No | Specimen No | Bar Diameter, db (mm) | Embedment Length | Max. Load at Failure, Pmax (N) | Bond Stress, τmax (MPa) | Average Bond Stress, τmax *a (MPa) | Standard Error of Mean | Mode of Failure |

|---|---|---|---|---|---|---|---|---|

| 1 | 6-1-1 | 6 | 5 db | 1313.21 | 2.32 | 3.30 | 2.41 | Pull-out |

| 2 | 6-1-2 | 6 | 5 db | 5849.67 | 10.34 # | Pull-out | ||

| 3 | 6-1-3 | 6 | 5 db | 2420.91 | 4.28 | Pull-out | ||

| 4 | 6-2-1 | 6 | 10 db | 4337.71 | 3.84 | 3.49 | 0.36 | Pull-out |

| 5 | 6-2-2 | 6 | 10 db | 3120.17 | 2.76 | Pull-out | ||

| 6 | 6-2-3 | 6 | 10 db | 4388.16 | 3.88 | Pull-out | ||

| 7 | 6-3-1 | 6 | 15 db | 14,529.08 | 8.56 | 7.57 | 1.68 | Pull-out |

| 8 | 6-3-2 | 6 | 15 db | 11,161.75 | 6.58 | Pull-out | ||

| 9 | 6-3-3 | 6 | 15 db | 4803.68 | 2.83 # | Pull-out | ||

| 10 | 10-1-1 | 10 | 5 db | 14,195.87 | 9.04 | 9.98 | 0.90 | Pull-out |

| 11 | 10-1-2 | 10 | 5 db | 18,504.16 | 11.78 | Pull-out | ||

| 12 | 10-1-3 | 10 | 5 db | 14,318.88 | 9.12 | Pull-out | ||

| 13 | 10-2-1 | 10 | 10 db | 21,830.84 | 6.95 | 6.86 | 1.09 | Pull-out |

| 14 | 10-2-2 | 10 | 10 db | 15,498.56 | 4.93 | Pull-out | ||

| 15 | 10-2-3 | 10 | 10 db | 27,340.62 | 8.70 | Pull-out | ||

| 16 | 10-3-1 | 10 | 15 db | 25,295.03 | 5.37 | 5.41 | 0.05 | Pull-out *b |

| 17 | 10-3-2 | 10 | 15 db | 25,947.93 | 5.51 | Pull-out *b | ||

| 18 | 10-3-3 | 10 | 15 db | 25,180.94 | 5.34 | Pull-out *b | ||

| 19 | S-10-1 | 10 | 5 db | 9066.53 | 5.77 # | 13.93 | 2.72 | Pull-out |

| 20 | S-10-2 | 10 | 5 db | 21,528.76 | 13.71 | Pull-out | ||

| 21 | S-10-3 | 10 | 5 db | 22,234.29 | 14.15 | Pull-out |

| Sl.No: | Standard Guideline | Bond Strength Prediction Equation | FRP Bar Type | Remark |

|---|---|---|---|---|

| 1 | ACI 440.1R-06 | τmax = 0.083√fc(4.0 + 0.3c/d + 100 d/l) | Glass, E-glass, Carbon, Aramid | No specific coefficients of factors to account for the type and material of FRP bar |

| 2 | ACI 440.1R-03 | τmax = 20.23√fc/d | Glass, E-glass, Carbon, Aramid | |

| 3 | CSA-S806-02 | τmax = dcs √f’c/1.15(k1 k2 k3 k4 k5)πdb | Glass, E-glass, Carbon, Aramid | Considers fibre type and profile of bar |

| Specimen No. | Experimental Value of Bond Stress, MPa | Predicted Values of Bond Stress, MPa | ||

|---|---|---|---|---|

| ACI 440.1R-06 [3] | ACI440.1R-03 [4] | CSA S806-02 [5] | ||

| 6-1-1 | 3.30 | 13.12 | 21.32 | 25.01 |

| 6-2-1 | 3.49 | 7.87 | 21.32 | 25.01 |

| 6-3-1 | 7.57 | 6.12 | 21.32 | 25.01 |

| 10-1-1 | 9.08 | 12.91 | 12.79 | 14.59 |

| 10-2-1 | 7.83 | 7.66 | 12.79 | 14.59 |

| 10-3-1 | 5.36 | 5.91 | 12.79 | 14.59 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, S.K.; Al-Ameri, R. Experimental Investigation and Artificial Neural Network Based Prediction of Bond Strength in Self-Compacting Geopolymer Concrete Reinforced with Basalt FRP Bars. Appl. Sci. 2021, 11, 4889. https://doi.org/10.3390/app11114889

Rahman SK, Al-Ameri R. Experimental Investigation and Artificial Neural Network Based Prediction of Bond Strength in Self-Compacting Geopolymer Concrete Reinforced with Basalt FRP Bars. Applied Sciences. 2021; 11(11):4889. https://doi.org/10.3390/app11114889

Chicago/Turabian StyleRahman, Sherin Khadeeja, and Riyadh Al-Ameri. 2021. "Experimental Investigation and Artificial Neural Network Based Prediction of Bond Strength in Self-Compacting Geopolymer Concrete Reinforced with Basalt FRP Bars" Applied Sciences 11, no. 11: 4889. https://doi.org/10.3390/app11114889

APA StyleRahman, S. K., & Al-Ameri, R. (2021). Experimental Investigation and Artificial Neural Network Based Prediction of Bond Strength in Self-Compacting Geopolymer Concrete Reinforced with Basalt FRP Bars. Applied Sciences, 11(11), 4889. https://doi.org/10.3390/app11114889