Sustainability Levels in Comparison with Mechanical Properties and Durability of Pumice High-Performance Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Volcanic Pumice Pozzolan

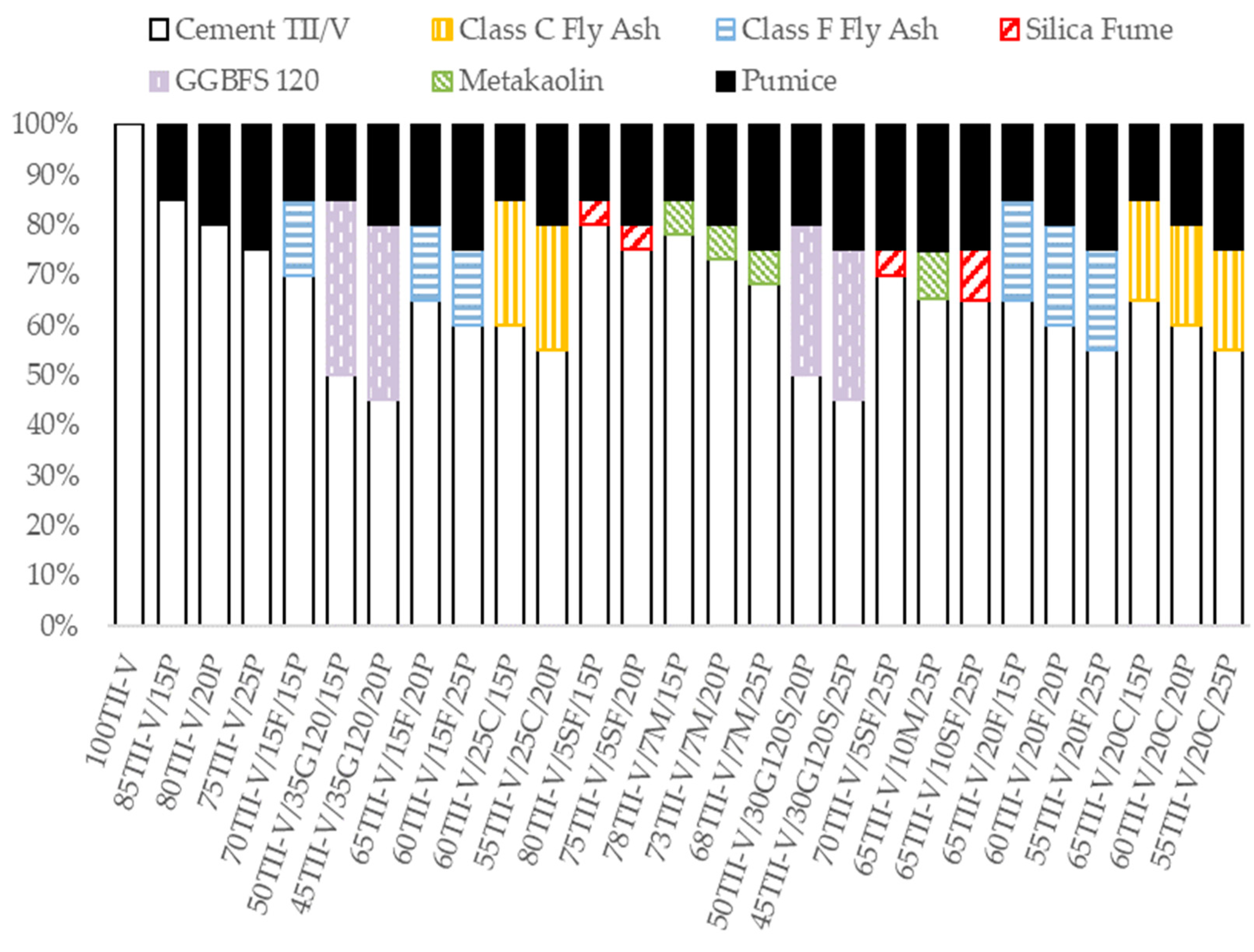

2.2. Investigated Mixture Composition

2.3. Material Properties

2.4. Sustainability Indicator

- R is the performance—suitable for the mechanical characteristics of concrete, namely, compressive strength [MPa]

- L is the service life—using a suitable analytical model (see e.g., [6,7]), the service life of L [years] is then determined. Instead of the model, alternatively, a quantity characterizing the service life related to a certain degradation phenomenon can be used for L—in the present case, it is a diffusion parameter used to calculate the resistance of concrete to chloride ions and in connection with corrosion of reinforcement [9,10]

- E is the eco-cost, i.e., the amount that could be spent to reduce the environmental impact to a sustainable level. It includes the impact of mining and processing of materials

- Rref, Lref, and Eref are optional values, in this case, relevant to the reference concrete mixture (OPC).

- C is the cost, i.e., the price of all materials according to the specific composition of concrete, depending mainly on the region or country

- Cref is a cost related to the reference concrete.

3. Results

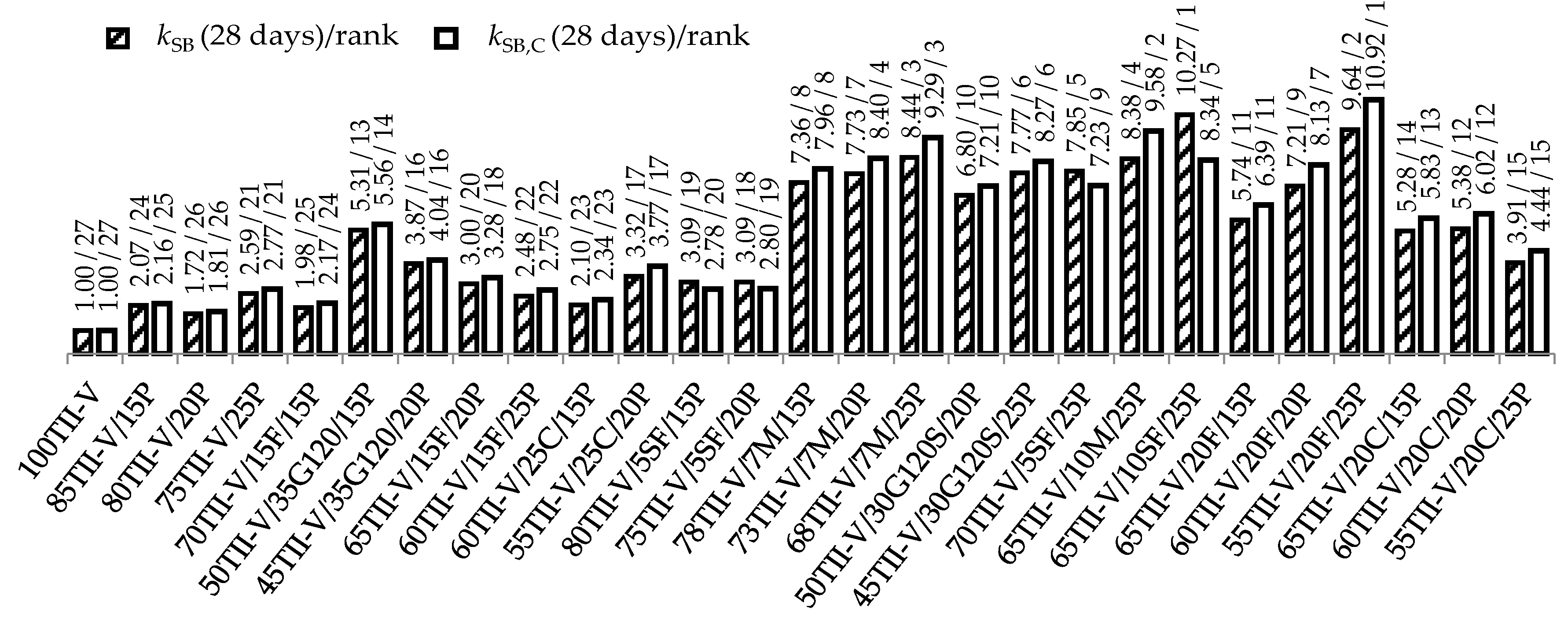

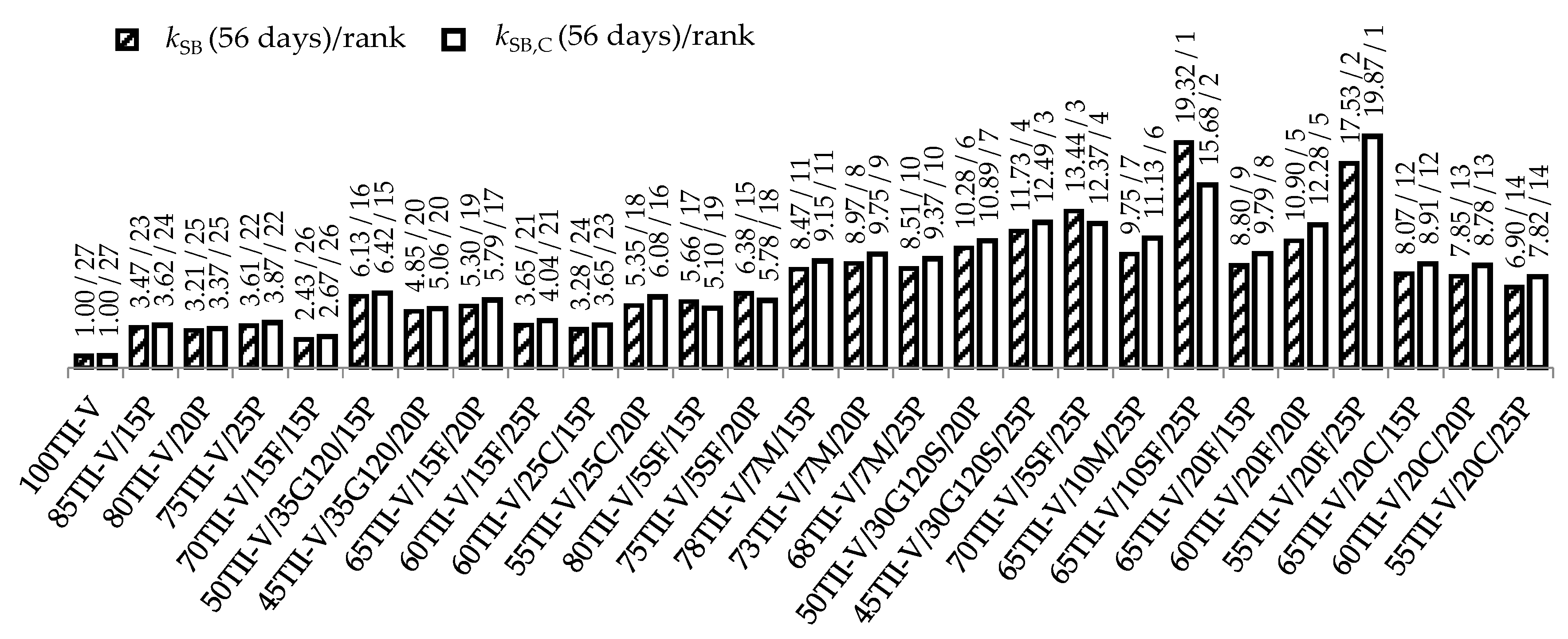

3.1. Rank of Concrete Mixtures

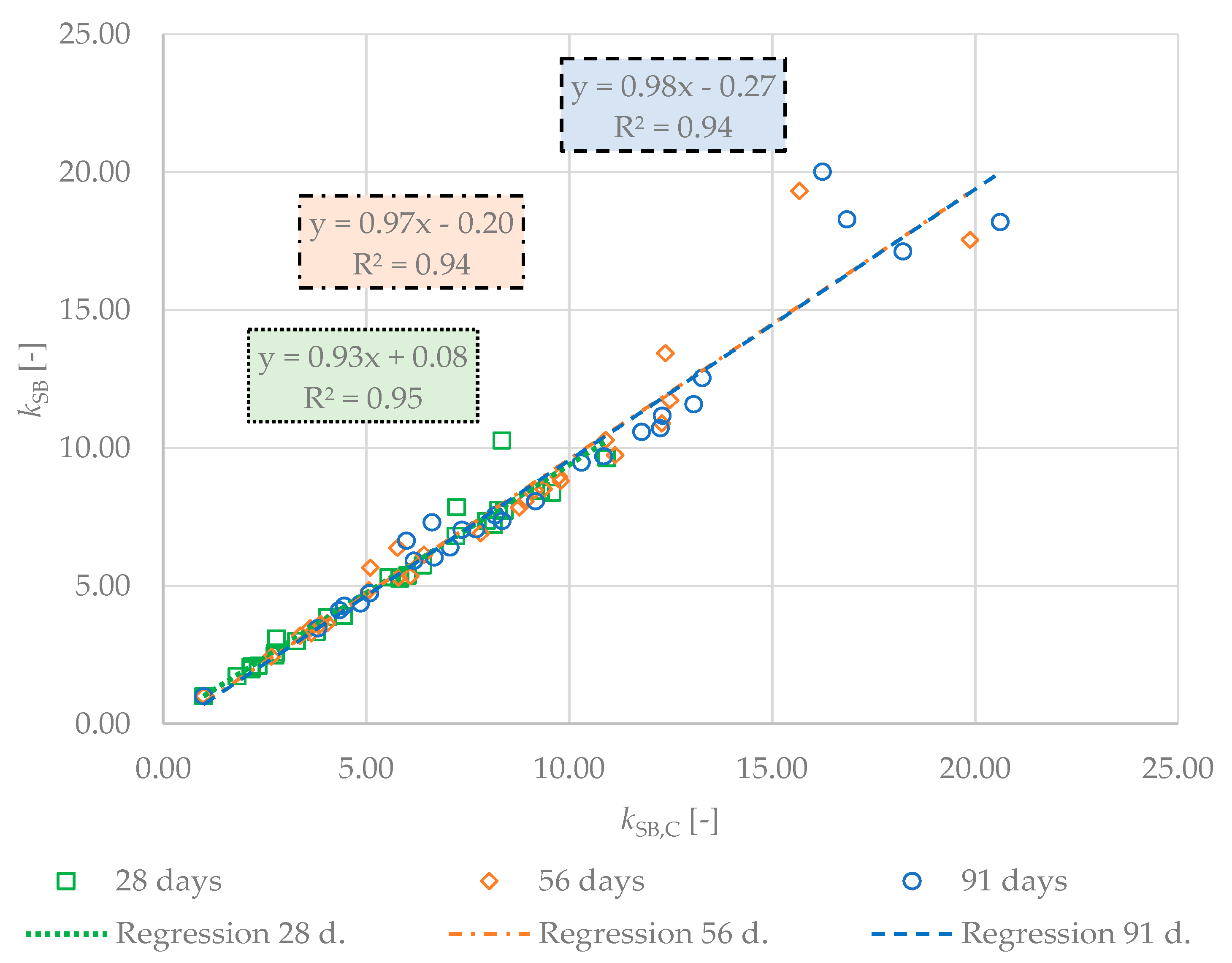

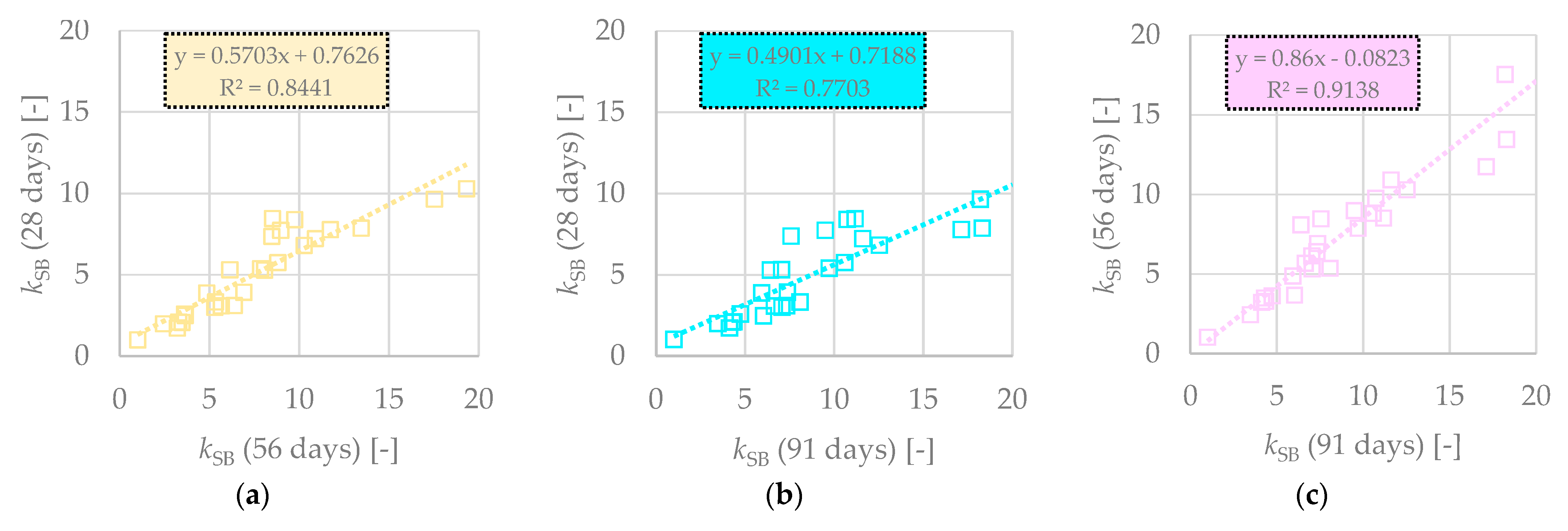

3.2. Correlation between Sustainability Indicators

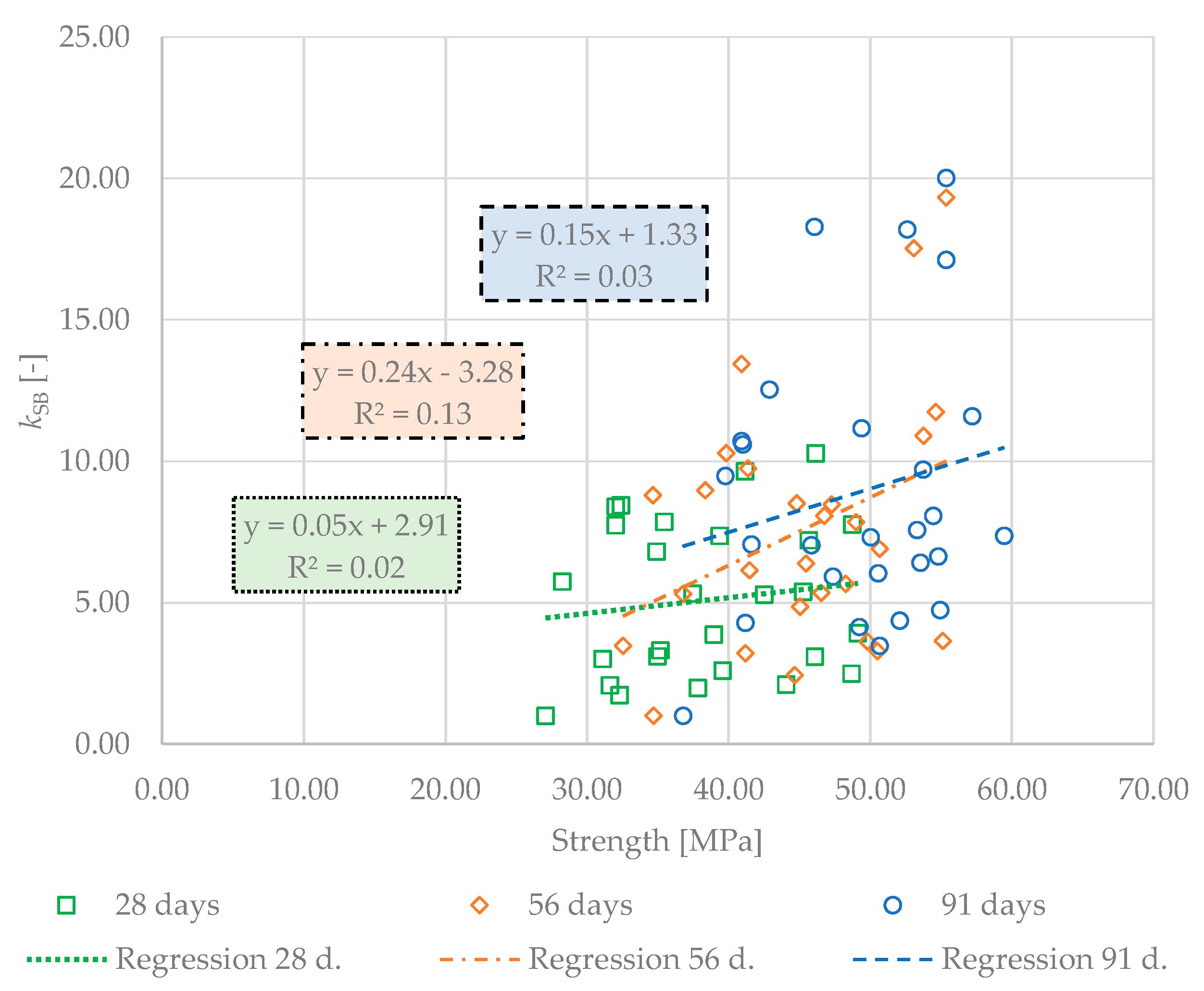

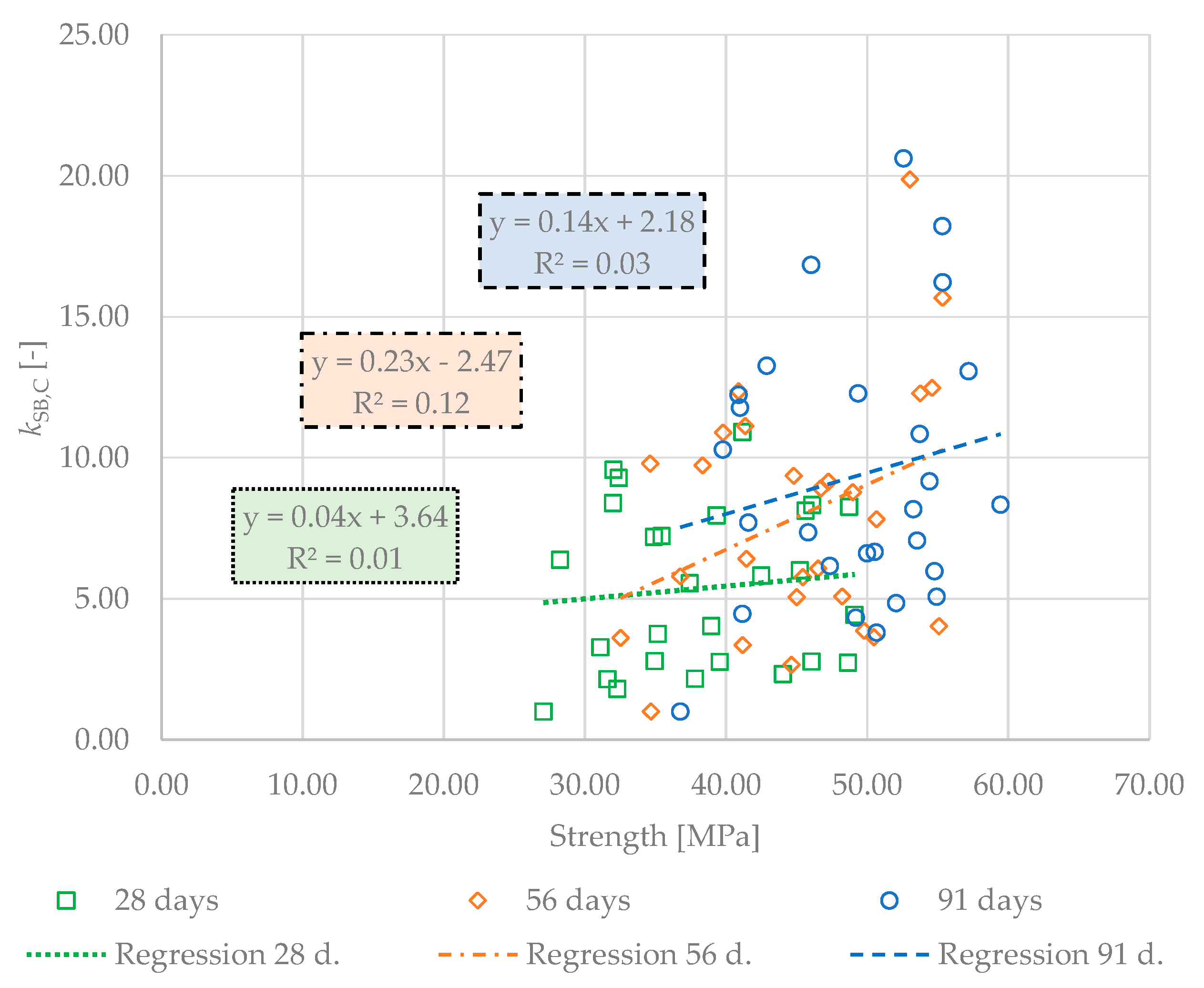

3.3. Correlation between Sustainability Indicators and Strength

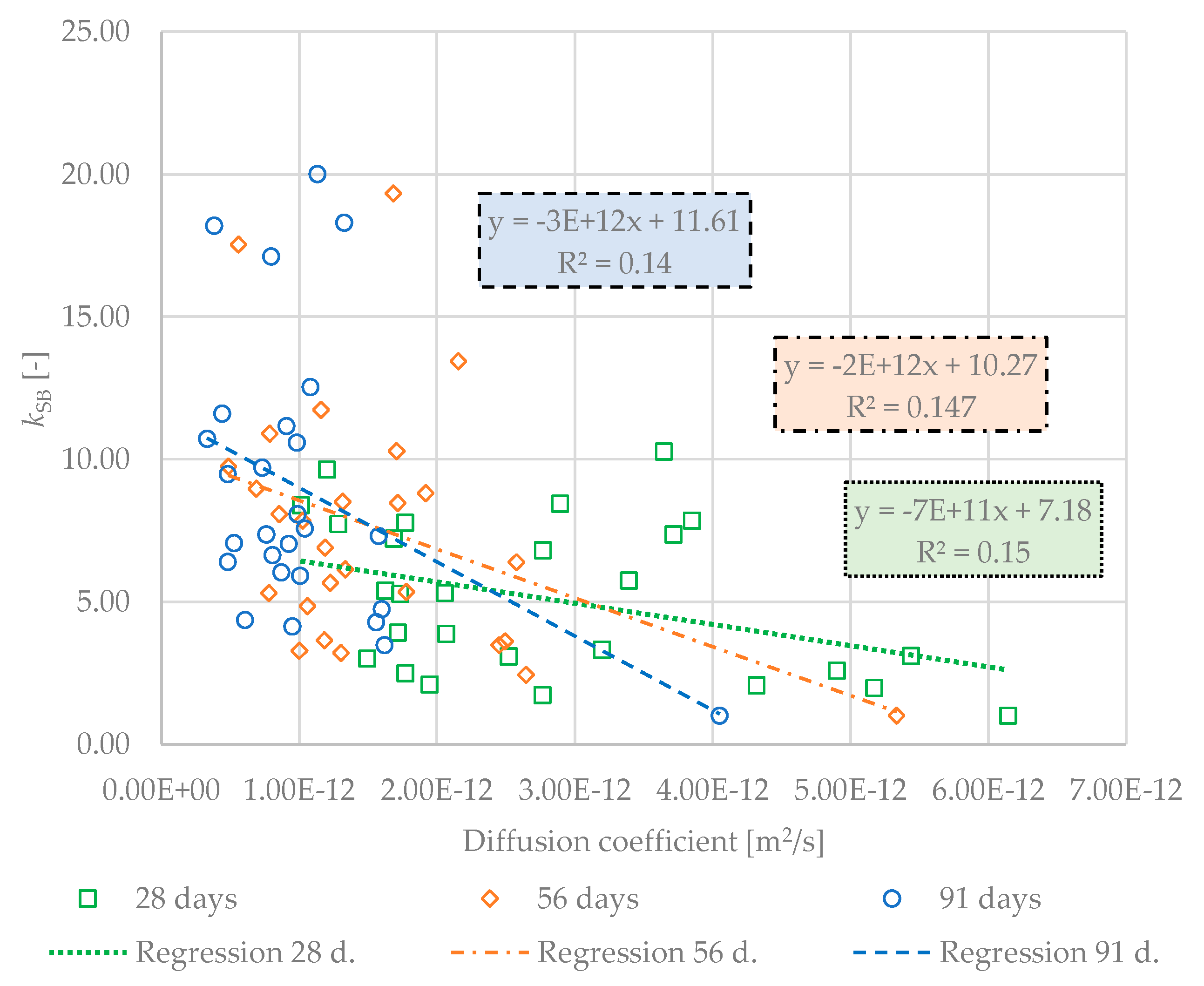

3.4. Correlation between Sustainability Indicators and Diffusion Coefficient

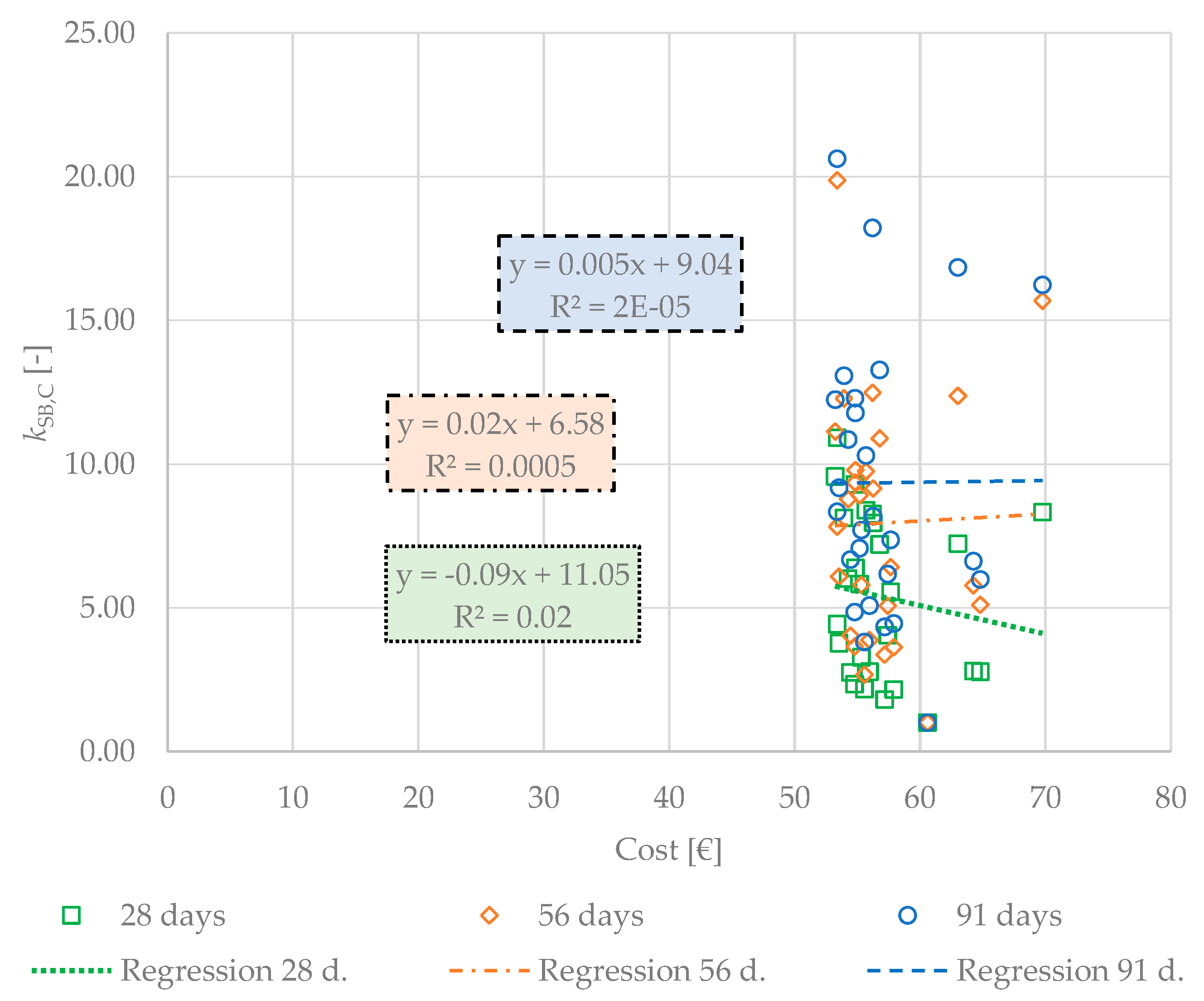

3.5. Correlation between Sustainability Indicator and Costs

4. Discussion

5. Conclusions

- The sustainability assessment of volcanic pumice concrete mixture indicated that VPP is a suitable SCM for civil engineering infrastructures, considering eco-friendly aspects. The mixture containing 65% of Portland Cement Type II–V, 10% of Silica fume, and 25% of Volcanic Pumice Pozzolan showed the best values in terms of sustainability, without considering cost.

- The highest value, considering cost, was assigned to the mixture containing 55% of Portland Cement Type II–V, 20% of Class F fly Ash, and 25% of Volcanic Pumice Pozzolan.

- The pumice mixtures significantly over performed other SCM-based mixtures on the basis of the evaluated sustainability indicator.

- The rank of the mixtures was different at different concrete maturity, but the trend was very similar.

- There was no correlation of strength and the diffusion parameter with sustainability indicators.

- The present study shows that the kSB and kSB,C sustainability indexes are suitable for quantifying the level of sustainability. Therefore, this study might help the industry to tackle sustainability issues in civil engineering in a rather simple way.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Angst, U.M. Challenges and opportunities in corrosion of steel in concrete. Mater. Struct. 2018, 51, 4. [Google Scholar] [CrossRef] [Green Version]

- Durastanti, C.; Moretti, L. Environmental Impacts of Cement Production: A Statistical Analysis. Appl. Sci. 2020, 10, 8212. [Google Scholar] [CrossRef]

- Katzer, J.; Domski, J. Quality and mechanical properties of engineered steel fibres used as reinforcement for concrete. Constr. Build. Mater. 2012, 34, 243–248. [Google Scholar] [CrossRef]

- Horňáková, M.; Lehner, P. Relationship of surface and bulk resistivity in the case of mechanically damaged fibre reinforced red ceramic waste aggregate concrete. Materials 2020, 13, 5501. [Google Scholar] [CrossRef]

- Lloyd, N.A.; Rangan, B.V. Geopolymer concrete: A review of development and opportunities. In Proceedings of the 35th Conference on Our World in Concrete and Structures, Singapore Concrete Institute, Singapore, 25–27 August 2010; pp. 25–27. [Google Scholar]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Purnell, P. Material nature versus structural nurture: The embodied carbon of fundamental structural elements. Environ. Sci. Technol. 2012, 46, 454–461. [Google Scholar] [CrossRef]

- Damineli, B.L.; Kemeid, F.M.; Aguiar, P.S.; John, V.M. Measuring the eco-efficiency of cement use. Cem. Concr. Compos. 2010, 32, 555–562. [Google Scholar] [CrossRef]

- Barker, D.J.; Turner, S.A.; Napier-Moore, P.A.; Clark, M.; Davison, J.E. CO2 Capture in the Cement Industry. Energy Procedia 2009, 1, 87–94. [Google Scholar] [CrossRef] [Green Version]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Lippiatt, N.; Ling, T.-C.; Pan, S.-Y. Towards carbon-neutral construction materials: Carbonation of cement-based materials and the future perspective. J. Build. Eng. 2020, 28, 101062. [Google Scholar] [CrossRef]

- de Brito, J.; Kurda, R. The past and future of sustainable concrete: A critical review and new strategies on cement-based materials. J. Clean. Prod. 2021, 281, 123558. [Google Scholar] [CrossRef]

- Zhao, H.; Sun, W.; Wu, X.; Gao, B. The properties of the self-compacting concrete with fly ash and ground granulated blast furnace slag mineral admixtures. J. Clean. Prod. 2015, 95, 66–74. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Zou, J.; Reid, A.; Wang, H. Toward an indexing approach to evaluate fly ashes for geopolymer manufacture. Cem. Concr. Res. 2016, 85, 163–173. [Google Scholar] [CrossRef]

- Younsi, A.; Turcry, P.; Rozière, E.; Aït-Mokhtar, A.; Loukili, A. Performance-based design and carbonation of concrete with high fly ash content. Cem. Concr. Compos. 2011, 33, 993–1000. [Google Scholar] [CrossRef] [Green Version]

- Sujjavanich, S.; Suwanvitaya, P.; Chaysuwan, D.; Heness, G. Synergistic effect of metakaolin and fly ash on properties of concrete. Constr. Build. Mater. 2017, 155, 830–837. [Google Scholar] [CrossRef]

- Ghosh, P.; Tran, Q. Correlation Between Bulk and Surface Resistivity of Concrete. Int. J. Concr. Struct. Mater. 2015, 9, 119–132. [Google Scholar] [CrossRef]

- Lehner, P.; Konečný, P.; Ponikiewski, T. Comparison of material properties of scc concrete with steel fibres related to ingress of chlorides. Crystals 2020, 10, 220. [Google Scholar] [CrossRef] [Green Version]

- Millar, S.; Wilsch, G.; Eichler, T.; Gottlieb, C.; Wiggenhauser, H. Laser Induced Breakdown Spectroscopy (LIBS) in civil engineering—Innovative analysis of building materials [Laser Induced Breakdown Spectroscopy (LIBS) im Bauwesen—Automatisierte Baustoffanalyse]. Beton-und Stahlbetonbau 2015, 110, 501–510. [Google Scholar] [CrossRef]

- Nguyen, P.T.; Bastidas-Arteaga, E.; Amiri, O.; El Soueidy, C.P. An Efficient Chloride Ingress Model for Long-Term Lifetime Assessment of Reinforced Concrete Structures Under Realistic Climate and Exposure Conditions. Int. J. Concr. Struct. Mater. 2017, 11, 199–213. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Lachemi, M. Performance of volcanic ash and pumice based blended cement concrete in mixed sulfate environment. Cem. Concr. Res. 2006, 36, 1123–1133. [Google Scholar] [CrossRef]

- Anwar Hossain, K.M. Properties of volcanic pumice based cement and lightweight concrete. Cem. Concr. Res. 2004, 34, 283–291. [Google Scholar] [CrossRef]

- Ulusu, H.; Aruntas, H.Y.; Gencel, O. Investigation on characteristics of blended cements containing pumice. Constr. Build. Mater. 2016, 118, 11–19. [Google Scholar] [CrossRef]

- Nozahic, V.; Amziane, S.; Torrent, G.; Saïdi, K.; De Baynast, H. Design of green concrete made of plant-derived aggregates and a pumice–lime binder. Cem. Concr. Compos. 2012, 34, 231–241. [Google Scholar] [CrossRef]

- Yadollahi, M.M.; Benli, A.; Demirboğa, R. The effects of silica modulus and aging on compressive strength of pumice-based geopolymer composites. Constr. Build. Mater. 2015, 94, 767–774. [Google Scholar] [CrossRef]

- Tran, Q.; Ghosh, P. Influence of pumice on mechanical properties and durability of high performance concrete. Constr. Build. Mater. 2020, 249, 118741. [Google Scholar] [CrossRef]

- Biondini, F.; Frangopol, D.M. Probabilistic limit analysis and lifetime prediction of concrete structures. Struct. Infrastruct. Eng. 2008, 4, 399–412. [Google Scholar] [CrossRef]

- Teplý, B.; Podroužek, J. Service life, reliability and their role in the life cycle analysis of concrete structures. Adv. Environ. Res. 2017, 55, 47–63. [Google Scholar]

- Kumar, R.; Gardoni, P.; Sanchez-Silva, M. Effect of cumulative seismic damage and corrosion on the life-cycle cost of reinforced concrete bridges. Earthq. Eng. Struct. Dyn. 2009. [Google Scholar] [CrossRef] [Green Version]

- Martín-Pérez, B.; Zibara, H.; Hooton, R.; Thomas, M.D. A study of the effect of chloride binding on service life predictions. Cem. Concr. Res. 2000, 30, 1215–1223. [Google Scholar] [CrossRef]

- Matthews, S. fib Model Code 2020—A new development in structural codes. Struct. Concr. 2017, 651–652. [Google Scholar] [CrossRef] [Green Version]

- Kloepffer, W. Life cycle sustainability assessment of products. Int. J. Life Cycle Assess. 2008, 13, 89–95. [Google Scholar] [CrossRef]

- Hrabova, K.; Teply, B.; Vymazal, T. Sustainability assessment of concrete mixes. IOP Conf. Ser. Earth Environ. Sci. 2020, 444, 012021. [Google Scholar] [CrossRef]

- Teplý, B.; Rovnaníková, P.; Vymazal, T. Sustainability Quantification of Concrete Structures. In Advances in Environmental Research; NOVA Science Publishers: New York, NY, USA, 2018; ISBN 978-1-53613-918-1. [Google Scholar]

- Müller, H.S. Sustainable structural concrete—From today’s approach to future challenge. Struct. Concr. 2013, 14, 299–300. [Google Scholar] [CrossRef]

- Konečný, P.; Ghosh, P.; Hrabová, K.; Lehner, P.; Teplý, B. Effective methodology of sustainability assessment of concrete mixtures. Mater. Struct. Constr. 2020, 53. [Google Scholar] [CrossRef]

- Opon, J.; Henry, M. An indicator framework for quantifying the sustainability of concrete materials from the perspectives of global sustainable development. J. Clean. Prod. 2019, 218, 718–737. [Google Scholar] [CrossRef]

- ACI Committee 318. Building Code Requirements for Structural Concrete: (ACI 318-95); and Commentary (ACI 318R-95); American Concrete Institute: Farmington Hills, MI, USA, 1995. [Google Scholar]

- Matthews, S. Fib Model Code 2020. Struct. Concr. 2019, 20, 860–866. [Google Scholar] [CrossRef]

- De Schepper, M.; Van den Heede, P.; Van Driessche, I.; De Belie, N. Life Cycle Assessment of Completely Recyclable Concrete. Materials 2014, 7, 6010–6027. [Google Scholar] [CrossRef] [Green Version]

- Chappex, T.; Scrivener, K. Alkali fixation of C-S-H in blended cement pastes and its relation to alkali silica reaction. Cem. Concr. Res. 2012. [Google Scholar] [CrossRef]

- ASTM C1202 Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. Am. Soc. Test. Mater. 2012, 1–8. [CrossRef]

- Paredes, M.; Jackson, N.M.; El Safty, A.; Dryden, J.; Joson, J.; Lerma, H.; Hersey, J. Precision Statements for the Surface Resistivity of Water Cured Concrete Cylinders in the Laboratory. Adv. Civ. Eng. Mater. 2012, 1, 1–23. [Google Scholar] [CrossRef]

- Lu, X. Application of the Nernst-Einstein equation to concrete. Cem. Concr. Res. 1997, 27, 293–302. [Google Scholar] [CrossRef]

- Eco Costs Data Design-4-Sustainability: Inspiration and Knowledge by Designers for Designers. Available online: http://www.design-4-sustainability.com/ecocosts (accessed on 1 January 2021).

- The Model of the Eco-Costs/Value Ratio (EVR). Available online: http://www.ecocostsvalue.com/ (accessed on 1 January 2021).

- Vymazal, T.; Teply, B.; Hrabova, K. The assessment and prediction of concrete sustainability. IOP Conf. Ser. Mater. Sci. Eng. 2019, 583, 012035. [Google Scholar] [CrossRef]

| Chemical [%] | Cement Type II/V | Class C Fly Ash | Class F Fly Ash | Slag G120 | Silica Fume | Metakaolin | Pumice |

|---|---|---|---|---|---|---|---|

| SiO2 | 21.20 | 34.02 | 45.05 | 36.81 | 97.90 | 51.95 | 87.40 |

| Al2O3 | 3.90 | 18.20 | 23.71 | 9.66 | 0.18 | 44.27 | 10.52 |

| Fe2O3 | 3.50 | 6.59 | 16.43 | 0.61 | 0.07 | 0.41 | 0.174 |

| MgO | 2.10 | 5.06 | 0.88 | 10.03 | 0.21 | 0.05 | 0.126 |

| CaO | 2.70 | 2.70 | 0.68 | - | 0.17 | 0.02 | - |

| Na2O + K2O | 63.10 | 27.18 | 3.78 | 36.77 | 0.42 | 0.06 | - |

| MnO | 0.54 | 1.91 | 2.26 | 0.66 | 0.71 | 0.30 | - |

| ZnO | - | - | - | - | 0.03 | - | - |

| SiO2 | - | - | - | - | 0.08 | - | - |

| SrO | - | - | - | 1.10 | - | - | - |

| Cl | - | - | - | 0.05 | - | - | - |

| Fe2O4 | - | - | - | - | 0.09 | - | 0.194 |

| Na | - | - | - | - | - | - | 0.128 |

| K | - | - | - | - | - | - | 0.099 |

| Ca | - | - | - | - | - | - | 0.090 |

| TiO2 | - | - | - | - | - | - | 0.0074 |

| SO4 | - | - | - | - | - | - | 0.0041 |

| H2O | 1.110 |

| Mix ID | Dc (28 Days) ×10−12 [m2/s] | Dc (56 Days) ×10−12 [m2/s] | Dc (91 Days) ×10−12 [m2/s] | Strength (28 Days) [MPa] | Strength (56 Days) [MPa] | Strength (91 Days) [MPa] | Eco-Costs [€/m3] | Costs [€/m3] |

|---|---|---|---|---|---|---|---|---|

| 100TII–V | 6.14 | 5.33 | 4.05 | 27.08 | 34.70 | 36.76 | 51.66 | 60.59 |

| 85TII-V/15P | 4.90 | 2.49 | 1.60 | 39.58 | 49.81 | 54.92 | 45.82 | 57.91 |

| 80TII-V/20P | 5.44 | 2.57 | 1.58 | 34.96 | 45.45 | 50.02 | 43.85 | 57.19 |

| 75TII-V/25P | 3.85 | 2.15 | 1.33 | 35.44 | 40.89 | 46.05 | 41.89 | 55.97 |

| 70TII-V/15F/15P | 4.32 | 2.45 | 1.56 | 31.60 | 32.54 | 41.16 | 43.44 | 55.57 |

| 50TII-V/35G120/15P | 2.06 | 1.33 | 0.92 | 37.43 | 41.45 | 45.82 | 40.37 | 57.65 |

| 45TII-V/35G120/20P | 2.77 | 1.71 | 1.08 | 34.92 | 39.81 | 42.89 | 38.4 | 57.42 |

| 65TII-V/15F/20P | 3.72 | 1.71 | 1.04 | 39.35 | 47.27 | 53.28 | 41.47 | 55.33 |

| 60TII-V/15F/25P | 3.39 | 1.92 | 0.98 | 28.26 | 34.63 | 41.00 | 39.51 | 54.44 |

| 60TII-V/25C/15P | 5.17 | 2.64 | 1.62 | 37.81 | 44.66 | 50.67 | 41.01 | 54.77 |

| 55TII-V/25C/20P | 3.20 | 1.78 | 0.99 | 35.16 | 46.53 | 54.44 | 39.05 | 53.55 |

| 80TII-V/5SF/15P | 2.76 | 1.30 | 0.95 | 32.31 | 41.18 | 49.21 | 43.91 | 64.81 |

| 75TII-V/5SF/20P | 2.89 | 1.31 | 0.91 | 32.39 | 44.80 | 49.37 | 41.95 | 64.25 |

| 78TII-V/7M/15P | 1.77 | 1.18 | 0.87 | 48.65 | 55.10 | 50.55 | 43.91 | 56.26 |

| 73TII-V/7M/20P | 1.77 | 1.16 | 0.80 | 48.72 | 54.63 | 55.34 | 41.94 | 55.7 |

| 68TII-V/7M/25P | 1.71 | 1.19 | 0.76 | 49.11 | 50.66 | 59.45 | 39.98 | 54.81 |

| 50TII-V/30G120S/20P | 1.95 | 1.00 | 0.61 | 44.05 | 50.50 | 52.06 | 39.18 | 56.78 |

| 45TII-V/30G120S/25P | 1.73 | 0.85 | 0.48 | 42.49 | 46.74 | 53.54 | 37.22 | 56.21 |

| 70TII-V/5SF/25P | 1.69 | 0.79 | 0.44 | 45.65 | 53.75 | 57.19 | 39.99 | 63.03 |

| 65TII-V/10M/25P | 1.62 | 1.02 | 0.73 | 45.24 | 48.99 | 53.72 | 39.16 | 53.23 |

| 65TII-V/10SF/25P | 1.20 | 0.56 | 0.38 | 41.15 | 53.04 | 52.60 | 38.08 | 69.76 |

| 65TII-V/20F/15P | 1.49 | 0.78 | 0.53 | 31.11 | 36.78 | 41.60 | 42.64 | 54.84 |

| 60TII-V/20F/20P | 1.28 | 0.69 | 0.48 | 32.00 | 38.34 | 39.77 | 40.68 | 53.95 |

| 55TII-V/20F/25P | 1.01 | 0.49 | 0.33 | 32.02 | 41.37 | 40.91 | 38.72 | 53.39 |

| 65TII-V/20C/15P | 2.07 | 1.06 | 1.01 | 38.96 | 45.04 | 47.36 | 41.97 | 55.17 |

| 60TII-V/20C/20P | 2.52 | 1.23 | 0.81 | 46.06 | 48.26 | 54.79 | 40.01 | 54.28 |

| 55TII-V/20C/25P | 3.65 | 1.68 | 1.13 | 46.12 | 55.36 | 55.36 | 38.05 | 53.39 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hrabová, K.; Lehner, P.; Ghosh, P.; Konečný, P.; Teplý, B. Sustainability Levels in Comparison with Mechanical Properties and Durability of Pumice High-Performance Concrete. Appl. Sci. 2021, 11, 4964. https://doi.org/10.3390/app11114964

Hrabová K, Lehner P, Ghosh P, Konečný P, Teplý B. Sustainability Levels in Comparison with Mechanical Properties and Durability of Pumice High-Performance Concrete. Applied Sciences. 2021; 11(11):4964. https://doi.org/10.3390/app11114964

Chicago/Turabian StyleHrabová, Kristýna, Petr Lehner, Pratanu Ghosh, Petr Konečný, and Břetislav Teplý. 2021. "Sustainability Levels in Comparison with Mechanical Properties and Durability of Pumice High-Performance Concrete" Applied Sciences 11, no. 11: 4964. https://doi.org/10.3390/app11114964

APA StyleHrabová, K., Lehner, P., Ghosh, P., Konečný, P., & Teplý, B. (2021). Sustainability Levels in Comparison with Mechanical Properties and Durability of Pumice High-Performance Concrete. Applied Sciences, 11(11), 4964. https://doi.org/10.3390/app11114964