Code Calibration of the Eurocodes

Abstract

Featured Application

Abstract

1. Introduction

1.1. Limitations

- Selection of the load factor, γL = 1.2, is selected here.

- Selection of the primary material, timber, VM = 0.2, is selected here.

- A method to set the material factors, no unsafe design cases are allowed, and the load cases including less than 20% permanent load or variable load is omitted.

1.2. Review

1.3. Weaknesses

- The load factors are dissimilar, γG ≠ γQ, i.e., the permanent load safety factor is different from the variable load safety factor, which increases the required calculation work, complicates the codes, and makes the codes prone to design errors. The basic assumptions in the partial safety factor approach are that the characteristic value of the permanent load is the mean, and the characteristic value of the variable load is the 0.98-fractile of the one-year load. These assumptions result in dissimilar load factors, γG ≠ γQ. As these assumptions have not been questioned earlier, partial safety factor codes with the same load factors have not been proposed previously.

- The characteristic load of the variable load is the same for all variable loads, which is the 0.98-fractile of the one-year distribution, regardless of the load variation, and the variable load safety factor (γQ = 1.5) is the same for all variable loads in the design of normal structures. This creates excess safety and material waste for the variable loads with low variation. The article explains that this deficiency is mainly overcome by setting the characteristic load of the variable load changeable and the function on the alterability of the variable load. It means that each variable load has its own characteristic load. As the variable load characteristic values are changeable, this feature is used to obtain another positive result, i.e., the load factors are fixed as the same.

- In the current Eurocodes, various materials fit differently with the reliability model. The design of some materials is more accurate regarding the target reliability than others. The proposed procedure allows the formulation of codes where one material can be selected to have an almost ideal fit with the target reliability and with virtually no reliability error. The timber, VM = 0.2, is selected here to be the ideal material. Other materials have higher reliability variations. This article presents two options in which the material safety factors are functions of the load proportions when all materials fit well with the reliability model.

- The current Eurocodes may include wide reliability variation regarding the target, about −20% to 20%, i.e., a variability ratio (high safety factor or reliability index regarding the low value) of about 1.4 [14,19]. The high-reliability variability is due to the fixed characteristic load of the variable load, the independent load combination and the indirect safety factor setting procedure using the reliability index as a reference. In this article, the safety factors are calculated directly without using the reliability index as a calculation aid, and the variability ratio is about 1.03–1.07.

- Current codes include several safety factors with rounding errors. This article explains a method to eliminate the rounding errors in the safety factors.

- This article proposes partial safety factor codes with the same load factors, γG = γQ. Thus, the proposed codes can be used as the design value format, i.e., as allowable stress codes, by removing the load factors and by multiplying the characteristic resistance values with the load factors.

1.4. Two Major Objectives

- The characteristic load of the variable load is fixed; it is the 0.98-fractile of the one-year distribution, which induces excess safety for loads with low variation.

- The loads are combined independently, which demands considerably different material safety factors in various permanent-variable load ratios.

- The current safety factor setting procedure induces large variability, as constraints for big errors are missing.

- The current safety factors are calculated indirectly using the reliability index as a reference, which induces extra error [18].

2. Materials and Methods

2.1. Assumptions

2.2. The Target Reliability

2.3. Permanent Load

2.4. Variable Load

2.5. Materials

2.6. Uncertainty

2.7. The Basic Equations

3. Results

3.1. The Material Factors with the Current Characteristic Values

3.2. Alternating Characteristic Load of the Variable Load

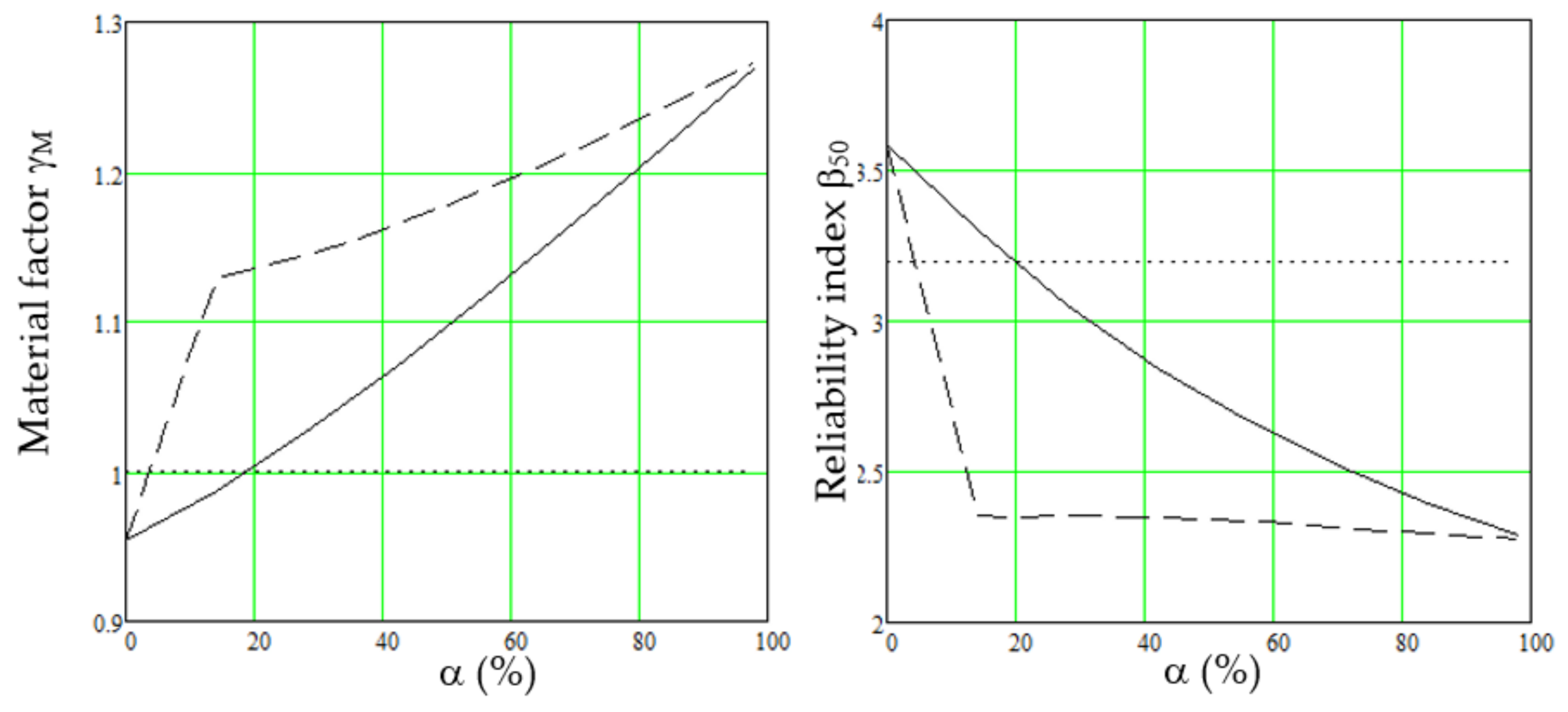

3.3. Alternating Material Safety Factors

3.3.1. Linear Concept

3.3.2. Variable Concept

3.4. Rounding Errors

4. Discussion

- The codes are simpler as the load factors are the same, γG = γQ = 1.2, and therefore there are less design errors.

- The codes result in less calculation work, less design output, and less design checking as the load factors are the same, and therefore, one structural analysis often is sufficient instead of the current two analyses in the SLS and in the ULS.

- The codes can be equally used in the partial factor design approach and in the design value approach, and the proposal enables the use of the simplest design codes, i.e., the allowable stress design method.

- The proposed codes result in material saving due to better reliability accuracy and due to less excess safety and less material in the cases of variable loads with low variation.

- The unsafe design cases are less, and therefore, failures are less.

4.1. Discussion on the Steel Reliability

- In the calculation above, the variable load distribution is assumed to be Gumbel. This distribution has a robust upper tail that makes the distribution excessively safe [21], which especially applies to steel.

- Steel failures normally are ductile, which allows the redistribution of stresses with decreased stress peaks.

4.2. Economic Evaluation

4.3. Environmental Impact

4.4. Unique Characteristics

5. Conclusions

- The target reliability index is set at β50 = 3.2 [7].

- The load factors are set as γG = γQ = 1.2.

- The characteristic values for the variable loads VQ = 0.4 are 1.32 times higher than the current ones, and for loads VQ = 0.2, they are 1.15 times higher. The current variable load table values should be multiplied by 1.15–1.32.

- The material safety factors are the same for all materials, γM = 1, and the characteristic values of the basic materials, steel, timber and concrete, are in quantiles βq = 3.30, 2.61 and 2.72, respectively, which means that the fictitious material safety factors are γM = 1.18, 1.21 and 1.37, respectively, and γG = γQ = 1.2.

- As the characteristic values are higher than the current ones, the fictitious load factors compared with the current Eurocodes are γQ = 1.38 for loads VQ = 0.2 and γQ = 1.58 for loads VQ = 0.4.

- According to this study, the current Eurocodes are about 13% and 14% over safe in timber and concrete designs for β50 = 3.2, respectively, and steel designs are about 10% unsafe.

- The proposed codes have the same load tables as the corresponding design value codes and can be used as the design value codes by setting the load factors at unity γG = γQ = 1 and by multiplying the material factors by 1.2.

- The proposed codes result in savings in structural material, especially in timber and concrete and savings in design work. The codes are simpler and result in fewer design errors, less design output and less design checking, the reliability accuracy is better, the unsafe design cases are negligible, and the environmental impact is improved.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- CEN. Draft prEN 1990:2020 Eurocode—Basis of Structural Design; CEN: Brussels, Belgium, 2020. [Google Scholar]

- CEN. EN 1992-1-1:2005, Eurocode 2. Design of Concrete Structures; CEN: Brussels, Belgium, 2005. [Google Scholar]

- CEN. EN 1993-1-1:2005, Eurocode 3. Design of Steel Structures; CEN: Brussels, Belgium, 2005. [Google Scholar]

- CEN. EN 1995-1-1:2004, Eurocode 5. Design of Timber Structures; CEN: Brussels, Belgium, 2004. [Google Scholar]

- International Organization for Standardization. ISO 8930 General Principles of Reliability of Structures; International Organization for Standardization: Geneva, Switzerland, 1987. [Google Scholar]

- International Organization for Standardization. ISO 2394, General Principles of Reliability of Structures, List of Equivalent Terms; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- JCSS. Probabilistic Model Code, Parts 1 to 4, Basis of Design, Load and Resistance. Available online: https://www.jcss-lc.org/jcss-probabilistic-model-code/ (accessed on 20 January 2021).

- Gulvanessian, H.; Calgaro, J.-A.; Holicky, M. Designer’s Guide to EN 1990, EUROCODE: Basis of Structural Design; Thomas Telford Publishing: London, UK, 2002. [Google Scholar]

- JRC. Implementation of Eurocodes, Handbook 2, Reliability Backgrounds; JRC: Prague, Czech Republic, 2005; Available online: https://eurocodes.jrc.ec.europa.eu/showpublication.php?id=63 (accessed on 20 January 2021).

- Gulvanessian, H.; Holicky, M. Eurocodes: Using reliability analysis to combine action effects. Proc. Inst. Civ. Eng. Struct. Build. 2005, 158, 243–252. [Google Scholar] [CrossRef]

- Ranta-Maunus, A.; Fonselius, M.; Kurkela, J.; Toratti, T. Reliability Analysis of Timber Structures, VTT Research Notes 2109, Espoo. 2001. Available online: https://www.vtt.fi/inf/pdf/tiedotteet/2001/T2109.pdf (accessed on 26 March 2021).

- Joint Committee on Structural Safety. Reliability-Based Code Calibration. Available online: http://www.jcss.byg.dtu.dk/codecal (accessed on 20 January 2021).

- Poutanen, T.; Pursiainen, S.; Länsivaara, T. Combination of permanent and variable load is dependent. Appl. Sci. 2021, 11, 4434. [Google Scholar] [CrossRef]

- Köhler, J.; Sørensen, J.D.; Baravalle, M. Calibration of existing semi-probabilistic design codes. In Proceedings of the 13th International Conference on Application of Statics and Probability in Civil Engineering, ICASP13, Seoul, Korea, 26–30 May 2019. [Google Scholar]

- Köhler, J.; Baravalle, M. Risk-based decision making and the calibration of the structural design codes—prospects and challenges. Civ. Eng. Environ. Syst. 2019, 36, 55–72. [Google Scholar] [CrossRef]

- Baravalle, M.; Köhler, J. A risk-based approach for calibrating of design codes. Struct. Saf. 2019, 78, 63–75. [Google Scholar] [CrossRef]

- Nadolski, V.; Rózsás, Á.; Sýkora, M. Calibrating Partial Factors—Methodology, Input Data and Case Study of Steel Structures. Period. Polytech. Civ. Eng. 2019, 63, 222–242. [Google Scholar] [CrossRef]

- Poutanen, T.; Länsivaara, T.; Pursiainen, S.; Mäkinen, J.; Asp, O. Calculation of safety factors of the Eurocodes. Appl. Sci. 2021, 11, 208. [Google Scholar] [CrossRef]

- Poutanen, T. Uusi Rakenteiden Mitoitusmenetelmä (New method for structural design). Raken. Mek. 2011, 45, 201–212. Available online: http://rmseura.tkk.fi/rmlehti/2012/nro4/RakMek_45_4_2012_2.pdf (accessed on 20 January 2021).

- Poutanen, T.; Pursiainen, S.; Mäkinen, J.; Länsivaara, T. Combination of permanent and variable loads. Raken. Mek. 2018, 51, 1–9. Available online: https://rakenteidenmekaniikka.journal.fi/article/view/65175/35889 (accessed on 20 January 2021).

- Poutanen, T. Variable Load Distribution. Second International Conference on Vulnerability and Risk Analysis and Management (ICVRAM) and the Sixth International Symposium on Uncertainty, Modeling, and Analysis (ISUMA), Liverpool, UK. 2014. Available online: https://ascelibrary.org/doi/abs/10.1061/9780784413609.100 (accessed on 6 April 2021).

| Material | VM | μM | σM | γM |

|---|---|---|---|---|

| Steel | 0.1 | 1.1841 | 0.1184 | 1.0 |

| Timber | 0.2 | 1.4125 | 0.2825 | 1.3 |

| Concrete | 0.3 | 1.6921 | 0.5076 | 1.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poutanen, T. Code Calibration of the Eurocodes. Appl. Sci. 2021, 11, 5474. https://doi.org/10.3390/app11125474

Poutanen T. Code Calibration of the Eurocodes. Applied Sciences. 2021; 11(12):5474. https://doi.org/10.3390/app11125474

Chicago/Turabian StylePoutanen, Tuomo. 2021. "Code Calibration of the Eurocodes" Applied Sciences 11, no. 12: 5474. https://doi.org/10.3390/app11125474

APA StylePoutanen, T. (2021). Code Calibration of the Eurocodes. Applied Sciences, 11(12), 5474. https://doi.org/10.3390/app11125474