Multi-Objective Optimisation of Tyre and Suspension Parameters during Cornering for Different Road Roughness Profiles

Abstract

:1. Introduction

2. Methods and Materials

2.1. Vehicle Model

2.2. Suspension Designs

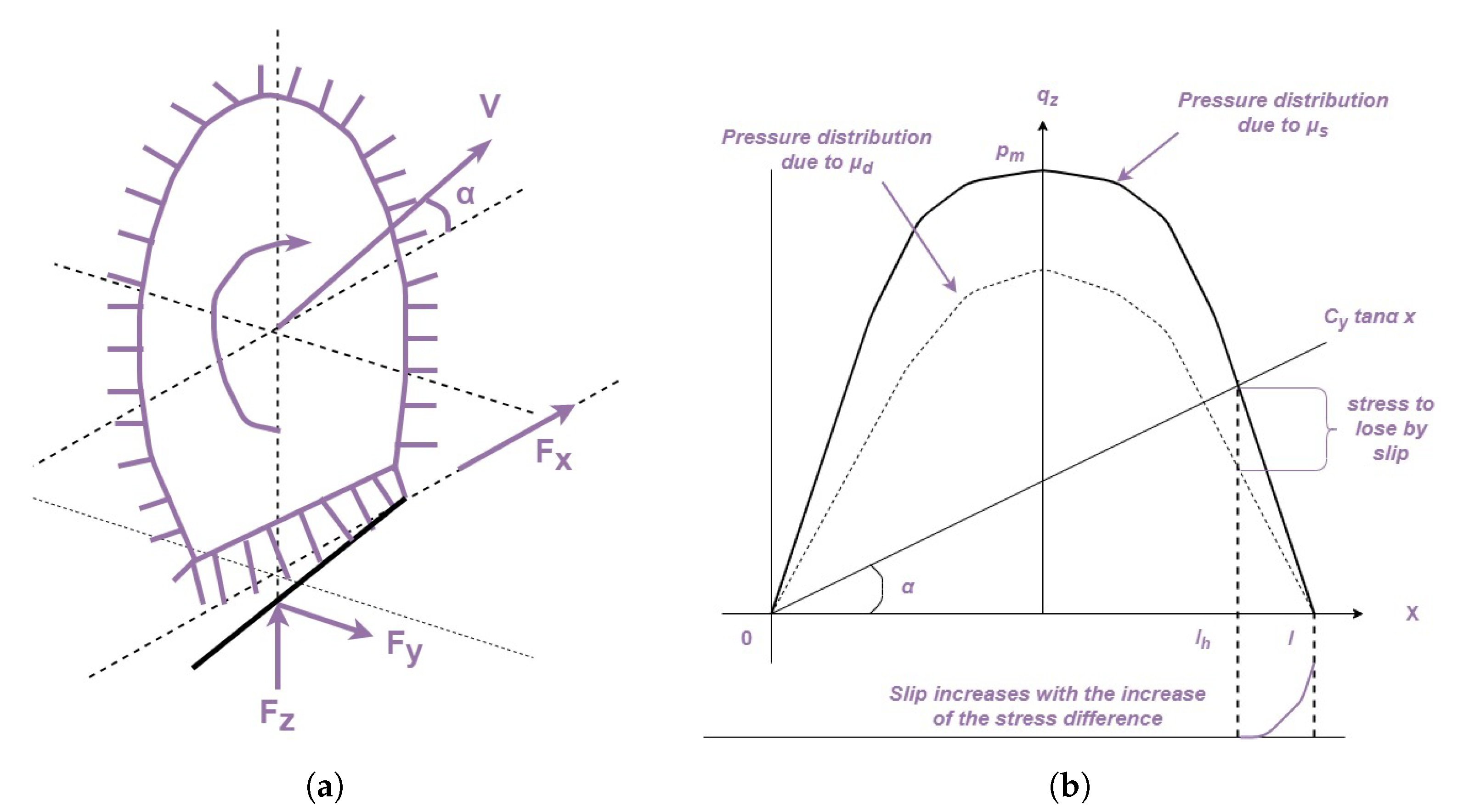

2.3. Tread Model

2.4. Vehicle Performance Assessment

2.4.1. Tyre Wear Quantity

2.4.2. Ride Comfort

2.4.3. Vehicle Handling

2.5. Road Profiles and Path

3. Validation of the Model with IPG CarMaker 8.0

- The sliding distance () is calculated according to Equation (12).

- The parameter () is calculated as follows:

- The sliding force is obtained by integrating the maximum possible frictional force distribution () over the sliding region :

- Finally, the wear energy per contact area according to Equation (26) is evaluated by multiplying the sliding force with the slipping distance () and dividing it by the contact area:

4. Optimisation Configuration

4.1. Objectives

4.2. Design Variables: Scenario 1

4.3. Design Variables: Scenario 2

5. Results

- Scenario 1 investigates the tyre optimisation in a vehicle being employed with a passive suspension and driven over an S-Path, in which road surfaces of Class A (Case 1) and B (Case 2) are assigned. The optimisation results are illustrated in Figure 8 and Figure 9, which display the Pareto fronts with regards to the objectives (Figure 8a,b) and the design variables (Figure 9a–e). Having obtained the optimal solution alternatives for the two cases, common solutions are sought between them, requiring to provide similar wear in the two cases (<8% difference) and have close design variable values (<9% difference). The common solutions identified with the above characteristics are illustrated in Figure 8 and Figure 9 alongside the alternatives, while their values are listed in Table 5. In addition, in Figure 10, the final circumferential tread profiles for the optimum designs are compared with the initial tyre design, after driving over the Class B S-Path twenty times back and forth.

- Scenario 2 explores the suspension optimisation for two road cases and various suspension types (PS, SH-2, ADD, SH-ADD-2, GH-2, PDD and SH-PDD). The optimisation results are illustrated in Figure 11, which presents the Pareto fronts of the optimum solutions for the two cases. For each suspension type, a common solution is identified among the optimal alternatives provided by the two optimisation cases, requiring them to have close design variables values (<3–15% difference according to the cases). Finally, the values of the identified common solutions are presented in Table 6 alongside with the threshold of difference that was allowed.

5.1. Optimum Tyre Design Solutions

Optimisation Results

5.2. Optimum Suspension Design

6. Conclusions

- Comfort illustrates the same conflicting relation with wear as with vehicle stability. This means that the increase of the suspension travel, hence degradation of handling, leads to an increase in wear but to an improvement in comfort.

- Wear could increase up to 21% in different road profiles, while the appropriate tyre design could provide only 2% increase if the road roughness changes from Class A to B. The appropriate tyre design could be extracted using the optimisation method proposed in the current work.

- For the same tyre design, two pressures could optimally combine comfort, wear and stability in two road roughness cases but also maintain wear at the same levels in these two cases. The recursive feasibility of this outcome should be tested, but it is an interesting remark for the current case study.

- Regarding suspension types, according to the results, the type and their control algorithm should be selected with regards to tyre wear damage. In the current case study, SH-2 and SH-ADD-2 seemed to be able to provide the best wear performance. After the selection of the control algorithm, the tuning of the suspension parameters, i.e., stiffness and damping coefficient, should take place mainly with regards to comfort and vehicle handling. This is because according to the results it seems that different configurations do not affect wear to a great extent.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Sambito, M.; Severino, A.; Freni, G.; Neduzha, L. A systematic review of the hydrological, environmental and durability performance of permeable pavement systems. Sustainability 2021, 13, 4509. [Google Scholar] [CrossRef]

- Jan Kole, P.; Löhr, A.J.; Van Belleghem, F.G.; Ragas, A.M. Wear and tear of tyres: A stealthy source of microplastics in the environment. Int. J. Environ. Res. Public Health 2017, 14, 1265. [Google Scholar] [CrossRef]

- Grigoratos, T.; Gustafsson, M.; Eriksson, O.; Martini, G. Experimental investigation of tread wear and particle emission from tyres with different treadwear marking. Atmos. Environ. 2018, 182, 200–212. [Google Scholar] [CrossRef]

- Wik, A.; Dave, G. Occurrence and effects of tire wear particles in the environment—A critical review and an initial risk assessment. Environ. Pollut. 2009, 157, 1–11. [Google Scholar] [CrossRef]

- Webster, B. Tyres of electric cars add to air pollution, experts warn. The Times. 7 December 2020. Available online: https://www.thetimes.co.uk/article/electric-car-tyres-are-growing-source-of-air-pollution-28276fmdp#:~:text=Electric%20cars%20with%20heavy%20batteries,road%20surface%2C%20experts%20have%20recommended (accessed on 25 June 2021).

- Fuller, G. Pollutionwatch: How smart braking could help cut electric car emissions. The Guardian. 29 January 2021. Available online: https://www.theguardian.com/environment/2021/jan/29/pollutionwatch-how-smart-braking-could-help-cut-electric-car-emissions (accessed on 25 June 2021).

- Knisley, S. A correlation between rolling tire contact friction energy and indoor tread wear. Tire Sci. Technol. TSTCA 2002, 30, 83–99. [Google Scholar] [CrossRef]

- Huang, H.; Chiu, Y.; Wang, C.; Jin, X. Three-dimensional global pattern prediction for tyre tread wear. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2015, 229, 197–213. [Google Scholar] [CrossRef]

- Nakajima, Y. Advanced Tire Mechanics; Springer: Singapore, 2019; pp. 1–1265. [Google Scholar] [CrossRef]

- Maître, O.L.; Süssner, M.; Zarak, C. Evaluation of Tire Wear Performance; SAE Technical Papers; SAE International: Warrendale, PA, USA, 1998. [Google Scholar] [CrossRef]

- Ma, B.; Xu, H.g.; Chen, Y.; Lin, M.y. Evaluating the tire wear quantity and differences based on vehicle and road coupling method. Adv. Mech. Eng. 2017, 9, 168781401770006. [Google Scholar] [CrossRef] [Green Version]

- da Silva, M.M.; Cunha, R.H.; Neto, A.C. A simplified model for evaluating tire wear during conceptual design. Int. J. Automot. Technol. 2012, 13, 915–922. [Google Scholar] [CrossRef]

- Sueoka, A.; Ryu, T.; Kondou, T.; Togashi, M.; Fujimoto, T. Polygonal Wear of Automobile Tire. JSME Int. J. Ser. C 1997, 40, 209–217. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Zuo, S.; Lei, L.; Yang, X.; Wu, X. Analysis of impact factors of tire wear. J. Vib. Control 2011, 18, 833–840. [Google Scholar] [CrossRef]

- Stalnaker, D.; Turner, J.; Parekh, D.; Whittle, B.; Norton, R. Indoor Simulation of Tire Wear: Some Case Studies. Tire Sci. Technol. TSTCA 1996, 24, 94–118. [Google Scholar] [CrossRef]

- Knuth, E.F.; Stalnaker, D.O.; Turner, J.L. Advances in Indoor Tire Tread Wear Simulation; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2006. [Google Scholar] [CrossRef]

- Lupker, H.; Cheli, F.; Braghin, F.; Gelosa, E.; Keckman, A. Numerical prediction of car tire wear. Tire Sci. Technol. TSTCA 2004, 32, 164–186. [Google Scholar] [CrossRef]

- Braghin, F.; Cheli, F.; Melzi, S.; Resta, F. Tyre wear model: Validation and sensitivity analysis. Meccanica 2006, 41, 143–156. [Google Scholar] [CrossRef]

- Farroni, F.; Sakhnevych, A.; Timpone, F. Physical modelling of tire wear for the analysis of the influence of thermal and frictional effects on vehicle performance. Proc. Inst. Mech. Eng. Part J. Mater. Des. Appl. 2017, 231, 151–161. [Google Scholar] [CrossRef]

- Emami, A.; Khaleghian, S.; Bezek, T.; Taheri, S. Design and development of a new portable test setup to study friction and wear. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 234, 730–742. [Google Scholar] [CrossRef]

- Lepine, J.; Na, X.; Cebon, D. An Empirical Tire-Wear Model for Heavy-Goods Vehicles. Tire Sci. Technol. 2021, 49. [Google Scholar] [CrossRef]

- Yamazaki, S.; Fujikawa, T.; Hasegawa, A.; Ogasawara, S. Indoor Test Procedures for Evaluation of Tire Treadwear and Influence of Suspension Alignment. Tire Sci. Technol. 1989, 17, 236–273. [Google Scholar] [CrossRef]

- Tandy, D.F.; Pascarella, R.J.; Neal, J.W.; Baldwin, J.M.; Rehkopf, J.D. Effect of Tire Wear on Tire Force and Moment Characteristics. Tire Sci. Technol. 2010, 38, 47–79. [Google Scholar] [CrossRef]

- Tamada, R.; Shiraishi, M. Prediction of Uneven Tire Wear Using Wear Progress Simulation. Tire Sci. Technol. 2017, 45, 87–100. [Google Scholar] [CrossRef]

- Koishi, M.; Shida, Z. Multi-Objective Design Problem of Tire Wear and Visualization of Its Pareto Solutions. Tire Sci. Technol. 2006, 34, 170–194. [Google Scholar] [CrossRef]

- Serafinska, A.; Kaliske, M.; Zopf, C.; Graf, W. A multi-objective optimization approach with consideration of fuzzy variables applied to structural tire design. Comput. Struct. 2013, 116, 7–19. [Google Scholar] [CrossRef]

- Papaioannou, G.; Koulocheris, D. An approach for minimizing the number of objective functions in the optimization of vehicle suspension systems. J. Sound Vib. 2018, 435, 149–169. [Google Scholar] [CrossRef]

- Papaioannou, G.; Koulocheris, D. Multi-objective optimization of semi-active suspensions using KEMOGA algorithm. Eng. Sci. Technol. Int. J. 2019, 22, 1035–1046. [Google Scholar] [CrossRef]

- Anderson, J.R.; McPillan, E. Simulation of the Wear and Handling Performance Trade-off by Using Multi-objective Optimization and TameTire. Tire Sci. Technol. 2016, 44, 280–290. [Google Scholar] [CrossRef]

- Karnopp, D.; Crosby, M.J.; Harwood, R.A. Vibration control using semi-active force generators. J. Manuf. Sci. Eng. Trans. 1974, 96, 619–626. [Google Scholar] [CrossRef]

- Savaresi, S.M.; Silani, E.; Bittanti, S. Acceleration-Driven-Damper (ADD): An Optimal Control Algorithm For Comfort-Oriented Semiactive Suspensions. J. Dyn. Syst. Meas. Control 2005, 127, 218. [Google Scholar] [CrossRef]

- Savaresi, S.M.; Spelta, C. A Single-Sensor Control Strategy for Semi-Active Suspensions. IEEE Trans. Control Syst. Technol. 2009, 17, 143–152. [Google Scholar] [CrossRef]

- Morselli, R.; Zanasi, R. Control of port Hamiltonian systems by dissipative devices and its application to improve the semi-active suspension behaviour. Mechatronics 2008, 18. [Google Scholar] [CrossRef]

- Liu, Y.; Zuo, L. Mixed Skyhook and Power-Driven-Damper: A New Low-Jerk Semi-Active Suspension Control Based on Power Flow Analysis. J. Dyn. Syst. Meas. Control 2016, 138, 081009. [Google Scholar] [CrossRef]

- Valasek, M.; Kortum, W.; Sika, Z.; Magdolen, L.; Vaculín, O. Development of semi-active road-friendly truck suspensions. Control Eng. Pract. 1998, 6, 735–744. [Google Scholar] [CrossRef]

- Li, Y.; Zuo, S.; Duan, X.; Guo, X.; Jiang, C. Theory analysis of the steady-state surface temperature on rolling tire. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 226, 1278–1289. [Google Scholar] [CrossRef]

- ISO2631. Mechanical Vibration and Shock-Evaluation of Human Exposure to Whole-Body Vibration—Part 1: General Requirements; ISO 2631-1:1997; Technical Report; ISO: Geneva, Switzerland, 1997. [Google Scholar]

- ISO8608. Mechanical Vibration-Road Surface Profiles-Reporting of Measured Data; Technical Report; ISO: Geneva, Switzerland, 1995. [Google Scholar]

| Masses [kg] | Springs [N/m] | Dampers [Nm/s] | ||||||

|---|---|---|---|---|---|---|---|---|

| = | 1301/4 | = | 25000 | = | 2500 | |||

| = | 43 | = | 0.80 | = | 2508 | |||

| = | Equation (6) | = | 367240 | = | 508 | |||

| Case | Description | Control Law a |

|---|---|---|

| 1 | SH-2 | |

| 3 | ADD | |

| 4 | SH-ADD-2 b | |

| 5 | GH-2 | |

| 6 | PDD | |

| 7 | SH-PDD |

| Wear and Tread Model Parameters | ||||

|---|---|---|---|---|

| [KPa] | [m] | [m] | [m] | [m] |

| 250 | 0.1950 | 0.3175 | 0.1660 | 0.1550 |

| Scenario 1 | Scenario 2 | ||||

|---|---|---|---|---|---|

| Design Variable | Bounds | Design Variable | Bounds | ||

| P[KPa] | 150 | 350 | [N/m] | 15,000 | 60,000 |

| c[m] | 0.14 | 0.22 | [Ns/m] | 500 | 5000 |

| d[m] | 0.27 | 0.35 | [Ns/m] | 500 | 2500 |

| [m] | 0.12 | 0.19 | [Ns/m] | 2500 | 5000 |

| [m] | 0.12 | 0.20 | [rad/s] a | 10 | 60 |

| Solution | Optimum Design Variables | ||||

|---|---|---|---|---|---|

| P[KPa] | c[m] | d[m] | [m] | [m] | |

| 1 | 252 | 0.1889 | 0.2728 | 0.1215 | 0.1420 |

| 2 | 192 | 0.1883 | 0.2746 | 0.1206 | 0.1441 |

| Solution | Optimum Design Variables | ||||

|---|---|---|---|---|---|

| [N/m] | [Nm/s] | [Nm/s] | [rad/sec] | Threshold () | |

| PS | 16,042 | 3675 | - | - | 6.0% |

| SH-2 | 43,181 | 2275 | 4394 | - | 9.5% |

| GH-2 | 16,160 | 2415 | 3327 | - | 3.0% |

| ADD | 41,406 | 2452 | 4530 | - | 5.0% |

| PDD | 15,534 | 1442 | 4045 | - | 5.0% |

| SH-PDD | 42,281 | 2416 | 4749 | - | 5.0% |

| SH-ADD2 | 17,246 | 684 | 3515 | 23.5 | 15.0% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papaioannou, G.; Jerrelind, J.; Drugge, L. Multi-Objective Optimisation of Tyre and Suspension Parameters during Cornering for Different Road Roughness Profiles. Appl. Sci. 2021, 11, 5934. https://doi.org/10.3390/app11135934

Papaioannou G, Jerrelind J, Drugge L. Multi-Objective Optimisation of Tyre and Suspension Parameters during Cornering for Different Road Roughness Profiles. Applied Sciences. 2021; 11(13):5934. https://doi.org/10.3390/app11135934

Chicago/Turabian StylePapaioannou, Georgios, Jenny Jerrelind, and Lars Drugge. 2021. "Multi-Objective Optimisation of Tyre and Suspension Parameters during Cornering for Different Road Roughness Profiles" Applied Sciences 11, no. 13: 5934. https://doi.org/10.3390/app11135934

APA StylePapaioannou, G., Jerrelind, J., & Drugge, L. (2021). Multi-Objective Optimisation of Tyre and Suspension Parameters during Cornering for Different Road Roughness Profiles. Applied Sciences, 11(13), 5934. https://doi.org/10.3390/app11135934