1. Introduction

Integration of thermal energy storage in ventilation systems can be advantageous to decrease system-associated costs, including capital and operational, and contribute to peak power savings [

1,

2]. Latent Thermal Energy Storage (LTES) is a favorable solution due to the large storage capacity of Phase Change Materials (PCM) and its low volume. The major obstacle associated with the LTES is the low thermal conductivity of the Phase Change Materials [

3]. This results in a low charging/discharging power, requiring enhancement in heat transfer mechanisms [

4]. The thermal performance of such a system is intensified even further in cases where air is used as the heat transfer fluid (HTF) [

5].

The thermal performance of LTES systems working with air was addressed in some research [

6,

7,

8,

9,

10]. Dolado et al. [

6], working on a real scale air–PCM heat exchanger, pointed out that the bottleneck of the heat transfer, particularly at low air flow rates, could be due to the high resistance on the air side. The analysis showed that the system performance was improved by increasing the flow rate of air or decreasing the air channel thickness; however, at the cost of having a higher fan energy consumption.

Vakilaltojjar and Saman [

7] analyzed a plate encapsulating PCM system working with air and reported that the thermal performance could be improved by decreasing the dimensions of the air channels and the PCM slabs.

Marin et al. [

8] investigated an LTES system, enhanced with graphite, and concluded that in cases with the PCM–graphite composite, as the storage medium, the thermal performance of the LTES was controlled by the resistance on the air side, due to the reduced resistance of the storage medium. On the other hand, in cases where pure PCM was employed, the resistances on the PCM and the airside were competitive.

Herbinger et al. [

10] performed a parametric study of an air–PCM heat exchanger for ventilation systems, considering square channels of 2 × 2 cm

2, 4 × 4 cm

2 and 6 × 6 cm

2. They found that as the channel dimension decreased, the charging/discharging power increased, and the best thermal performance was achieved for the smallest channels. However, in the study, the influence of reducing the hydraulic diameter of the channels and subsequently the increase in the heat transfer coefficient of air and its effect on the thermal performance was lacking.

The hydraulic diameter (

) of the flow passages can be reduced significantly by using mini- and micro-channels. Mini/micro-channels proved to be significantly beneficial in various industries and applications such as the refrigeration/heat pump industry and electronics cooling [

11,

12,

13,

14]. Kandlikar et al. [

11] classified the passages based on the dimensions of the hydraulic diameter (

) to conventional channels for

> 3 mm, mini-channels for 0.2 mm <

< 3 mm and micro-channels for 0.01 mm <

< 0.2 mm. Kandlikar et al. [

11] showed that the fluid heat transfer coefficients for circular passages are inversely proportional to the hydraulic diameter, given a fixed flow rate. However, the increase in heat transfer coefficient is achieved at a considerable cost of an increase in the pressure drop. Besides the hydraulic diameter, with rectangular channels, the aspect ratio of the channels as a fraction of the width to the height can influence the heat transfer coefficient. Wibulawas [

15], in a study on laminar flow in heat transfer in non-circular ducts, showed that, given a constant Graetz number (Gz =

), the Nusselt number either under constant heat flux or constant wall temperature conditions increases with the increase in the aspect ratios of the channels.

Rectangular mini-channels with low hydraulic diameters and high area-to-volume ratios have the potential to enhance the heat transfer on both the air and PCM sides with having relatively high PCM packing factors (PF). This is particularly beneficial in LTES applications related to air as the HTF, where there are needs for enhancement due to low thermal conductivities of air and PCMs.

Mini/micro-channels can be fabricated conventionally using extrusion or Additive Manufacturing (AM) processes [

16,

17,

18,

19,

20]. However, an extrusion process is associated with certain limitations and restrictions in producing complex features. Additive Manufacturing (AM), known as 3D printing, is an alternative new fabrication method capable of manufacturing complex geometric features, including the embedding of internal/external thermal enhancers and bypassing many limitations associated with conventional methods. However, 3D printing is also associated with certain disadvantages such as higher surface roughness, limited options in printing materials, and higher cost per part in mass productions, as compared to the conventional methods [

21].

This paper numerically investigates the novel idea of incorporating mini-channel profiles into LTES components with dry air as the HTF. Three-dimensional simulations of transient phase change were performed using ANSYS Fluent 19.5. An enthalpy–porosity method is used in this commercial software for solid–liquid phase change simulations. In this method, the mushy zone at which the phase change is happening is dealt with as a porous structure, and the liquid flow in this zone is treated as a liquid flow through a porous structure [

22,

23].

Two types of mini-channels were studied. The first channel is an existing extruded aluminum profile and the second channel, with and without external fins, is a conceptual design capable of being manufactured via 3D printing. The mini-channels have relatively similar volumes but different internal hydraulic diameters ( = 1.6 and = 2.3) and aspect ratios ( = 0.86 and = 20). The compact LTESs are modeled three-dimensionally for a laminar air flow regime. The thermal performance of the LTES in charging/discharging with varying number of channels and ranging flow rates was analyzed and evaluated.

3. Results and Discussion

The symmetrical simulated domains of channel-1 and un-finned channel-2, with the ranging number of channels of 60–100 and 72–96, respectively, have different dimensions in width and height. Thus, to have a fair performance assessment of the two channels, the evaluation is made for cases with possibly similar PCM packing factors (PF). The melt fraction contours for the configurations of channel-1 with PF = 82.4% and the bare and finned configurations of channel-2 with PF = 82% and PF = 80.2%, respectively, are shown in

Figure 6 and

Figure 7. A comparison of melting and solidification processes shows that in both processes, the growing phase change structure is rather symmetric. This indicates the weak presence of the natural convection in melting and the dominancy of conduction in both melting and solidification.

The phase change progress for the bare channels is more dominant on the sides of the mini-channels and weaker on the tips. The simulated domain for channel-1 is thinner in width and longer in height than that of channel-2. This results in a rapid phase change progress on the side walls of the former, while the phase change of the PCM around the tips of the channel takes a longer time. In the case of channel-2, a rapid phase change occurs around the tips, given the considerably smaller distance between the tips (3 mm). As the phase change completes around the tips, it progresses afterward on the side walls. In the case of finned channel-2, the fins contribute primarily to the phase change of PCM between the fins as it takes a longer time for the phase change of the PCM around the corners of the domain. The major mechanism at which the fins contribute to the phase change is conduction, given the small 5.3 mm distance between fins.

In all the cases, the phase change process evolves axially. As the phase change gets completed at the inlet of the channels, the phase change front develops in the length of the channels, showing a significant axial variation in the HTF temperature.

Figure 8 shows the transient outlet air temperature of the minimum and maximum simulated flow rates within the phase change time for the configurations of channel-1 (PF = 82.4%) and for the bare and finned configurations of channel-2 (PF = 82% and PF = 80.2%). As observed, the outlet temperature increases in melting and decreases in solidification steeply at the beginning of the phase change process due to the sensible heat transfer prior to the initiation of phase change along the channel length. As the PCM at the outlet reaches the onset temperature of the phase change and the entire PCM axially adjacent to the channel wall undergoes the phase change process, the outlet temperature varies less steeply, approaching the inlet temperature at the end of the process. The rather large temperature difference between the outlet and inlet for both melting (Tin = 30 °C) and solidification (Tin = 15 °C) indicates the significant axial HTF temperature variations. The axial air temperature change diminishes as the PCM approaches the complete phase change. This could be observed for both the lower and upper bounds of the investigated flow rate range; however, the temperature difference is significantly larger for the former. The outlet air temperature for channel-1 (PF = 82.4%) and the bare channel-2 (PF = 82%) is rather similar throughout the phase change processes, resulting in similar phase change times. The incorporation of fins results in a lower and higher outlet temperature in melting and solidification, respectively, as compared to the other configurations, and a modest reduction in the phase change time. In the finned configuration (PF = 80.2%), with the minimum total air flow rate of 7 L/s, the phase change time in melting and solidification, respectively, has decreased by 16% and 10%, as compared to the bare channel-2 configuration. On the contrary, the influence of increasing the air flow rate is rather considerable for all the shown cases. For a packing factor range of 86.8% to 77.4%, varying the air flow rate from 7 to 24 L/s reduces the melting and solidification time by 41% to 53% and 39% to 53%, respectively.

The effect of air flow rate increase on the transient power during phase change as a function of relative accumulated energy is shown in

Figure 9. At the minimum air flow rate, the transient power is rather similar for the shown cases of channel-1 and channel-2, and the gain in the finned channel-2 is insignificant. Increasing the flow rate to the upper bound of 24 L/s increases the transient power considerably, indicating the resistance on the air side is not negligible. However, the enhancement effect of the increased air flow rate is accompanied by a significant increase in the pressure drop. A comparison of the channels at the maximum flow rate shows that the channel-1 case gives a slightly higher transient power up to about 70% of the relative stored/extracted energy, as compared to the channel-2 case. For the rest of the process, the channel-2 case has a higher power. The rapid reduction in the power of channel-1 at the end of the processes is attributed to the completion of the phase change adjacent to the side walls and the relatively weaker heat transfer around the tips of channel-1. In the case of channel-2, the phase change is ongoing adjacent to the side walls throughout the entire process. The finned channel-2 case shows a higher rate of heat transfer in both melting and solidification processes than the bare channel-2, despite having a lower mass of PCM with about 1.8% lower packing factor.

To be able to evaluate and compare the designs with a varying number of channels and packing factors, normalized mean power (represented by the mean UA-value) as an indicator of the thermal performance was used in the following. The mean UA-values are calculated based on 98% completion of the phase change.

Figure 10 shows the dependency of UA values as a function of the PCM packing factor for the total range of the simulated air flow rate. The reduction in the packing factor indicates the increase in the number of channels as the vertical data points for a given packing factor designates the variation in the air flow rate.

Figure 10 shows that as the PCM packing factor reduces, the mean UA value increases for all the simulated configurations in both melting and solidification processes.

For a constant air flow rate, the increase in the number of channels increases the mean power of phase change. As the number of channels is increased or fins are used (in the case of channel-2), the PCM packing factor reduces, resulting in a reduction in the latent storage capacity. Given a constant total flow rate of the HTF entering the cuboid, the increase in the number of channels reduces the flow rate per channel, resulting in a reduction in the heat transfer coefficient on the air side. However, the effect of the extended heat transfer surface as the number of channels increases is dominant over the reduction in the internal heat transfer coefficient, eventually increasing the total UA value and improving the thermal performance.

Increasing the flow rate improves the normalized mean power for all the cases, particularly for the enhanced case of finned channel-2. For instance, for the configurations of channel-1 with PF = 82.4%, channel-2 with PF = 82% and finned channel-2 with PF = 80.2%, increasing the total flow rate of the HTF from 7 L/s to 24 L/s increases the mean UA values of melting by 30%, 35% and 44%, respectively.

The interesting point is that adding fins to the cases of channel-2 instead of increasing the number of channels can result in higher mean UA values, attributed to the higher air flow per channel in the former case. As an example, given the flow rate range of 7–24 L/s, adding fins to the case with 72 channels (PF = 83%) increases the UA mean value of melting by 21–31%, as compared to the un-finned case with 72 channels (PF = 84.6%). Whereas increasing the number of un-finned channels from 72 (PF = 84.6%) to 84 (PF = 80.2%) enhances the mean UA value of melting by 13–24%. In total, the relative enhancements in the mean UA values of the finned channel-2 cases, as compared to the un-finned cases, lie within 15–31% for the entire range of simulated flow rates and packing factors.

The difference in the air heat transfer coefficient of the two channels has an insignificant effect on their thermal performance within the phase change.

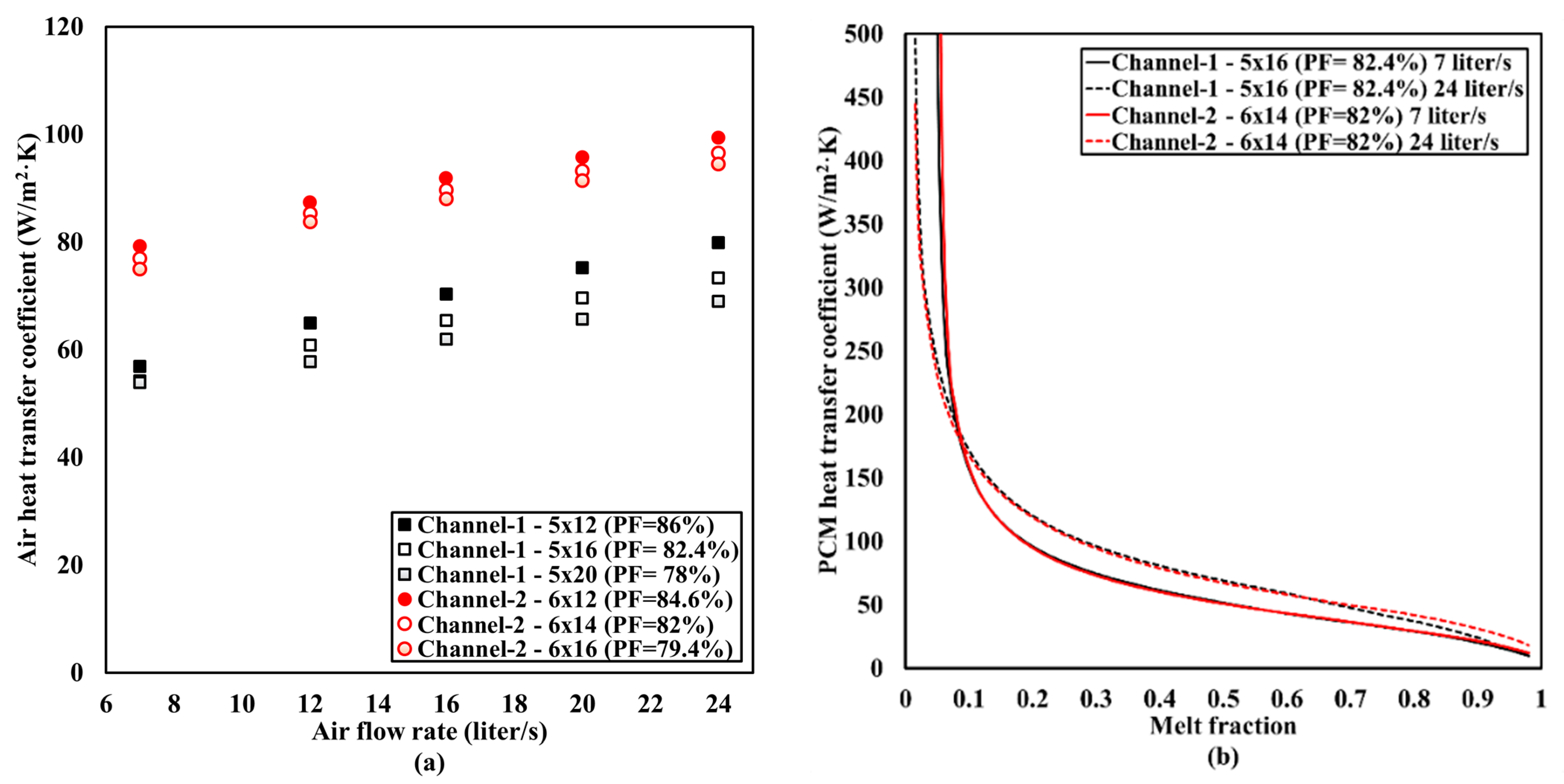

Figure 11a shows the air heat transfer coefficients of channel-1 and bare channel-2 averaged over melting as functions of the total air flow rate. Channel-2 has a modestly higher heat transfer coefficient on the air side within the simulated air flow rate, despite its higher hydraulic diameter as compared to channel-1. This is due to the higher aspect ratio of the flow passage. Even though there is a considerable distinction in the air heat transfer coefficient between channel-1 and channel-2, as shown in

Figure 11a, the heat transfer coefficient on the PCM side remains unaffected.

Figure 11b shows the heat transfer coefficient on the PCM side for channel-1 and channel-2 cases with PF = 82.4% and PF = 82%, respectively, for flow rates of 7 and 24 L/s as functions of melt fraction in the melting process. The PCM heat transfer values drop quickly from the high values at the beginning of the process to levels below the heat transfer coefficients of air, shifting the thermal resistance from the air side to the PCM side.

As observed, the PCM heat transfer coefficients of channel-1 and channel-2 relatively overlap throughout the process. A clear distinction is seen from the lower bound of the air flow rate to the upper bound, implying the PCM heat transfer coefficient could be a function of the internal air flow rate.

The major disadvantage of extending the surface area and UA value through fin incorporation rather than increasing the number of channels is the higher flow rate per channel in the former, given a fixed total flow rate, unfavorably resulting in a higher pressure drop.

Figure 12 shows the pressure drop for channel-1 and channel-2 configurations. As seen, with high packing factors and a lower number of channels, the air flow entering each channel increases. In the cases with high packing factors, as the total flow rate increases, the pressure drop increases significantly while the internal air heat transfer coefficient increases modestly. Increasing the number of channels reduces the pressure drop considerably, particularly at high total air flow rates. As an example, at the flow rate of 24 L/s, the pressure drop for channel-1 reduces by 31% and 47% as the number of channels increases from 60 to 80 and 100, and for channel-2 it reduces by 17% and 30% as the number of channels increases from 72 to 84 and 96, respectively. Interesting to point out is the relatively lower pressure drop of channel-2 than channel-1. This is credited mainly to the higher hydraulic diameter of channel-2.

Having a low pressure drop and, consequently, a low fan power as possible is a crucial matter in employing mini-channels in LTES components. This contributes to achieving a higher gain in terms of charging/discharging thermal energy in exchange for fan power. The performance evaluation criterion (PEC) of the compact component defined as the ratio of the mean phase change power to the fan work (Equation (15)) is shown in

Figure 13 for the simulated configurations as a function of the total air flow rate. Considering the increase in the total air flow rate, the PEC for both melting and solidification reduces dramatically, indicating a more significant increase in the pressure drop compared to the modest gain in the mean phase change power. The same trend is observed as the number of channels reduces and the packing factor increases. Given a constant total flow rate, channel-2 is superior to channel-1 due to both the relatively higher mean phase change power and the considerably lower pressure drop. In addition, in the case of finned channel-2, fins were able to increase the PEC modestly. Since the pressure drops in the finned channel-2 cases are the same as the un-finned channel-2 cases, the gain in the PEC comes from the modest increase in the mean phase change power.

4. Conclusions

This incorporation of rectangular mini-channels with internal air passages into an LTES component was studied, considering two types of configurations. Three-dimensional phase change simulations of RT22 in a cuboid of 0.15 × 0.15 × 0.1 m3, with vertically oriented channels, were carried out. The channels have different hydraulic diameters and aspect ratios of the internal flow passages while having almost similar volume and external heat transfer surfaces. In channel-2, fins were also investigated to enhance thermal performance.

The simulation results show that the thermal performance of the system is enhanced as the number of channels increases in both the channel-1 and channel-2 cases. The mean UA value increases as the number of channels increases and the PCM packing factor decreases. The enhancement is majorly attributed to the increase in the external surface area with a higher number of channels, while the air flow rate per channel decreases given a constant total air flow rate entering the cuboid.

Increasing the flow rate improves the mean UA value in both melting and solidification. For instance, for channel-1 with PF = 82.4%, channel-2 with PF = 82% and finned channel-2 with PF = 80.2%, the mean UA value of melting increases by 30%, 35% and 44% as the total flow rate of the HTF increases from 7 L/s to 24 L/s, respectively.

The comparison of channel-1 and channel-2 with similar packing factors shows that the difference in the air heat transfer coefficient has an insignificant effect on the mean phase change powers and the mean UA values. For instance, the air heat transfer coefficients of channel-2 with PF = 82.0% are about 30–40% higher than those of channel-1 with PF = 82.4%, for the simulated total flow rate of 7–24 L/s. However, the enhancement in the mean UA values of the former lies within 1–5%, as compared to the latter, credited to its minor higher external surface area. Adding fins to the channel-2 cases, doubling the heat transfer area on the PCM side, can increase the mean UA values by 15–31% for the entire ranges of simulated flow rates and packing factors.

Another benefit with channel-2 is the considerably lower pressure drop as compared to channel-1. This is due to its higher hydraulic diameter, particularly with high total flow rates and high packing factors. Given a constant flow rate, the channel-2 configurations have higher PEC than the channel-1 configurations, achieving a higher gain in stored/extracted thermal energy in exchange for the used fan power.

The results show that the mini-channels could be optimized to have a higher performance in heat transfer with a lower pressure drop. The metal 3D printing method, as an alternative method in manufacturing conceptual designs, could be used in implementing innovative features. This includes optimization of the hydraulic diameter and the aspect ratio of the HTF passages, maximizing the area-to-volume ratio of the channels and manufacturing innovative fin configurations to enhance the heat transfer on the PCM side. Finally, optimization, manufacturing and experimental testing of the mini-channels under laboratory conditions could be the next steps paving the commercialization of such products and their usage on a large scale.