1. Introduction

The Differential Drive Wheeled Mobile Robot (DDWMR) can perform many different tasks in many fields. To fulfill its series of tasks in different places, the robot has to move from one place to another place in a known or an unknown environment. Therefore, motion control problems such as path tracking, “go-to-goal”, “point-to-point”, waypoints tracking, pose tracking, etc. of a mobile robot are still the crucial and fundamental problems for the robot operation. These control problems have been widely researched and published, such as the obstacle avoidance with minimum travel time [

1], the go-to-goal control without obstacle avoidance [

2,

3], the leader following control [

4], the trajectory tracking control [

5,

6,

7], the wall-following control [

8], the obstacle avoidance [

9,

10,

11]. For the robot motion control, both conventional control methods and modern control methods have been applied. Several well-known controllers such as the controller proposed by Kanayama and Robins Mathew, the feedback-based controller for the circular path, the Lyapunov-based controller, the clever trigonometry-based controller, and the Dubins path-based controller, have been discussed in [

12].

On the one hand, the conventional control techniques such as the back-stepping, the linearization, the PID, etc. depend largely on precise mathematical modeling. So, the absence of an accurate analytical model makes it quite difficult to design an appropriate controller. In practice, robots are nonlinear systems and usually have to operate in unstructured environments with uncertainties, which leads to even more complex tasks for the robots. On the other hand, intelligent control algorithms such as the Fuzzy Logic (FL) control, the neural network control, etc. allow us to drive the DDWMR without a detailed mathematical model and thus they are preferred over others. The FL control algorithms can deliver fast and precise dynamic responses, which allows information analysis through a true-and-false scale, and are generally robust, tolerant to uncertainties and noise in the input data [

13].

It should be mentioned that many different FL control algorithms such as (1) Conventional FL control methods and hybrid fuzzy-PID control algorithms [

2,

4,

6]; (2) Adaptive FL algorithms, for example, an adaptive fuzzy output feedback control of a Wheeled Mobile Robot (WMR) [

7], an adaptive FL control based on harmony search [

14], an adaptive fuzzy output feedback simultaneous posture stabilization and tracking control [

15], a robust adaptive fuzzy variable structure tracking control for a WMR [

16]; (3) A hybrid fuzzy-neural network, such as navigation of a WMR using adaptive network-based fuzzy inference system [

9], an adaptive network fuzzy inference system based navigation controller for mobile robot [

10], a fuzzy-neuro based navigational strategy for mobile robot [

11]; (4) Bio-inspired optimization techniques applied for FL control methods, such as using the particle swarm optimization [

1], the Genetic Algorithm [

8,

17,

18,

19,

20,

21], etc. have been used to control a WMR so that the robot can perform its different tasks. However, most of the above-mentioned control algorithms only focus on solving the robot motion control problems, i.e., making the robot move smoothly, with no or minimum vibration, tire slipping, etc. Currently, just a few authors have mentioned and solved the problem of robot motion with the minimum energy consumption criterion [

22,

23,

24,

25,

26,

27,

28].

It is necessary to reduce the energy consumption of the DDWMR to perform more missions efficiently with a limited energy supply. Several methods which have been published are able to deal with the finite energy of batteries, such as focusing on motion planning to reduce energy consumption [

22,

23], selecting robot’s components which use less energy [

24], using energy management techniques in the WMR [

25], generating speed profiles to reduce energy consumption, avoiding sudden accelerations and decelerations of the WMR [

26], prolonging the time of operation by increasing the number of batteries or by diverting the robot back to the charging station [

27], or improving the quality of the battery [

28], etc. Among these methods, the optimal path planning to reduce the energy consumption is more effective and widely applied than the others. In general, the optimal path is the shortest path with several sharp turns [

22]. These sharp turns force the robot to decelerate and accelerate as required by that path, which leads to the consumption of extra energy. To tackle that problem, Liu and Sun [

22] have used Bézier curves to smooth the path which will minimize the energy consumption. In [

23], Manas Chaudhari et al. have used Dubins path to smooth the path so that the energy consumption of the robot is reduced.

From the above-mentioned studies, it can be derived that motion planning without considering the energy consumption of the robot is not efficient planning in the energy sense. Therefore, a better solution would be to integrate both optimal path planning and minimum energy robot motion control. If an optimal path has been already planned, an optimal motion controller is needed for the robot so that it can go to the destination with the minimum energy consumption.

The main goals of this paper are: (1) To propose an optimal fuzzy logic controller using the genetic algorithm (GA_FLC) to reduce the energy consumption of the DDWMR more effectively than the other algorithms; (2) To create a software in Google Colab® and Jupyter platforms using Python language in order to execute the full optimization process for the Fuzzy Logic Controller (FLC); (3) To publish this software as an open-source code for all the users who want to use and improve it.

The rest of this paper is organized as follows. The problem is described in

Section 2. The optimization of the FLC is introduced in

Section 3. Result collection and final discussion are presented in

Section 4. The conclusion is stated in

Section 5.

2. Problem Description

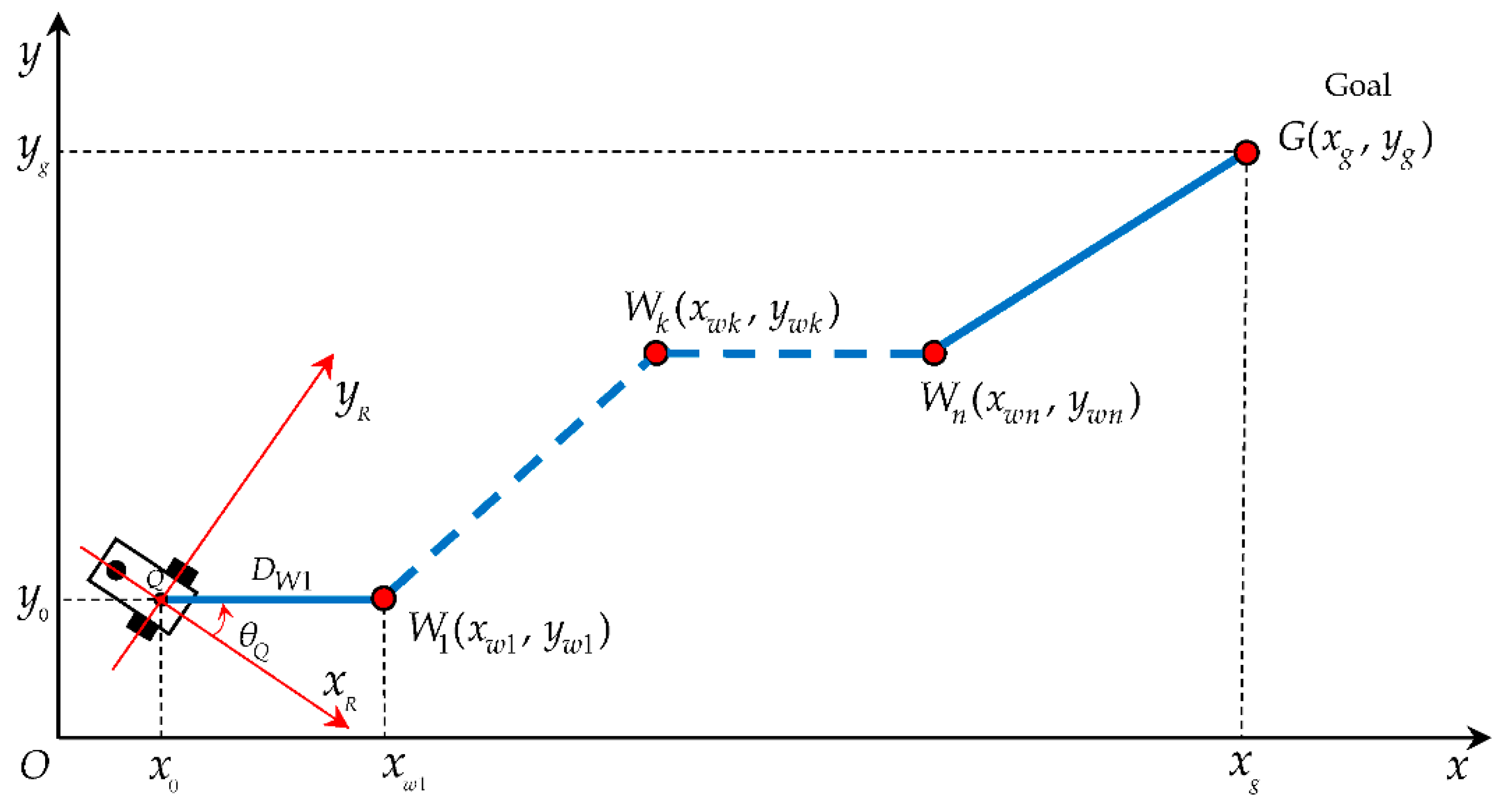

Without loss of generality, let us assume that the optimal path has been planned (in this case, the optimal path is optimized based on the A* algorithm with several waypoints [

22], which is depicted in

Figure 1); therefore the energy-efficient motion control problem of the DDWMR becomes the problem of designing an energy-efficient motion controller so that the robot can go to the goal through all waypoints efficiently.

In

Figure 1, the differential drive wheeled mobile robot tracks the optimal path connecting the waypoints from the starting point (

x0, y0) to the goal

G(

xg, yg) through several waypoints

Wk(

xwk, ywk),

k = 2, 3, …,

n − 1. (

n is the total number of waypoints). The waypoints are determined by the planning layer of the robot (using the supervisory controller).

Navigating the DDWMR to the goal can be done with help of many different motion control algorithms. A general motion control system of the differential drive wheeled mobile robot is depicted in

Figure 2. This scheme can be applied to most motion control algorithms to navigate the DDWMR to a given destination.

At first, an FLC is designed to navigate the DDWMR to the goal through all the waypoints sequentially. Then, a GA-based method is used to optimize the input and output membership functions for the FLC. To execute the optimization process of the FLC using the GA, as an optimizer of created Fitness Function (FF) based on simulated FLC performance, the “pymoo” library is employed.

A kinematic model and an energy model of the DDWMR are needed to design the optimal FLC. Thus, the following subsections will present them.

2.1. Kinematic Model of the Differential Drive Wheeled Mobile Robot

The geometry and kinematic parameters of the DDWMR are shown in

Figure 3 [

12].

In

Figure 3, the DDWMR has the important parameters as follows:

v is the robot linear velocity (m/s);

θ is the robot orientation (rad);

ωr is the angular velocity of the right wheel (rad/s);

ωl is the angular velocity of the left wheel (rad/s);

vr is the linear velocity of the right wheel (m/s);

vl is the linear velocity of the left wheel (m/s);

r is the radius of the right and the left wheels (m);

b is the distance between the right and the left wheels (m);

Q is the center of the axis between the right and the left wheels;

G is the center of gravity of the DDWMR;

a is the distance between

Q and

G (m).

- -

The wheels are rolling without slipping,

- -

The center of gravity G coincides with the point Q,

- -

The guidance axis is perpendicular to the robot plane.

Based on

Figure 3 and refer to [

12,

29], it is easy to get the kinematic model of the DDWMR as follows:

2.2. Energy Model of the Differential Drive Wheeled Mobile Robot

The main energy losses of the DDWMR consist of the losses inside the motors, the kinetic energy losses, the losses due to friction, and the losses in the electronics [

22,

28]. The energy consumed by motors consists of two main parts, which are the energy transformed into robot kinetic energy and the energy to overcome traction resistance. In practice, the energy consumption is mainly transformed into robot kinetic energy.

For the design of an energy-efficient controller, it is necessary to have an appropriate energy model. To simplify the energy consumption model, only the kinetic energy losses of the robot have been considered. This simplification is based on the hypothesis that accelerations and decelerations change the kinetic energy of the robot body. The kinetic energy of the robot at any time is [

12,

22,

28]

where

m and

I denote the mass and the moment of inertia of the differential drive wheeled mobile robot respectively;

v and

ω are the linear velocity and the angular velocity of the robot at time

t.

When implementing movement of the DDWMR in the software, the discrete time is used. Thus, the kinetic energy of the robot at time

ti is calculated by Equation (3). The difference in kinetic energy between the two states is calculated by Equation (4).

where:

i = 1, 2, 3, …,

m (

m is the number of sampling times).

The robot motion may include acceleration, deceleration, and moving with constant velocity. It is assumed that kinetic energy is not recuperated and stored in the battery; thus, every acceleration followed by deceleration leads to energy loss. To sum up all those energy differences, the state of the robot is inspected and the total energy consumption is calculated. Therefore, in the simulation, the total energy consumption of the DDWMR is calculated based on Equations (3) and (4), the kinetic energy changes in the deceleration phase are considered as a loss.

5. Conclusions

In this paper, the FLC has been introduced and successfully applied for the DDWMR control for robot movement on the given path. However, it is too complex and time-consuming to manually search for the proper parameters of the MFs, and its performances of motion control are still poor. To tackle such problems, an optimal FLC (GA_FLC) has been found with the use of the GA and the minimum energy consumption criterion. In many studies, scientists have only optimized the output MFs. However, in this study, the GA automatically tunes all the parameters of input/output MFs of the FLC. Such an approach leads to fast and effective tuning. For the optimal parameters’ identification of the MFs for the FLC, the zigzag path has been used in the optimization process at first. The fitness function has been derived from the energy consumption and after that minimized. Also, the length of the traveled path has been considered. Finally, the performance of suboptimal FLC has been tested on the benchmark paths and its results have been compared to the results of several controllers based on another approaches. The comparisons have shown that the GA_FLC is much better than all used well-known controllers in terms of energy consumption while the other performances of the motion parameters are still good.

To keep all experiments reproducible, the GA_FLC and several well-known controllers including the Circle-based controller, the Mathew-based controller, the Chaudhari-based controller, the Thoa-based controller, the Expert-based controller, and the Mohammadi-based FLC controllers have been successfully implemented in the Google Colab® by using the Python language and made freely available for all the readers who are interested in them.