Modulus of Elasticity for Grain-Supported Carbonates—Determination and Estimation for Preliminary Engineering Purposes

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

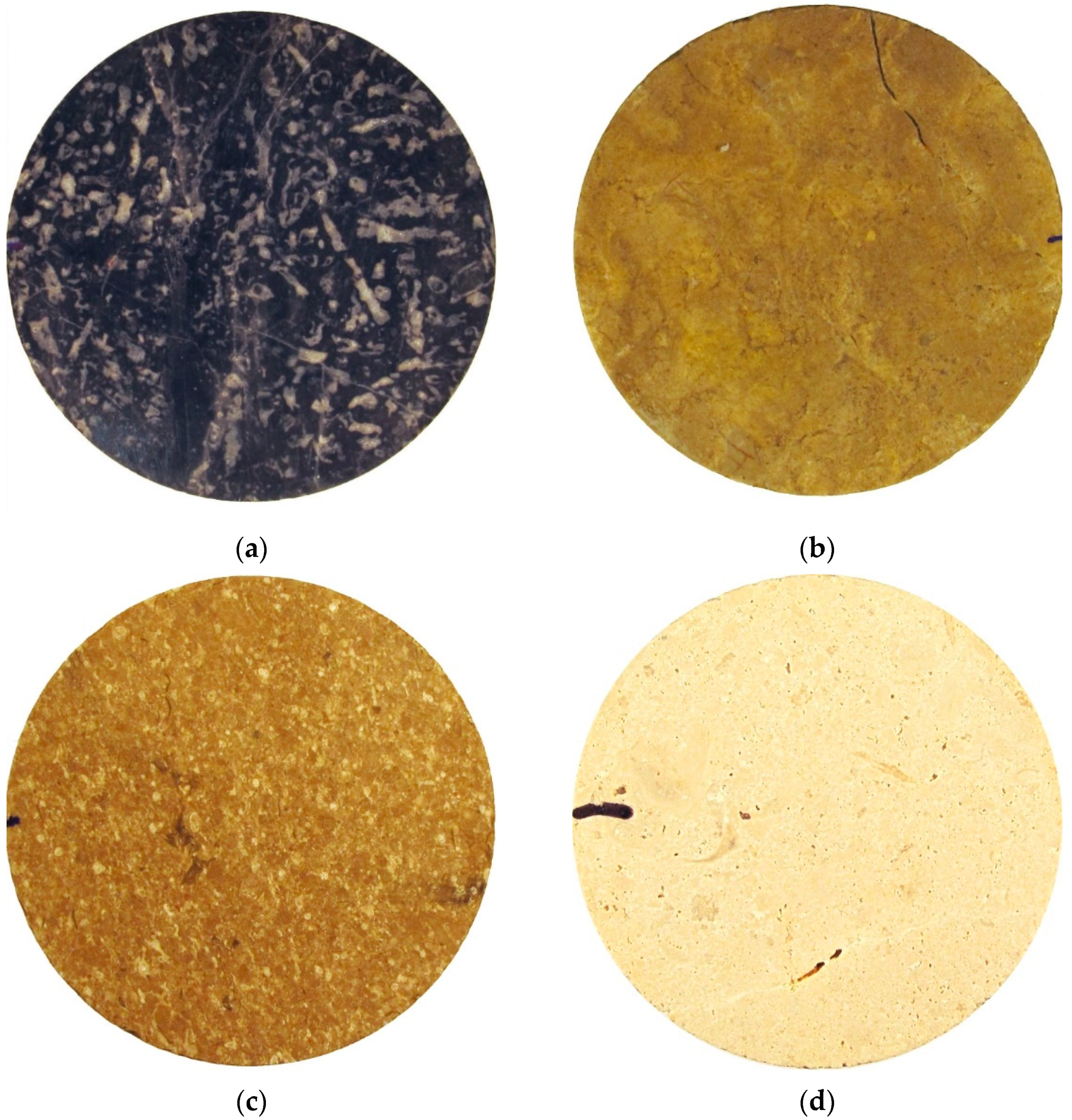

2.1. Grain-Supported Carbonates

2.2. Methods for Determining Young’s Modulus and Other Properties

2.3. Use of R Statistical Environment for Estimating Youngs Moduli

3. Results

3.1. Petrographic Characteristics and Physical-Mechanical Properties

3.2. Models for Estimating Modulus of Elasticity

4. Discussion

5. Conclusions

- Petrographic characteristics of rocks have proven to be extremely important since they directly affect the physical and mechanical properties and modulus of elasticity. According to the obtained results, the packstone and grainstone carbonates from Croatia show similar properties and can be mutually combined when estimating the modulus of elasticity of carbonates. Still, it is important to point out that presented results consider low porosity carbonates without or with minor secondary defects. Other types of carbonate rock materials may have considerably different properties, therefore better results, it is suggested that each group of carbonates is considered and estimated separately.

- It is useful in engineering terms to create simple estimation models based on multiple regression and regression trees, and in this sense, the R statistical environment has proven to be a viable and accessible platform.

- Regression tree models can be used to easily estimate the modulus of elasticity for carbonates with packstone and grainstone textures with input parameters of P-velocity, uniaxial compressive strength, and point load test index.

- The bagging tree model showed the best evaluation results. Its performance parameters are 0.8934 for R2 and 0.8687 for adjusted R2. This model can be used with input parameters listed in the previous point, as well as density, porosity and Schmidt rebound hardness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lanciano, C.; Salvini, R. Monitoring of Strain and Temperature in an Open Pit Using Brillouin Distributed Optical Fiber Sensors. Sensors 2020, 20, 1924. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moayedi, H.; Kalantar, B.; Abdullahi, M.M.; Rashid, A.S.A.; Nazir, R.; Nguyen, H. Determination of Young Elasticity Modulus in Bored Piles Through the Global Strain Extensometer Sensors and Real-Time Monitoring Data. Appl. Sci. 2019, 9, 3060. [Google Scholar] [CrossRef] [Green Version]

- Zhussupbekov, A.; Alibekova, N.; Akhazhanov, S.; Sarsembayeva, A. Development of a Unified Geotechnical Database and Data Processing on the Example of Nur-Sultan City. Appl. Sci. 2021, 11, 306. [Google Scholar] [CrossRef]

- Mohyla, M.; Vojtasik, K.; Hrubesova, E.; Stolarik, M.; Nedoma, J.; Pinka, M. Approach for Optimisation of Tunnel Lining Design. Appl. Sci. 2020, 10, 6705. [Google Scholar] [CrossRef]

- Rybacki, E.; Reinicke, A.; Meier, T.; Makasi, M.; Dresen, G. What controls the mechanical properties of shale rocks?—Part I: Strength and Young’s modulus. J. Pet. Sci. Eng. 2015, 135, 702–722. [Google Scholar] [CrossRef]

- Wetzel, M.; Kempka, T.; Kühn, M. Predicting macroscopic elastic rock properties requires detailed information on microstructure. Energy Procedia 2017, 125, 561–570. [Google Scholar] [CrossRef]

- Wetzel, M.; Kempka, T.; Kühn, M. Diagenetic Trends of Synthetic Reservoir Sandstone Properties Assessed by Digital Rock Physics. Minerals 2021, 11, 151. [Google Scholar] [CrossRef]

- Małkowski, P.; Ostrowski, Ł. The methodology for the Young modulus derivation for rocks and its value. Proceedia. Eng. 2017, 191, 134–141. [Google Scholar] [CrossRef]

- Malkowski, P.; Ostrowski, L.; Brodny, J. Analysis of Young’s modulus for Carboniferous sedimentary rocks and its relationship with uniaxial compressive strength using different methods of modulus determination. J. Sustain. Min. 2018, 17, 145–157. [Google Scholar] [CrossRef]

- Kuhinek, D.; Zoric, I.; Hrzenjak, P. Measurement uncertainty in testing of uniaxial compressive strength and deformability of rock samples. Meas. Sci. Rev. 2011, 11, 112–117. [Google Scholar] [CrossRef] [Green Version]

- Abdelaziz, A.; Grasselli, G. How believable are published laboratory data? A deeper look into system-compliance and elastic modulus. J. Rock Mech. Geotech. Eng. 2021, 13, 487–499. [Google Scholar] [CrossRef]

- Briševac, Z.; Hrženjak, P.; Buljan, R. Models for estimating uniaxial compressive strength and elastic modulus. Građevinar 2016, 68, 19–28. [Google Scholar] [CrossRef] [Green Version]

- The R Project for Statistical Computing. Available online: https://www.r-project.org/about.html (accessed on 7 June 2021).

- James, G.; Witten, D.; Hastie, T.; Tibshirani, R. An Introduction to Statistical Learning with Applications in R; Springer: New York, NY, USA, 2017; pp. 59–126. [Google Scholar]

- Johnson, K.; Kuhn, M. Applied Predictive Modelling; Springer: New York, NY, USA, 2016; pp. 173–203. [Google Scholar]

- Zhang, H.; Zhou, J.; Jahed Armaghani, D.; Tahir, M.M.; Pham, B.T.; Huynh, V.V. A Combination of Feature Selection and Random Forest Techniques to Solve a Problem Related to Blast-Induced Ground Vibration. Appl. Sci. 2020, 10, 869. [Google Scholar] [CrossRef] [Green Version]

- Briševac, Z.; Špoljarić, D.; Gulam, V. Estimation of uniaxial compressive strength based on regression tree models. Min. Geol. Pet. Eng. Bull. 2014, 29, 39–47. [Google Scholar]

- Liang, M.; Mohamad, E.T.; Faradonbeh, R.S.; Armaghani, D.J.; Ghoraba, S. Rock strength assessment based on regression tree technique. Eng. Comput. 2016, 32, 343–354. [Google Scholar] [CrossRef]

- Dinçer, I.; Acar, A.; Çobanoğlu, I.; Cobanoglu, I.; Uras, Y. Correlation between Schmidt hardness, uniaxial compressive strength and Young’s modulus for andesites, basalts and tuffs. Bull. Eng. Geol. Environ. 2004, 63, 141–148. [Google Scholar] [CrossRef]

- Yasar, E.; Erdogarg, Y. Correlating sound velocity with the density, compressive strength and Young’s modulus of carbonate rocks. Int. J. Rock Mech. Min. Sci. 2004, 41, 871–875. [Google Scholar] [CrossRef]

- Kahraman, S.; Yeken, T. Determination of physical properties of carbonate rocks from P-wave velocity. Bull. Eng. Geol. Environ. 2008, 67, 277–281. [Google Scholar] [CrossRef]

- Moradian, Z.A.; Behnia, M. Predicting the uniaxial compressive strength and static young’s modulus of intact sedimentary rocks using the ultrasonic test. Int. J. Geomech. ASCE 2009, 9, 14–19. [Google Scholar] [CrossRef]

- Yagiz, S. Predicting uniaxial compressive strength, modulus of elasticity and index properties of rocks using the Schmidt hammer. Bull. Eng. Geol. Environ. 2009, 68, 55–63. [Google Scholar] [CrossRef]

- Azimian, A.; Ajalloeian, R. Empirical correlation of physical and mechanical properties of marly rocks with P wave velocity. Arab. J. Geosci. 2015, 8, 2069–2079. [Google Scholar] [CrossRef]

- Gokceoglu, C.; Zorlu, K. A fuzzy model to predict the uniaxial compressive strength and the modulus of elasticity of a problematic rock. Eng. Appl. Artif. Intell. 2004, 17, 61–72. [Google Scholar] [CrossRef]

- Yilmaz, I.; Yuksek, G. Prediction of the strength and elasticity modulus of gypsum using multiple regression, ANN, and ANFIS models. Int. J. Rock Mech. Min. Sci. 2008, 46, 803–810. [Google Scholar] [CrossRef]

- Heidari, M.; Khanlari, G.R.; Momeni, A.A. Prediction of elastic modulus of intact rocks using artificial neural networks and nonlinear regression methods. Aust. J. Basic Appl. Sci. 2010, 4, 5869–5879. [Google Scholar]

- Ocak, I.; Seker, S.E. Estimation of Elastic Modulus of Intact Rocks by Artificial Neural Network. Rock Mech. Rock Eng. 2012, 45, 1047–1054. [Google Scholar] [CrossRef]

- Ceryan, N.; Can, N.K. Prediction of the uniaxial compressive strength of rocks materials. In Handbook of Research on Trends and Digital Advances in Engineering Geology; Ceryan, N., Ed.; Igi Global: Hershey, PA, USA, 2018; pp. 31–96. [Google Scholar]

- Aboutaleb, S.; Behnia, M.; Bagherpour, R.; Bluekian, B. Using non-destructive tests for estimating uniaxial compressive strength and static Young’s modulus of carbonate rocks via some modeling techniques. Bull. Eng. Geol. Environ. 2018, 77, 1717–1728. [Google Scholar] [CrossRef]

- Acar, M.C.; Kaya, B. Models to estimate the elastic modulus of weak rocks based on least square support vector machine. Arab. J. Geosci. 2020, 13, 590. [Google Scholar] [CrossRef]

- Leite, M.H.; Ferland, F. Determination of Unconfined Compressive Strength and Young’s Modulus of Porous Materials by Indentation Tests. Eng. Geol. 2001, 59, 267–280. [Google Scholar] [CrossRef]

- Lashkaripour, G.R. Predicting mechanical properties of mudroek from index parameters. Bull. Eng. Geol. Environ. 2002, 61, 73–77. [Google Scholar] [CrossRef]

- Pollak, D.; Gulam, V.; Bostjančić, I. A visual determination method for uniaxial compressive strength estimation based on Croatian carbonate rock materials. Eng. Geol. 2017, 231, 68–80. [Google Scholar] [CrossRef]

- Han, Z.; Zhang, L.; Zhou, J. Numerical Investigation of Mineral Grain Shape Effects on Strength and Fracture Behaviors of Rock Material. Appl. Sci. 2019, 9, 2855. [Google Scholar] [CrossRef] [Green Version]

- Lakirouhani, A.; Asemi, F.; Zohdi, A.; Medzvieckas, J.; Kliukas, R. Physical parameters, tensile and compressive strength of dolomite rock samples: Influence of grain size. J. Civ. Eng. Manag. 2020, 26, 789–799. [Google Scholar] [CrossRef]

- Park, K.; Kim, K.; Lee, K.; Kim, D. Analysis of Effects of Rock Physical Properties Changes from Freeze-Thaw Weathering in Ny-Ålesund Region: Part 1—Experimental Study. Appl. Sci. 2020, 10, 1707. [Google Scholar] [CrossRef] [Green Version]

- Briševac, Z.; Hrženjak, P.; Cotman, I. Estimate of uniaxial compressive strength and Young’s modulus of the elasticity of natural stone giallo d’Istria. Procedia Eng. 2017, 191, 434–441. [Google Scholar] [CrossRef]

- Pollak, D. Dependence of the Engeneerig-Geologycal Quality of the Carbonate Rocks abot Their Sedimentological and Petrological Charachteristics (Adriatic Motorway—Section “Tunnel Sveti Rok—Maslenica”). Master’s Thesis, University of Zagreb, Faculty of Mining, Geology and Petroleum Engineering, Zagreb, Croatia, 2002. [Google Scholar]

- Maričić, A.; Starčević, K.; Barudžija, U. Physical and mechanical properties of dolomites related to sedimentary and diagenetic features—Case study of the Upper Triassic dolomites from Medvednica and Samobor Mts., NW Croatia. Min. Geol. Pet. Eng. Bull. 2018, 33, 33–44. [Google Scholar] [CrossRef] [Green Version]

- Palchik, V. On the ratios between elastic modulus and uniaxial compressive strength of heterogeneous carbonate rocks. Rock Mech. Rock Eng. 2011, 44, 121–128. [Google Scholar] [CrossRef]

- Barudžija, U.; Maričić, A.; Brčić, V. Influence of Lithofacies and Diagenetic Processes on the Physical and Mechanical Properties of Carbonate Rocks—Case Study from Sinawin-Sha’wa Area, Libya. Min. Geol. Pet. Eng. Bull. 2015, 30, 19–36. [Google Scholar] [CrossRef]

- Madhubabu, N.; Singh, P.K.; Kainthola, A.; Mahanta, B.; Tripathy, A.; Singh, T.N. Prediction of compressive strength and elastic modulus of carbonate rocks. Measurement 2016, 88, 202–213. [Google Scholar] [CrossRef]

- Palchik, V. Simple stress-strain model of very strong limestones and dolomites for engineering practice. Geomech. Geophys. Geo-energy Geo-Resour. 2019, 5, 345–356. [Google Scholar] [CrossRef]

- Crnković, B.; Jovičić, D. Dimension stone deposits in Croatia. Min. Geol. Pet. Eng. Bull. 1993, 5, 136–163. [Google Scholar]

- Fio Firi, K.; Maričić, A. Usage of the Natural Stones in the City of Zagreb (Croatia) and Its Geotouristical Aspect. Geoheritage 2020, 12, 62. [Google Scholar] [CrossRef]

- Vlahović, I.; Tišljar, J.; Velić, I.; Matičec, D. Evolution of the Adriatic Carbonate Platform: Palaeogeography, main events and depositional dynamics. Palaeogeogr. Palaeoclimatol. Palaeoecol. 2005, 220, 333–360. [Google Scholar] [CrossRef]

- Dunham, R.J. Classification of Carbonate Rocks According to Theirdepositional Texture. Classification of Carbonate Rocks—A Symposium; Ham, W.E., Ed.; AAPG Memoir: Tulsa, OK, USA, 1962; Volume 1, pp. 108–121. [Google Scholar]

- Tucker, M.E.; Wright, V.P. Carbonate Sedimentology; Blackwell Scientific Publication: London, UK, 1990; pp. 365–400. [Google Scholar] [CrossRef]

- ISRM Turkish National Group. The Blue Book: “The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974–2006”; Ulusay, R., Hudson, J.A., Eds.; ISRM Turkish National Group: Ankara, Turkey, 2007; 628p. [Google Scholar]

- Vaneghi, R.G.; Thoeni, K.; Dyskin, A.V.; Sharifzadeh, M.; Sarmadivaleh, M. Strength and Damage Response of Sandstone and Granodiorite under Different Loading Conditions of Multistage Uniaxial Cyclic Compression. Int. J. Geomech. 2020, 20, 04020159. [Google Scholar] [CrossRef]

- Kuhinek, D.; Zorić, I.; Hrženjak, P.P. Development of Virtual Instrument for Uniaxial Compression Testing of Rock Samples. Meas. Sci. Rev. 2011, 11, 99–103. [Google Scholar] [CrossRef] [Green Version]

- Marinos, P.; Hoek, E. Estimating the geotechnical properties of heterogeneous rock masses such as flysch. Bull. Eng. Geol. Environ. 2001, 60, 85–92. [Google Scholar] [CrossRef]

| General Statistics | n | Is(50) | SRH | vp | σc | E | |

|---|---|---|---|---|---|---|---|

| min | 2376 | 0.14 | 0.5 | 38.2 | 4944 | 51.44 | 38.38 |

| max | 2823 | 11.25 | 6.8 | 72.5 | 6378 | 181.36 | 93.26 |

| average | 2634.64 | 3.22 | 4.30 | 59.05 | 5710.12 | 126.81 | 57.11 |

| standard deviation | 122.10 | 3.01 | 1.43 | 8.98 | 389.80 | 32.45 | 12.99 |

| Coefficient of variation (%) | 4.63 | 93.48 | 33.26 | 15.21 | 6.83 | 25.59 | 22.75 |

| Location | Lithology | Depositional Texture | Number of In Situ Samples |

|---|---|---|---|

| Škrobotnik, Brušane | dolomite | dolograinstone | 7 |

| Korenići, Salakovci | limestone | grainstone | 7 |

| Međurače, Debelo brdo, Trget, Kanfanar | limestone | packstone | 19 |

| Linear Model | RMSECV Rank (Value) | Adjusted R2 Rank (Value) |

|---|---|---|

| (17) | 1. (10.0025) | 4. (0.5129) |

| (18) | 2. (10.0313) | 7. (0.4890) |

| (19) | 3. (10.0798) | 8. (0.4837) |

| Models | RMSECV | R2 | Adjusted R2 |

|---|---|---|---|

| Regression tree (Figure 8) | 10.2387 | 0.7624 | 0.7285 |

| Pruned tree (Figure 9) | 10.0712 | 0.7424 | 0.7157 |

| Bagging (m = 6) | 9.8033 | 0.8934 | 0.8687 |

| Random Forest (m = 2) | 10.1133 | 0.8736 | 0.8652 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Briševac, Z.; Pollak, D.; Maričić, A.; Vlahek, A. Modulus of Elasticity for Grain-Supported Carbonates—Determination and Estimation for Preliminary Engineering Purposes. Appl. Sci. 2021, 11, 6148. https://doi.org/10.3390/app11136148

Briševac Z, Pollak D, Maričić A, Vlahek A. Modulus of Elasticity for Grain-Supported Carbonates—Determination and Estimation for Preliminary Engineering Purposes. Applied Sciences. 2021; 11(13):6148. https://doi.org/10.3390/app11136148

Chicago/Turabian StyleBriševac, Zlatko, Davor Pollak, Ana Maričić, and Andreja Vlahek. 2021. "Modulus of Elasticity for Grain-Supported Carbonates—Determination and Estimation for Preliminary Engineering Purposes" Applied Sciences 11, no. 13: 6148. https://doi.org/10.3390/app11136148