Identification of the Effect of Ultrasonic Friction Reduction in Metal-Elastomer Contacts Using a Two-Control-Loop Tribometer

Abstract

:1. Introduction

2. Experimental Setup

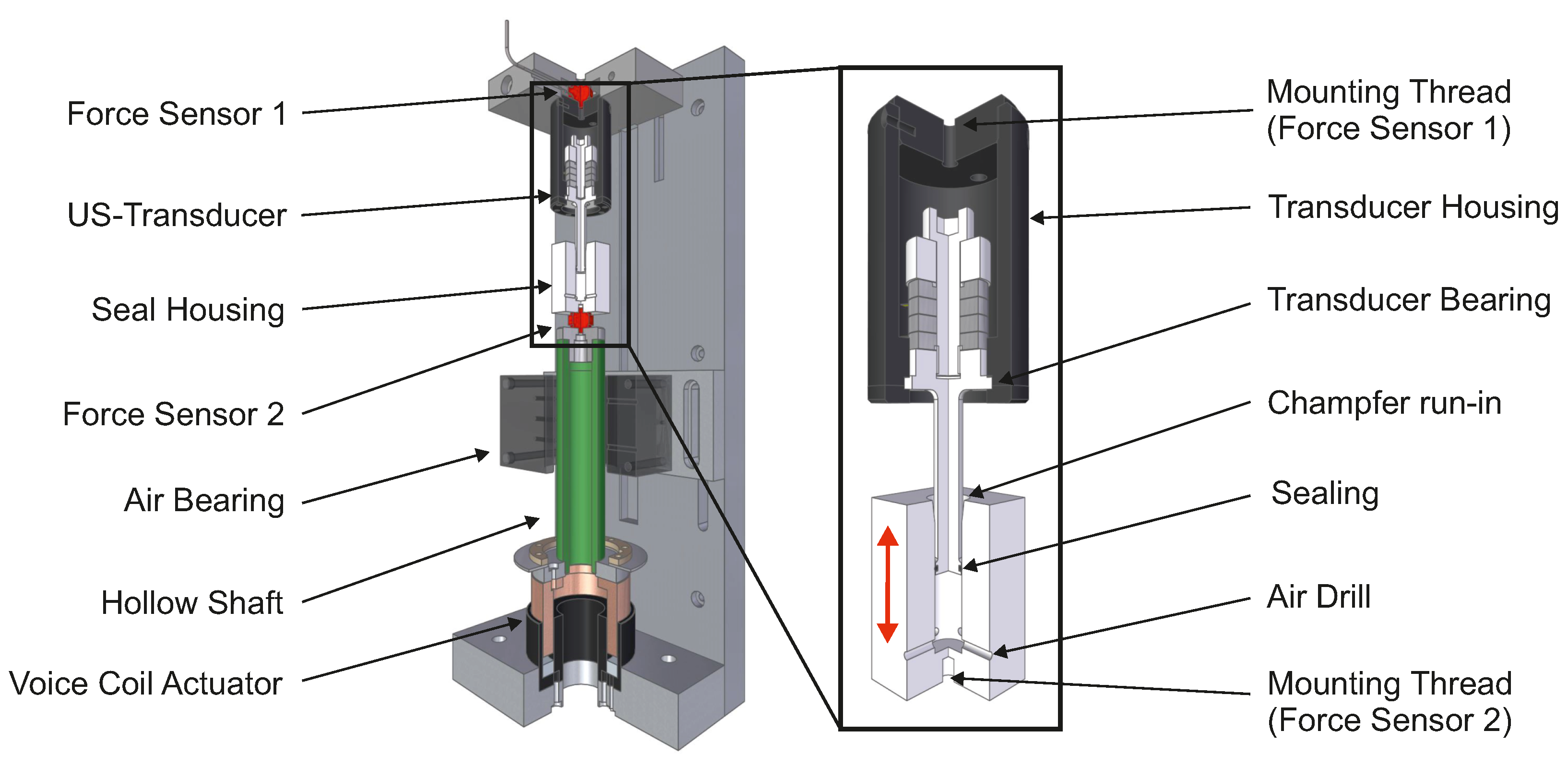

2.1. Topology of Linear Tribometer

2.2. Ultrasonic Transducer Design

3. Design of the Experiment and Experimental Procedures

3.1. Identification of Dynamic Friction

3.2. Identification of Breakaway Transients

4. Results

4.1. Sliding Friction Force

4.2. Breakaway Force

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gao, H.; Zhu, D.; Bao, G.; Xiao, C.; Cheng, T. Ultrasonic friction reduction investigation on a longitudinal-vibration-mode pneumatic cylinder. In Proceedings of the International Conference on Fluid Power and Mechatronics (FPM), Harbin, China, 5–7 August 2015; pp. 426–430. [Google Scholar]

- Siegert, K.; Ulmer, J. Reduction of sliding friction in wire and tube drawing with ultrasonic waves. Prod. Eng. 1998, 5, 9–12. [Google Scholar]

- Littmann, W.; Storck, H.; Wallaschek, J. Sliding friction in the presence of ultrasonic oscillations: Superimposing of longitudinal oscillations. Arch. Apllied Mech. 2001, 71, 549–554. [Google Scholar] [CrossRef]

- Popov, V.L.; Starcevic, J.; Filippov, A.E. Influence of Ultrasonic In-Plane Oscillations on Static and Sliding Friction and Intrinsic Length Scale of Dry Friction Processes. Tribol. Lett. 2010, 39, 25–30. [Google Scholar] [CrossRef]

- Bharadwaj, S. Active Friction Control via Piezoelectrically Generated Ultrasonic Vibrations. Ph.D. Thesis, The Ohio State University, Columbus, OH, USA, 2009. [Google Scholar]

- Pohlmann, R.; Lehfeld, E. Influence of Ultrasonic Vibration on Metallic Friction. Ultrasonics 1966, 4, 178–185. [Google Scholar] [CrossRef]

- Storck, H.; Littmann, W.; Wallaschek, J.; Mracek, M. The effect of friction reduction in presence of ultrasonic vibrations and its relevance to travelling wave ultrasonic motors. Ultrasonics 2002, 40, 379–383. [Google Scholar] [CrossRef]

- Kapelke, S.; Seemann, W. On the Effect of Longitudinal Vibrations on Dry Friction: Modelling Aspects and Experimental Investigations. Tribol. Lett. 2018, 66–79. [Google Scholar] [CrossRef]

- Kumar, V.; Hutchings, I.M. Reduction of the sliding friction of metals by the application of longitudinal or transverse ultrasonic vibration. Tribol. Int. 2004, 37, 833–840. [Google Scholar] [CrossRef]

- Gao, H.; Volder, M.D. A Pneumatic Actuator Based on Vibration Friction Reduction with Bending/Longitudinal Vibration mode. Sens. Actuators 2016, A 252, 112–119. [Google Scholar] [CrossRef]

- Pham, T.M.; Twiefel, J. Ultrasonic Friction Reduction in Elastomer-Metal Contacts and Application to Pneumatic Actuators. Phys. Procedia 2015, 70, 55–58. [Google Scholar] [CrossRef] [Green Version]

- Dong, S.; Dapino, J.M. Dynamic System Model for Ultrasonic Lubrication in Perpendicular Configuration. Ultrasonics 2017, 75, 98–105. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shoyama, T.; Fujimoto, K. Calculation of high-frequency dynamic properties of squeezed O-ring for bearing support. Mech. Eng. J. 2018, 5, 17-00444. [Google Scholar] [CrossRef] [Green Version]

- Shoyama, T.; Fujimotob, K. Direct measurement of high-frequency viscoelastic properties of predeformed Rubber. Polym. Test. 2018, 67, 399–408. [Google Scholar] [CrossRef]

- Bogoslovov, R.B.; Rolanda, C.M.; Gamache, R.M. Impact-induced glass transition in elastomeric coatings. Appl. Phys. Lett. 2007, 90, 221910. [Google Scholar] [CrossRef] [Green Version]

- Ille, I.; Twiefel, J. Model-Based Feedback Control of an Ultrasonic Transducer for Ultrasonic Assisted Turning Using a Novel Digital Controller. Phys. Procedia 2015, 70, 63–67. [Google Scholar] [CrossRef] [Green Version]

- Mojrzisch, S.; Twiefel, J. Phase-controlled frequency response measurement of a piezoelectric ring at high vibration amplitude. Arch Appl. Mech. 2016, 86, 1763–1769. [Google Scholar] [CrossRef]

- Chen, D.; Yang, W.; Pan, M. Design of Impedance Measuring Circuits Based on Phase-Sensitive Demodulation Technique. IEEE Trans. Instrum. Meas. 2011, 60, 1276–1282. [Google Scholar] [CrossRef]

- Bao, X.; Bar-Cohen, Y.; Chang, Z.; Dolgin, B.P.; Sherrit, S.; Pal, D.S.; Du, S.; Peterson, T. Modeling and Computer Simulation of Ultrasonic/Sonic Driller/Corer (USDC). IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2003, 50, 9. [Google Scholar]

- Wurpts, W.; Bruns, P.; Twiefel, J. A transfer matrix method for the design of resonant piezoelectric devices. In Proceedings of the International Workshop on Piezoelectric Materials and Applications in Actuators, Hannover, Germany, 14–17 July 2013. [Google Scholar]

- ANSYS Homepage. Available online: https://www.ansys.com/ (accessed on 28 June 2021).

- PI Ceramic Material Data. Available online: https://www.physikinstrumente.de/fileadmin/user_upload/physik_instrumente/files/datasheets/PI_Ceramic_Material_Data.pdf (accessed on 4 July 2021).

- Mofidi, M.; Prakash, B. Frictional behaviour of some sealing elastomers in lubricated sliding. In Proceedings of the 15th Nordic Symposium on Tribology—NordTrib, Trondheim, Norway, 12–15 June 2012. [Google Scholar]

- Biagiotti, L.; Melchiorri, C. Trajectory Planning for Automatic Machines and Robots, 1st ed.; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008; pp. 72–76. [Google Scholar]

- Constantinescu, D.; Croft, E.A. Smooth and Time-Optimal Trajectory Planning for Industrial Manipulators along Specified Paths. J. Robot. Syst. 2000, 17.5, 233–249. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weinstein, M.; Nowroth, C.; Twiefel, J.; Wallaschek, J. Identification of the Effect of Ultrasonic Friction Reduction in Metal-Elastomer Contacts Using a Two-Control-Loop Tribometer. Appl. Sci. 2021, 11, 6289. https://doi.org/10.3390/app11146289

Weinstein M, Nowroth C, Twiefel J, Wallaschek J. Identification of the Effect of Ultrasonic Friction Reduction in Metal-Elastomer Contacts Using a Two-Control-Loop Tribometer. Applied Sciences. 2021; 11(14):6289. https://doi.org/10.3390/app11146289

Chicago/Turabian StyleWeinstein, Michael, Christian Nowroth, Jens Twiefel, and Jörg Wallaschek. 2021. "Identification of the Effect of Ultrasonic Friction Reduction in Metal-Elastomer Contacts Using a Two-Control-Loop Tribometer" Applied Sciences 11, no. 14: 6289. https://doi.org/10.3390/app11146289