Analysis of the Influence of CO2 Concentration on a Spark Ignition Engine Fueled with Biogas

Abstract

:Featured Application

Abstract

1. Introduction

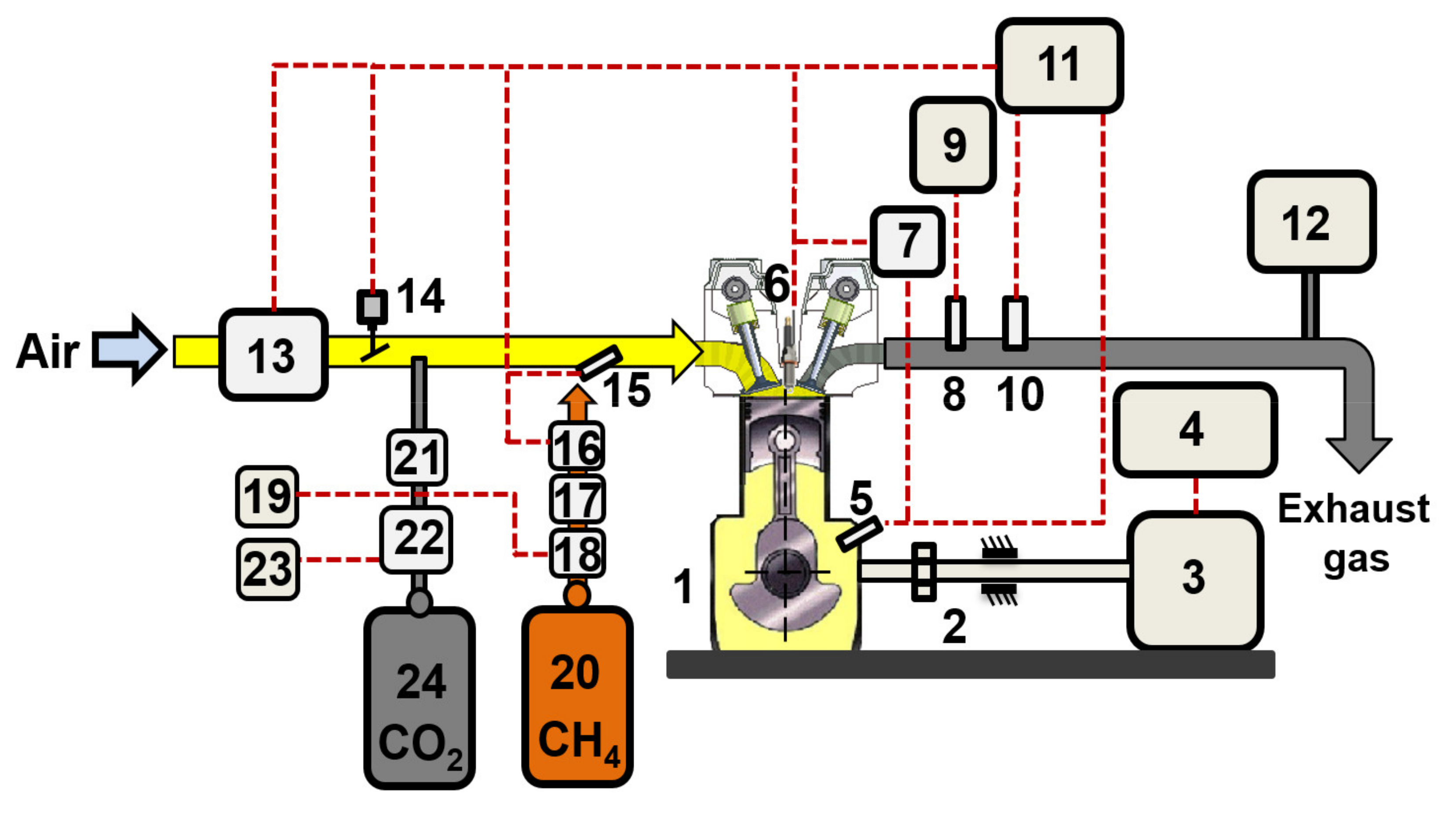

2. Materials and Methods

3. Results and Discussion

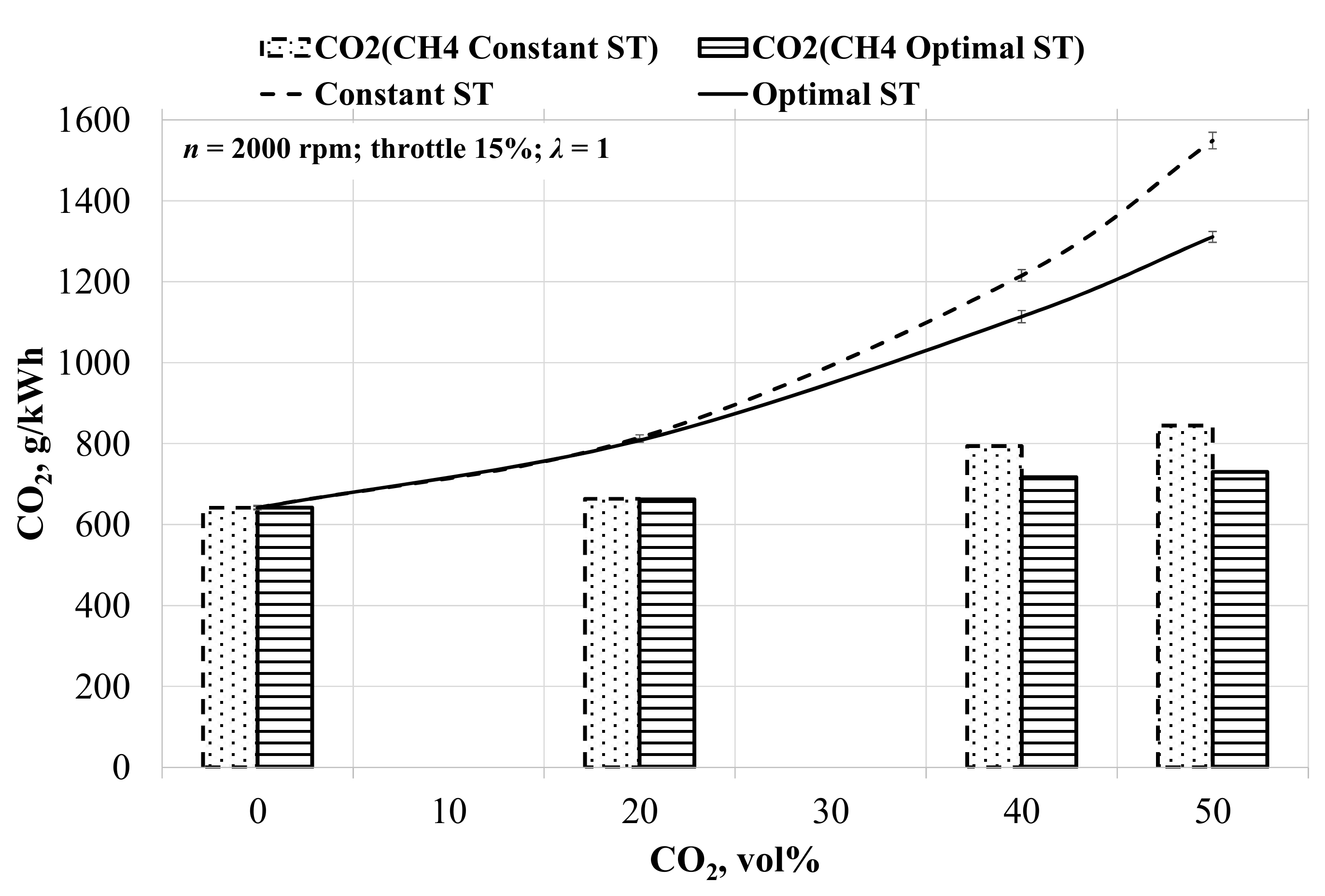

3.1. Energy Indicators

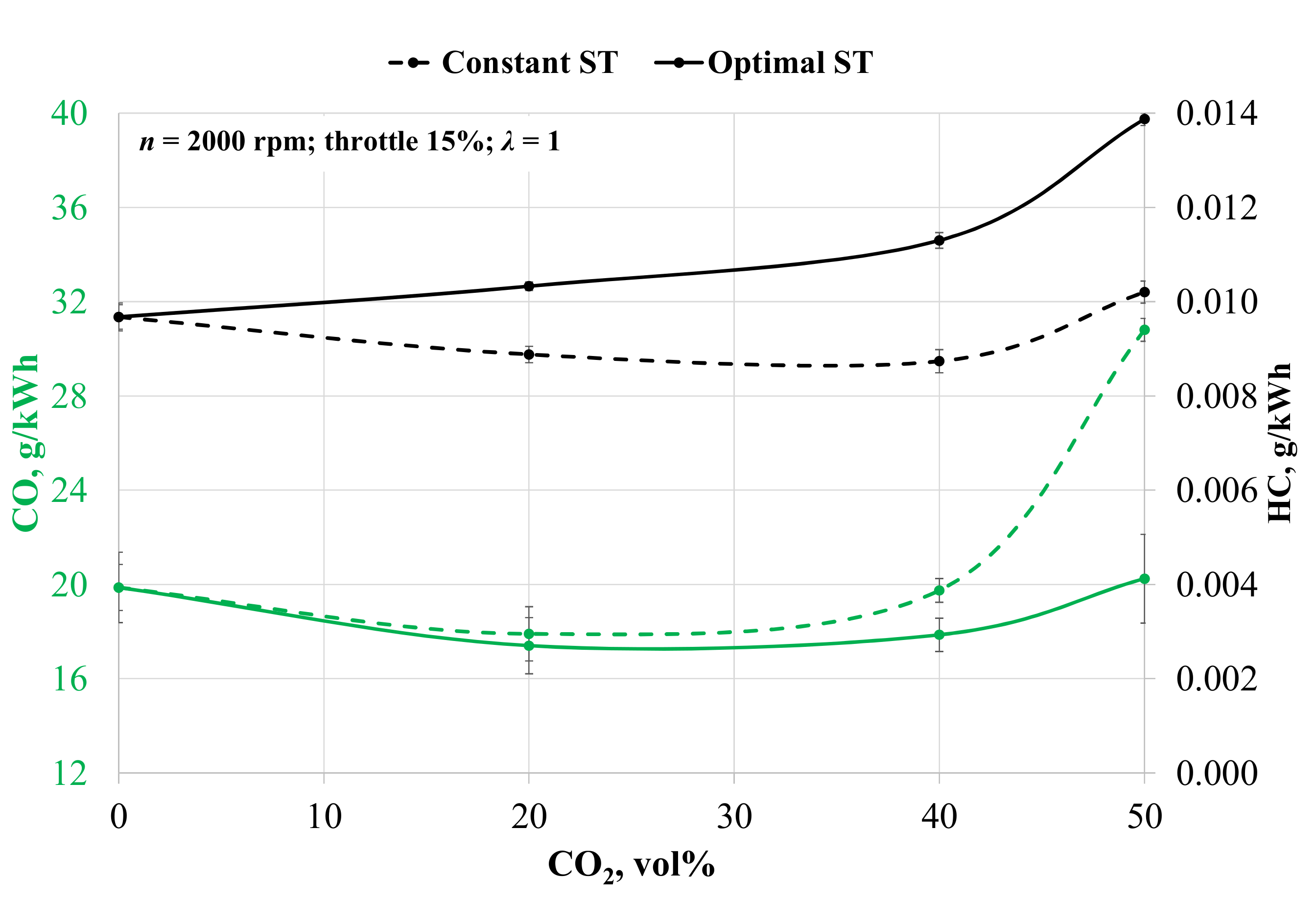

3.2. Environmental Indicators

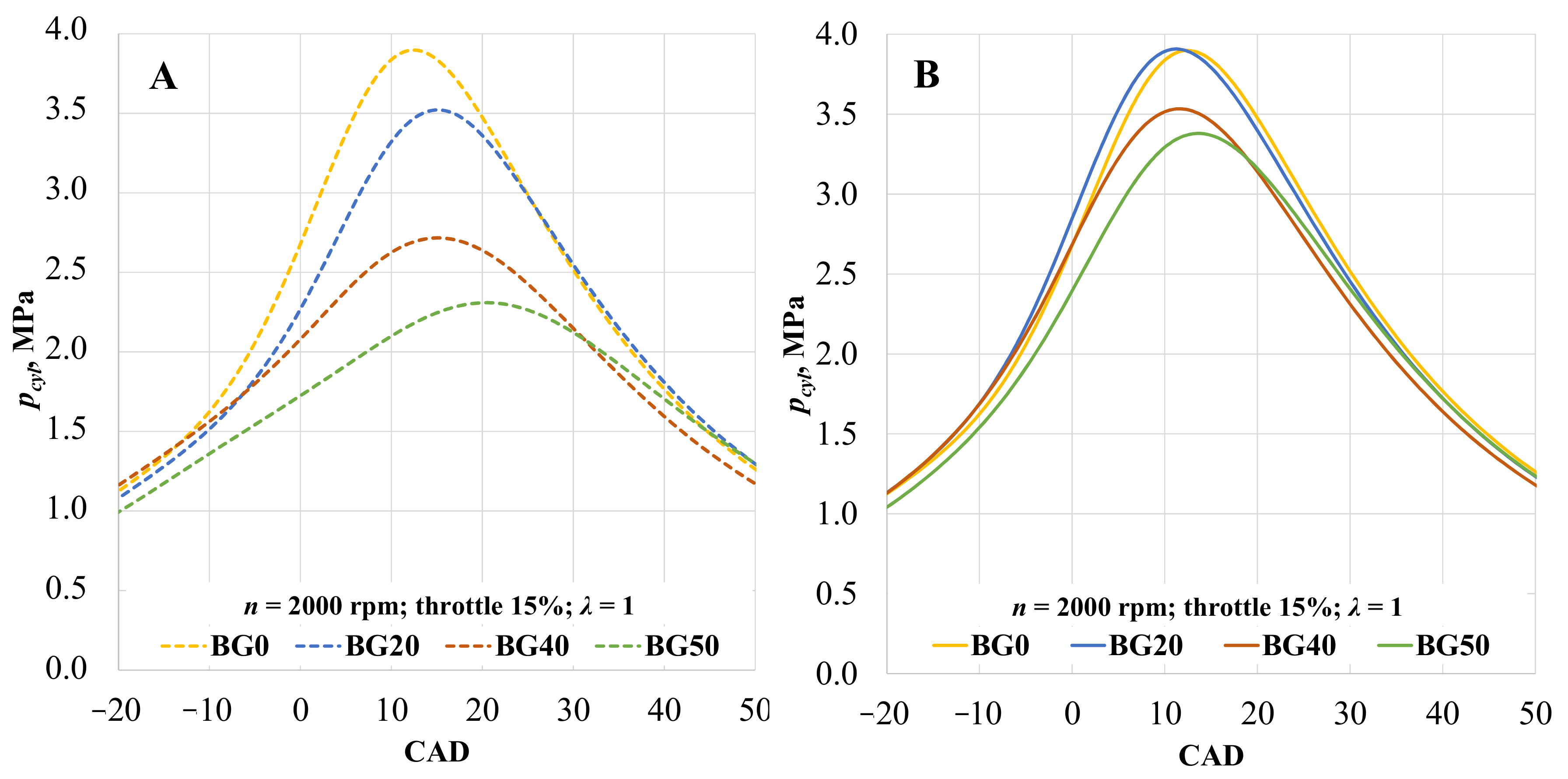

3.3. Combustion Indicators

4. Conclusions

- BSEC rises as the CO2 concentration in biogas increases, because the carbon dioxide reduces the biogas lower heat value (BG40—by 64.8% and BG50—by 73.6%) and reduces the combustion and flame propagation speed. Optimal ST compensates for the low combustion speed of biogas and BSEC increased by 6.39% and 16.6% for BG40 and BG50, respectively, compared to constant ST.

- Engine brake thermal efficiency decreases when adding CO2. Additionally, BG40 and BG50 increase the amount of fuel flow, and therefore, they reduce the volumetric efficiency of the engine. Carbon dioxide increases the combustion duration and flame propagation time; therefore, it increases the exhaust losses. For a constant ST of 26 CAD BTDC, exhaust losses increase by 1.6%, 3.7% and 8.7% with BG20, BG40 and BG50, respectively, compared to BG0. At the same time, heat losses increase due to the increased heat transfer time to the cylinder walls. Optimal ST shortened the combustion duration and increased the combustion speed, therefore, the time for heat transfer is reduced. In this case, heat losses are reduced by 8.6% and exhaust losses by 5.4% when comparing BG50 with different ST cases.

- Biogas is considered a short carbon cycle fuel; therefore, only CO2 formed from the combustion of methane is assessed. In the optimized ST case using BG20, BG40 and BG50, CO2 emission increases just by 3.1%, 11.8% and 13.8%, respectively, compared to BG0. The emission raised due to increased BSEC and fuel consumption, because a larger amount of fuel with lower LHV is needed.

- The concentration of NOx decreases in all measuring points. Lower LHV of biogas decreases the in-cylinder pressure, fuel burning speed and in-cylinder temperature. Constant ST reduced the NOX emissions by 13.5%, 26.2% and 16.3% more than optimal ST (using BG20, BG40 and BG50), because the peak in-cylinder pressure moves further away from TDC and more fuel burns in the exhaust. This is confirmed by the increase in the exhaust gas temperature (0.22%, 1.01% and 2.50% with BG20, BG40 and BG50, respectively, compared with BG0).

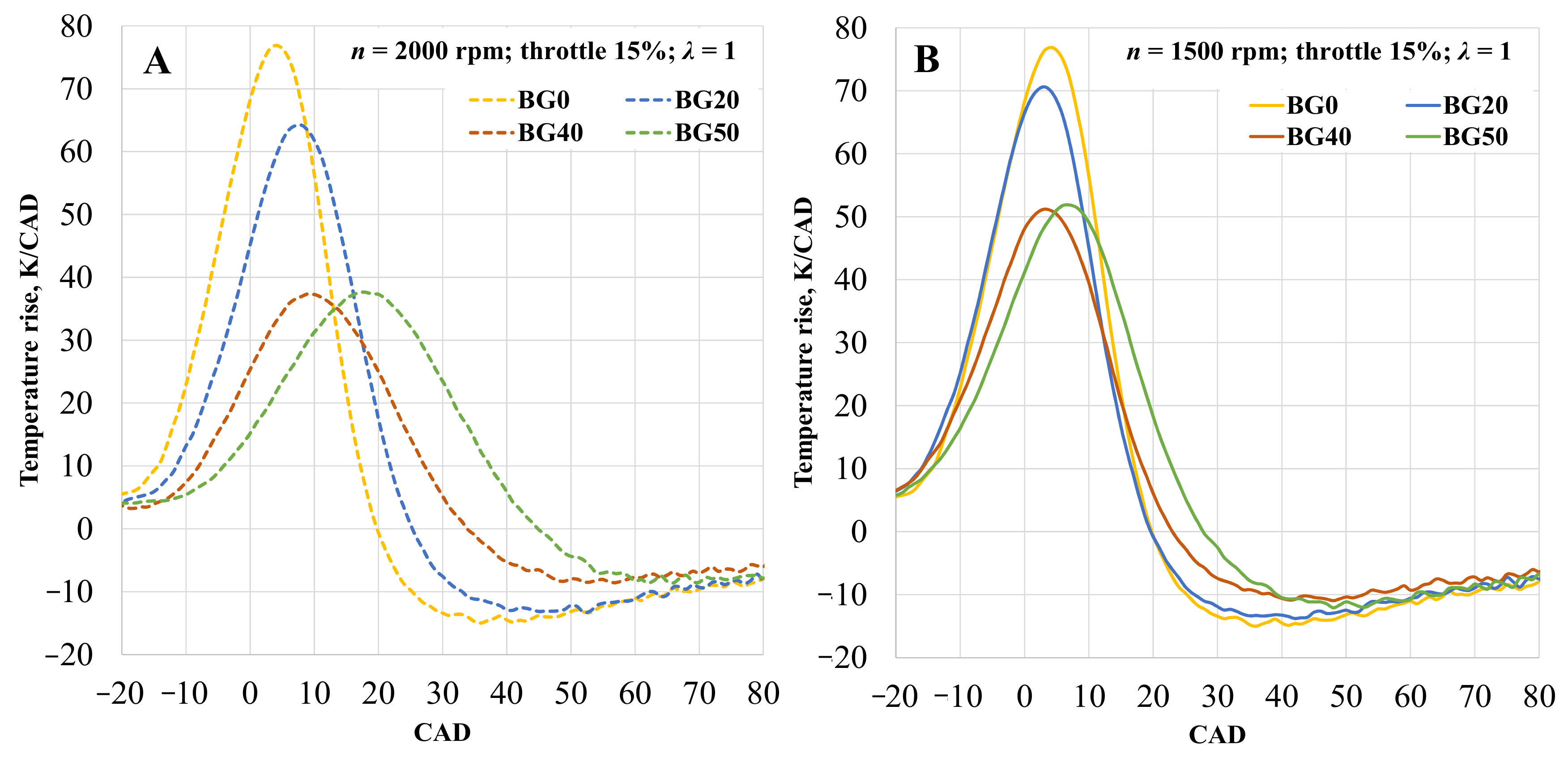

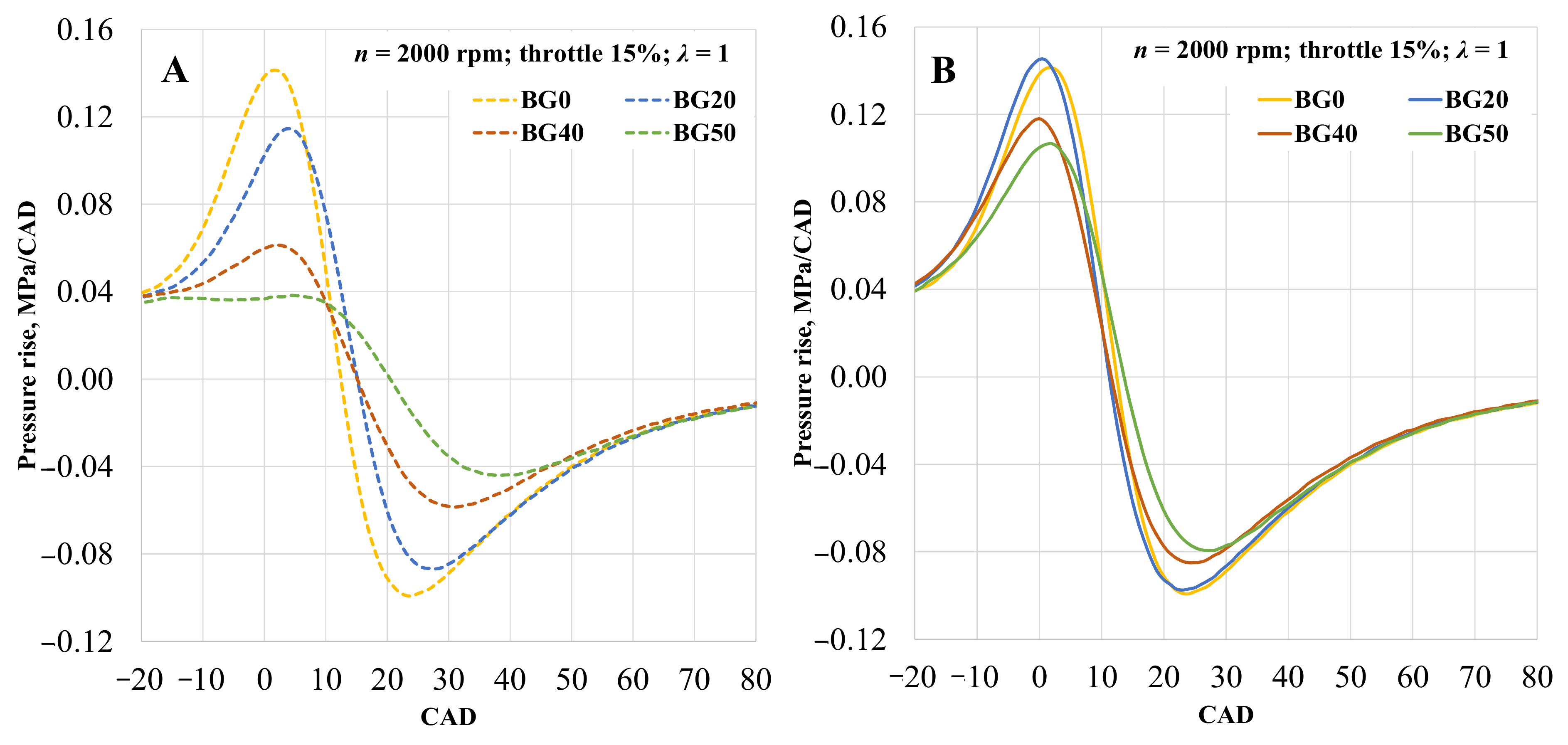

- Increasing the CO2 concentration in biogas decreases the combustion speed and increases the combustion delay. Therefore, the peak in-cylinder pressure moves further from TDC and the maximum in-cylinder pressure drops by 9.6%, 30.3% and 40.7% when comparing BG20, BG40 and BG50, respectively, to BG0 at 26 CAD BTDC. The optimal ST moves the peak in-cylinder pressure in the range of 12–14 CAD ATDC and increases the maximum value of the in-cylinder pressure.

- The optimal ST increases the 10% of MBF time due to the combustion at a higher cylinder volume and distance from air and fuel molecules; therefore, the combustion speed decreases. In case of 90% MBF time, the combustion duration is reduced by 8.4% and 10.6% (BG40 and BG50, respectively, compared to constant ST), because the main fraction of combustion occurs closer to TDC and fuel burns at a lower volume and at a higher speed.

- The pressure rise decreases at a constant spark timing for all CO2 concentrations, because the flame formation phase extends and prolongs the combustion duration of BG. The maximum pressure rise value shifts further from TDC and the main fraction of biogas burns in a larger cylinder volume. The optimal ST increases the BTE of the engine and the combustion parameters; therefore, the PR increases by 40.1% and 48.4% compared to BG40 and BG50, respectively, at 26 CAD BTDC.

- The constant ST case is not suitable for the SI engine, because the exhaust gas temperature increases with increased CO2 concentration, which could cause damage to the exhaust valves. Additionally, the BTE and the energy share for generating brake power decrease.

- When comparing all four BG mixtures, the ecological and energy parameters of BG20 are closest to BG0, but partial removal of CO2 in biogas is required to prepare this composition. When comparing BG40 and BG50 mixtures with BG0, the BTE values are decreased by 3.3% and 5.0%, respectively, while the time of 10% MBF increases by 2.2% using BG50. Additionally, the HC and CO emission increases for mixtures with 40 vol% of CO2. Considering the ecological and energy parameters of the mixtures, it can be said that the biogas production process should be adjusted for manufacturing biogas with 40 vol% of CO2 to keep engines running efficiently and ecologically.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Environment Agency. Greenhouse Gas Emissions from Transport in Europe. Available online: https://www.eea.europa.eu/data-and-maps/indicators/transport-emissions-of-greenhouse-gases/transport-emissions-of-greenhouse-gases-10 (accessed on 3 September 2020).

- Ecologic Institute: Science and Policy for a Sustainable World. Evaluating 15 Years of Transport and Environmental Policy Integration. Available online: https://www.ecologic.eu/13108 (accessed on 3 September 2020).

- White Paper Roadmap to a Single European Transport Area—Towards a Competitive and Resource Efficient Transport System. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52011DC0144&from=en (accessed on 3 September 2020).

- Chen, H.; He, J.; Zhong, X. Engine combustion and emission fuelled with natural gas: A review. J. Energy Inst. 2019, 92, 1123–1136. [Google Scholar] [CrossRef]

- Owczuk, M.; Matuszewska, A.; Kruczyński, S.; Kamela, W. Evaluation of using biogas to supply the dual fuel diesel engine of an agricultural tractor. Energies 2019, 12, 1071. [Google Scholar] [CrossRef] [Green Version]

- Kanth, S.; Debbarma, S.; Das, B. Effect of hydrogen enrichment in the intake air of diesel engine fuelled with honge biodiesel blend and diesel. Int. J. Hydrogen Energy 2020, 45, 32521–32533. [Google Scholar] [CrossRef]

- Yusri, I.M.; Mamat, R.; Azmi, W.H.; Najafi, G.; Sidik, N.A.C.; Awad, O.I. Experimental investigation of combustion, emissions and thermal balance of secondary butyl alcohol-gasoline blends in a spark ignition engine. Energy Convers. Manag. 2016, 123, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Awad, O.I.; Mamat, R.; Ali, O.M.; Sidik, N.A.C.; Yusaf, T.; Kadirgama, K.; Kettner, M. Alcohol and ether as alternative fuels in spark ignition engine: A review. Renew. Sustain. Energy Rev. 2018, 82, 2586–2605. [Google Scholar] [CrossRef]

- Alrazen, H.A.; Ahmad, K.A. HCNG fueled spark-ignition (SI) engine with its effects on performance and emissions. Renew. Sustain. Energy Rev. 2018, 82, 324–342. [Google Scholar] [CrossRef]

- Yilmaz, I.T.; Gumus, M. Investigation of the effect of biogas on combustion and emissions of TBC diesel engine. Fuel 2017, 188, 69–78. [Google Scholar] [CrossRef]

- Porpatham, E.; Ramesh, A.; Nagalingam, B. Investigation on the effect of concentration of methane in biogas when used as a fuel for a spark ignition engine. Fuel 2008, 87, 1651–1659. [Google Scholar] [CrossRef]

- Pukalskas, S.; Kriaučiūnas, D.; Rimkus, A.; Przybyła, G.; Droździel, P.; Barta, D. Effect of hydrogen addition on the energetic and ecologic parameters of an si engine fueled by biogas. Appl. Sci. 2021, 11, 742. [Google Scholar] [CrossRef]

- Makareviciene, V.; Sendzikiene, E.; Pukalskas, S.; Rimkus, A.; Vegneris, R. Performance and emission characteristics of biogas used in diesel engine operation. Energy Convers. Manag. 2013, 75, 224–233. [Google Scholar] [CrossRef]

- Karagöz, M.; Sarıdemir, S.; Deniz, E.; Çiftçi, B. The effect of the CO2 ratio in biogas on the vibration and performance of a spark ignited engine. Fuel 2018, 214, 634–639. [Google Scholar] [CrossRef]

- BP Energy Outlook 2035. 2015. Available online: https://www.bankofcanada.ca/wp-content/uploads/2015/05/bp-energy-outlook-2035.pdf (accessed on 3 May 2020).

- Kan, X.; Zhou, D.; Yang, W.; Zhai, X.; Wang, C.-H. An investigation on utilization of biogas and syngas produced from biomass waste in premixed spark ignition engine. Appl. Energy 2018, 212, 210–222. [Google Scholar] [CrossRef]

- Benato, A.; Macor, A.; Rossetti, A. Biogas engine emissions: Standards and on-site measurements. Energy Proc. 2017, 126, 398–405. [Google Scholar] [CrossRef]

- European Biogas Association EBA. Statistical Report. 2018. Available online: https://www.europeanbiogas.eu/eba-statistical-report-2018/ (accessed on 18 May 2020).

- EurObserv’ER. Biogas Barometer. 2017. Available online: https://www.eurobserv-er.org/biogas-barometer-2017/ (accessed on 1 May 2020).

- European Commission. Optimal Use of Biogas From Waste Streams. 2016. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/ce_delft_3g84_biogas_beyond_2020_final_report.pdf (accessed on 1 May 2020).

- Capodaglio, A.G.; Callegari, A.; Lopez, M.V. European framework for the diffusion of biogas uses: Emerging technologies, acceptance, incentive strategies, and institutional-regulatory support. Sustainability 2016, 8, 298. [Google Scholar] [CrossRef] [Green Version]

- Rupf, G.V.; Bahri, P.A.; de Boer, K.; McHenry, M.P. Broadening the potential of biogas in Sub-Saharan Africa: An assessment of feasible technologies and feedstocks. Renew. Sustain. Energy Rev. 2016, 61, 556–571. [Google Scholar] [CrossRef]

- Valenti, F.; Porto, S.M.C.; Dale, B.E.; Liao, W. Spatial analysis of feedstock supply and logistics to establish regional biogas power generation: A case study in the region of Sicily. Renew. Sustain. Energy Rev. 2018, 97, 50–63. [Google Scholar] [CrossRef]

- Stürmer, B. Feedstock change at biogas plants—Impact on production costs. Biomass Bioenergy 2017, 98, 228–235. [Google Scholar] [CrossRef]

- Zabed, H.M.; Akter, S.; Yun, J.; Zhang, G.; Zhang, Y.; Qi, X. Biogas from microalgae: Technologies, challenges and opportunities. Renew. Sustain. Energy Rev. 2020, 117, 109503. [Google Scholar] [CrossRef]

- Dutta, K.; Daverey, A.; Lin, J.-G. Evolution retrospective for alternative fuels: First to fourth generation. Renew. Energy 2014, 69, 114–122. [Google Scholar] [CrossRef]

- Rattanapan, C.; Sinchai, L.; Tachapattaworakul Suksaroj, T.; Kantachote, D.; Ounsaneha, W. Biogas production by co-digestion of canteen food waste and domestic wastewater under organic loading rate and temperature optimization. Environments 2019, 6, 16. [Google Scholar] [CrossRef] [Green Version]

- Capa, A.; García, R.; Chen, D.; Rubiera, F.; Pevida, C.; Gil, M.V. On the effect of biogas composition on the H2 production by sorption enhanced steam reforming (SESR). Renew. Energy 2020, 160, 575–583. [Google Scholar] [CrossRef]

- Sendzikiene, E.; Rimkus, A.; Melaika, M.; Makareviciene, V.; Pukalskas, S. Impact of biomethane gas on energy and emission characteristics of a spark ignition engine fuelled with a stoichiometric mixture at various ignition advance angles. Fuel 2015, 162, 194–201. [Google Scholar] [CrossRef]

- Khatri, N.; Khatri, K.K. Hydrogen enrichment on diesel engine with biogas in dual fuel mode. Int. J. Hydrogen Energy 2020, 45, 7128–7140. [Google Scholar] [CrossRef]

- Simsek, S.; Uslu, S. Investigation of the impacts of gasoline, biogas and LPG fuels on engine performance and exhaust emissions in different throttle positions on SI engine. Fuel 2020, 279, 118528. [Google Scholar] [CrossRef]

- Heywood, J. Internal Combustion Engine Fundamentals, 2nd ed.; MC Graw Hill Education: New York, NY, USA, 2018; ISBN 9781260116113. [Google Scholar]

- Malenshek, M.; Olsen, D.B. Methane number testing of alternative gaseous fuels. Fuel 2009, 88, 650–656. [Google Scholar] [CrossRef]

- Melaika, M. Research of a Combustion Process in a Spark Ignition Engine, Fuelled with Gaseous Fuel Mixtures. Ph.D. Thesis, Vilnius Gediminas Technical University, Vilnius, Lithuania, 2016. [Google Scholar]

- Gómez Montoya, J.P.; Amell, A.A.; Olsen, D.B. Prediction and measurement of the critical compression ratio and methane number for blends of biogas with methane, propane and hydrogen. Fuel 2016, 186, 168–175. [Google Scholar] [CrossRef]

- Gómez Montoya, J.P.; Amador Diaz, G.J.; Amell Arrieta, A.A. Effect of equivalence ratio on knocking tendency in spark ignition engines fueled with fuel blends of biogas, natural gas, propane and hydrogen. Int. J. Hydrogen Energy 2018, 43, 23041–23049. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, M.; Zhang, Z.; Zhang, D. Combustion and Emission characteristics of a spark ignition engine fuelled with biogas from two-phase anaerobic digestion (T-PAD). Energy Proc. 2017, 105, 137–142. [Google Scholar] [CrossRef]

- Subramanian, K.A.; Mathad, V.C.; Vijay, V.K.; Subbarao, P.M.V. Comparative evaluation of emission and fuel economy of an automotive spark ignition vehicle fuelled with methane enriched biogas and CNG using chassis dynamometer. Appl. Energy 2013, 105, 17–29. [Google Scholar] [CrossRef]

- Kim, Y.; Kawahara, N.; Tsuboi, K.; Tomita, E. Combustion characteristics and NOX emissions of biogas fuels with various CO2 contents in a micro co-generation spark-ignition engine. Appl. Energy 2016, 182, 539–547. [Google Scholar] [CrossRef]

- Kruczek, G.; Przybyła, G.; Ziółkowski, Ł.; Adamczyk, W.P. Comparative assessment of the application of methane and biogas in energy production: An experimental and numerical investigation. Renew. Energy 2019, 143, 1519–1530. [Google Scholar] [CrossRef]

- Schiaroli, N.; Lucarelli, C.; Sanghez de Luna, G.; Fornasari, G.; Vaccari, A. Ni-based catalysts to produce synthesis gas by combined reforming of clean biogas. Appl. Catal. A Gen. 2019, 582, 117087. [Google Scholar] [CrossRef]

- Lee, S.; Yi, U.H.; Jang, H.; Park, C.; Kim, C. Evaluation of emission characteristics of a stoichiometric natural gas engine fueled with compressed natural gas and biomethane. Energy 2021, 220, 119766. [Google Scholar] [CrossRef]

- Valipour Berenjestanaki, A.; Kawahara, N.; Tsuboi, K.; Tomita, E. Performance, Emissions and end-gas autoignition characteristics of PREMIER combustion in a pilot fuel-ignited dual-fuel biogas engine with various CO2 ratios. Fuel 2021, 286, 119330. [Google Scholar] [CrossRef]

- Abdallah, M.S.; Mansour, M.S.; Allam, N.K. Mapping the stability of free-jet biogas flames under partially premixed combustion. Energy 2021, 220, 119749. [Google Scholar] [CrossRef]

- Bouguessa, R.; Tarabet, L.; Loubar, K.; Belmrabet, T.; Tazerout, M. Experimental investigation on biogas enrichment with hydrogen for improving the combustion in diesel engine operating under dual fuel mode. Int. J. Hydrogen Energy 2020, 45, 9052–9063. [Google Scholar] [CrossRef]

- Gong, C.; Si, X.; Liu, F. Combustion and emissions behaviors of a stoichiometric GDI engine with simulated EGR (CO2) at low load and different spark timings. Fuel 2021, 295, 120614. [Google Scholar] [CrossRef]

- Khoa, N.X.; Lim, O. The effects of combustion duration on residual gas, effective release energy, engine power and engine emissions characteristics of the motorcycle engine. Appl. Energy 2019, 248, 54–63. [Google Scholar] [CrossRef]

- Hotta, S.K.; Sahoo, N.; Mohanty, K. Comparative assessment of a spark ignition engine fueled with gasoline and raw biogas. Renew. Energy 2019, 134, 1307–1319. [Google Scholar] [CrossRef]

- Talibi, M.; Hellier, P.; Ladommatos, N. Combustion and exhaust emission characteristics, and in-cylinder gas composition, of hydrogen enriched biogas mixtures in a diesel engine. Energy 2017, 124, 397–412. [Google Scholar] [CrossRef]

- Li, J.; Huang, H.; Huhetaoli; Osaka, Y.; Bai, Y.; Kobayashi, N.; Chen, Y. Combustion and heat release characteristics of biogas under hydrogen- and oxygen-enriched condition. Energies 2017, 10, 1200. [Google Scholar] [CrossRef] [Green Version]

- European Biogas Association. Avoided Emissions from Biogas and Biomethane Can Lead to a Negative Carbon Footprint. Available online: https://www.europeanbiogas.eu/avoided-emissions-from-biogas-and-biomethane-can-lead-to-a-negative-carbon-footprint/ (accessed on 8 April 2021).

- Xie, F.-X.; Li, X.-P.; Wang, X.-C.; Su, Y.; Hong, W. Research on using EGR and Ignition timing to control load of a spark-ignition engine fueled with methanol. Appl. Therm. Eng. 2013, 50, 1084–1091. [Google Scholar] [CrossRef]

- Porpatham, E.; Ramesh, A.; Nagalingam, B. Effect of spark timing on the performance of a spark ignition engine running on biogas–hydrogen blends. Biofuels 2017, 8, 635–642. [Google Scholar] [CrossRef]

- Rimkus, A.; Stravinskas, S.; Matijošius, J. Comparative study on the energetic and ecologic parameters of dual fuels (diesel–NG and HVO–biogas) and conventional diesel fuel in a CI engine. Appl. Sci. 2020, 10, 359. [Google Scholar] [CrossRef] [Green Version]

- Slefarski, R. Study on the combustion process of premixed methane flames with CO2 dilution at elevated pressures. Energies 2019, 12, 348. [Google Scholar] [CrossRef] [Green Version]

| Property | BG41 | BG34 | BG13 |

|---|---|---|---|

| Composition (vol%) | CH4–57% CO2–41% CO–0.18% H2–0.18% | CH4–65% CO2–34% CO–traces H2–traces | CH4–87% CO2–13% CO–traces H2–traces |

| Lower heating value (LHV) at 1 atm and 15 °C (MJ/kg) | 17.0 | 21.7 | 35.5 |

| Density at 1 atm and 15 °C (kg/m3) | 1.20 | 1.15 | 0.68 |

| Stoichiometric A/F (kg of air/kg of fuel) | 5.8 | 9.5 | 12.2 |

| Leaner flammability limits (vol% in air) | 7.5 | 7.5 | 7.5 |

| Richer flammability limits (vol% in air) | 14 | 14 | 14 |

| Methane number | 142 | 135 | 110 |

| Autoignition temperature (°C) | 650 | 650 | 650 |

| Carbon/total mass ratio | 0.43 | 0.47 | 0.61 |

| Oxygen/total mass ratio | 0.48 | 0.43 | 0.21 |

| Property | Pressure Sensor ZI31_Y7S | Property | Signal Amplifier DiTEST DPM 800 |

|---|---|---|---|

| Measuring range | 0–200 bar | Input range | 6000 pC |

| Sensitivity | 12 pC/bar | Signal output | 1 mV/pC |

| Capacitance | 5 pF | Zero offset | 0.5 V |

| Acceleration sensitivity | 0.001 bar/g | Signal amplitude | 0.5–4.5 V |

| Temperature range | 40–350 °C | Temperature range | −10–120 °C |

| Linearity | ±0.5% | Power supply | 8 V–32 V |

| Natural frequency | 130 kHz | Dimensions | l = 131 mm, d = 13.8 mm |

| Parameter | Measurement Principle | Measuring Range | Resolution |

|---|---|---|---|

| CO | Non dispersive infrared | 0–10%, by vol. | 0.01% |

| CO2 | Non dispersive infrared | 0–20%, by vol. | 0.1% |

| HC | Non dispersive infrared | 0–20,000 ppm, by vol. | 1 ppm |

| NOx | Electrochemical | 0–5000 ppm, by vol. | 1 ppm |

| O2 | Electrochemical | 0–25%, by vol. | 0.01% |

| λ | Calculation | 0–9.999 | 0.001 |

| Marking | CO2, vol% | CH4, vol% | LHV, MJ/kg | Methane Number | Stoichiometric A/F Ratio | ST, CAD BTDC 1 | |

|---|---|---|---|---|---|---|---|

| Constant | Optimal | ||||||

| BG0 | 0 | 100 | 50.0 | 100 | 17.2 | 26 | 26 |

| BG20 | 20 | 80 | 29.7 | 118 | 10.2 | 26 | 30 |

| BG40 | 40 | 60 | 17.7 | 140 | 6.1 | 26 | 35 |

| BG50 | 50 | 50 | 13.4 | 151 | 4.6 | 26 | 40 |

| Marking | ST, CAD BTDC | SOC 1, CAD BTDC | 10% MBF 2, CAD BTDC | 50% MBF, CAD ATDC 3 | 90% MBF, CAD ATDC |

|---|---|---|---|---|---|

| BG0 | 26 | 22.5 | 4.1 | 7.0 | 22.9 |

| BG20 | 30 | 23.8 | 5.5 | 6.0 | 24.0 |

| 26 | 20.1 | 1.8 | 10.4 | 25.5 | |

| BG40 | 35 | 27.8 | 5.6 | 7.3 | 28.0 |

| 26 | 19.3 | −1.2 | 15.9 | 40.3 | |

| BG50 | 40 | 27.0 | 3.9 | 9.7 | 28.2 |

| 26 | 17.8 | −4.7 | 21.2 | 42.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kriaučiūnas, D.; Pukalskas, S.; Rimkus, A.; Barta, D. Analysis of the Influence of CO2 Concentration on a Spark Ignition Engine Fueled with Biogas. Appl. Sci. 2021, 11, 6379. https://doi.org/10.3390/app11146379

Kriaučiūnas D, Pukalskas S, Rimkus A, Barta D. Analysis of the Influence of CO2 Concentration on a Spark Ignition Engine Fueled with Biogas. Applied Sciences. 2021; 11(14):6379. https://doi.org/10.3390/app11146379

Chicago/Turabian StyleKriaučiūnas, Donatas, Saugirdas Pukalskas, Alfredas Rimkus, and Dalibor Barta. 2021. "Analysis of the Influence of CO2 Concentration on a Spark Ignition Engine Fueled with Biogas" Applied Sciences 11, no. 14: 6379. https://doi.org/10.3390/app11146379

APA StyleKriaučiūnas, D., Pukalskas, S., Rimkus, A., & Barta, D. (2021). Analysis of the Influence of CO2 Concentration on a Spark Ignition Engine Fueled with Biogas. Applied Sciences, 11(14), 6379. https://doi.org/10.3390/app11146379