Smart Factory Web—A Blueprint Architecture for Open Marketplaces for Industrial Production

Abstract

:Featured Application

Abstract

1. Motivation

1.1. Platform Economy

- Business managers ask:

- What are the associated business models, for each of the stakeholders involved?

- How shall they be designed such that, for all stakeholders involved, there are fair conditions as well as sufficient incentives to participate?

- System architects resp. IT experts ask:

- What is the best IT strategy and technical architecture to support these business models?

- What are the resulting system requirements that serve as design parameters for the architecture?

1.2. Business Models

- BM2 Affiliation, BM37 Peer to Peer, BM52 Two-sided Market: support others to market products; brokering of peer to peer relationships; lending/sharing resources with trustworthy and efficient transactions; facilitate interactions between independent groups of customers, e.g., between providers and users of a technology or machine; broker deals between buyers and sellers

- BM30 Mass Customization: efficient product customization to meet customer needs; using standardized modular product architectures with standardized product description formats.

- BM32 Open Business: open, collaborative value creation chains; collaborative product design and production engineering. The aim is to establish an ecosystem of synergetic companies to create greater customer value.

- BM34 Orchestrator: coordination and matching of individual value creation activities in a value chain. The orchestrating company manages and directs the entire value chain, focusing on its key strengths and outsourcing other activities.

- BM54 User Design: platform supports customers to design and market their products. There is a strong focus on co-design in a network of partners. The main process steps are idea initiation, product co-design, production and sales.

1.3. Structure of the Paper

2. System Requirements

- The term “service” always refers to a production service.

- The term “industrial marketplace” denotes a marketplace for industrial production. The applicability to other application domains beyond “production” is possible, of course, but not considered in this paper.

- The term “asset” refers to an “entity which is owned by or under the custodial duties of an organization, having either a perceived or actual value to the organization” [2].

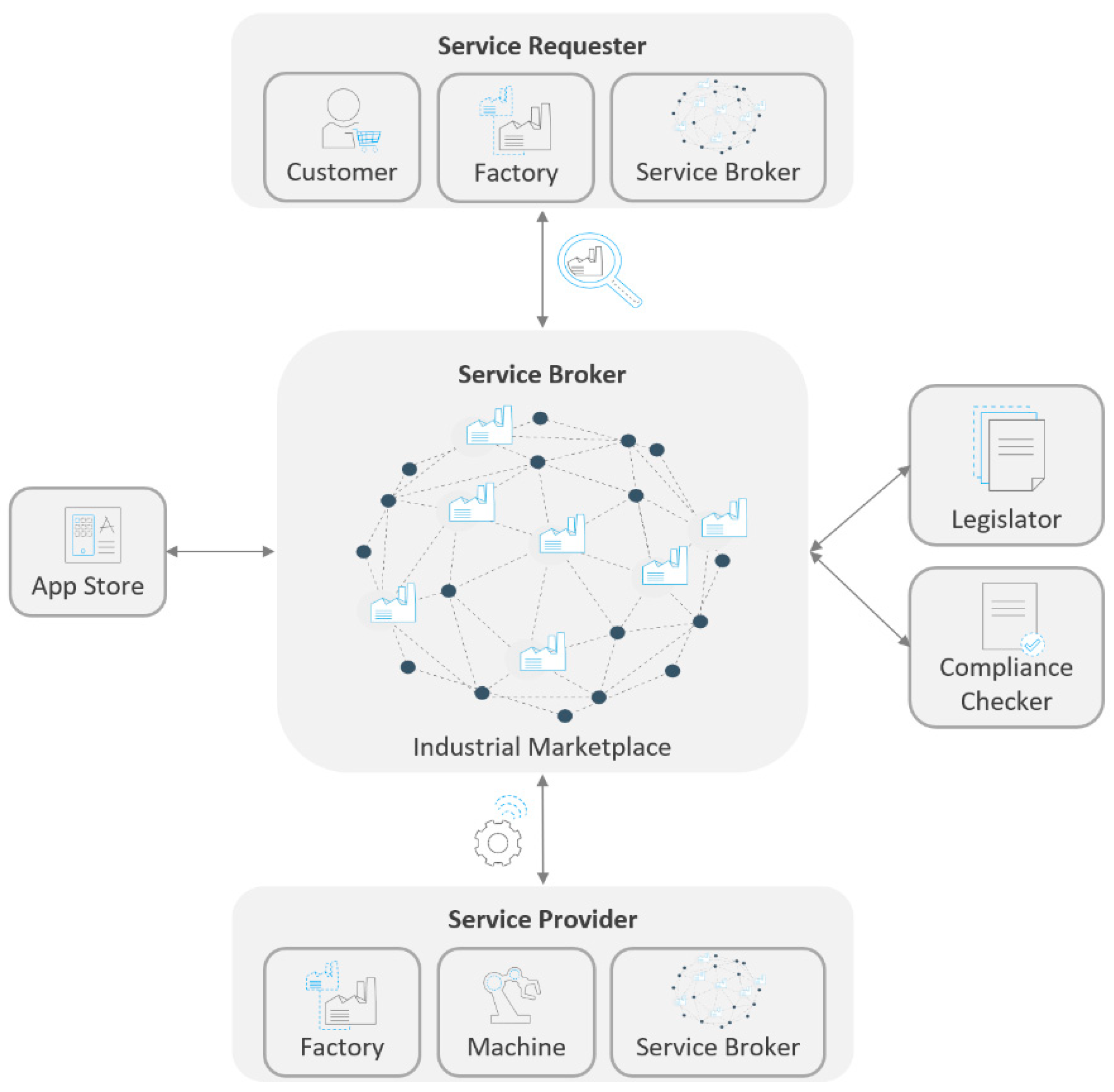

2.1. Stakeholders

2.2. Functional and Non-Functional Requirements

3. State of the Art

3.1. Manufacturing as a Service (MaaS)

- CNC machining;

- Three-dimensional printing;

- Urethane casting;

- Sheet metal fabrication;

- Injection molding.

- Min and max of the product sizes;

- Minimum hole size;

- Tolerances;

- Production time;

- Field of application (e.g., exclusion of fields where products must be certified).

3.2. Industrial APP Marketplace

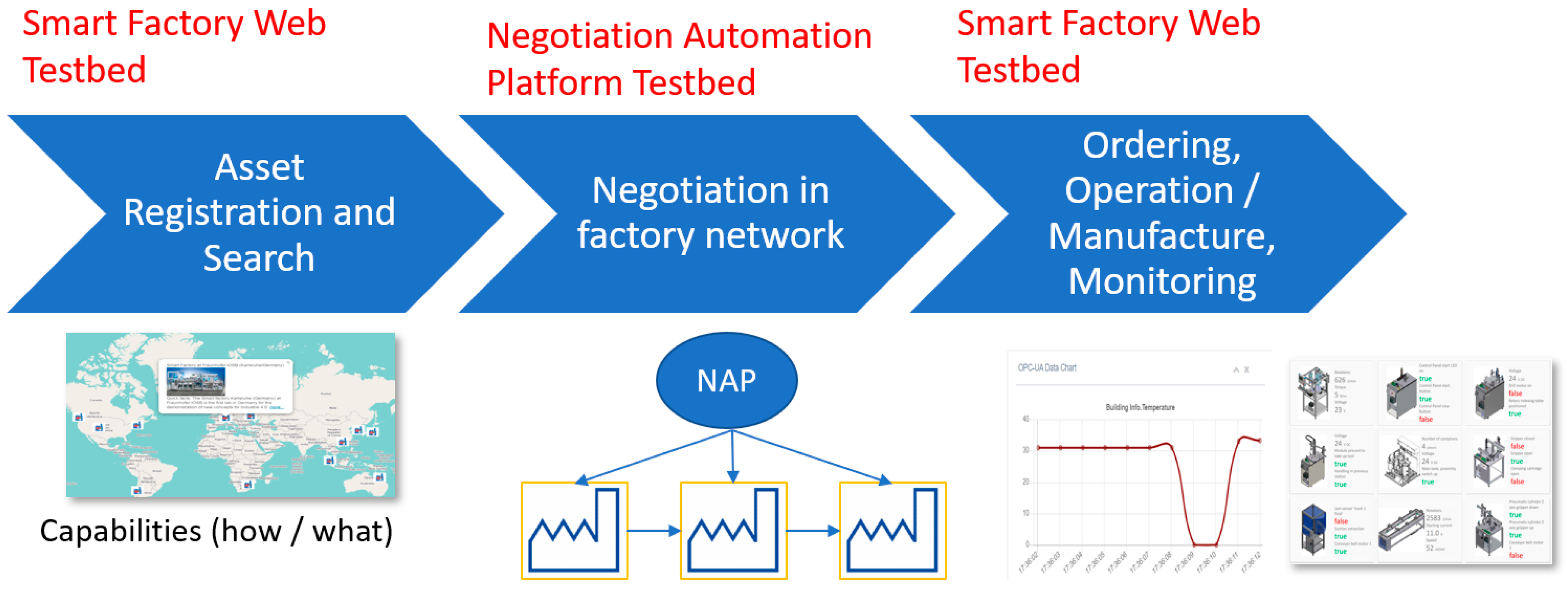

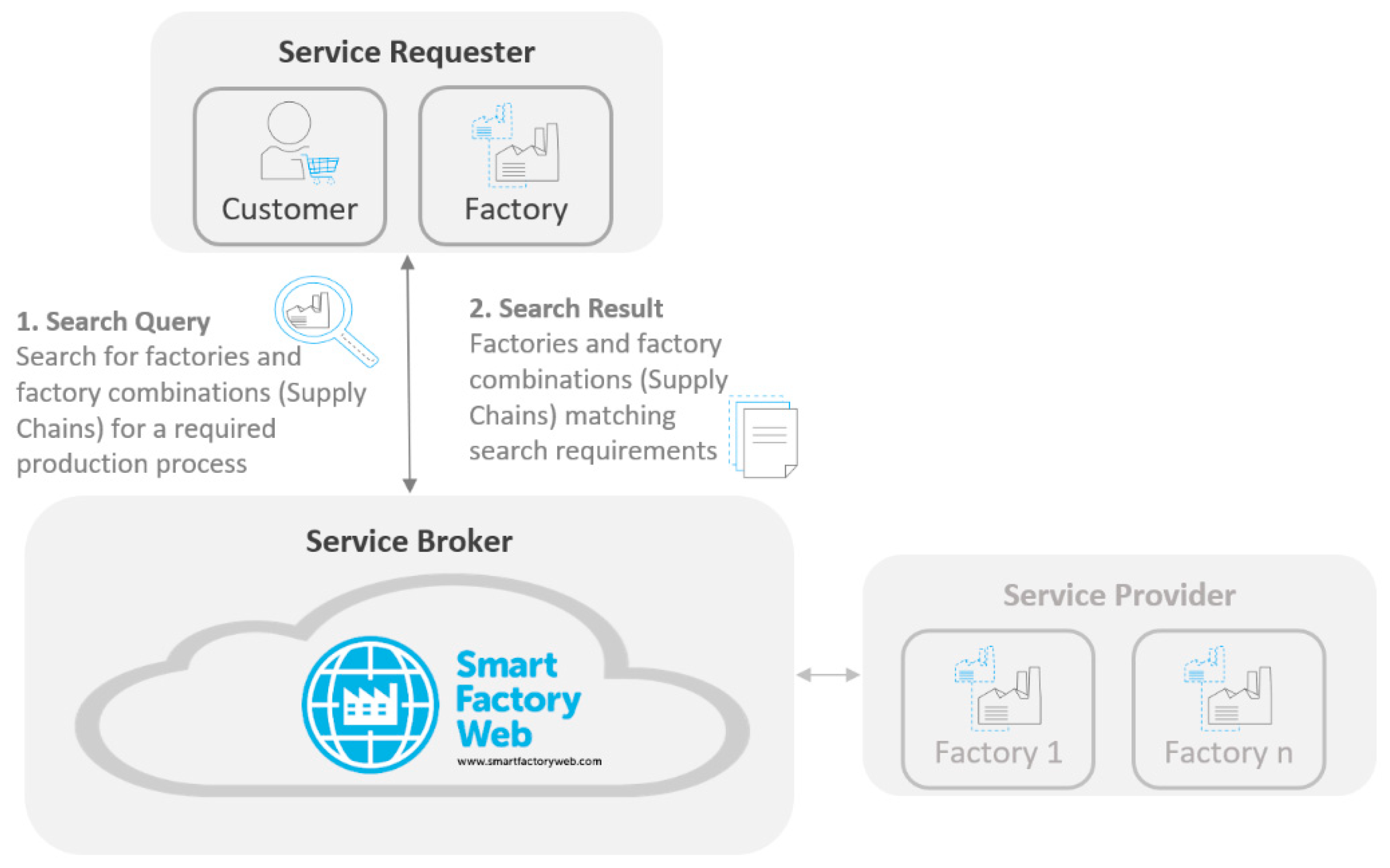

4. IIC Testbed Smart Factory Web

- Achieve a flexible adaptation of production capabilities and sharing of resources and assets in a web of Smart Factories to improve order fulfillment.

- Provide the technical basis for new business models with flexible assignment and sharing of production resources.

5. Smart Factory Web Approach

5.1. Motivation

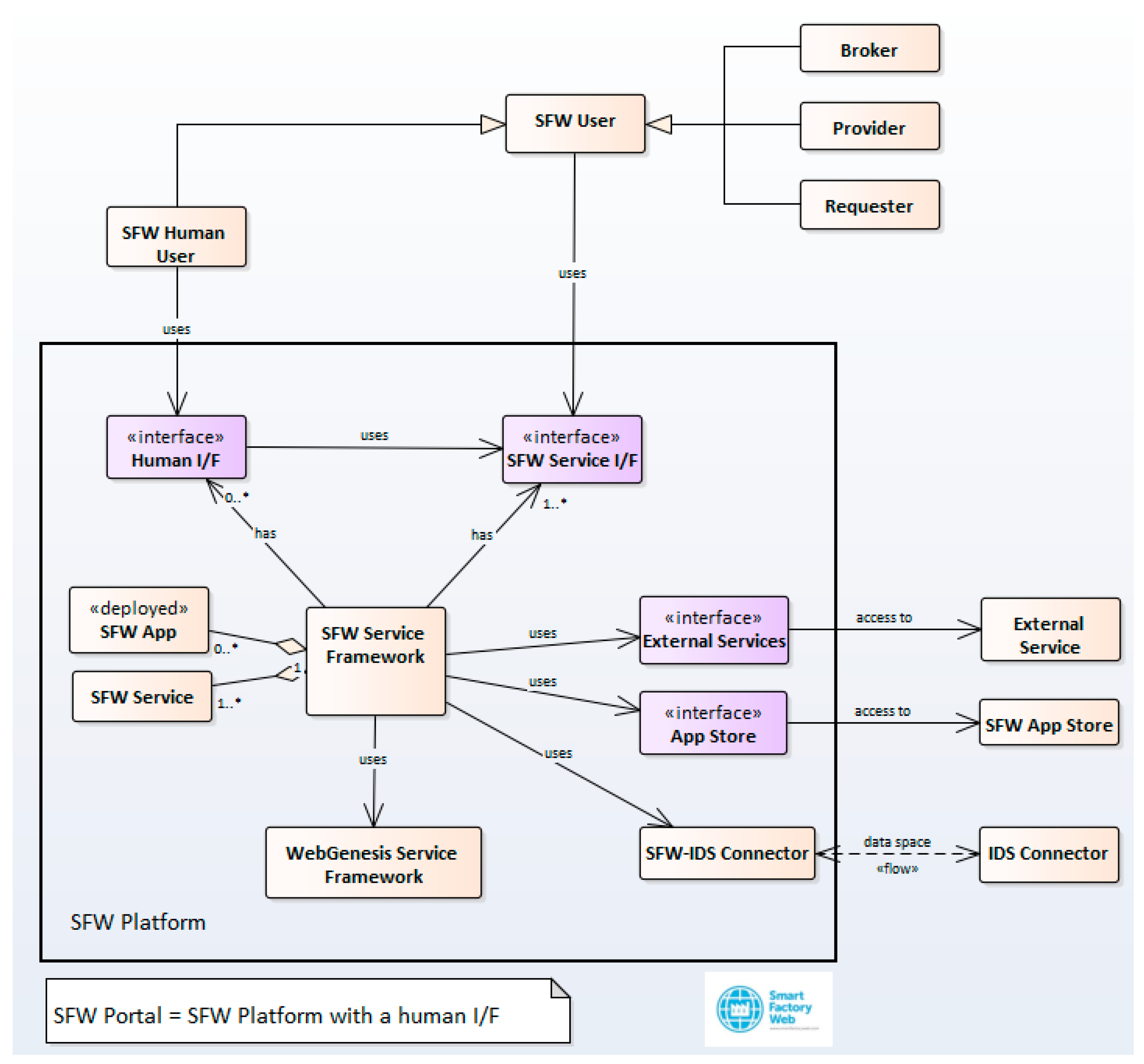

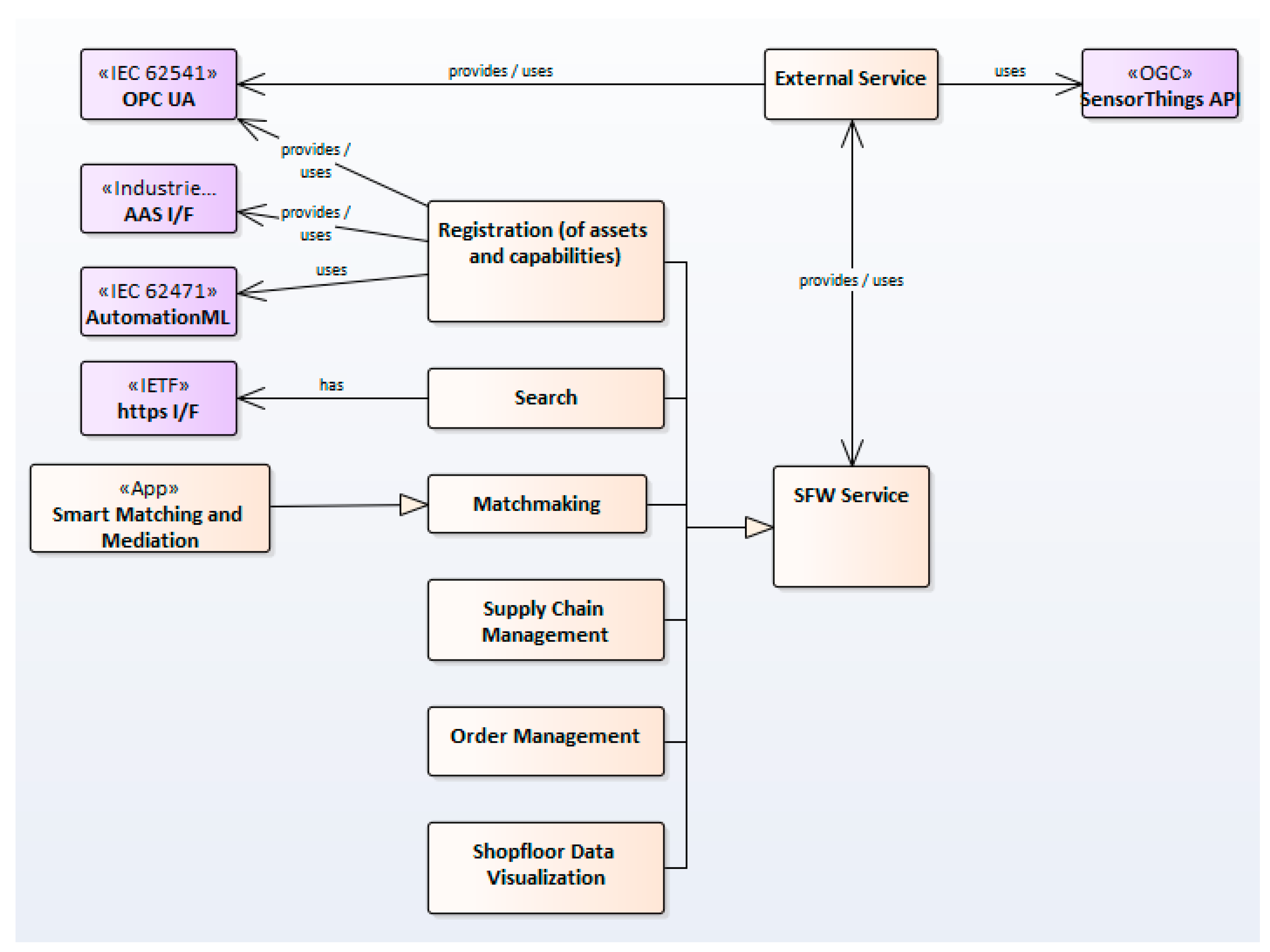

5.2. Architecture Overview

- AAS or AutomationML for factory registration.

- Open Geospatial Consortium (OGC) SensorThings API and IEC 62541 OPC UA for connecting machines and sensors.

- IDS for secure and trusted data exchange in business ecosystems [15].

5.3. Factory Registration and Interoperability

- Providers are aware of the SFW capability ontology and have prepared their registration information as instances of this ontology, or;

- Developers should be involved to ensure that provider information is accurately mapped to the SFW capability ontology. This requires negotiation with each provider individually to agree the mappings.

5.4. Search for Production Capabilities

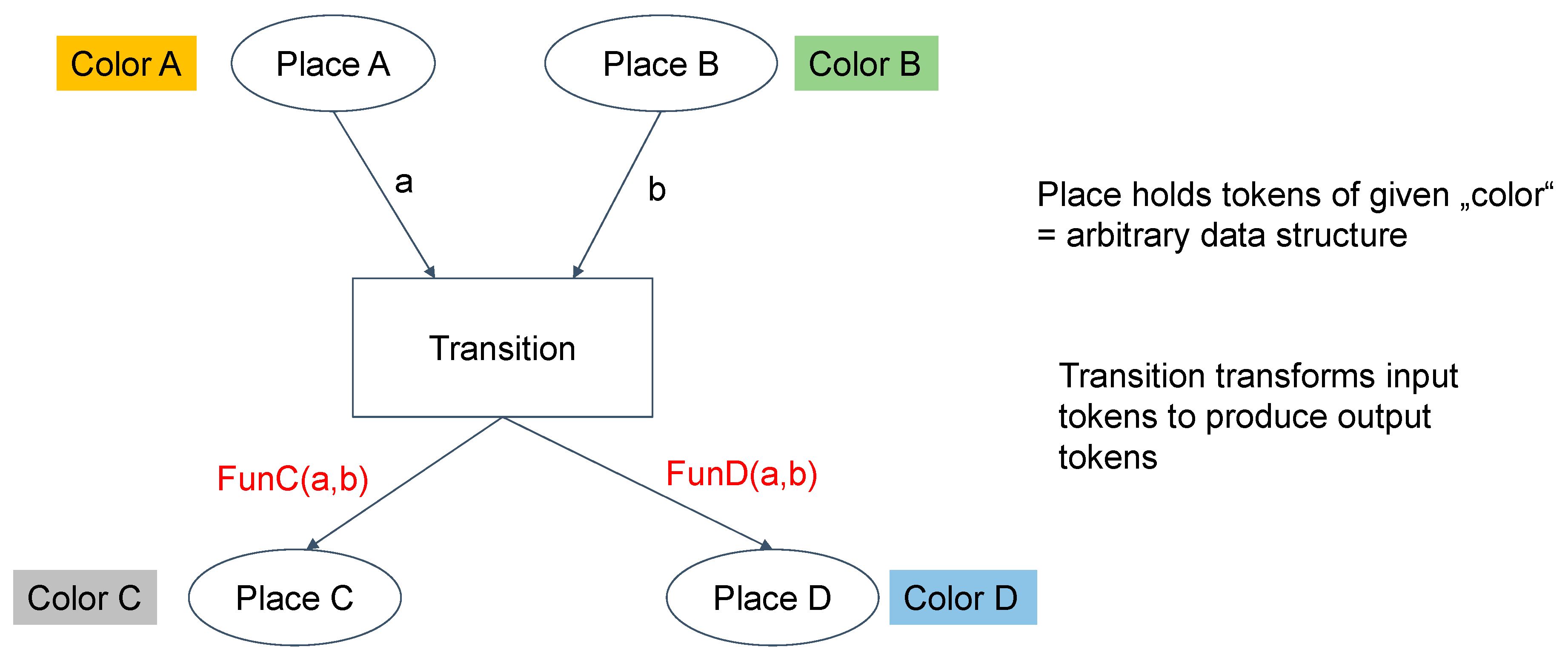

5.4.1. Process Description with Colored Petri Nets

- It must be able to describe a flexible network of assets (resources), materials, process steps and intermediate products in a production diagram.

- It should be possible to flexibly assign properties (attributes) to entities.

- The model must be able to handle synchronization and timing in order to describe the scheduling dependencies in a production diagram.

- It must be possible to formulate constraints on process steps such as restrictions on properties of input products.

- The model shall support a modular approach and a hierarchy of submodels. This allows several engineers to work on the same overall model, allows models to be re-used and allows the modeling process to be structured with a top-down or bottom-up approach.

- Models shall be linkable through I/O interfaces.

- A model shall have a formal, mathematical foundation to enable model validation and the deployment of analysis tools to assess the model behavior (e.g., to find deadlocks or to simulate the model execution.

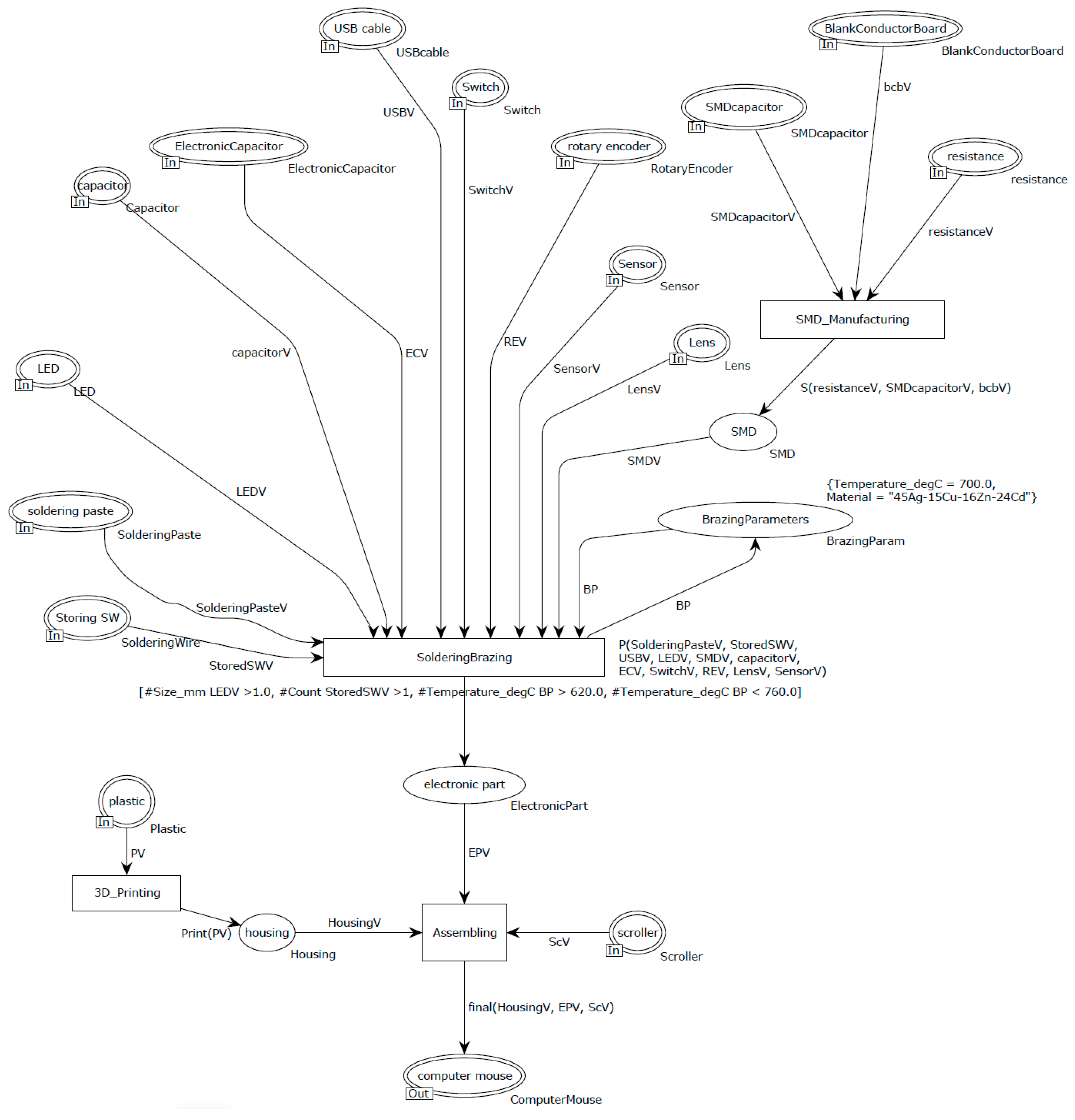

- SolderingBrazing: to join the component products LED, Capacitor, ElectronicCapacitor, USBcable, Switch, RotaryEncoder, Sensor, Lens and SMD (Surface Mounted Device) using SolderingWire and SolderingPaste.

- SMD_Manufacturing: to make an SMD from the input products SMDcapacitor, BlankConductorBoard and resistance.

- 3D_Printing: to produce the mouse Housing from plastic with a set price and color.

- Assembling: to assemble the Scroller, ElectronicPart and Housing for the final product ComputerMouse.

5.4.2. Search for Factories and Factory Combinations (Supply Chains)

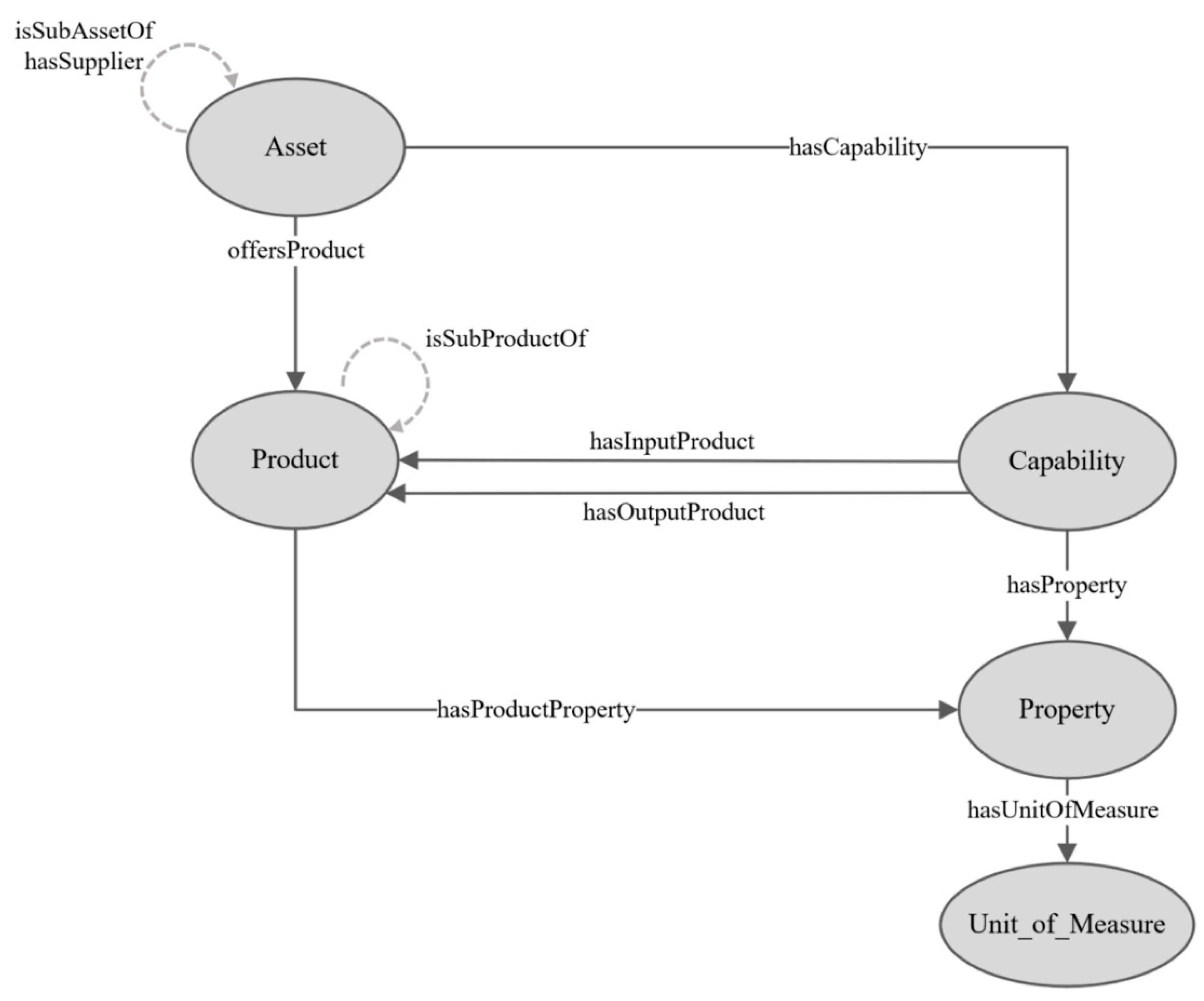

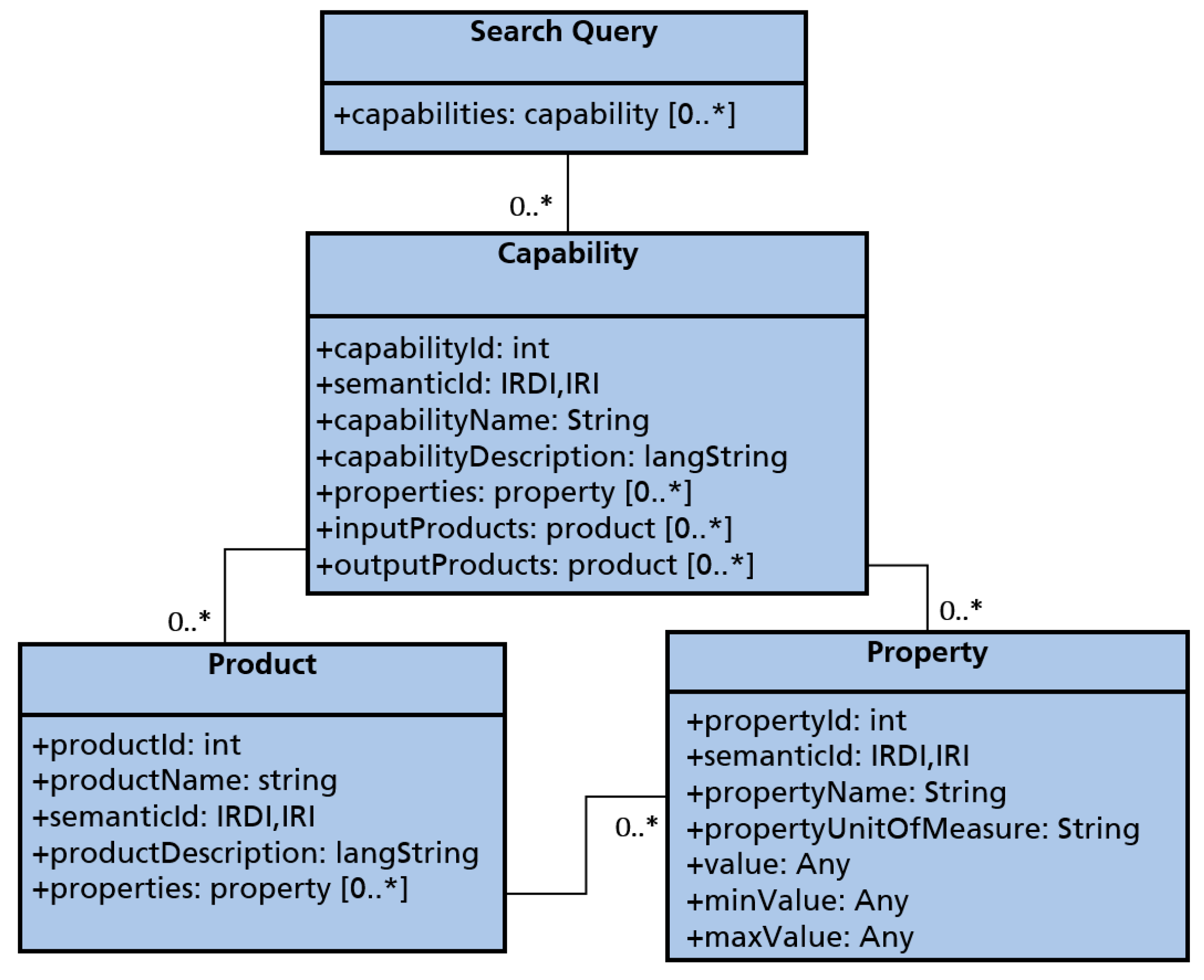

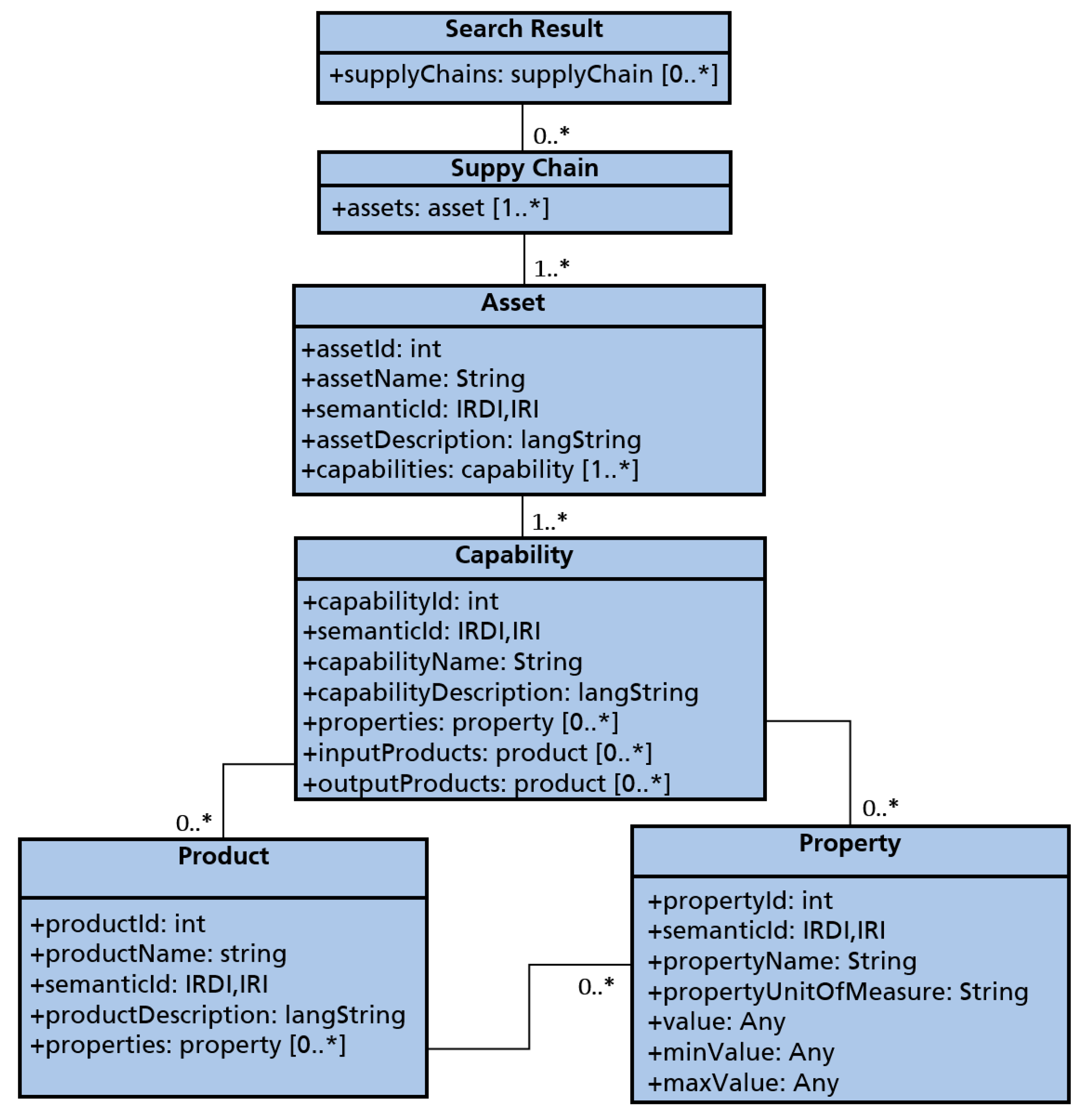

- Capability (of an asset) is described in terms of its input and output products and their respective properties, and/or in terms of how the product can be produced. The capability concept enables the modeling of process steps (BOP Bill of Process, e.g., manufacturing processes for the production of a product). The capability description is comprised of the three sections covering (1) the properties of the production process itself, (2) the input products and their properties and (3) the output products and their properties.

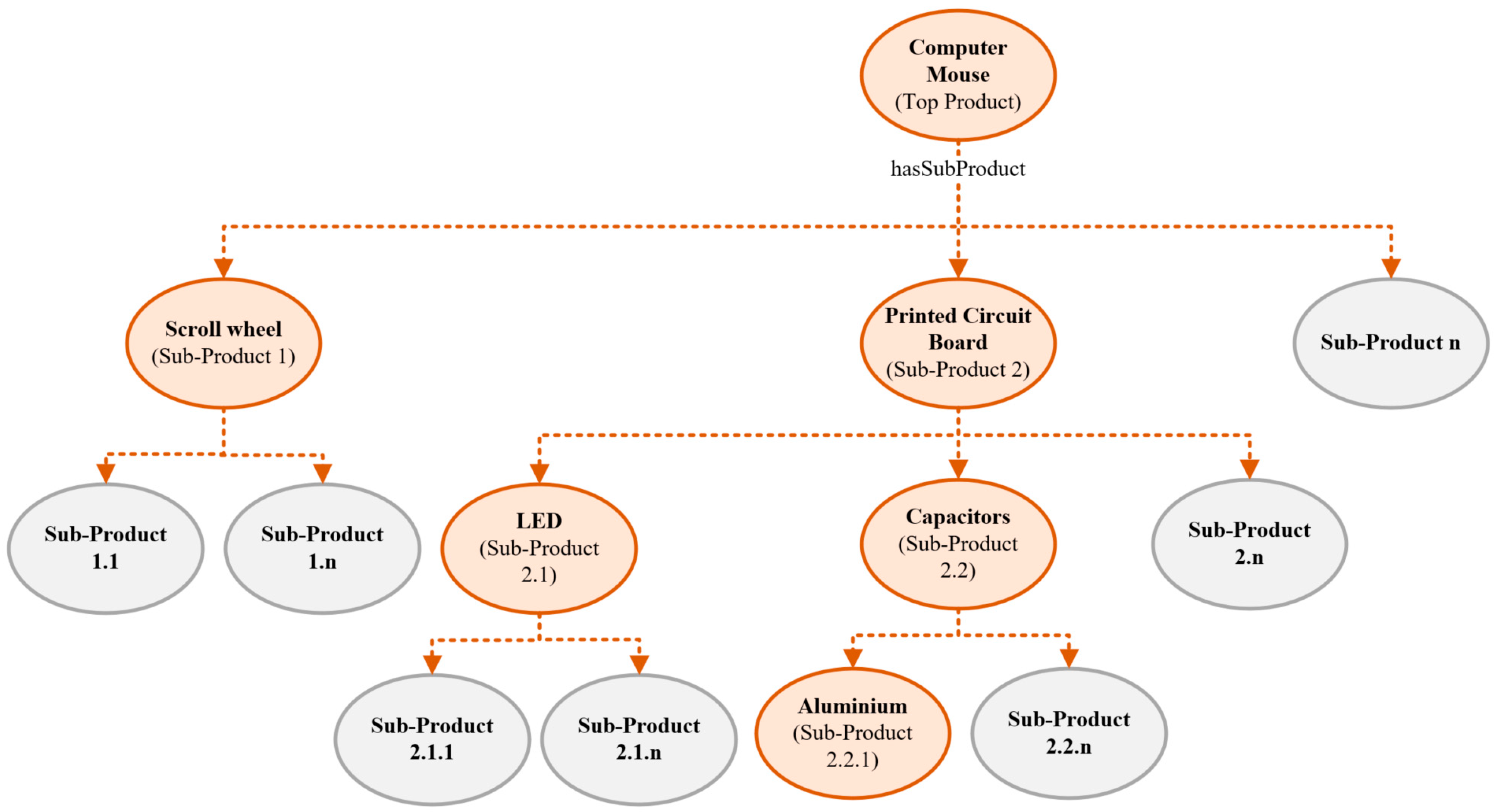

- Product: The product structure (BOM Bill of Material) for both input and output products.

- Property: The property concept is used to describe capabilities and products in more detail.

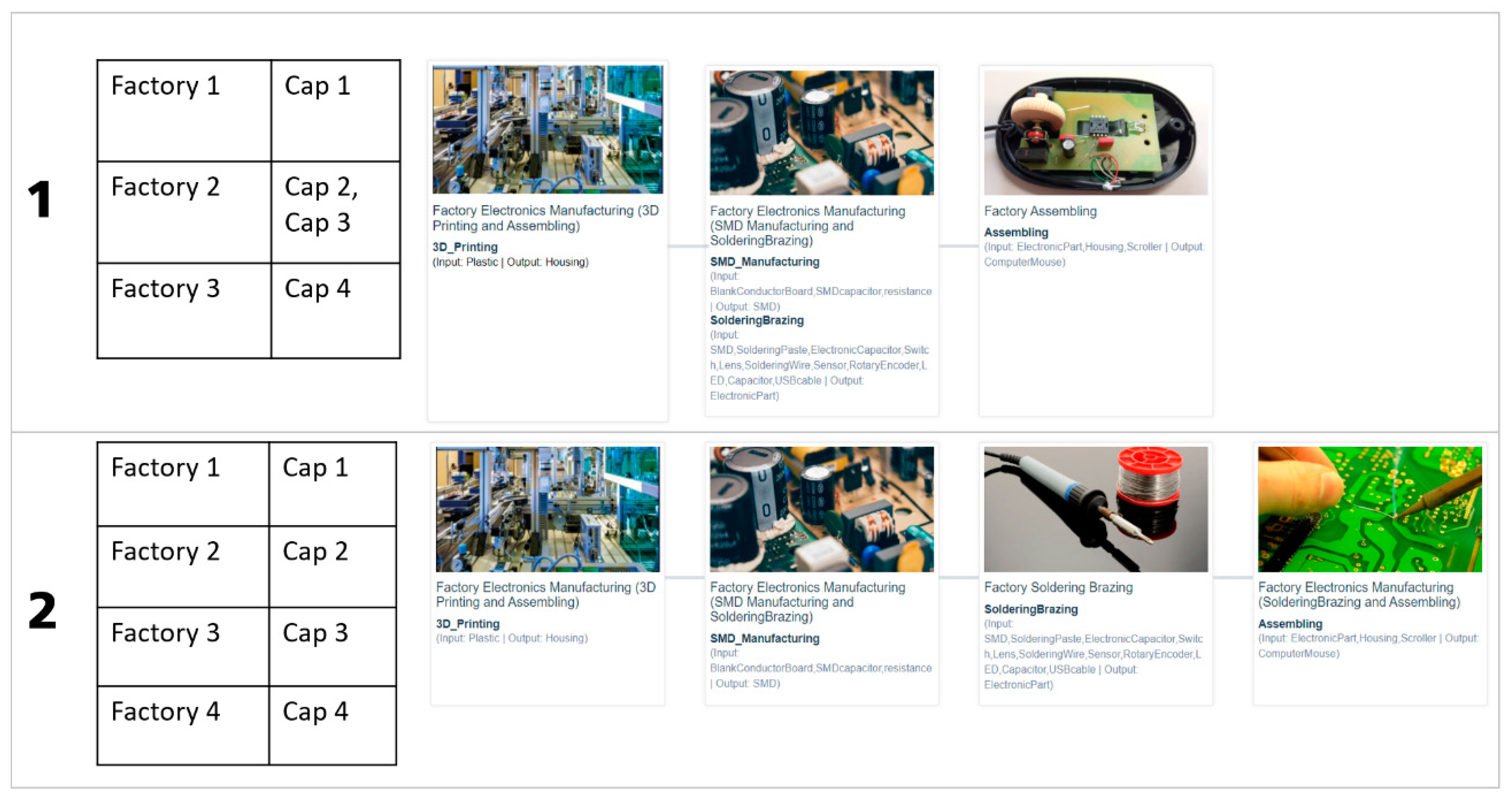

- Search for factories that possess the requested capabilities: For each capability or process step searched, a list of all factories is generated that possess this capability, including constraints regarding properties and input/output products, or that can execute the production step.

- Generate Cartesian product: Then, the Cartesian product of these factory sets is generated to obtain all possible factory combinations (supply chains).

- Merge factory combinations: In the last step, these supply chains are merged once again. Thereby, factories with several capabilities are identified and the supply chain is simplified (see Figure 10).

5.4.3. Search Result

- Asset data: unique ID, name, semanticID, description, capabilities;

- Capability data: unique ID, name, semanticID, description, properties, products (input/output);

- Product (input/output) data: unique ID, name, semanticID, description, properties;

- Property data: unique ID, name, semanticID, value or value range (minValue, maxValue), unit of measure.

- The first supply chain consists of three factories (Factory 1–3) to fulfill the required capabilities (Cap1, Cap2, Cap3, Cap4) together. Factory 2 executes two production steps (Cap2, Cap3). Factory 1 and 3 execute one production step.

- The second supply chain consists of four factories (Factory 1–4) to fulfill the required capabilities (Cap1, Cap2, Cap3, Cap4) together. Each factory executes one production step.

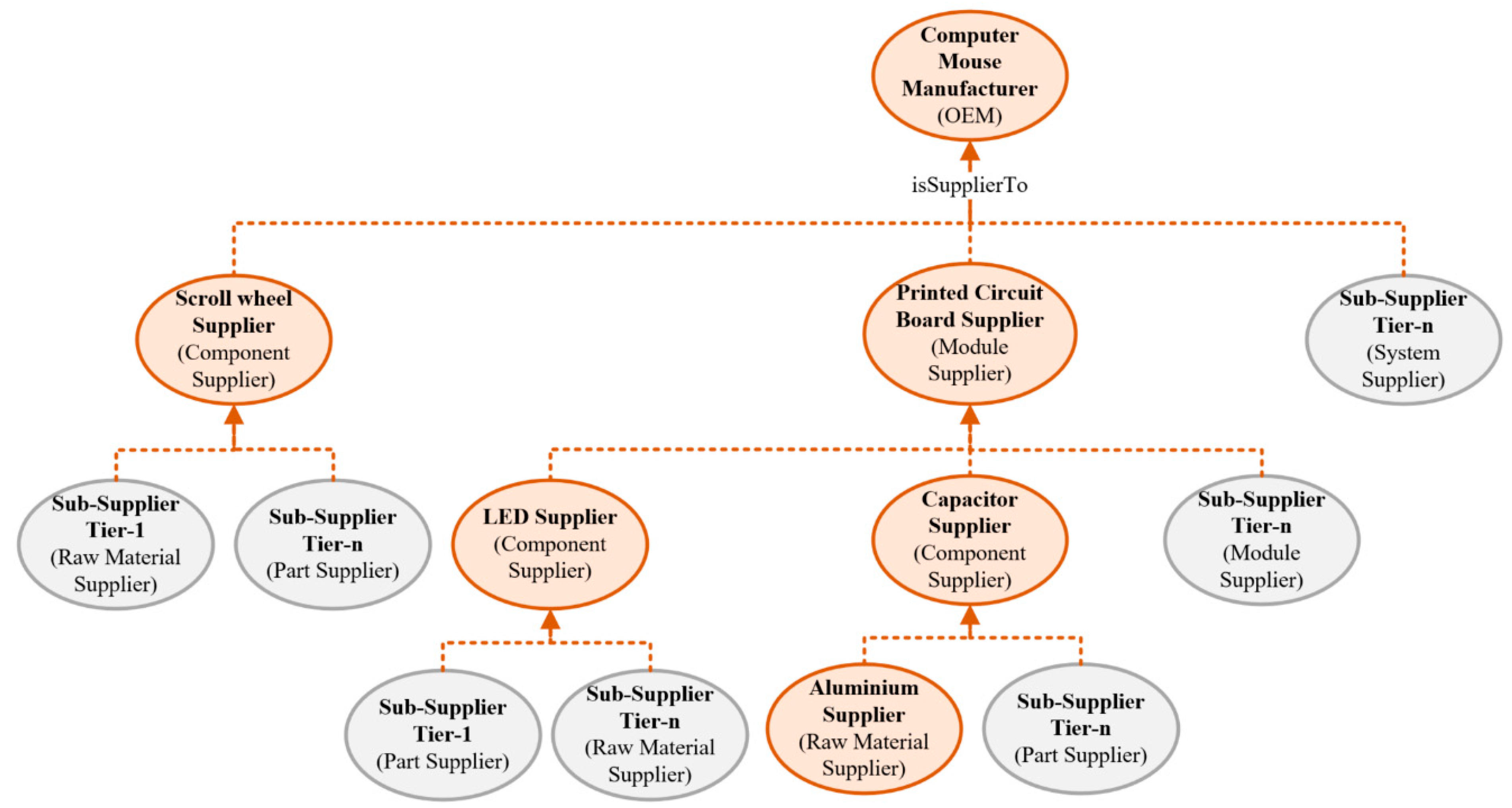

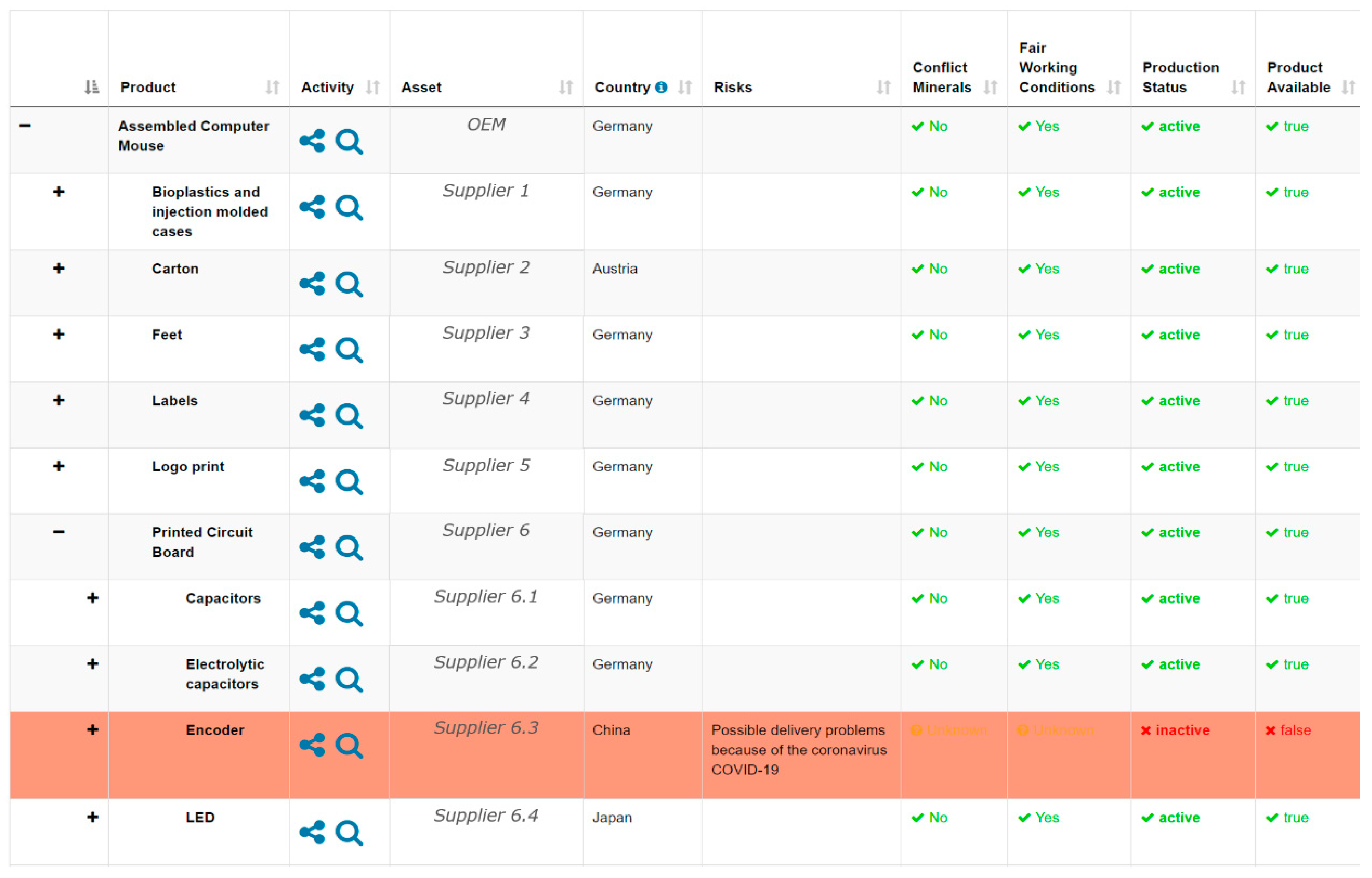

5.5. Supply Chain and Supply Network Modelling

5.6. Visualization of Supply Networks and Supply Chains

5.7. Trustworthiness

6. Evaluation

7. Validation in International Smart Factory Markets

7.1. Negotiation Automation Platform in Japan

- To adapt their transport systems to the current business situation, respectively;

- To reduce logistics costs;

- To avoid redundant traffic and reduce the total traffic amount in society.

7.2. Smart Factory Networks in South Korea

- Process Automation Market: Development and proof of concept of Batch Process Orchestration technology based on an OPC UA information model. It shows how modularity of water treatment processes may be realized by means of OPC UA in order to increase the flexibility and changeability.

- Parts Processing Market: KPI prediction by applying the concept of digital twins to virtual commissioning, e.g., to predict design and engineering accuracy and precision, and to optimize the process and complete the product w.r.t. energy consumption, material usage, time, waste, etc.

7.3. European Project Eur3ka

8. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kenney, M.; Zysman, J. The Rise of the Platform Economy. Issues in Science and Technology 32, No. 3 (Spring 2016). Available online: https://issues.org/rise-platform-economy-big-data-work/ (accessed on 15 July 2021).

- Platform Industrie 4.0. Glossary. Available online: https://www.plattform-i40.de/PI40/Navigation/EN/Industrie40/Glossary/glossary.html (accessed on 15 July 2021).

- Hevner, A.R.; March, S.T.; Park, J. Design Science in Information System Research. Manag. Inf. Syst. Q. 2004, 28, 75–105. [Google Scholar] [CrossRef] [Green Version]

- Gassmann, O.; Frankenberger, K.; Csik, M. The Business Model Navigator; Pearson Education Ltd.: London, UK, 2014; ISBN 9781292064816. [Google Scholar]

- Moser, D.J. The Platform Economy—Strategies, Governance, and Business Models. Ph.D. Thesis, University of St. Gallen, St. Gallen, Switzerland, 2018. [Google Scholar]

- Soltysova, Z.; Modrak, V. Challenges of the Sharing Economy for SMEs: A Literature Review. Sustainability 2020, 12, 6504. [Google Scholar] [CrossRef]

- Usländer, T. Service-Oriented Design of Environmental Information Systems; KIT Scientific Publishing: Karlsruhe, Germany, 2010. [Google Scholar] [CrossRef]

- Council of Supply Chain Management Professionals (CSCMP). Supply Chain Management Definitions and Glossary. Available online: https://cscmp.org/CSCMP/Academia/SCM_Definitions_and_Glossary_of_Terms/CSCMP/Educate/SCM_Definitions_and_Glossary_of_Terms.aspx (accessed on 15 July 2021).

- Baudoin, C.; Bournival, E.; Buchheit, M.; Guerrero, R. The Industrial Internet of Things Vocabulary, Version V2.3: An Industrial Internet Consortium Framework Publication. Available online: https://www.iiconsortium.org/pdf/Vocabulary-Report-2.3.pdf (accessed on 22 April 2021).

- Heymann, S. Industrial APP Marketplace: Auf dem Weg zu Einem Neuen Marktplatz für die Intelligente Produktion. Available online: https://smartfactory-owl.de/portfolio-item/industrial-app-marketplace/ (accessed on 21 May 2021).

- Peters, M.; Kulawik, J. Volkswagen Brings Additional Partners to Industrial Cloud. Available online: https://www.volkswagen-newsroom.com/en/press-releases/volkswagen-brings-additional-partners-to-industrial-cloud-6258 (accessed on 21 May 2021).

- Babarinow, M. Industrial IoT Application Store: The Next Big Thing? Available online: https://www.linkedin.com/pulse/industrial-iot-application-store-next-big-thing-maxim-babarinow/ (accessed on 21 May 2021).

- Watson, K.; Becker, K.; Heymann, S.; Okon, M.; Schnebel, B.; Schöppenthau, F.; Stojanovic, L. Usage of Standards in the Smart Factory Web Testbed: An Industrial Internet Consortium White Paper. Available online: https://www.iiconsortium.org/pdf/Usage_of_Standards_in_Smart_Factory_Web_TB_White_Paper_2020-06-29.pdf (accessed on 16 July 2021).

- Heymann, S.; Stojanovic, L.; Watson, K.; Nam, S.; Song, B.; Gschossmann, H.; Schriegel, S.; Jasperneite, J. Cloud-based Plug and Work architecture of the IIC Testbed Smart Factory Web. In Proceedings of the IEEE 23rd International Conference on Emerging Technologies and Factory Automation (ETFA 2018), Torino, Italy, 4–7 September 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 187–194, ISBN 9781538671085. [Google Scholar]

- Hillermeier, O.; Punter, M.; Schweichhart, K.; Usländer, T. (Eds.) Data Sovereignty—Critical Success Factor for the Manufcaturing Industry. Available online: https://internationaldataspaces.org/wp-content/uploads/IDSA-Position-Paper-Data-Sovereignty%E2%80%93Critical-Success-Factor-for-the-Manufacturing-Industry.pdf (accessed on 16 July 2021).

- DIN SPEC 27070:2020-03. Reference Architecture of a Security Gateway for the Exchange of Industry Data and Services. Beuth Verlag. Available online: https://www.beuth.de/de/technische-regel/din-spec-27070/319111044 (accessed on 15 July 2021).

- IEC 62264-1. Enterprise-Control System Integration—Part 1: Models and Terminology, 2nd ed.; International Organization for Standardization: Geneva, Switzerland, 2013. [Google Scholar]

- Jensen, K.; Kristensen, L.M. Coloured Petri Nets: Modelling and Validation of Concurrent Systems; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 9783642002830. [Google Scholar]

- ISO/IEC 15909-1:2019. Software and System Engineering—High-Level Petri Nets—Part 1: Concepts, Definitions and Graphical Notation, 2nd ed.; International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

- Drakaki, M.; Tzionas, P. Manufacturing Scheduling Using Colored Petri Nets and Reinforcement Learning. Appl. Sci. 2017, 7, 136. [Google Scholar] [CrossRef]

- van der Aalst, W.M.P. Decomposing Petri nets for process mining: A generic approach. Distrib. Parallel Databases 2013, 31, 471–507. [Google Scholar] [CrossRef] [Green Version]

- Press and Information Office of the Federal Government. Supply Chain Act (Lieferkettengesetz): Greater Protection for People and the Environment in the Global Economy. Available online: https://www.bundesregierung.de/breg-en/news/supply-chain-act-1872076 (accessed on 14 June 2021).

- Schöppenthau, F. Modellierung und Visualisierung von Liefernetzwerken für Produktionsmarktplätze im Kontext von Industrie 4.0 (Modeling and Visualization of Supply Networks for Production Marketplaces in the Context of Industry 4.0). Bachelor Thesis, Duale Hochschule Baden-Württemberg Karlsruhe (DHBW), Karlsruhe, Germany, 6 May 2019. Available online: http://publica.fraunhofer.de/dokumente/N-583005.html (accessed on 15 July 2021).

| Role Name | Description |

|---|---|

| [Service] Provider | Provider of production capabilities by means of production assets (e.g., factory or machine within a production plant) |

| [Service] Requester | Requester of services to be provided by manufacturers, suppliers, systems, etc. |

| [Service] Broker | Mediates the (production) service between the service requestor and service provider according to the constraints given by the legislator and compliant to defined rules Note: A service broker may act as both service requestor and service provider in order to generate federations of marketplaces |

| Legislator | Defines and provides the legal, ethical and trade constraints for the production ecosystem |

| Compliance Checker | Checks if the constraints given by the legislator are fulfilled |

| App Store | Provides software applications that may be loaded into the service broker in order to support and enable its functionalities |

| No | Requirement | Stakeholder Roles | Business Models | Priority |

|---|---|---|---|---|

| FR01 | Provision of a flexible, domain-independent data model to describe production assets, capabilities and properties, including supply chain characteristics | Broker | all | M |

| FR02 | Registration of factories based on the capability model and open standards (e.g., of the Platform Industrie 4.0) to describe the production capabilities and capacities of the factories | Provider | BM {2,37,52}, BM30, BM34 | M |

| FR03 | Search for factories, factory assets and supply chains for a required production process | Requester, Broker | BM {2,37,52}, BM30, BM34 | M |

| FR04 | Matchmaking between production process description of a production request and the capabilities and capacities of registered factories, including their supply chains | Broker | BM {2,37,52}, BM30, BM34 | M |

| FR05 | Ranking of search results according to user preferences | Requester, Broker | all | O |

| FR06 | Query the availabilities of factories and factory asset in (near) real time, i.e., respecting the time constraints of the use case | Requester, Provider | BM {2,37,52}, BM30, BM34 | O |

| FR07 | Generate, manage, query and analyze supply chains. | Broker | BM {2,37,52}, BM {30,32,34} | O |

| FR08 | Visualization of shop floor data (machines, etc.) | Provider | BM30, BM34 | M |

| FR09 | Visualization of supply chains/supply networks | Provider | BM30, BM34 | M |

| FR10 | Detection and visualization of supply chain interruptions | Provider | BM30, BM34 | O |

| FR11 | Defining redundant supplier structures | Provider | all | O |

| FR12 | Validation of quality/sustainability criteria along the supply chain (e.g., carbon footprint) | Compliance Checker | BM {2,37,52}, BM {30,32,34} | O |

| FR13 | Provision of additional functionalities for the use of the marketplace via an app store | Requester | all | O |

| FR14 | Provision of an open, standardized interface for connecting external platforms/marketplaces (federations) | Broker | all | O |

| FR15 | Provision of a means to download software applications from an app store to enhance or tailor the functionality | Broker | all | O |

| FR16 | Provision of means to adapt the information model and functionality of the service broker to new contexts and situations | Broker | all | M |

| Number | Requirement | Priority |

|---|---|---|

| NFR01 | Interoperability with other industrial marketplaces and software systems (support for federations) | M |

| NFR02 | Applicability to new industrial domains and sub-domains | O |

| NFR03 | Openness in the sense of supporting international and national standards to avoid vendor lock-in and follow future technological trends | M |

| NFR04 | Adaptability to new business models | M |

| NFR05 | Scalability of user, data and app management | M |

| NFR06 | Security to protect company data from unauthorized access and assure its integrity | M |

| NFR07 | Data Sovereignty to maintain control over the complete processing chain of data and also the independent decision on who is permitted to have access to it | M |

| NFR08 | Extensibility to support new types of production assets (e.g., virtual assets such as production-related services) | O |

| MaaS Platform | URL | Range of Manufacturing | Main Market |

|---|---|---|---|

| fictiv | www.fictiv.com | 3D printing, CNC machining, injection molding and urethane casting | USA, China |

| Fractory | fractory.com | Sheet metal fabrication | UK |

| Haizol | www.haizol.com/en | Machining, molding, fabrication, casting, stamping | Asia |

| Hubs | www.hubs.com | CNC machining, 3D printing, sheet metal fabrication, injection molding | Worldwide |

| Istawerk | www.instawerk.de | CNC turning and milling | Germany |

| laserhub | laserhub.com | Laser cutting, metal forming, CNC milling | Germany, Austria, France |

| macrofab | macrofab.com | Printed circuit board assembly | North America |

| mipart (of BAM GmbH) | mipart.com | CNC turning and milling, rapid prototyping, small series | Focus Germany |

| Plethora | www.plethora.com | CNC machining (mainly for military and defence) | USA |

| spanflug | spanflug.de | CNC turning and milling | Focus Germany |

| up2parts | www.up2parts.com | Wide range of processes | Germany |

| Weerg | www.weerg.it | 3D printing, CNC machining, finishing | Italy |

| Xometry | www.xometry.com | Wide range of processes | Worldwide, focus USA |

| Ontology Concept | Definition |

|---|---|

| Asset | Asset is a factory or part of the factory equipment hierarchy as defined in [17]. In the context of SFW, an asset can be a supplier for another factory. Examples of an asset in SFW: factory, supplier, manufacturer, distributor, retailer, production line, production machine, manufacturing resource, sensor, etc. |

| Capability | Capability (of an asset) is described in terms of its input and output products and their respective properties, and/or in terms of how the product can be produced. The capability concept enables the modeling of process steps (BOP Bill of Process, e.g., manufacturing processes for the production of a product). |

| Product | Input (materials, part products) or output (result) of a production process. The product structure (BOM Bill of Material—structured arrangement of objects, e.g., components) in the SFW platform can be described using the concept product and the corresponding inverse relation. |

| Property | The property concept is used to describe capabilities and products in more detail. There are no particular restrictions on properties. These may cover a broad spectrum such as production rates, physical dimensions, materials, carbon footprint, fair trade compliance, etc. |

| Unit of Measure | The Unit of Measure concept specifies units of measurement for properties (e.g., kilogram, liter, piece, etc.). |

| Ontology Relation | Definition |

|---|---|

| isSubAssetOf (isSuperAssetOf) | An asset, e.g., a production line, consists of several robots that work together. These can be related to the production line via the relation isSubAssetOf. |

| hasSupplier (isSupplierTo) | Enables the linking of assets, i.e., the description of supplier relationships between two factories. |

| offersProduct (offeredBy) | Allows an asset (e.g., manufacturer, supplier) to be associated with a product that is being manufactured or supplied. |

| isSubProductOf (hasSubProduct) | The subproducts of a product can be described with the relation isSubProductOf. The relation hasSubProduct allows conclusions to be drawn about the respective subproducts of a product. The subproducts in turn allow conclusions to be drawn about the producing companies that manufacture these subproducts (relation offeredBy). |

| hasInputProduct (isProcessedBy) | In a production process, input products (materials, subproducts, components, etc.) are further processed into output products. The relation hasInputProduct enables the link to the input products. |

| hasOutputProduct (isCreatedBy) | The relation hasOutputProduct enables the link to the created output products. |

| hasProductProperty (specifiesProduct) | Relation between a product and a property to describe the characteristics of a product in more detail. |

| hasCapability | Relation between an asset and an ability to specify the capabilities of an asset. |

| hasProperty | Relating a capability to a property to describe the characteristics of a capability in more detail. |

| hasUnitOfMeasure | Relation between a property and a unit of measurement to specify the properties definitively with the associated unit of measurement. |

| Number | Requirement | SFW Fulfillment |

|---|---|---|

| NFR01 | Interoperability with other industrial marketplaces and software systems (support for federations) | + |

| NFR02 | Applicability to new industrial domains and sub-domains | p |

| NFR03 | Openness in the sense of supporting international and national standards to avoid vendor lock-in and follow future technological trends | +++ |

| NFR04 | Adaptability to new business models | + |

| NFR05 | Scalability of user, data and app management | ++ |

| NFR06 | Security to protect company data from unauthorized access and assure its integrity | ++ |

| NFR07 | Data Sovereignty to maintain control over the complete processing chain of data and also the independent decision on who is permitted to have access to it | + |

| NFR08 | Extensibility to support new types of production assets(e.g., virtual assets such as production-related services) | p |

| No | Requirement | SFW Fulfillment |

|---|---|---|

| FR01 | Provision of a flexible, domain-independent data model to describe production assets, capabilities and properties, including supply chains characteristics | +++ |

| FR02 | Registration of factories based on the capability model and open standards (e.g., of the Platform Industrie 4.0) to describe the production capabilities and capacities of the factories | +++ |

| FR03 | Search for factories, factory assets and factory combinations (supply chains) for a required production process | + |

| FR04 | Matchmaking between production process description of a production request and the capabilities and capacities of registered factories | + |

| FR05 | Ranking of search results according to user preferences | p |

| FR06 | Query the availabilities of factories and factory assets in (near) real time, i.e., respecting the time constraints of the use case | + |

| FR07 | Generate, manage, query and analyze supply chains. | + |

| FR08 | Visualization of shop floor data (machines, etc.) | +++ |

| FR09 | Visualization of supply chains/supply networks | +++ |

| FR10 | Detection and visualization of supply chain interruptions | p |

| FR11 | Defining redundant supplier structures | + |

| FR12 | Validation of quality/sustainability criteria along the supply chain (e.g., carbon footprint) | - |

| FR13 | Provision of additional functionalities for the use of the marketplace via an app store | + |

| FR14 | Provision of an open, standardized interface for connecting external platforms/marketplaces (federations) | ++ |

| FR15 | Provision of a means to download software applications from an app store to enhance or tailor the functionality | p |

| FR16 | Provision of means to adapt the information model and functionality of the service broker to new contexts and situations | p |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Usländer, T.; Schöppenthau, F.; Schnebel, B.; Heymann, S.; Stojanovic, L.; Watson, K.; Nam, S.; Morinaga, S. Smart Factory Web—A Blueprint Architecture for Open Marketplaces for Industrial Production. Appl. Sci. 2021, 11, 6585. https://doi.org/10.3390/app11146585

Usländer T, Schöppenthau F, Schnebel B, Heymann S, Stojanovic L, Watson K, Nam S, Morinaga S. Smart Factory Web—A Blueprint Architecture for Open Marketplaces for Industrial Production. Applied Sciences. 2021; 11(14):6585. https://doi.org/10.3390/app11146585

Chicago/Turabian StyleUsländer, Thomas, Felix Schöppenthau, Boris Schnebel, Sascha Heymann, Ljiljana Stojanovic, Kym Watson, Seungwook Nam, and Satoshi Morinaga. 2021. "Smart Factory Web—A Blueprint Architecture for Open Marketplaces for Industrial Production" Applied Sciences 11, no. 14: 6585. https://doi.org/10.3390/app11146585

APA StyleUsländer, T., Schöppenthau, F., Schnebel, B., Heymann, S., Stojanovic, L., Watson, K., Nam, S., & Morinaga, S. (2021). Smart Factory Web—A Blueprint Architecture for Open Marketplaces for Industrial Production. Applied Sciences, 11(14), 6585. https://doi.org/10.3390/app11146585