Fine Dust Creation during Hardwood Machine Sanding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Hardwood Species

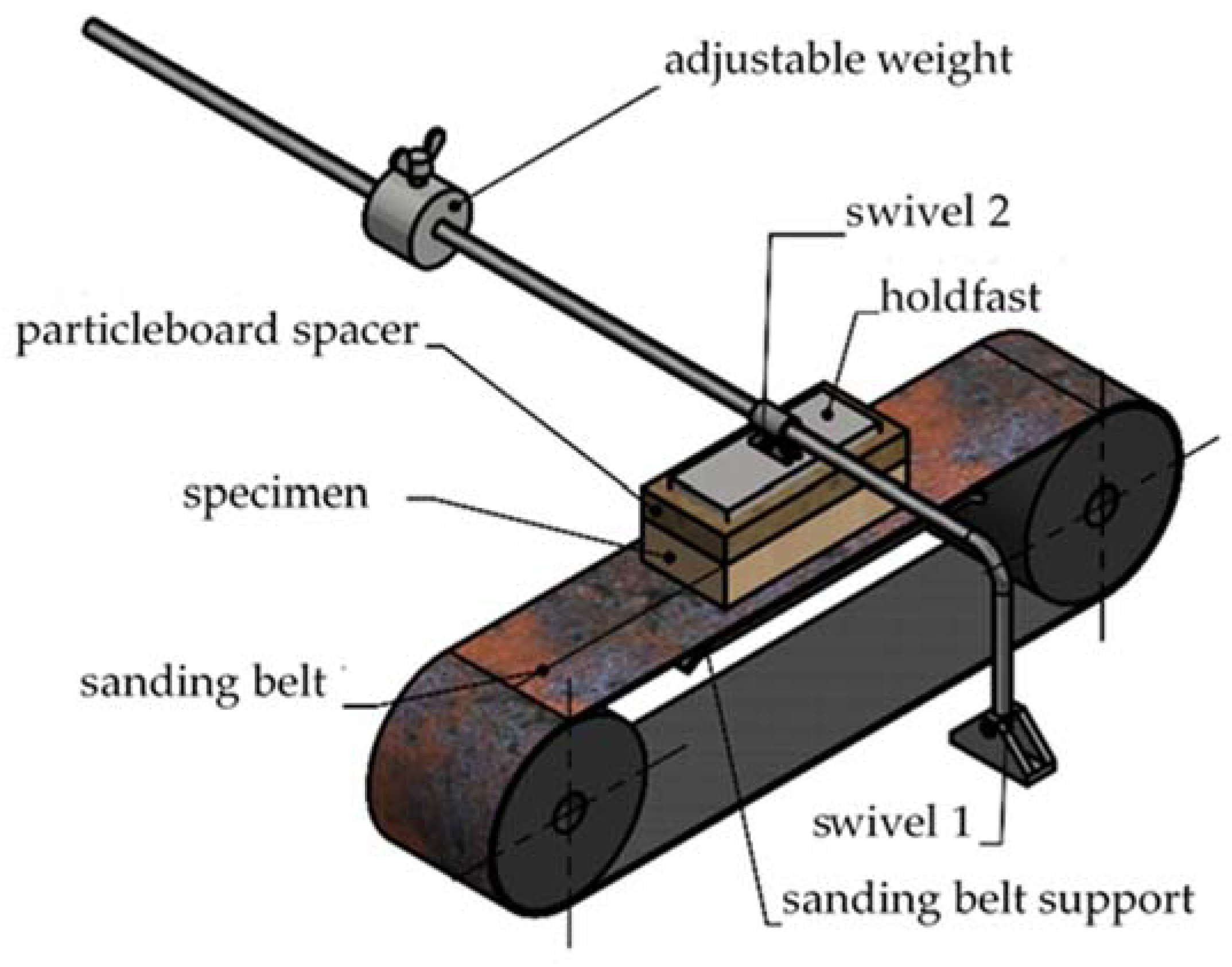

2.2. Sanding

2.3. Particle Size Determination

2.4. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Warguła, Ł.; Kaczmarzyk, P.; Dziechciarz, A. The Assessment of Fire Risk of Non-Road Mobile Wood Chopping Machines. J. Res. Appl. Agric. Eng. 2019, 64, 58–64. [Google Scholar]

- Pang, Z.; Zhu, N.; Cui, Y.; Li, W.; Xu, C. Experimental investigation on explosion flame propagation of wood dust in a semi-closed tube. J. Loss Prev. Process. Ind. 2020, 63, 1040282020. [Google Scholar] [CrossRef]

- Yuan, Z.; Khakzad, N.; Khan, F.; Amyotte, P. Dust explosions: A threat to the process industries. Process. Saf. Environ. Prot. 2015, 98, 57–71. [Google Scholar] [CrossRef]

- Beljo-Lučić, R.; Čavlović, A.O.; Jug, M. Definitions and Relation of Airborne Wood Dust Fractions. In Proceedings of the 4th International Scientific Conference–Woodworking Techniques, Prague, Czech Republic, 7 September 2011; pp. 25–32. [Google Scholar]

- Očkajová, A.; Stebila, J.; Rybakowski, M.; Rogoziński, T.; Krišťák, Ľ.; L’uptáková, J. The Granularity of Dust Particles when Sanding Wood and Wood-Based Materials. Adv. Mater. Res. 2014, 1001, 432–437. [Google Scholar] [CrossRef]

- Zigo, J.; Rantuch, P.; Balog, K. Experimental Analysis of Minimum Ignition Temperature of Dust Cloud Obtained from Thermally Modified Spruce Wood. Adv. Mater. Res. 2014, 919-921, 2057–2060. [Google Scholar] [CrossRef]

- Dudarski, G.; Kowal, M.; Częstochowski, C. Dust Explosion Hazard in Wood Processing. Ann. WULS-SGGW Wood Technol. 2015, 90, 61–65. [Google Scholar]

- Mračková, E.; Krišťák, Ľ.; Kučerka, M.; Gaff, M.; Gajtanska, M. Creation of Wood Dust during Wood Processing: Size Analysis, Dust Separation, and Occupational Health. Bioresources 2015, 11, 209–222. [Google Scholar] [CrossRef]

- Aro, M.D.; Geerts, S.M.; French, S.; Cai, M. Particle size analysis of airborne wood dust produced from sawing thermally modified wood. Eur. J. Wood Wood Prod. 2019, 77, 211–218. [Google Scholar] [CrossRef]

- Igaz, R.; Kminiak, R.; Krišťák, Ľ.; Němec, M.; Gergeľ, T. Methodology of Temperature Monitoring in the Process of CNC Machining of Solid Wood. Sustainability 2018, 11, 95. [Google Scholar] [CrossRef] [Green Version]

- Callé, S.; Klaba, L.; Thomas, D.; Perrin, L.; Dufaud, O. Influence of the size distribution and concentration on wood dust explosion: Experiments and reaction modelling. Powder Technol. 2005, 157, 144–148. [Google Scholar] [CrossRef]

- Amyotte, P.R.; Eckhoff, R.K. Dust explosion causation, prevention and mitigation: An overview. J. Chem. Health Saf. 2010, 17, 15–28. [Google Scholar] [CrossRef]

- Martinka, J.; Rantuch, P. Posúdenie Vplyvu Veľkosti Častíc Dubového Dreva Na Teplotu Vznietennia Rozvíreného Prachu. Acta Fac. Tech. 2013, 18, 75–82. [Google Scholar]

- Tureková, I.; Marková, I. Ignition of Deposited Wood Dust Layer by Selected Sources. Appl. Sci. 2020, 10, 5779. [Google Scholar] [CrossRef]

- Osvaldova, L.M.; Kadlicova, P.; Rychly, J. Fire Characteristics of Selected Tropical Woods without and with Fire Retardant. Coatings 2020, 10, 527. [Google Scholar] [CrossRef]

- Vandličková, M.; Marková, I.; Osvaldová, L.M.; Gašpercová, S.; Svetlík, J.; Vraniak, J. Tropical Wood Dusts—Granulometry, Morfology and Ignition Temperature. Appl. Sci. 2020, 10, 7608. [Google Scholar] [CrossRef]

- Mohan, M.; Aprajita, N.K.P. Effect of Wood Dust on Respiratory Health Status of Carpenters. J. Clin. Diagn. Res. 2013, 7, 1589–1591. [Google Scholar] [CrossRef] [PubMed]

- Hancock, D.G.; Langley, M.E.; Chia, K.L.; Woodman, R.; Shanahan, E.M. Wood dust exposure and lung cancer risk: A meta-analysis. Occup. Environ. Med. 2015, 72, 889–898. [Google Scholar] [CrossRef]

- Siew, S.S.; Martinsen, J.I.; Kjaerheim, K.; Sparén, P.; Tryggvadottir, L.; Weiderpass, E.; Pukkala, E. Occupational exposure to wood dust and risk of nasal and nasopharyngeal cancer: A case-control study among men in four nordic countries-With an emphasis on nasal adenocarcinoma. Int. J. Cancer 2017, 141, 2430–2436. [Google Scholar] [CrossRef] [Green Version]

- Matrat, M.; Radoi, L.; Févotte, J.; Guida, F.; Cénée, S.; Cyr, D.; Sanchez, M.; Menvielle, G.; Schmaus, A.; Marrer, E.; et al. Occupational exposure to wood dust and risk of lung cancer: The ICARE study. Occup. Environ. Med. 2019, 76, 901–907. [Google Scholar] [CrossRef]

- Nasir, V.; Cool, J. A review on wood machining: Characterization, optimization, and monitoring of the sawing process. Wood Mater. Sci. Eng. 2020, 15, 1–16. [Google Scholar] [CrossRef]

- Jacobsen, G.; Schaumburg, I.; Sigsgaard, T.; Schlünssen, V. Non-Malignant Respiratory Diseases and Occupational Exposure to Wood Dust. Part II. Dry Wood Industry. Ann. Agric. Environ. Med. 2010, 17, 29–44. [Google Scholar]

- Hejna, A.; Marć, M. Towards Understanding the Health Aspects of the Processing of Lignocellulosic Fillers. Proceedings 2020, 69, 34. [Google Scholar] [CrossRef]

- Nasir, V.; Cool, J. Characterization, optimization, and acoustic emission monitoring of airborne dust emission during wood sawing. Int. J. Adv. Manuf. Technol. 2020, 109, 2365–2375. [Google Scholar] [CrossRef]

- Baran, S.; Teul, I. Wood dust: An occupational hazard which increases the risk of respiratory disease. J. Physiol. Pharmacol. 2007, 58, 43–50. [Google Scholar]

- Lorincová, S.; Hitka, M.; Cambal, M.; Szabo, P.; Javorčíková, J. Motivation Factors Influencing Senior Managers in the Forestry and Wood-Processing Sector in Slovakia. Bioresources 2016, 11, 10339–10348. [Google Scholar] [CrossRef] [Green Version]

- Hnilica, R.; Jankovský, M.; Dado, M.; Messingerová, V.; Schwarz, M.; Veverková, D. Use of the analytic hierarchy process for complex assessment of the work environment. Qual. Quant. 2017, 51, 93–101. [Google Scholar] [CrossRef]

- Očkajová, A.; Kučerka, M.; Krišťák, Ľ.; Igaz, R. Granulometric Analysis of Sanding Dust from Selected Wood Species. Bioresources 2018, 13, 7481–7495. [Google Scholar] [CrossRef]

- IARC. Wood Dust. A Review of Human Carcinogens: Arsenic, Metals, Fibres, and Dusts. In IARC Monographs on the Evaluation of Carcinogenic Risks to Humans/World HEALTH Organization. Int. Agency Res. Cancer 2012, 100, 169–211. [Google Scholar]

- Bhatti, P.; Newcomer, L.; Onstad, L.; Teschke, K.; Camp, J.; Morgan, M.; Vaughan, T.L. Wood dust exposure and risk of lung cancer. Occup. Environ. Med. 2010, 68, 599–604. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Konopka, A.; Chuchala, D.; Orlowski, K.A.; Vilkovská, T.; Klement, I. The effect of beech wood (Fagus sylvatica L.) steaming process on the colour change versus depth of tested wood layer. Wood Mater. Sci. Eng. 2021, 1–9. [Google Scholar] [CrossRef]

- Chuchala, D.; Sandak, J.; Orlowski, K.A.; Muzinski, T.; Lackowski, M.; Ochrymiuk, T. Effect of the Drying Method of Pine and Beech Wood on Fracture Toughness and Shear Yield Stress. Materials 2020, 13, 4692. [Google Scholar] [CrossRef]

- Sydor, M.; Pinkowski, G.; Jasińska, A. The Brinell Method for Determining Hardness of Wood Flooring Materials. Forests 2020, 11, 878. [Google Scholar] [CrossRef]

- Lučić, R.B.; Kos, A.; Antonović, A.; Vujasinović, E.; Šimičić, I. Properties of Chipped Wood Generated during Wood Processing. Drvna Industrija 2005, 1, 11–19. [Google Scholar]

- Očkajová, A.; Beljaková, A.; Siklienka, M. Morphology of Dust Particles from the Sanding Process of the Chosen Tree Species. Wood Res. 2010, 55, 89–98. [Google Scholar]

- Očkajová, A.; Banski, A. Particle Size Wood Sanding Dust from the Narrow-Band Grinding Machines. Acta Facultatis Xylologiae Zvolen 2013, 85–90. [Google Scholar]

- Očkajová, A.; Kučerka, M.; Krišťák, Ľ.; Ružiak, I.; Gaff, M. Efficiency of Sanding Belts for Beech and Oak Sanding. Bioresources 2016, 11, 5242–5254. [Google Scholar] [CrossRef] [Green Version]

- Hlásková, L.; Rogoziński, T.; Dolny, S.; Kopecky, Z.; Jedinák, M. Content of Respirable and Inhalable Fractions in Dust Created While Sawing Beech Wood and Its Modifications. Drewno 2015, 58, 135–146. [Google Scholar] [CrossRef]

- Valcheva, L.; Savov, V. The Effect of Thickness of Medium Density Fiberboard Produced of Hardwood Tree Species on their Selected Physical and Mechanical Properties. Key Eng. Mater. 2016, 688, 115–121. [Google Scholar] [CrossRef]

- Rogoziński, T.; Wilkowski, J.; Górski, J.; Czarniak, P.; Podziewski, P.; Szymanowski, K. Dust Creation in CNC Drilling of Wood Composites. Bioresources 2015, 10, 3657–3665. [Google Scholar] [CrossRef] [Green Version]

- Rogoziński, T.; Wilkowski, J.; Górski, J.; Szymanowski, K.; Podziewski, P.; Czarniak, P. Fine Particles Content In Dust Created In CNC Milling Of Selected Wood Composites. Wood Fiber Sci. 2017, 49, 461–469. [Google Scholar]

- Marková, I.; Beljaková, A.; Luptáková, J. Granulometry of Selected Wood Dust Species of Dust from Orbital Sanders. Wood Res. 2016, 61, 983–992. [Google Scholar]

- Očkajová, A.; Beljaková, A.; Luptáková, J. Selected Properties of Spruce Dust Generated from Sanding Operations. Drvna Industrija 2008, 59, 3–10. [Google Scholar]

- Očkajová, A.; Kučerka, M. Granular Analysis of Sand Oak Wood Particles. Acta Fac. Tech. 2017, 22, 93–101. [Google Scholar]

- Očkajová, A.; Kučerka, M.; Kminiak, R.; Krišťák, Ľ.; Igaz, R.; Réh, R. Occupational Exposure to Dust Produced when Milling Thermally Modified Wood. Int. J. Environ. Res. Public Health 2020, 17, 1478. [Google Scholar] [CrossRef] [Green Version]

- Kvietková, M.; Barcík, Š.; Aláč, P. Impact of Angle Geometry of Tool on Granulometric Composition of Particles during the Flat Milling of Thermally Modified Beech. Wood Res. 2015, 60, 137–146. [Google Scholar]

- Koleda, P.; Barcík, Š.; Nociarová, A. Effect of technological parameters of machining on energy efficiency in face milling of heat-treated oak wood. Bioresources 2018, 13, 6133–6146. [Google Scholar] [CrossRef]

- Dzurenda, L.; Orlowski, K.A. The Effect of Thermal Modification of Ash Wood on Granularity and Homogeneity of Sawdust in the Sawing Process on a Sash Gang Saw Prw 15-M in View of Its Technological Usefulness. Drew. Pr. Nauk. Doniesienia Komun. 2011, 54, 27–37. [Google Scholar]

- Sandak, J.; Goli, G.; Cetera, P.; Sandak, A.; Cavalli, A.; Todaro, L. Machinability of Minor Wooden Species before and after Modification with Thermo-Vacuum Technology. Materials 2017, 10, 121. [Google Scholar] [CrossRef] [Green Version]

- Kminiak, R.; Orlowski, K.; Dzurenda, L.; Chuchala, D.; Banski, A. Effect of Thermal Treatment of Birch Wood by Saturated Water Vapor on Granulometric Composition of Chips from Sawing and Milling Processes from the Point of View of Its Processing to Composites. Appl. Sci. 2020, 10, 7545. [Google Scholar] [CrossRef]

- Council Directive 1999/38/EC of 29 April 1999 Amending for the Second Time Directive 90/394/EEC on the Protection of Workers from the Risks Related to Exposure to Carcinogens at Work and Extending It to Mutagens. Available online: https://Eur-Lex.Europa.Eu/Legal-Content/BG/TXT/?Uri=CELEX:31999L0038 (accessed on 22 June 2021).

- Directive (EU) 2017/2398 of the European Parliament and of the Council of 12 December 2017 Amending Directive 2004/37/EC on the Protection of Workers from the Risks Related to Exposure to Carcinogens or Mutagens at Work. Available online: http://Data.Europa.Eu/Eli/Dir/2017/2398/Oj (accessed on 20 June 2021).

- Scientific Committee on Occupational Exposure Limits (SCOEL). Recommendation from the Scientific Committee on Occupational Exposure Limits for Wood Dust; SCOEL/SUM/102B: Brussels, Belgium, 2002. [Google Scholar]

- Magagnotti, N.; Picchi, G.; Sciarra, G.; Spinelli, R. Exposure of Mobile Chipper Operators to Diesel Exhaust. Ann. Occup. Hyg. 2013, 58, 217–226. [Google Scholar] [CrossRef] [Green Version]

- Warguła, Ł.; Kukla, M.; Lijewski, P.; Dobrzyński, M.; Markiewicz, F. Influence of Innovative Woodchipper Speed Control Systems on Exhaust Gas Emissions and Fuel Consumption in Urban Areas. Energies 2020, 13, 3330. [Google Scholar] [CrossRef]

- Warguła, Ł.; Kukla, M.; Lijewski, P.; Dobrzyński, M.; Markiewicz, F. Impact of Compressed Natural Gas (CNG) Fuel Systems in Small Engine Wood Chippers on Exhaust Emissions and Fuel Consumption. Energies 2020, 13, 6709. [Google Scholar] [CrossRef]

- Warguła, Ł.; Kukla, M.; Lijewski, P.; Dobrzyński, M.; Markiewicz, F. Influence of the Use of Liquefied Petroleum Gas (LPG) Systems in Woodchippers Powered by Small Engines on Exhaust Emissions and Operating Costs. Energies 2020, 13, 5773. [Google Scholar] [CrossRef]

- Gulci, S.; Akay, A.E.; Spinelli, R.; Magagnotti, N. Assessing the Exposure of Chipper Operators to Wood Dust in a Roadside Landing Area. Fresenius Environ. Bull. 2018, 27, 4132–4138. [Google Scholar]

- Orlowski, K.A.; Chuchala, D.; Dzurenda, L. The Effect of Full-Cell Impregnation of Pine Wood (Pinus Sylvestris L.) on the Fine Dust Content during Sawing on a Frame Sawing Machine. Chip Chipless Woodwork. Process. 2018, 11, 131–137. [Google Scholar]

- Statistics Poland. Statistic Poland Statistical Yearbook of Forestry; Statistics Poland: Warsaw, Poland, 2020.

- McGlinchey, D. Characterisation of Bulk Solids; Wiley: Hoboken, NJ, USA, 2009; ISBN 978-1-4443-0545-6. [Google Scholar]

- Rogoziński, T.; Očkajová, A. Properties of Chips from Manufacturing of Wooden Garden Architecture. Chip Chipless Woodwork. Processes. 2016, 10, 153–158. [Google Scholar]

- Dukarska, D.; Pędzik, M.; Rogozińska, W.; Rogoziński, T.; Czarnecki, R. Characteristics of straw particles of selected grain species purposed for the production of lignocellulose particleboards. Part. Sci. Technol. 2021, 39, 213–222. [Google Scholar] [CrossRef]

- Piernik, M.; Rogoziński, T.; Krauss, A.; Pinkowski, G. The influence of the thermal modification of pine (Pinus sylvestris L.) wood on the creation of fine dust particles in plane milling. J. Occup. Health 2019, 61, 481–488. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Manual MaScontrol, (M)Illing (a)Nd (S)Izing (Control) Software for Laser-Partikel-Sizers and Mills Fritsch GmbH Milling and Sizing; Fritsch: Idar-Oberstein, Germany, 2009.

- Ratnasingam, J.; Scholz, F.; Natthondan, V.; Graham, M. Dust-generation characteristics of hardwoods during sanding processes. Eur. J. Wood Wood Prod. 2010, 69, 127–131. [Google Scholar] [CrossRef]

- Thorpe, A.; Brown, R. Factors Influencing the Production of Dust During the Hand Sanding of Wood. Am. Ind. Hyg. Assoc. J. 1995, 56, 236–242. [Google Scholar] [CrossRef]

- Papadopoulos, A.N. Advances in Wood Composites II. Polymers 2020, 12, 1552. [Google Scholar] [CrossRef] [PubMed]

- Kučerka, M.; Očkajová, A. Thermowood and Granularity of Abrasive Wood Dust. Acta Fac. Xylologiae Zvolen 2018, 60, 43–51. [Google Scholar] [CrossRef]

- Očkajová, A.; Barcík, Š.; Kučerka, M.; Koleda, P.; Korčok, M.; Vyhnáliková, Z. Wood Dust Granular Analysis in the Sanding Process of Thermally Modified Wood versus Its Density. Bioresources 2019, 14, 8559–8572. [Google Scholar] [CrossRef]

- Rogoziński, T.; Chuchala, D.; Pędzik, M.; Orlowski, K.A.; Dzurenda, L.; Muzinski, T. Influence of drying mode and feed per tooth rate on the fine dust creation in pine and beech sawing on a mini sash gang saw. Eur. J. Wood Wood Prod. 2021, 79, 91–99. [Google Scholar] [CrossRef]

- Papadopoulos, A. Advances in Wood Composites III. Polymers 2021, 13, 163. [Google Scholar] [CrossRef]

- Rogoziński, T.; Očkajová, A. Comparison of Two Methods for Granularity Determination of Wood Dust Particles. Ann. Warsaw Univ. Life Sci. SGGW For. Wood Technol. 2013, 81, 197–202. [Google Scholar]

- Mazzoli, A.; Favoni, O. Particle size, size distribution and morphological evaluation of airborne dust particles of diverse woods by Scanning Electron Microscopy and image processing program. Powder Technol. 2012, 225, 65–71. [Google Scholar] [CrossRef]

- Yepes, M.E.G.; Cremades, L.V. Characterization of wood dust from furniture by scanning electron microscopy and energy-dispersive X-ray analysis. Ind. Health 2011, 49, 492–500. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| No. | Hardwood Species | Density [kg.m−3] | Percentage of the Forest Area in Poland [%] |

|---|---|---|---|

| 1. | Black alder (Alnus glutinosa Gaertn.) | 446.3 | 5.6 |

| 2. | European ash (Fraxinus excelsior L.) | 621.3 | No data |

| 3. | Common walnut (Juglans regia L.) | 641.0 | No data |

| 4. | Pedunculate oak (Quercus robur L.) | 686.4 | 7.9 |

| 5. | European beech (Fagus sylvatica L.) | 686.6 | 6.1 |

| 6. | Hornbeam (Carpinus betulus L.) | 753.6 | 1.5 |

| Wood Species | Particle Arithmetic Mean Diameter (µm) | Mass Content of Particles (%) | |

|---|---|---|---|

| <10 µm | <2.5 µm | ||

| Black alder | 119.5 c ± 4.65 | 5.8 b ± 0.63 | 1.0 abc ± 0.24 |

| European ash | 94.7 b ± 3.45 | 7.5 bc ± 2.03 | 1.6 bc ± 1.49 |

| Common walnut | 144.7 d ± 0.40 | 2.8 a ± 0.46 | 0.4 a ± 0.06 |

| Pedunculate oak | 100.1 b ± 4.89 | 8.9 c ± 0.43 | 0.4 ab ± 0.23 |

| European beech | 76.5 a ± 5.60 | 7.5 bc ± 2.11 | 1.9 c ± 0.66 |

| Hornbeam | 102.7 b ± 0.09 | 7.3 bc ± 0.26 | 1.3 abc ± 0.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pędzik, M.; Rogoziński, T.; Majka, J.; Stuper-Szablewska, K.; Antov, P.; Kristak, L.; Kminiak, R.; Kučerka, M. Fine Dust Creation during Hardwood Machine Sanding. Appl. Sci. 2021, 11, 6602. https://doi.org/10.3390/app11146602

Pędzik M, Rogoziński T, Majka J, Stuper-Szablewska K, Antov P, Kristak L, Kminiak R, Kučerka M. Fine Dust Creation during Hardwood Machine Sanding. Applied Sciences. 2021; 11(14):6602. https://doi.org/10.3390/app11146602

Chicago/Turabian StylePędzik, Marta, Tomasz Rogoziński, Jerzy Majka, Kinga Stuper-Szablewska, Petar Antov, Lubos Kristak, Richard Kminiak, and Martin Kučerka. 2021. "Fine Dust Creation during Hardwood Machine Sanding" Applied Sciences 11, no. 14: 6602. https://doi.org/10.3390/app11146602

APA StylePędzik, M., Rogoziński, T., Majka, J., Stuper-Szablewska, K., Antov, P., Kristak, L., Kminiak, R., & Kučerka, M. (2021). Fine Dust Creation during Hardwood Machine Sanding. Applied Sciences, 11(14), 6602. https://doi.org/10.3390/app11146602