The Effect of Ageing on Chemical and Strength Characteristics of Nanoclay-Modified Bitumen and Asphalt Mixture

Abstract

:1. Introduction

2. Materials and Methods

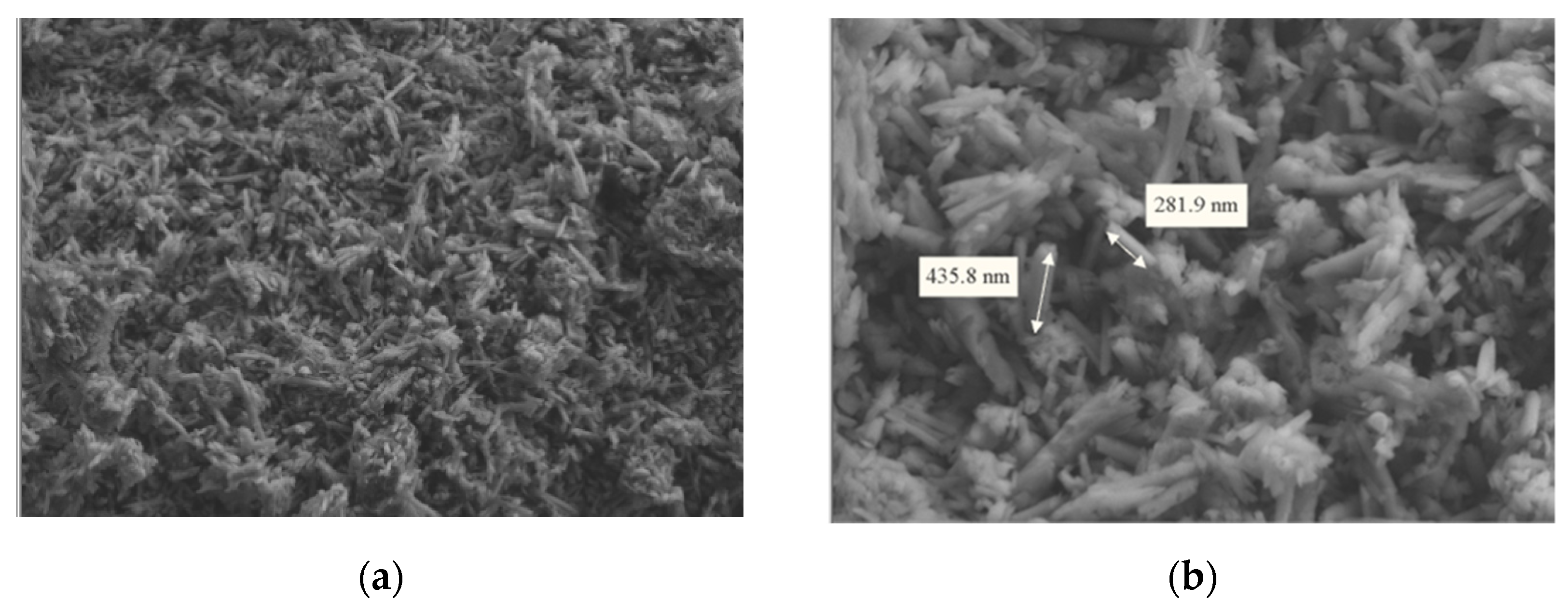

2.1. Materials and Sample Preparation

2.1.1. Bituminous Binders

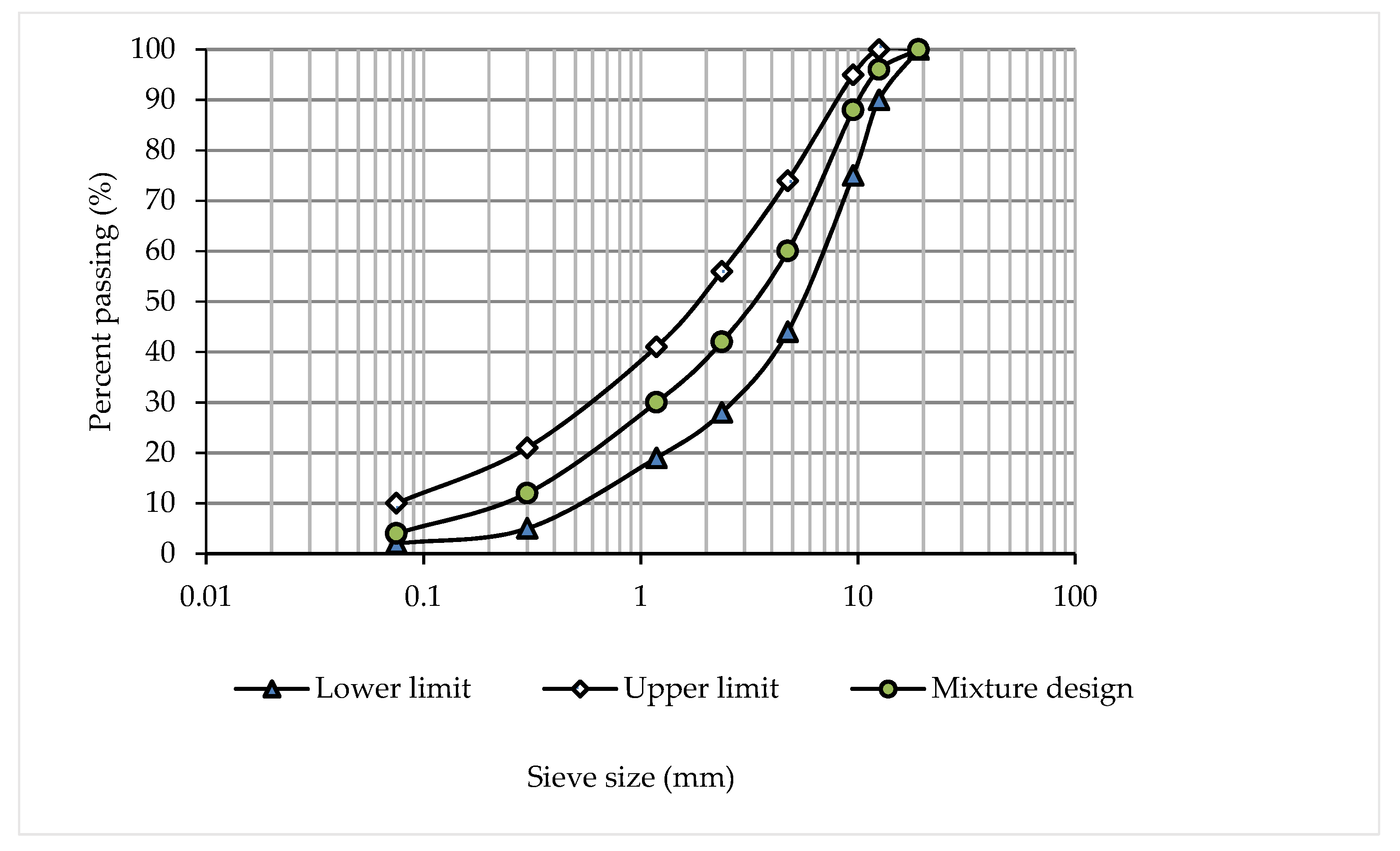

2.1.2. Asphalt Mixture

2.2. Consistency Tests

2.3. The Fourier Transform Infrared (FTIR) Test

2.4. Indirect Tensile Strength (ITS) Test

3. Results and Discussion

3.1. Consistency Tests

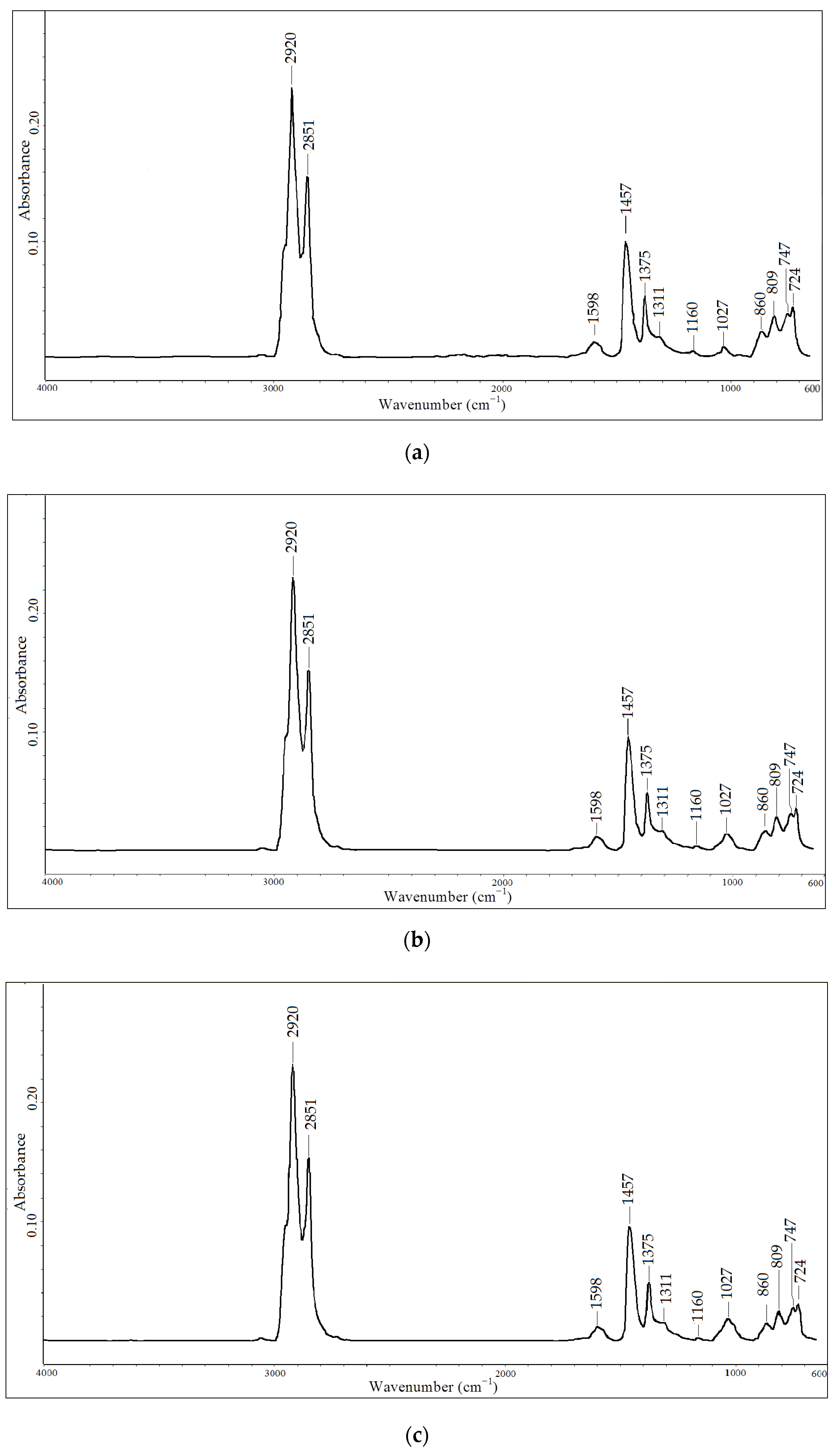

3.2. The Fourier Transform Infrared (FTIR) Test

3.2.1. Oxygen-Containing Compounds

3.2.2. Aliphatic Hydrocarbons

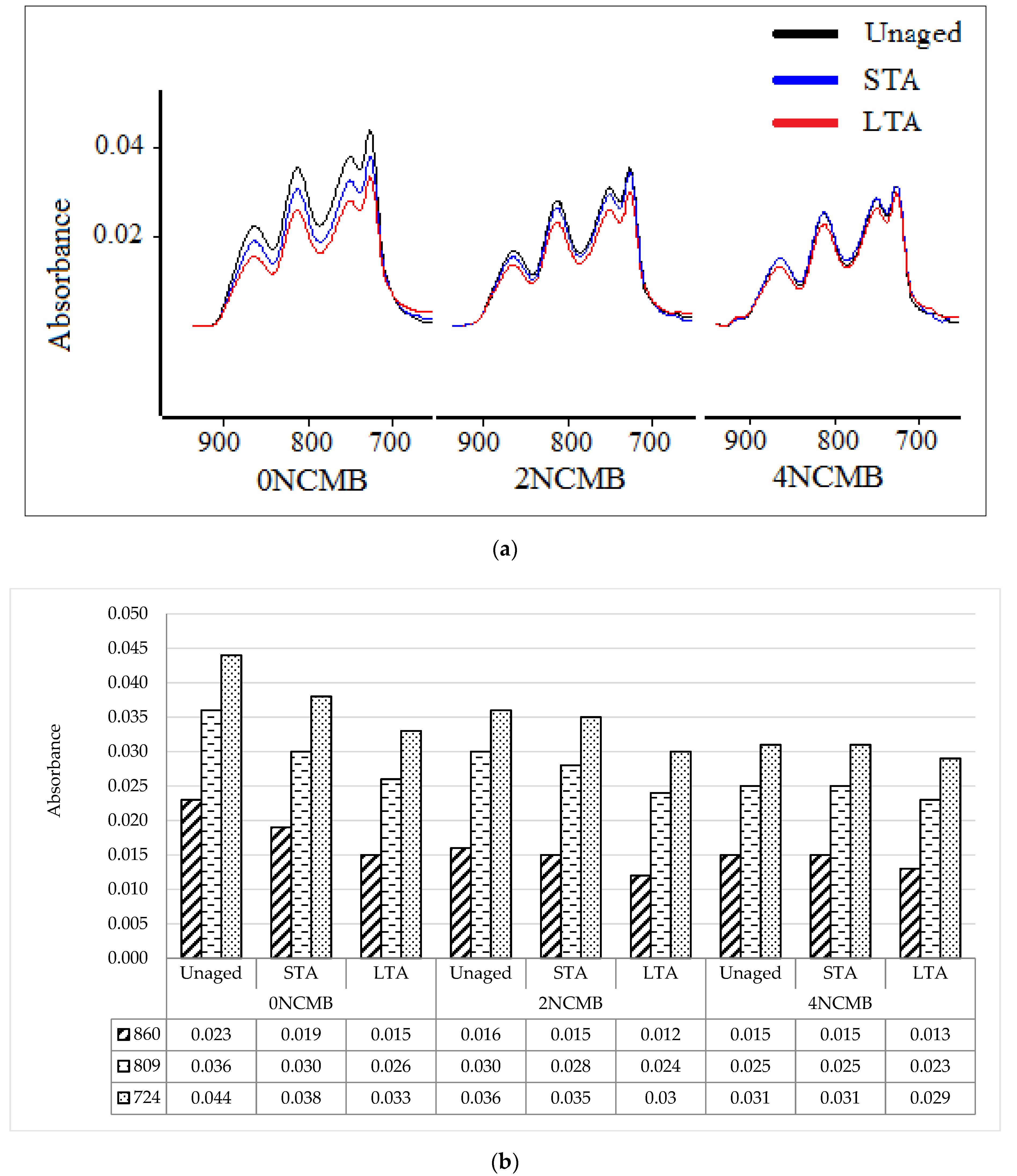

3.2.3. Aromatic Compounds

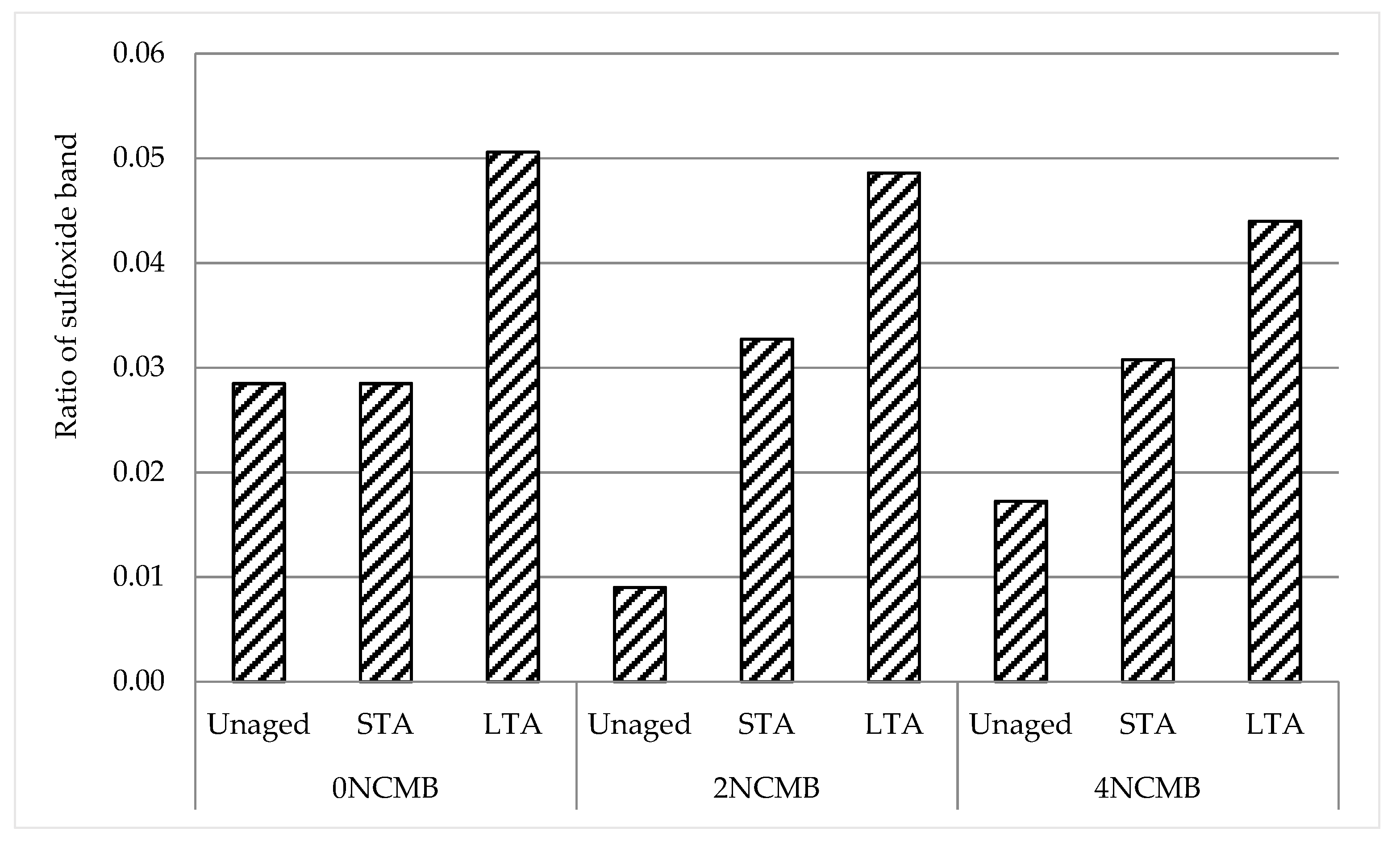

3.2.4. Sulfur Compounds

3.2.5. Quantification of Ageing Index

3.3. Indirect Tensile Strength (ITS) Test

4. Conclusions

- Reduction in fluidity caused by mixing was observed in 0 NCMB. However, the penetration grade was still in the range of 60–70, which means only a slight impact from mixing.

- The addition of nano-clay particles caused an increase in the viscosity of the unaged 2 NCMB and 4 NCMB, which means an increase in stiffness and a reduction in temperature susceptibility.

- All modified nano-clay bitumens were affected by ageing. However, the results of the consistency tests and their ageing index showed that 2 NCMB and 4 NCMB had better resistance against ageing than 0 NCMB. The increase in PI for 2 NCMB and 4 NCMB indicates an improvement in temperature susceptibility.

- The FTIR test demonstrated that there are no newly created bands after adding nano-clay particles for unaged 0 NCMB, 2 NCMB and 4 NCMB. This suggests that there is no chemical activity between nano-clay and bitumen.

- The FTIR results showed that the absorbance peak was affected by ageing for all selected functional groups in this study. The selected groups were oxygen-containing compounds, aliphatic hydrocarbons, aromatic compounds, and sulfur compounds. Based on the absorbance peak, 2 NCMB and 4 NCMB were less sensitive to ageing.

- Quantification of the changes in chemical bonding for the carbonyl band and the sulfoxide band were calculated. The increase in the ratio of these bands indicates an increase in asphaltene content. Based on the results, 4 NCMB was the best modified binder, showing less ageing sensitivity.

- The results of the ITS test were in line with previous results; STA and LTA resulted in increased ITS due to increased stiffness. The increase in the ITS of 2 NCMB and 4 NCMB indicates improved cohesion of the aged bitumen in the mixture, which could reflect improved resistance against cracking, leading to increased pavement durability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hunter, R.N.; Self, A.; Read, J.; Hobson, E. The Shell Bitumen Handbook; ICE Publishing: London, UK, 2015. [Google Scholar]

- Airey, G.D. State of the art report on ageing test methods for bituminous pavement materials. Int. J. Pavement Eng. 2003, 4, 165–176. [Google Scholar] [CrossRef]

- Sirin, O.; Paul, D.K.; Kassem, E. State of the art study on aging of asphalt mixtures and use of antioxidant additives. Adv. Civ. Eng. 2018, 3428961. [Google Scholar] [CrossRef] [Green Version]

- Tauste, R.; Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M. Understanding the bitumen ageing phenomenon: A review. Constr. Build. Mater. 2018, 192, 593–609. [Google Scholar] [CrossRef]

- Mousavi, M.; Pahlavan, F.; Oldham, D.; Hosseinnezhad, S.; Fini, E.H. Multiscale investigation of oxidative aging in biomodified asphalt binder. J. Phys. Chem. C 2016, 120, 17224–17233. [Google Scholar] [CrossRef]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef] [PubMed]

- Fernández-Gómez, W.D.; Quintana, H.A.R.; Lizcano, F.R. A review of asphalt and asphalt mixture aging. Ing. E Investig. 2013, 33, 5–12. [Google Scholar]

- Petersen, J.C. Quantitative functional group analysis of asphalts using differential infrared spectrometry and selective chemical reactions--theory and application. Transp. Res. Rec. 1986, 1096, 1–11. [Google Scholar]

- Petersen, J.C.; Branthaver, J.F.; Robertson, R.E.; Harnsberger, P.M.; Duvall, J.J.; Ensley, E.K. Effects of physicochemical factors on asphalt oxidation kinetics. Transp. Res. Rec. 1993, 1391, 1–10. [Google Scholar]

- Scholz, T.V. Durability of Bituminous Paving Mixtures; University of Nottingham: Nottingham, UK, 1995. [Google Scholar]

- Siddiqui, M.N.; Ali, M.F. Studies on the aging behavior of the Arabian asphalts. Fuel 1999, 78, 1005–1015. [Google Scholar] [CrossRef]

- Subhy, A. Advanced analytical techniques in fatigue and rutting related characterisations of modified bitumen: Literature review. Constr. Build. Mater. 2017, 156, 28–45. [Google Scholar] [CrossRef]

- Olabemiwo, O.M.; Akintomiwa, O.; Bakare, H. Preliminary investigation on modification of Agbabu natural bitumen with some polymeric materials. Int. J. Sci. Eng. Res 2015, 6, 1342. [Google Scholar]

- Dehouche, N.; Kaci, M.; Mokhtar, K.A. Influence of thermo-oxidative aging on chemical composition and physical properties of polymer modified bitumens. Constr. Build. Mater. 2012, 26, 350–356. [Google Scholar] [CrossRef]

- Zhu, J.; Balieu, R.; Wang, H. The use of solubility parameters and free energy theory for phase behaviour of polymer-modified bitumen: A review. Road Mater. Pavement Des. 2021, 22, 757–778. [Google Scholar] [CrossRef] [Green Version]

- Pyshyev, S.; Gunka, V.; Grytsenko, Y.; Bratychak, M. Polymer modified bitumen. Chem. Chem. Technol. 2016, 10, 631–636. [Google Scholar] [CrossRef]

- Crucho, J.; Picado-Santos, L.; Neves, J.; Capitão, S. A review of nanomaterials’ effect on mechanical performance and aging of asphalt mixtures. Appl. Sci. 2019, 9, 3657. [Google Scholar] [CrossRef] [Green Version]

- Martinho, F.C.; Farinha, J.P.S. An overview of the use of nanoclay modified bitumen in asphalt mixtures for enhanced flexible pavement performances. Road Mater. Pavement Des. 2019, 20, 671–701. [Google Scholar] [CrossRef]

- Ali Omar, H.; Mubaraki, M.; Abdullah, N.H.; Al-Sabaeei, A.; Memon, A.M.; Khan, M.I.; Sutanto, M.H.; Md Yusoff, N.I. Determining the Effect of Ageing of Nano-Clay Modified Bitumen Using Atomic Force Microscopy. Sci. Iran. 2021, 28. [Google Scholar] [CrossRef]

- López-Montero, T.; Crucho, J.; Picado-Santos, L.; Miró, R. Effect of nanomaterials on ageing and moisture damage using the indirect tensile strength test. Constr. Build. Mater. 2018, 168, 31–40. [Google Scholar] [CrossRef]

- Li, R.; Xiao, F.; Amirkhanian, S.; You, Z.; Huang, J. Developments of nano materials and technologies on asphalt materials–A review. Constr. Build. Mater. 2017, 143, 633–648. [Google Scholar] [CrossRef]

- Nejad, F.M.; Azarhoosh, A.; Hamedi, G.H.; Azarhoosh, M. Influence of using nonmaterial to reduce the moisture susceptibility of hot mix asphalt. Constr. Build. Mater. 2012, 31, 384–388. [Google Scholar] [CrossRef]

- Copeland, A.R. Influence of Moisture on Bond Strength of Asphalt-Aggregate Systems; Vanderbilt University: Nashville, TN, USA, 2007. [Google Scholar]

- Gao, Y.; Geng, D.; Huang, X.; Li, G. Degradation evaluation index of asphalt pavement based on mechanical performance of asphalt mixture. Constr. Build. Mater. 2017, 140, 75–81. [Google Scholar] [CrossRef]

- Islam, M.R.; Hossain, M.I.; Tarefder, R.A. A study of asphalt aging using Indirect Tensile Strength test. Constr. Build. Mater. 2015, 95, 218–223. [Google Scholar] [CrossRef]

- Rawtani, D.; Agrawal, Y. Multifarious applications of halloysite nanotubes: A review. Rev. Adv. Mater. Sci. 2012, 30, 282–295. [Google Scholar]

- Deng, S.; Zhang, J.; Ye, L. Effects of chemical treatment and mixing methods on fracture behaviour of halloysite-epoxy nanocomposites. In Proceedings of the 17th Internatioanl Conference on Composite Materials, Edinburgh, UK, 27–31 July 2009. [Google Scholar]

- Omar, H.A.; Yusoff, N.I.M.; Sajuri, Z.; Ceylan, H.; Jakarni, F.M.; Ismail, A. Determining the effects of aging on halloysite nano-tube modified binders through the pull-off test method. Constr. Build. Mater. 2016, 126, 245–252. [Google Scholar] [CrossRef]

- Lau, K.-t.; Gu, C.; Hui, D. A critical review on nanotube and nanotube/nanoclay related polymer composite materials. Compos. Part B: Eng. 2006, 37, 425–436. [Google Scholar] [CrossRef]

- Stuart, B.H. Infrared Spectroscopy: Fundamental and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Mirwald, J.; Werkovits, S.; Camargo, I.; Maschauer, D.; Hofko, B.; Grothe, H. Understanding bitumen ageing by investigation of its polarity fractions. Constr. Build. Mater. 2020, 250, 118809. [Google Scholar] [CrossRef]

- Mirwald, J.; Maschauer, D.; Hofko, B.; Grothe, H. Impact of reactive oxygen species on bitumen aging–The Viennese binder aging method. Constr. Build. Mater. 2020, 257, 119495. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, H.; Shi, C. Investigation of aging performance of SBS modified asphalt with various aging methods. Constr. Build. Mater. 2017, 145, 445–451. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, H.; Zhu, C.; Shi, C. Synergetic effect of multi-dimensional nanomaterials for anti-aging properties of SBS modified bitumen. Constr. Build. Mater. 2017, 144, 423–431. [Google Scholar] [CrossRef]

- Petersen, J.C. A review of the fundamentals of asphalt oxidation: Chemical, physicochemical, physical property, and durability relationships. Transp. Res. Circ. 2009. [Google Scholar] [CrossRef]

- Omar, H.A.; Yusoff, N.I.M.; Ceylan, H.; Rahman, I.A.; Sajuri, Z.; Jakarni, F.M.; Ismail, A. Determining the water damage resistance of nano-clay modified bitumens using the indirect tensile strength and surface free energy methods. Constr. Build. Mater. 2018, 167, 391–402. [Google Scholar] [CrossRef]

- Handle, F.; Harir, M.; Füssl, J.; Koyun, A.e.N.; Grossegger, D.; Hertkorn, N.; Eberhardsteiner, L.; Hofko, B.; Hospodka, M.; Blab, R. Tracking aging of bitumen and its saturate, aromatic, resin, and asphaltene fractions using high-field Fourier transform ion cyclotron resonance mass spectrometry. Energy Fuels 2017, 31, 4771–4779. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Effect of ageing on bitumen chemistry and rheology. Constr. Build. Mater. 2002, 16, 15–22. [Google Scholar] [CrossRef]

- Moschopedis, S.E.; Speight, J.G. Influence of metal salts on bitumen oxidation. Fuel 1978, 57, 235–240. [Google Scholar] [CrossRef]

- Yao, H.; Dai, Q.; You, Z. Fourier Transform Infrared Spectroscopy characterization of aging-related properties of original and nano-modified asphalt binders. Constr. Build. Mater. 2015, 101, 1078–1087. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, X.; Zhang, Z.; Zou, B.; Zhu, Z.; Lu, G.; Xu, W.; Yu, J.; Yu, H. Effect of aging on chemical and rheological properties of bitumen. Polymers 2018, 10, 1345. [Google Scholar] [CrossRef] [Green Version]

- Guduru, G.; Goli, A.K.; Matolia, S.; Kuna, K.K. Chemical and Performance Characteristics of Rejuvenated Bituminous Materials with High Reclaimed Asphalt Content. J. Mater. Civ. Eng. 2021, 33, 04020434. [Google Scholar] [CrossRef]

- Yao, H.; You, Z.; Li, L.; Goh, S.W.; Lee, C.H.; Yap, Y.K.; Shi, X. Rheological properties and chemical analysis of nanoclay and carbon microfiber modified asphalt with Fourier transform infrared spectroscopy. Constr. Build. Mater. 2013, 38, 327–337. [Google Scholar] [CrossRef]

- Wang, D.; Liu, Q.; Yang, Q.; Tovar, C.; Tan, Y.; Oeser, M. Thermal oxidative and ultraviolet ageing behaviour of nano-montmorillonite modified bitumen. Road Mater. Pavement Des. 2021, 22, 121–139. [Google Scholar] [CrossRef]

- Vallerga, B. Pavement deficiencies related to asphalt durability. In Proceedings of the Association of Asphalt Paving Technologists Proceedings, San Diego, CA, USA, 16–18 February 1981; Volume 50, pp. 481–491. [Google Scholar]

| Sample | Ageing | Penetration (0.1 mm) | Penetration Ageing Index | Softening Point (°C) | Softening Point Index | PI |

|---|---|---|---|---|---|---|

| 0 NCMB | unaged | 64.6 | - | 47.5 | - | −1.3 |

| STA | 52.3 | 0.81 | 52.2 | 1.10 | −0.6 | |

| LTA | 42.1 | 0.65 | 58.1 | 1.22 | 0.2 | |

| 2 NCMB | unaged | 54.0 | - | 53.4 | - | −0.2 |

| STA | 48.3 | 0.89 | 59.0 | 1.10 | 0.7 | |

| LTA | 39.8 | 0.74 | 62.3 | 1.16 | 0.9 | |

| 4 NCMB | unaged | 49.2 | - | 59.0 | - | 0.8 |

| STA | 43.2 | 0.88 | 61.6 | 1.04 | 1.0 | |

| LTA | 38.9 | 0.79 | 64.7 | 1.09 | 1.3 |

| Viscosity (Pa.s) at 135 °C | VAI | ||||

|---|---|---|---|---|---|

| NC % | Unaged | STA | LTA | STA | LTA |

| 0% | 606 | 820 | 1068 | 1.35 | 1.76 |

| 2% | 702 | 790 | 886 | 1.13 | 1.26 |

| 4% | 770 | 859 | 992 | 1.12 | 1.29 |

| Functional Group | Peak Position (cm−1) |

|---|---|

| C–H asymmetric stretching | 2920 |

| C–H symmetric stretching | 2851 |

| C=O stretching | 1694 |

| C=C stretching | 1597 |

| CH2 deformation | 1457 |

| CH3 deformation | 1375 |

| S=O stretch | 1027 |

| CH out-of-plane deformation | 900–690 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Omar, H.A.; Katman, H.Y.; Bilema, M.; Ahmed, M.K.A.; Milad, A.; Md Yusoff, N.I. The Effect of Ageing on Chemical and Strength Characteristics of Nanoclay-Modified Bitumen and Asphalt Mixture. Appl. Sci. 2021, 11, 6709. https://doi.org/10.3390/app11156709

Omar HA, Katman HY, Bilema M, Ahmed MKA, Milad A, Md Yusoff NI. The Effect of Ageing on Chemical and Strength Characteristics of Nanoclay-Modified Bitumen and Asphalt Mixture. Applied Sciences. 2021; 11(15):6709. https://doi.org/10.3390/app11156709

Chicago/Turabian StyleOmar, Hend Ali, Herda Yati Katman, Munder Bilema, Mohamed Khalifa Ali Ahmed, Abdalrhman Milad, and Nur Izzi Md Yusoff. 2021. "The Effect of Ageing on Chemical and Strength Characteristics of Nanoclay-Modified Bitumen and Asphalt Mixture" Applied Sciences 11, no. 15: 6709. https://doi.org/10.3390/app11156709