Buckling Behavior of Thin-Walled Stainless-Steel Lining Wrapped in Water-Supply Pipe under Negative Pressure

Abstract

:1. Introduction

2. Experimental Testing

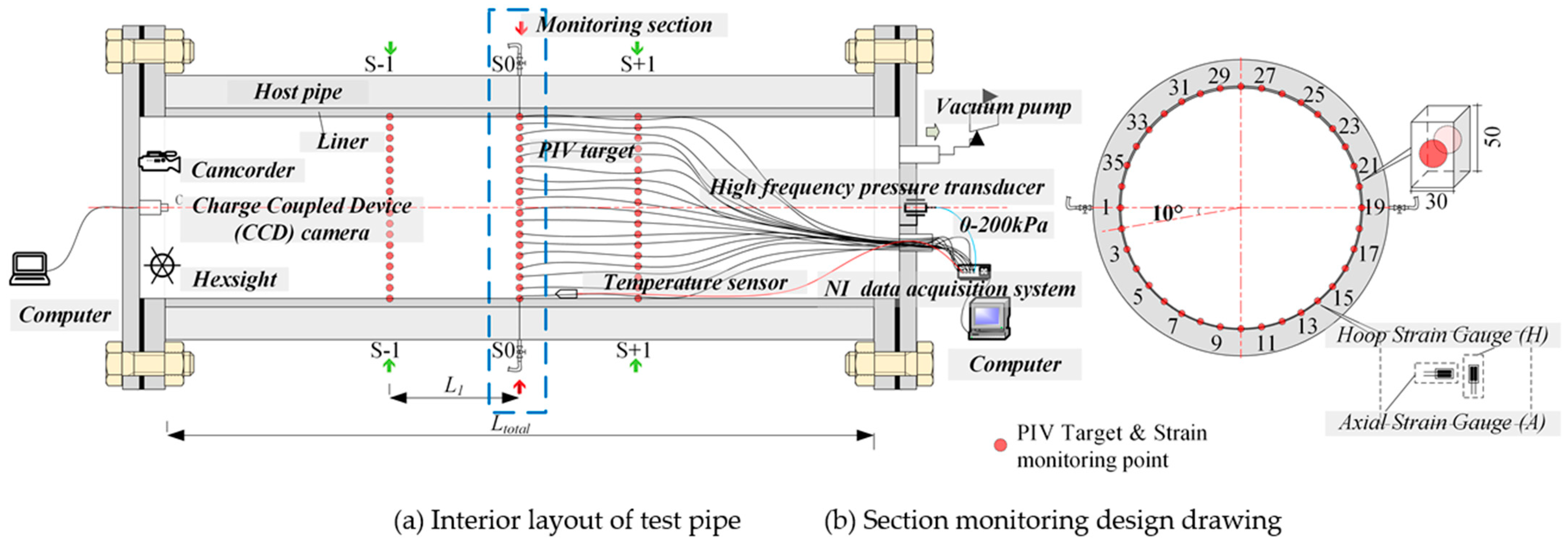

2.1. Experimental Setup

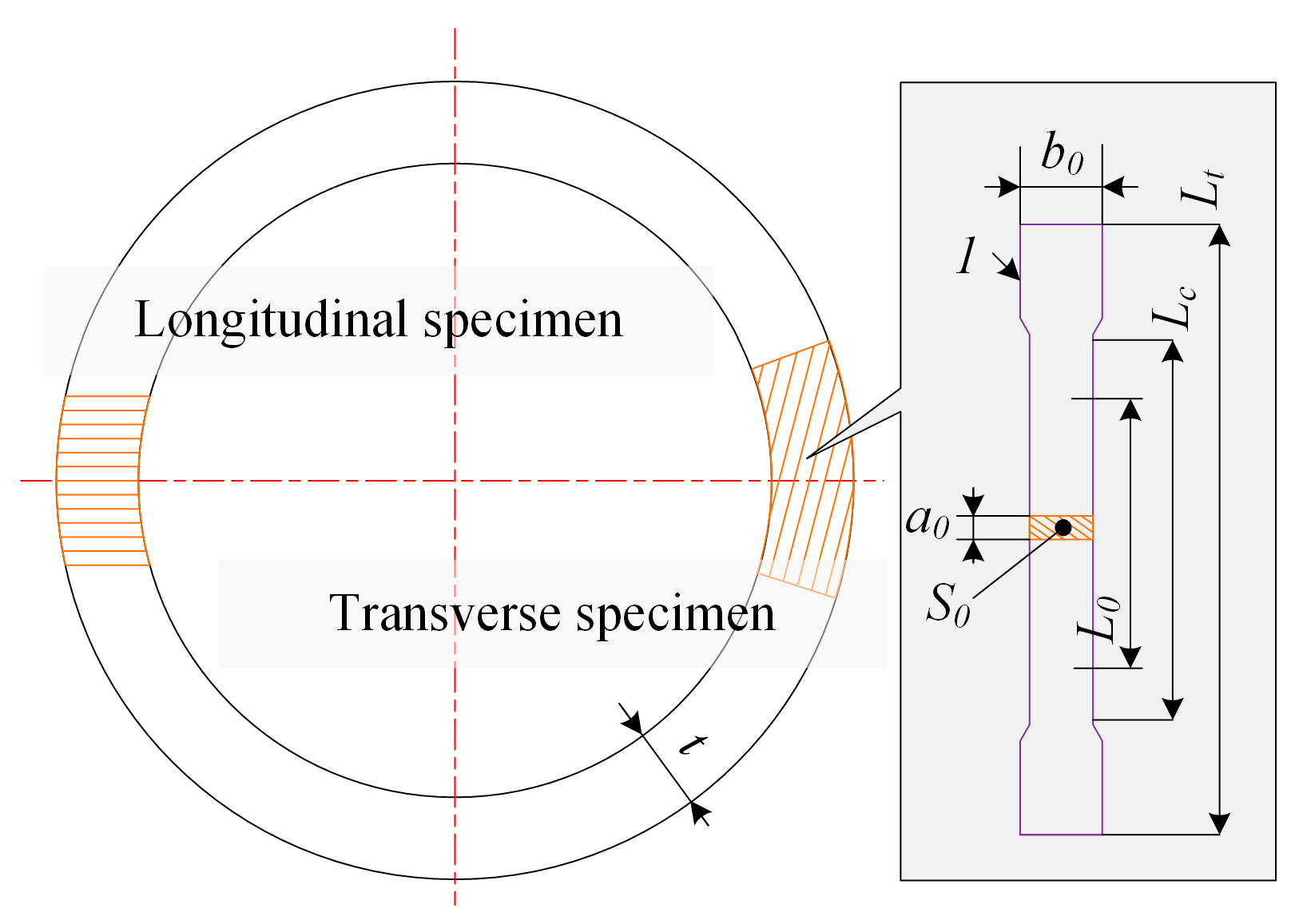

2.1.1. Basic Parameter Test

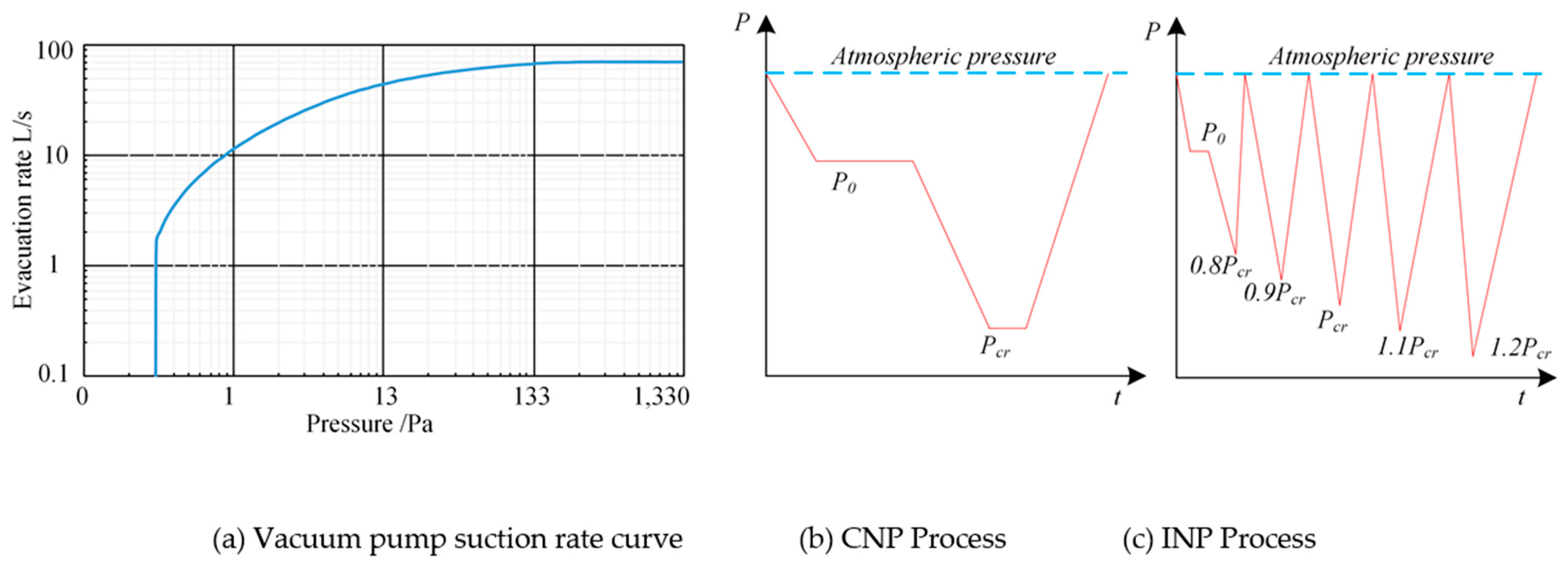

2.1.2. Negative Pressure Test

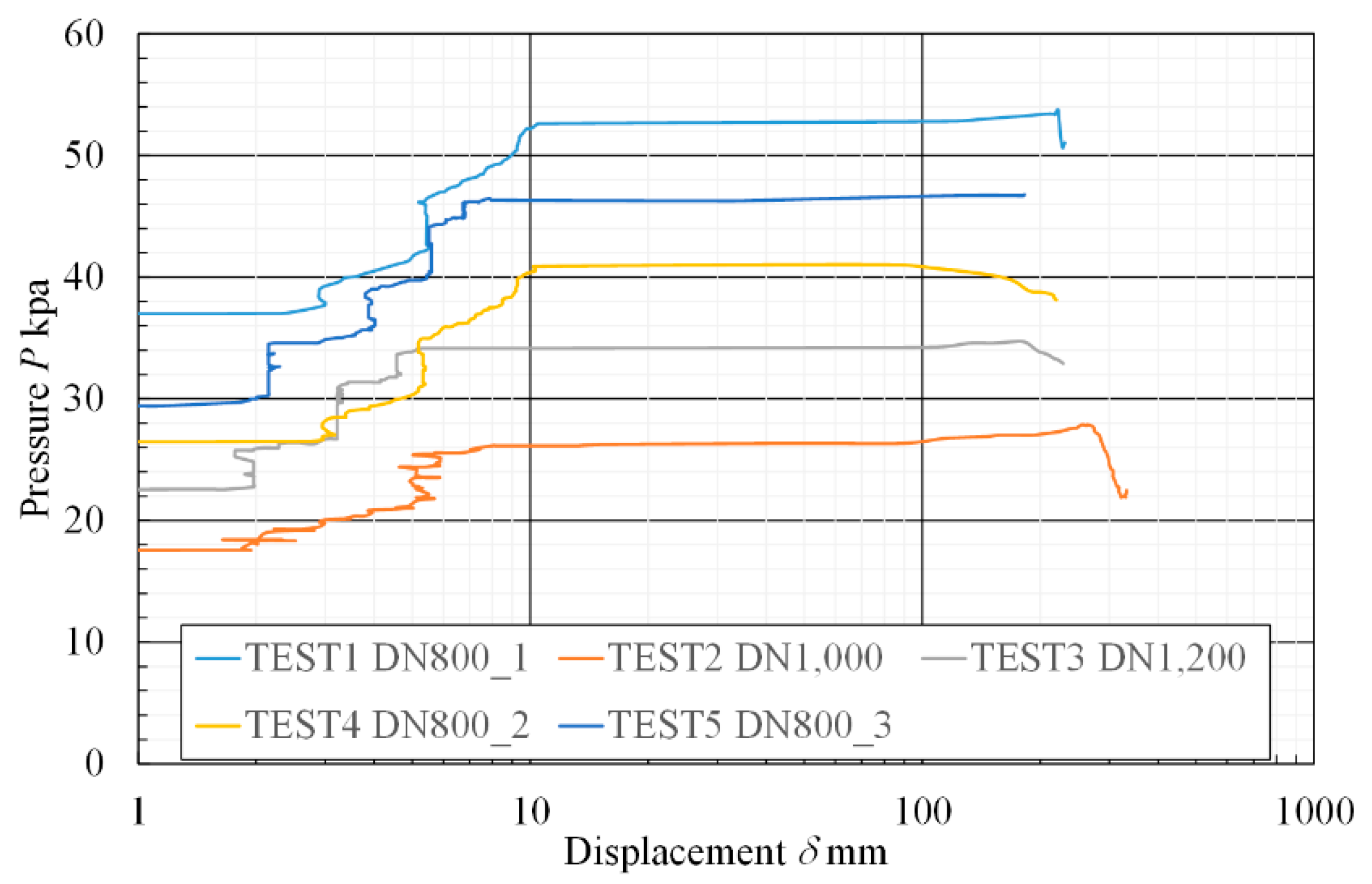

2.2. Experimental Result

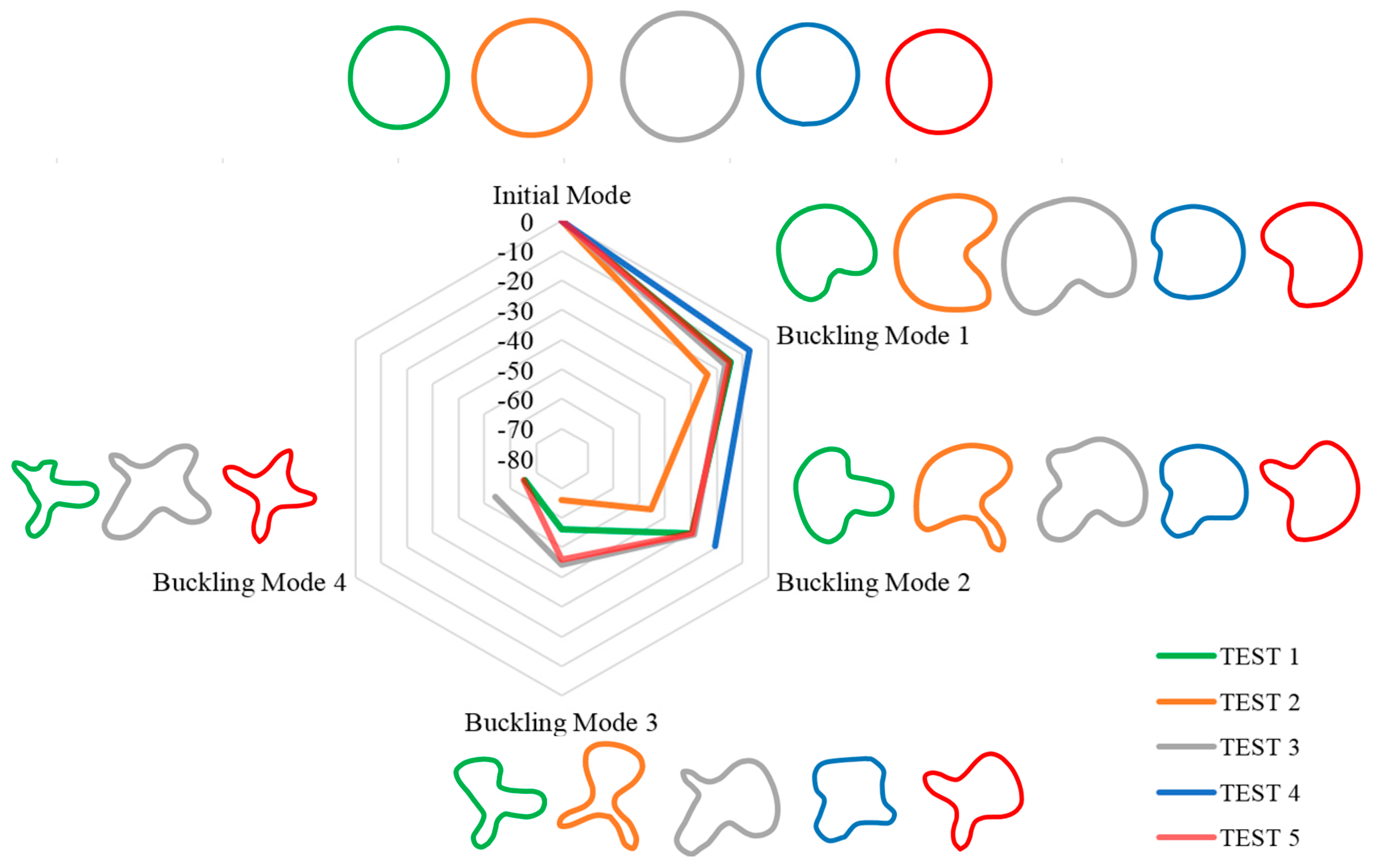

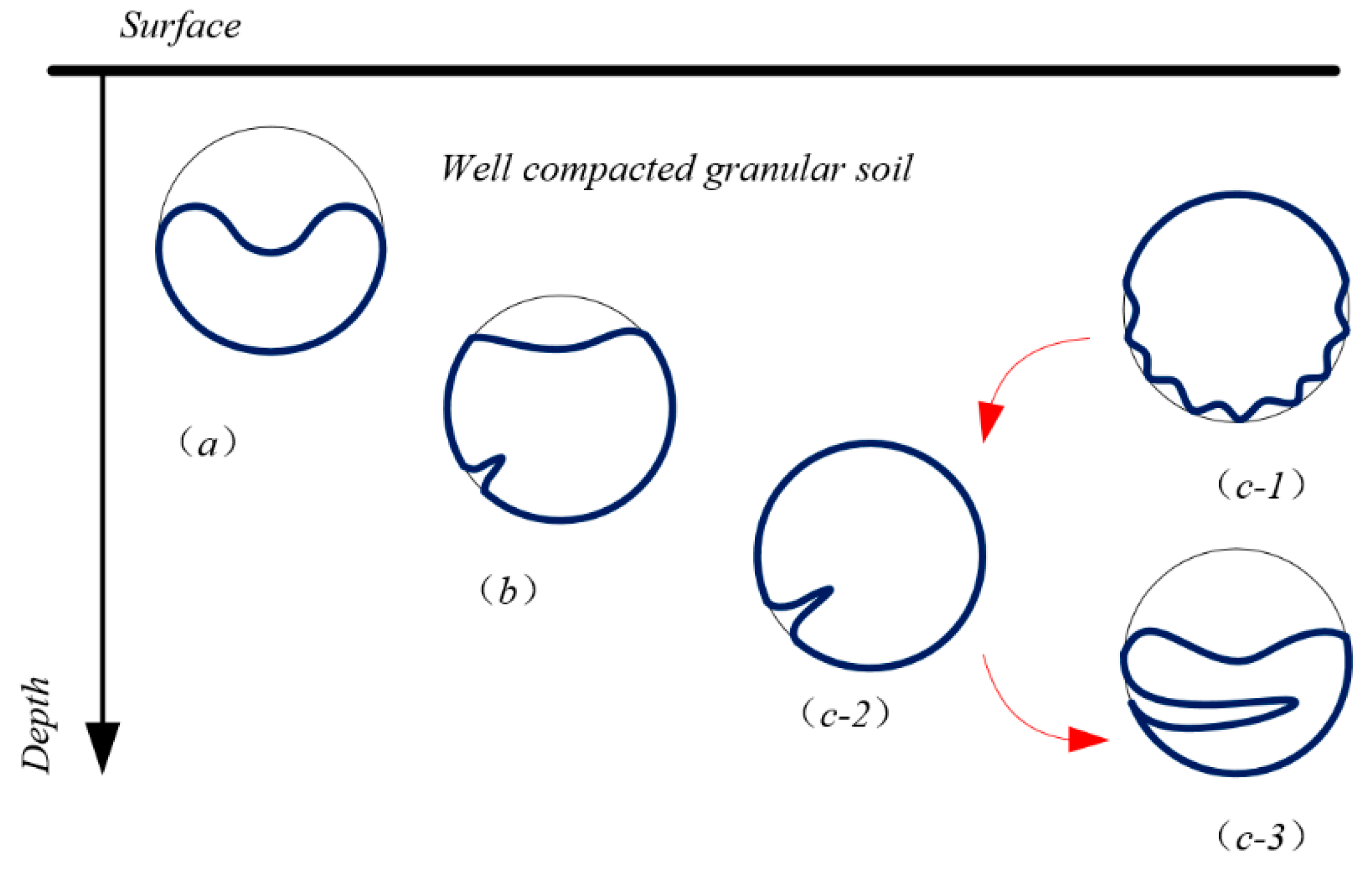

2.2.1. Visualization of Buckling Collapse

2.2.2. Critical Buckling Pressure

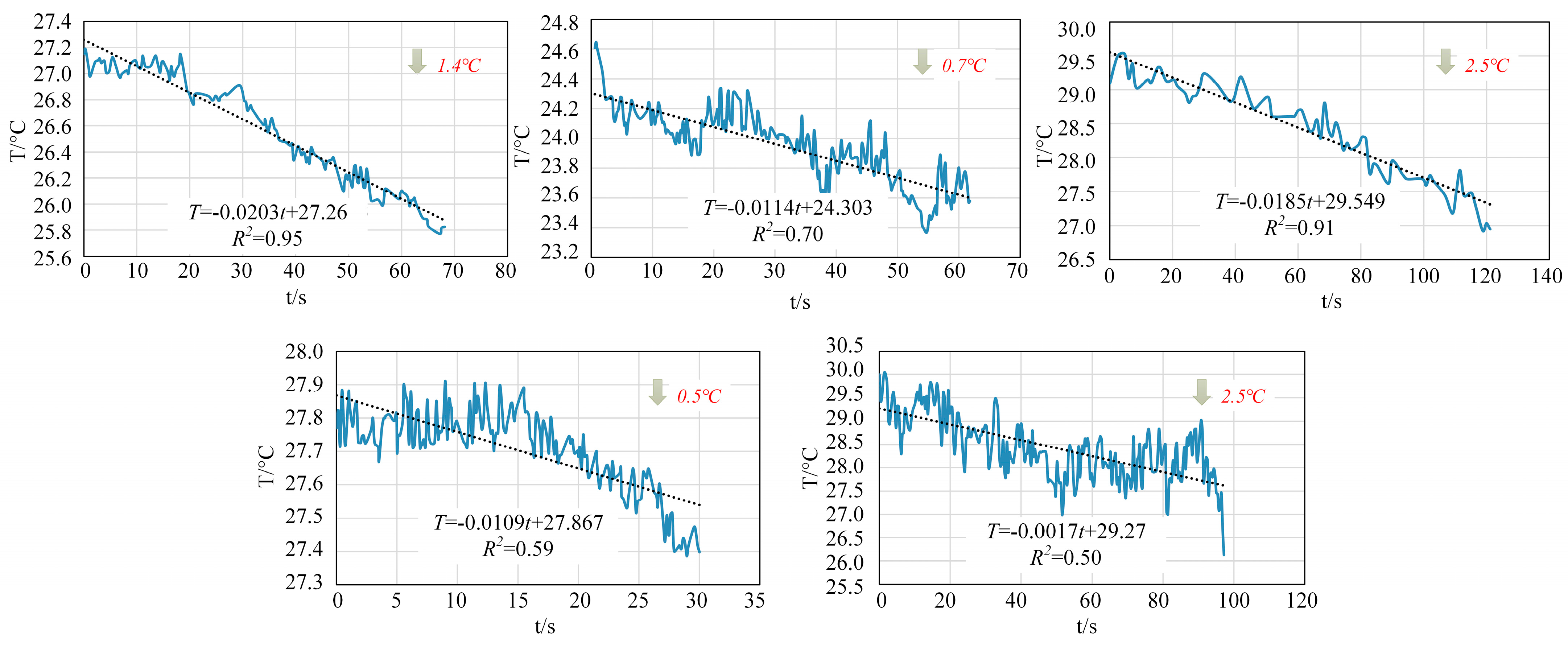

2.2.3. Temperature Variation

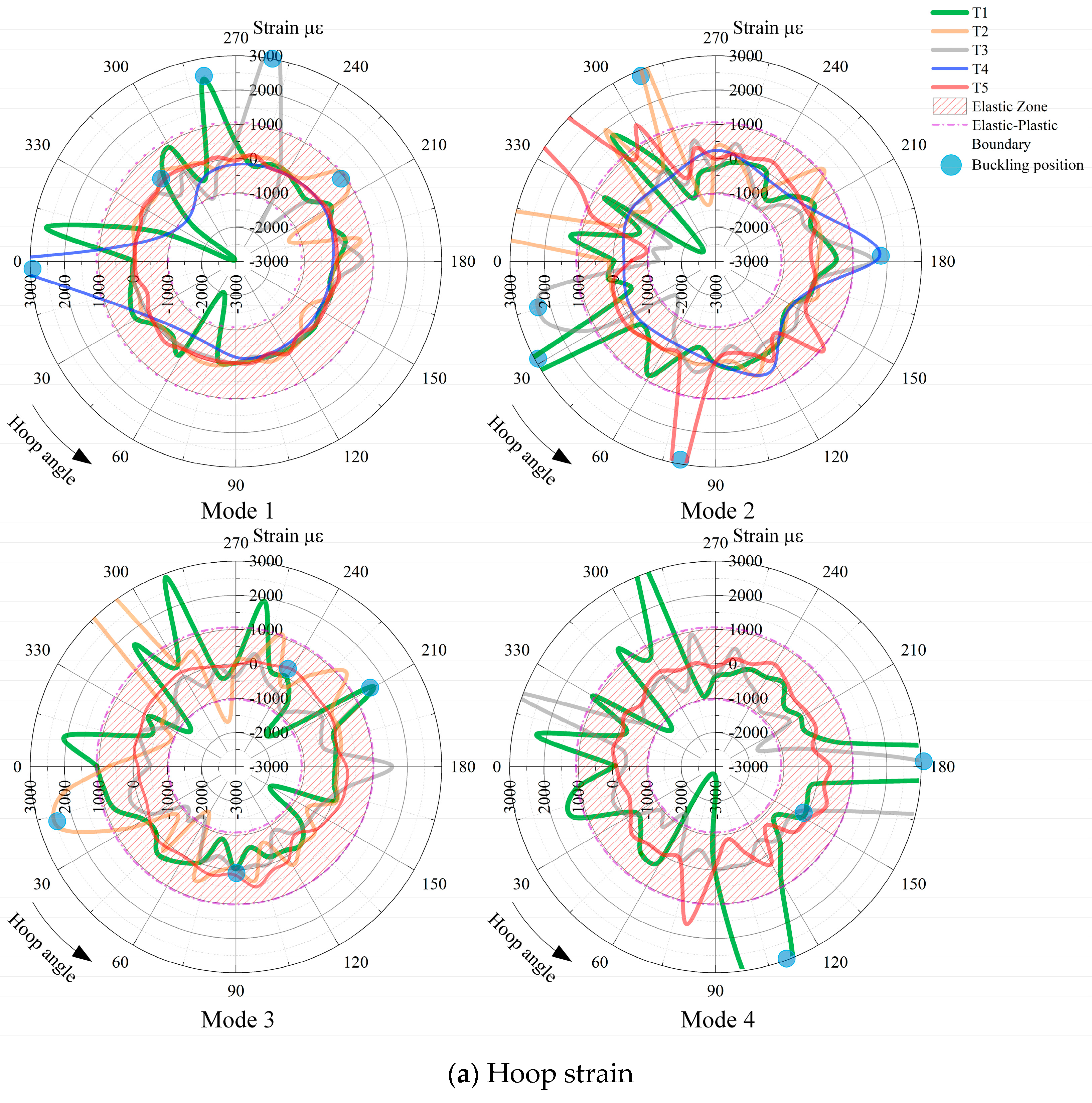

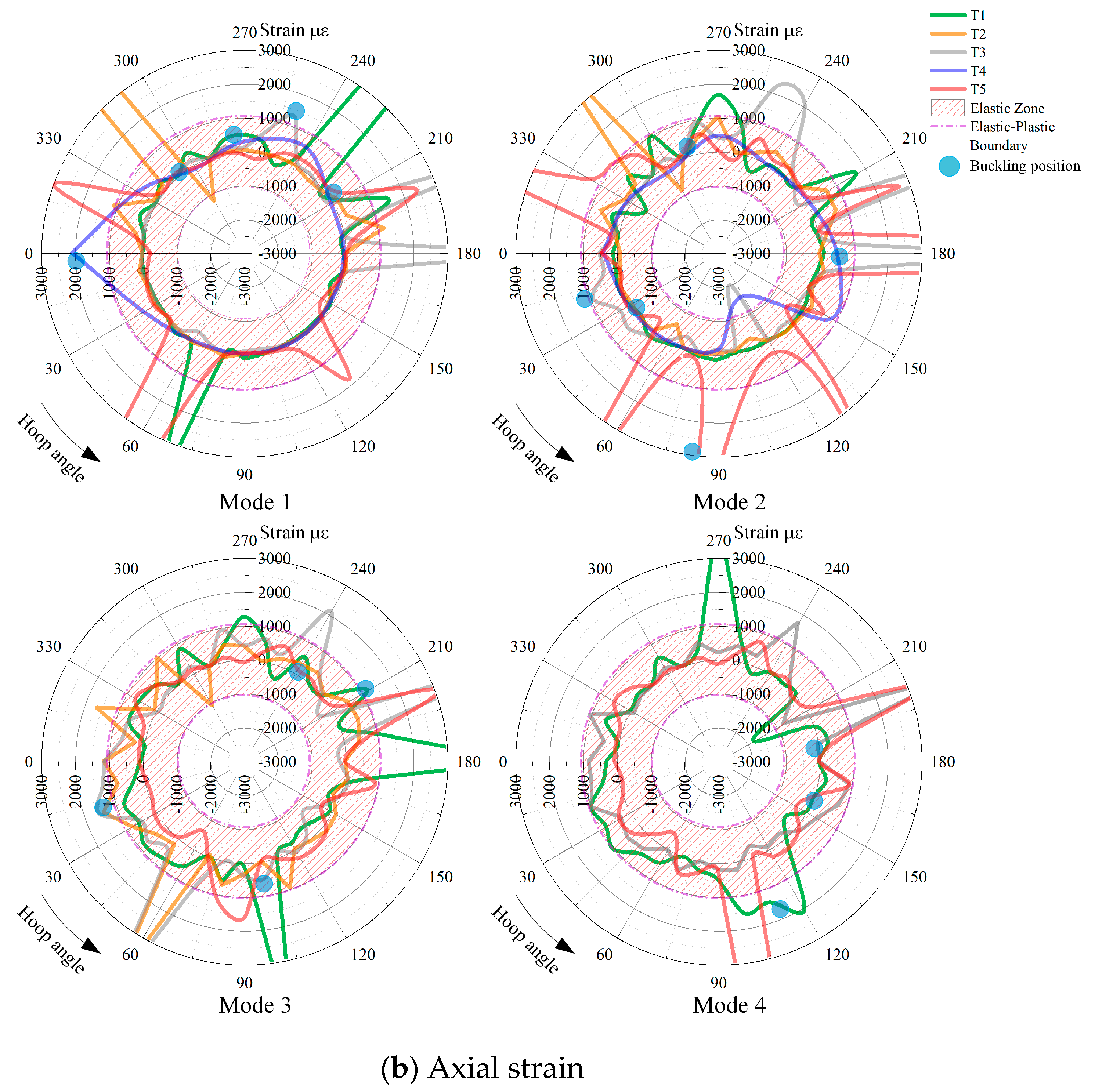

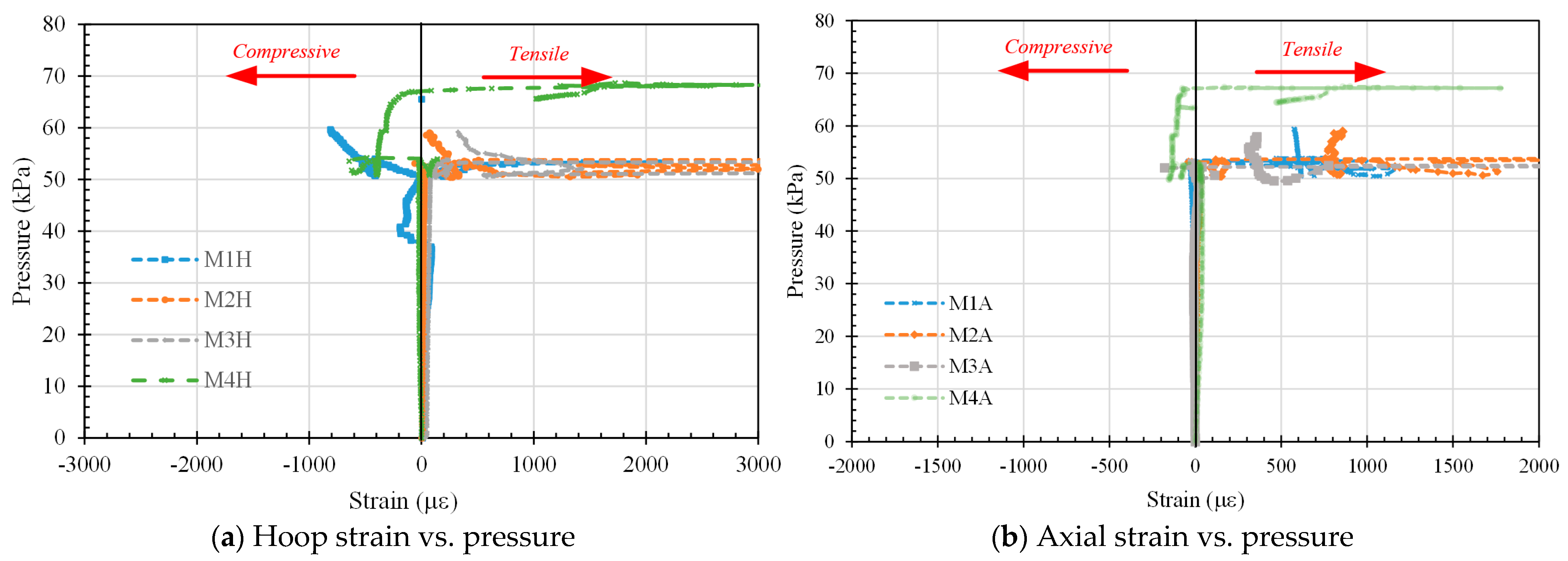

2.2.4. Hoop and Axial Strain

3. Analysis

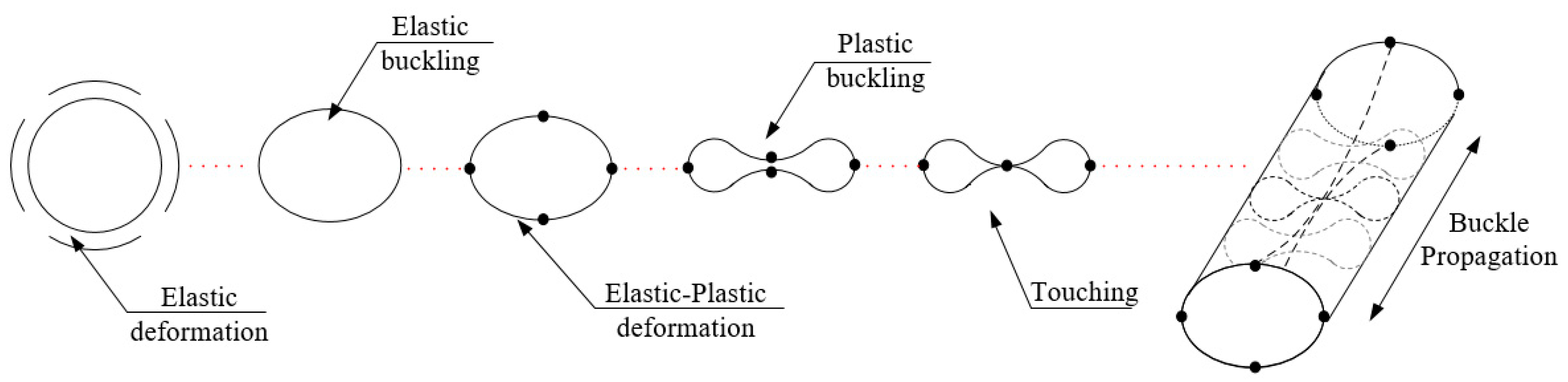

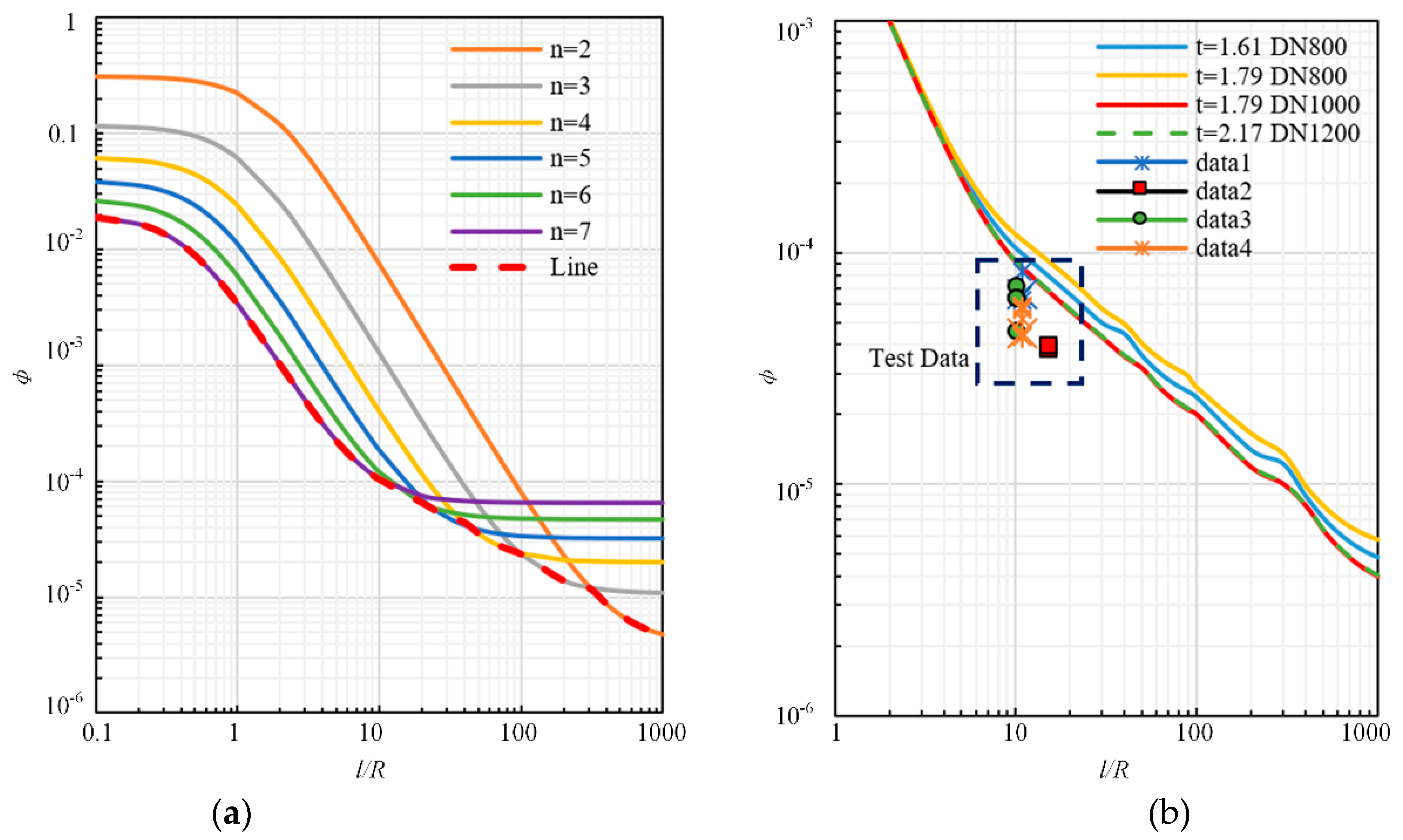

3.1. Classical Pipeline Buckling Model

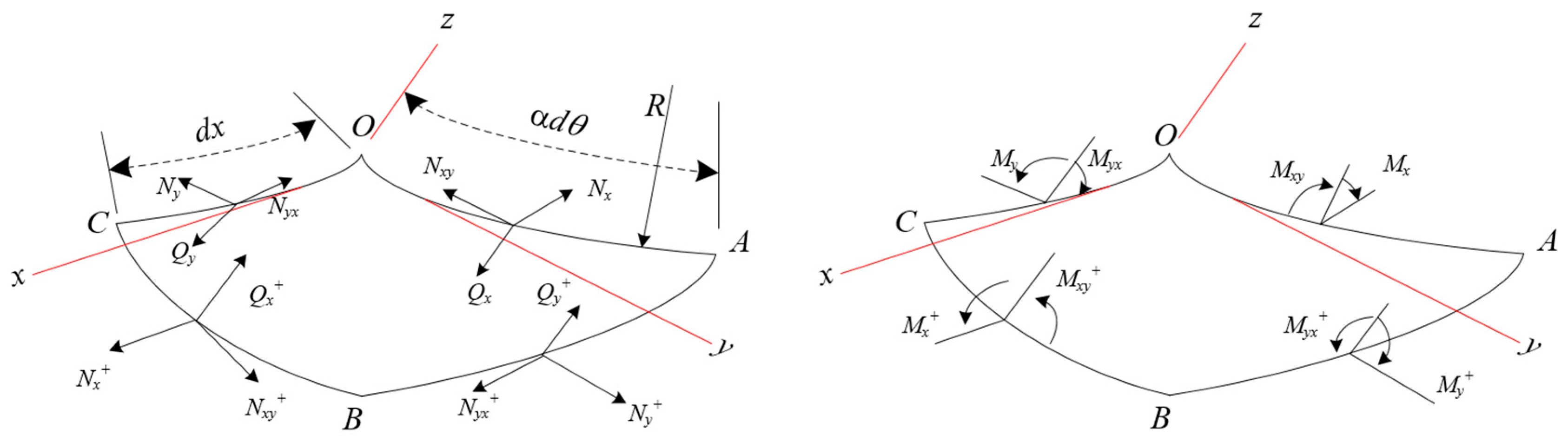

3.2. Free Ring and Thin-Shell Theory

- (1)

- The relative angular displacement of side BC for side OA about the x-axis is as follows:

- (2)

- The rotation of side BC about the y-axis of side OA is caused by the bending of the generatrix in the axial plane, and it is equal to the following:

- (3)

- The rotation of side BC about the z-axis of side OA is caused by the bending of the generatrix in the tangent plane, and it equals the following:

- (1)

- The relative angular displacement of side AB for side OC about the x axis is

- (2)

- The rotation of side AB about the y-axis of side OC is caused by the bending of the generatrix in the axial plane, and it equals the following:

- (3)

- The rotation of side AB about the z-axis of side OC is caused by the bending of the generatrix in the tangent plane, and it is equal to the following:

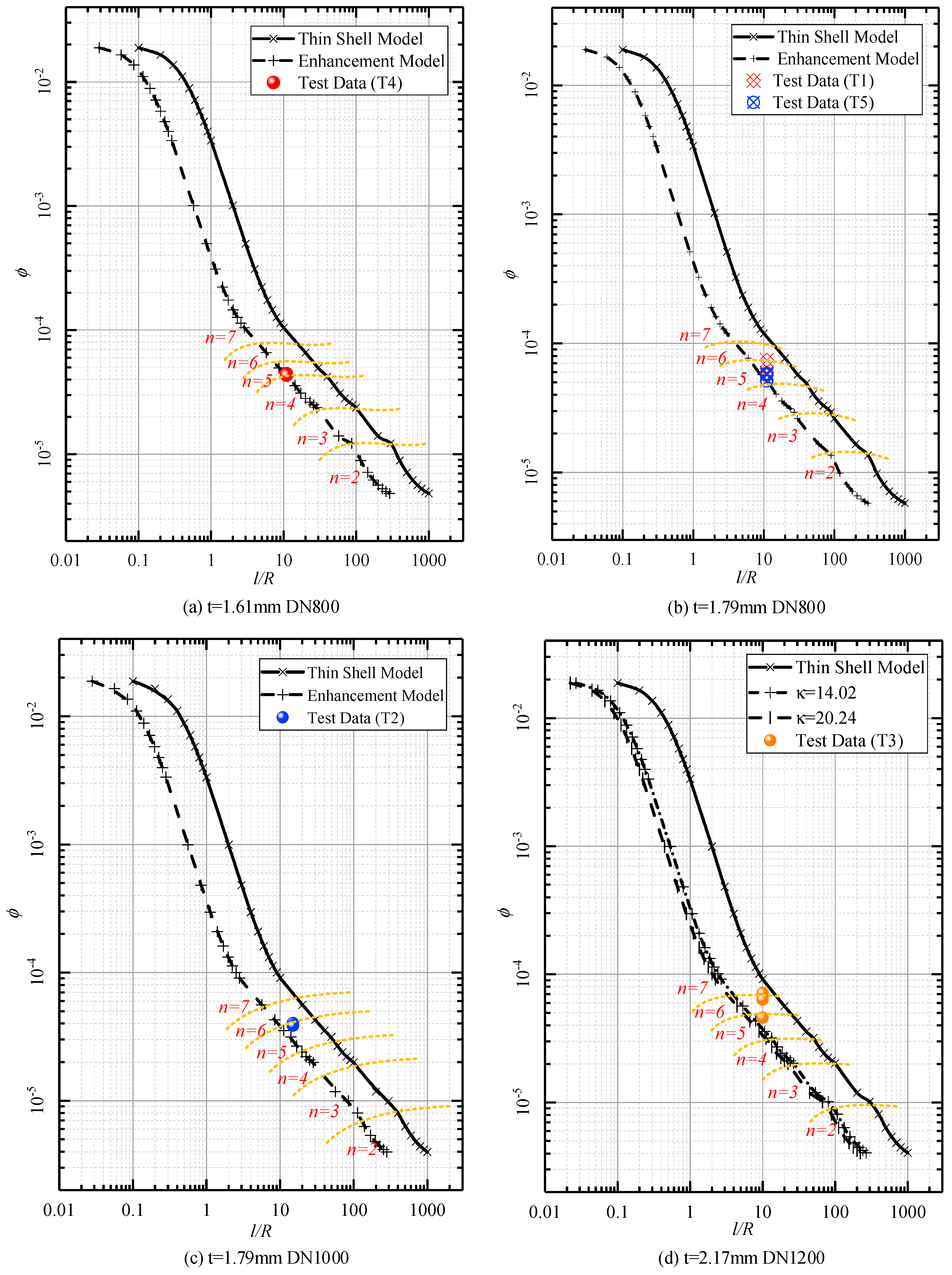

3.3. Comparison with Theoretical Predictions

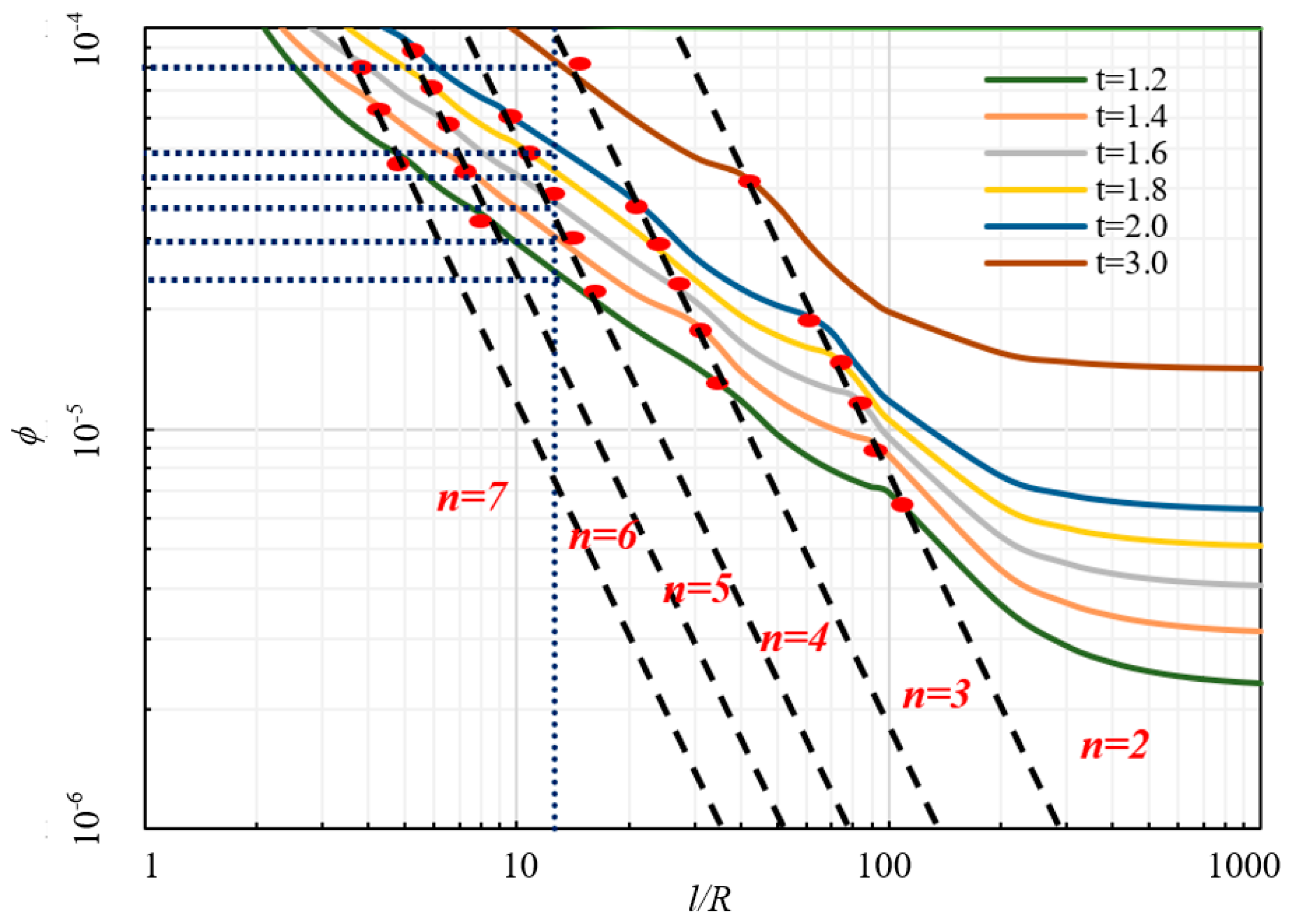

3.4. Design Procedures

- Pipe diameter: DN800 mm; Pipe length: 10 m;

- Lining material model: stainless steel 304;

- Elastic Modulus: 195,000 MPa;

- Poisson ratio: 0.247;

- Thickness: 1.2 mm.

- (1)

- Using the experimental results (Table 3), we take a relatively conservative value of 14.02 (The larger value of kaverage in T1–T5);

- (2)

- Then, according to the actual lining material performance parameters, the curves under different lobe number n are calculated and drawn;

- (3)

- Obtaining the envelope curve of the buckling value φ and l/R ratio (See figure line ‘t = 1.2′ in Figure 17);

- (4)

- Taking the actual l/R ratio to determine the corresponding φ value and reverse calculating the critical buckling pressure;

- (5)

- If the calculated pressure does not meet the specified vacuum negative pressure value, several groups of large wall mass are used for the new drawing. In this case, several scenarios are considered (t = 1.2 mm, t = 1.4 mm, t = 1.6 mm, t = 1.8 mm, t = 2.0 mm and t = 3.0 mm);

- (6)

- So far, the ratio of l/R can be set as the actual value and plotted in the figure to obtain the corresponding value of φ. Applying the definition of φ, the critical buckling pressure can be derived reversely. The critical buckling values in this case are 14.33 kPa for t = 1.2 mm, 20.82 kPa for t = 1.4 mm, 28.86 kPa for t = 1.6 mm, 37.73 kPa for t = 1.8 mm, 50.70 kPa for t= 2.0 and 120.0 kPa for t= 3.0 mm, respectively;

- (7)

- Finally, t = 2.0 mm is taken as the repair wall thickness of the lining under the negative pressure of the water-supply pipeline (The standard requires it to withstand negative pressure of −0.05 MPa). Moreover, the lining generates four random lobes in this circumstance.

4. Summary and Conclusions

- (1)

- When the pump and valve are switched on and off in the water supply network system, the inertia of the medium causes negative pressure and positive pressure, which can be considered as the local failure of the pipeline. The test equipment employed in this study is reliable and effective for the study of application of thin-wall stainless-steel trenchless repair technology to update the system stability of water-supply pipe network.

- (2)

- In the pre-buckling stage, the critical buckling pressure is closely related to the lining wall thickness and lining diameter. The smaller the lining wall thickness is, the smaller the critical buckling pressure is. Moreover, with the increase of pipe diameter, the critical buckling pressure of liner pipe with the same wall thickness tended to decrease.

- (3)

- The results show that the buckling behavior of the pipeline lining system is affected by the pressure change velocity. Under the condition of instantaneous negative pressure, it is easier to form lobes, but after the first lobe, the subsequent critical buckling pressure to form new lobes increases less than that of the continuous negative pressure test.

- (4)

- The buckling mode of inner liner under negative vacuum pressure is different from that of buried pipeline and deep-sea pipeline. The strain results indicate that with the increase of vacuum degree, the lining shows the elastic deformation of the full section, such as the elastic deformation of the lower end of the pipeline in Figure 12(c-1). After the material exceeds the elastic stage, the first lobe appears in the lining, and then the vacuum degree of the system decreases obviously. The system will reach a new equilibrium. With the increase of vacuum degree, new lobes will be formed. This process shows certain cyclic characteristics. The buckling position of several test liners is not the same, which is determined by the boundary constraints of the liners and host pipe.

- (5)

- One of the most important factors to consider in a water-supply pipeline is its ability to overflow. The critical buckling pressure of the subsequent lobes differs little from the critical buckling pressure of the first lobe. That is, as long as the buckling occurs, the subsequent lobes will be generated quickly. We believe that the overflow section in post-buckling is easier to reduce to the level of 50–60% of the original pipeline, which is unacceptable in the water supply network. Therefore, a reasonable design method should be applied to obtain the economic and reliable lining design’s wall thickness.

- (6)

- With the support of the existing pipe, the position where lining buckling produces greater tensile strain. The critical pressure of lining buckling deviates significantly from the theory of free ring. By comparing the two, the enhancement coefficient k, which ranges from 11.22 to 14.02, is obtained. The critical pressure calculation Equation given in the thin-shell theory can predict the number of buckling waves and critical buckling pressure, but it does not consider the supporting role of existing pipelines. The study shows that the enhancement coefficient k can be represented as the change of boundary conditions. By reducing the l/R ratio by times, the improved enhanced model can predict the buckling value of the lining and the number of possible buckling lobes.

- (7)

- The enhanced prediction model can be used to design the inner wall thickness of the water-supply pipeline repaired by SSL. When the negative pressure is taken into account, the number of possible lobe formations decreases with the increase of lining wall thickness. If the lining thickness reaches a certain value, the required buckling pressure has exceeded the vacuum limit. In this case, negative pressure is not needed to be considered. However, considering the cost of the thin-walled stainless-steel lining, the reinforcement model can be applied to obtain the optimal wall thickness, thus making the lining design economical and safe.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| a | Axial coefficient of thermal expansion of liner, generally a = 1.2 × 10−5 mm/(mm °C); |

| Ez | Axial elastic modulus; |

| ΔT | The difference between the test temperature and the installation temperature of the lining. |

| H | The burial depth of the pipeline (From the crown to the surface); |

| R | The shell radius; |

| u, v, w | Displacement in the x, y and z directions; |

| Nx, Ny, Nxy, Nyx | The normal force and shear force per unit length on the middle surface of the shell; |

| Qx,Qy | The shear force per unit length of shell; |

| P | System internal pressure; |

| Mx, My, Mxy | Bending moment and torque per unit length of shell; |

| ε1, ε2, γ | The normal strain in the 1, 2 direction and shear strain; |

| χx, χy, χxy | Variation in curvature per unit length of shell; |

| E | Elastic modulus of liner; |

| t | The average thickness of liner; |

| μ | Poisson ratio; |

| n | The lobe number; |

| l | The length of pipeline; |

| ki | Enhancement coefficient of wall support; |

| λ | πR/l. |

References

- Tamminen, S.; Ramos, H.; Covas, D. System Performance for Different Pipe Materials Part I: Water Quality Analysis. Water Resour. Manag. 2008, 22, 1579–1607. [Google Scholar] [CrossRef] [Green Version]

- Barton, N.A.; Farewell, T.S.; Hallett, S.H.; Acland, T.F. Improving pipe failure predictions: Factors affecting pipe failure in drinking water networks. Water Res. 2019, 164, 114926. [Google Scholar] [CrossRef]

- Orlikowski, J.; Zielinski, A.; Darowicki, K.; Krakowiak, S.; Zakowski, K.; Slepski, P.; Jazdzewska, A.; Gruszka, M.; Banas, J. Research on causes of corrosion in the municipal water supply system. Case Stud. Constr. Mater. 2016, 4, 108–115. [Google Scholar] [CrossRef] [Green Version]

- Cassa, A.M.; Van Zyl, J.E.; Laubscher, R.F. A numerical investigation into the effect of pressure on holes and cracks in water supply pipes. Urban Water J. 2010, 7, 109–120. [Google Scholar] [CrossRef]

- Boot, J.C. Elastic buckling of cylindrical pipe linings with small imperfections subject to external pressure. Tunn. Undergr. Space Technol. 1997, 12, 3–15. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, L.; Liu, D.; Wang, J.; Zhang, X.; Chen, C. Early period corrosion and scaling characteristics of ductile iron pipe for ground water supply with sodium hypochlorite disinfection. Water Res. 2020, 176, 115742. [Google Scholar] [CrossRef] [PubMed]

- Greyvenstein, B.; Van Zyl, J.E. An experimental investigation into the pressure-leakage relationship of some failed water pipes. J. Water Supply Res. Technol. AQUA 2007, 56, 117–124. [Google Scholar] [CrossRef]

- Misiunas, D.; Lambert, M.; Simpson, A.; Olsson, G. Burst detection and location in water distribution networks. Water Sci. Technol. Water Supply 2005, 5, 71–80. [Google Scholar] [CrossRef]

- Xin, K.L.; Tao, T.; Li, S.; Yan, H. Contamination accidents in China’s drinking water distribution networks: Status and countermeasures. Water Policy 2017, 19, 13–27. [Google Scholar] [CrossRef] [Green Version]

- Ma, B.; Najafi, M. Development and applications of trenchless technology in China. Tunn. Undergr. Space Technol. 2008, 23, 476–480. [Google Scholar] [CrossRef]

- ISO 11298-1. Plastics Piping Systems for Renovation of Underground Water Supply Networks—Part 1: General. 2018. Available online: https://www.iso.org/standard/70121.html (accessed on 1 March 2018).

- Sterling, R.L. No-dig techniques and challenges. J. Geoengin. 2010, 5, 63–67. [Google Scholar]

- Percival, S.L.; Beech, I.B.; Edyvean, R.G.J.; Knapp, J.S.; Wales, D.S. Biofilm Development on 304 and 316 Stainless Steels in a Potable Water System. Water Environ. J. 1997, 11, 289–294. [Google Scholar] [CrossRef]

- Baddoo, N.R. Stainless steel in construction: A review of research, applications, challenges and opportunities. J. Constr. Steel Res. 2008, 64, 1199–1206. [Google Scholar] [CrossRef]

- Agatemor, C.; Okolo, P.O. Studies of corrosion tendency of drinking water in the distribution system at the University of Benin. Environmentalist 2008, 28, 379–384. [Google Scholar] [CrossRef]

- Jang, H.J.; Choi, Y.J.; Ka, J.O. Effects of diverse water pipe materials on bacterial communities and water quality in the annular reactor. J. Microbiol. Biotechnol. 2011, 21, 115. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deng, D.; Murakawa, H. Numerical simulation of temperature field and residual stress in multi-pass welds in stainless steel pipe and comparison with experimental measurements. Comput. Mater. Sci. 2006, 37, 269–277. [Google Scholar] [CrossRef]

- Zhou, W.; Li, C.; Ma, B.; Najafi, M. Buckling Strength of a Thin-Wall Stainless Steel Liner Used to Rehabilitate Water Supply Pipelines. J. Pipeline Syst. Eng. Pract. 2016, 7, 04015017. [Google Scholar] [CrossRef]

- Dong, S.; Zhou, W.; Zhang, H.; Ma, B. An updated structure for a stainless steel liner and the estimation of its buckling strength. Tunn. Undergr. Space Technol. 2018, 72, 9–16. [Google Scholar] [CrossRef]

- ASTM Committee F17. Standard Practice for Rehabilitation of Existing Pipelines and Conduits by the Inversion and Curing of a Resin-Impregnated Tube, 1st ed.; ASTM F1216, 2016; American Society for Testing and Materials: West Conshohocken, PA, USA, 1989. [Google Scholar]

- German Association for Water, Wastewater and Waste. Static Calculations for the Rehabilitation of Sewers with Lining and Assembly Procedures; ATV-M 127-2, 2000; Water Ass: Hennef, Germany, 2000; (Available in English Language). [Google Scholar]

- Knight, M.A.; Bontus, G. Pressure Testing of CIPP Liners to Failure. In Pipelines 2018: Condition Assessment, Construction, and Rehabilitation 2018; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 444–453. [Google Scholar]

- National Technical Committee on Steel of Standardization Administration of China. Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature; GB/T 228.1, 2010; (ISO 6892-1: 2009, MOD); Standard Press: Beijing, China, 2011. [Google Scholar]

- National Technical Committee on Steel of Standardization Administration of China. Metallic Materials- Determination of Modulus of Elasticity and Poisson’s Ratio; GB/T 22315, 2008; Standard Press: Beijing, China, 2009. [Google Scholar]

- Steel and Steel Products- Location and Preparation of Samples and Test Pieces for Mechanical Testing; GB/T 2975, 2018; (ISO 377: 2017, MOD); Standard Press: Beijing, China, 2019.

- El-Sawy, K.; Moore, I.D. Stability of Loosely Fitted Liners Used to Rehabilitate Rigid Pipes. J. Struct. Eng. 1998, 124, 1350–1357. [Google Scholar] [CrossRef]

- Shahandeh, R.; Showkati, H. Influence of ring-stiffeners on buckling behavior of pipelines under hydrostatic pressure. J. Constr. Steel Res. 2016, 121, 237–252. [Google Scholar] [CrossRef]

- Yuan, L.; Kyriakides, S. Plastic bifurcation buckling of lined pipe under bending. Eur. J. Mech. A/Solids 2014, 47, 288–297. [Google Scholar] [CrossRef]

- Karampour, H.; Alrsai, M.; Albermani, F.; Guan, H.; Jeng, D.S. Propagation buckling in subsea pipe-in-pipe systems. J. Eng. Mech. 2017, 143, 04017113. [Google Scholar] [CrossRef] [Green Version]

- Gavriilidis, I.; Karamanos, S.A. Bending and buckling of internally-pressurized steel lined pipes. Ocean Eng. 2019, 171, 540–553. [Google Scholar] [CrossRef] [Green Version]

- Bulson, P.S. Buried Structures: Static and Dynamic Strength, 1st ed.; Chapman and Hall Ltd.: London, UK, 1985. [Google Scholar]

- Timoshenko, S.P.; Gere, J.M. Theory of Elastic Stability; Courier Corporation: North Chelmsford, MA, USA, 1961. [Google Scholar]

| Specimen | D SSL (mm) | t (mm) | L (m) | OV (%) | g (%) |

|---|---|---|---|---|---|

| T1 | 800 | 1.79 | 5.0 | 0.91 | 1.64 |

| T2 | 1000 | 1.79 | 7.5 | 1.34 | 0.61 |

| T3 | 1200 | 2.17 * | 8.0 | 0.90 | 0.63 |

| T4 | 800 | 1.61 | 5.0 | 0.75 | 1.14 |

| T5 | 800 | 1.79 | 5.0 | 1.56 | 2.00 |

| Specimen Number | n = 1 | Gr | n = 2 | Gr | n = 3 | Gr | n = 4 | Gr |

|---|---|---|---|---|---|---|---|---|

| T1 | 55.12 | 0 | 52.44 | −4.86% | 54.45 | +3.82% | 68.84 | +26.43% |

| T2 | 28.47 | 0 | 29.46 | +3.49% | 28.16 | −4.42% | / | / |

| T3 | 34.44 | 0 | 53.59 | +55.60% | 47.70 | −10.99% | 47.84 | −0.29% |

| T4 | 41.37 | 0 | 40.30 | −2.58% | / | / | / | / |

| T5 | 47.57 | 0 | 52.87 | +11.15% | 54.02 | +2.17% | 54.38 | +0.67% |

| No. | Theoretical Value of Free Ring Model/kPa | k1 Lobe 1 | k2 Lobe 2 | k3 Lobe 3 | k4 Lobe 4 | kaverage |

|---|---|---|---|---|---|---|

| Test 1 | 4.65 | 11.85 | 11.27 | 11.70 | 14.80 | 12.40 |

| Test 2 | 2.26 | 12.57 | 13.01 | 12.43 | NAN | 12.67 |

| Test 3 | 2.46 | 14.02 | 21.82 | 19.42 | 19.48 | 14.02/20.24 |

| Test 4 | 3.39 | 12.22 | 11.90 | NAN | NAN | 12.06 |

| Test 5 | 4.65 | 10.23 | 11.36 | 11.61 | 11.69 | 11.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, C.; Ariaratnam, S.T.; Yan, X.; Ma, B.; Zhao, Y.; Xiang, W. Buckling Behavior of Thin-Walled Stainless-Steel Lining Wrapped in Water-Supply Pipe under Negative Pressure. Appl. Sci. 2021, 11, 6781. https://doi.org/10.3390/app11156781

Lu C, Ariaratnam ST, Yan X, Ma B, Zhao Y, Xiang W. Buckling Behavior of Thin-Walled Stainless-Steel Lining Wrapped in Water-Supply Pipe under Negative Pressure. Applied Sciences. 2021; 11(15):6781. https://doi.org/10.3390/app11156781

Chicago/Turabian StyleLu, Chunqing, Samuel T. Ariaratnam, Xuefeng Yan, Baosong Ma, Yahong Zhao, and Weigang Xiang. 2021. "Buckling Behavior of Thin-Walled Stainless-Steel Lining Wrapped in Water-Supply Pipe under Negative Pressure" Applied Sciences 11, no. 15: 6781. https://doi.org/10.3390/app11156781

APA StyleLu, C., Ariaratnam, S. T., Yan, X., Ma, B., Zhao, Y., & Xiang, W. (2021). Buckling Behavior of Thin-Walled Stainless-Steel Lining Wrapped in Water-Supply Pipe under Negative Pressure. Applied Sciences, 11(15), 6781. https://doi.org/10.3390/app11156781