Preparation and Properties of Wood Plastic Composites with Desirable Features Using Poplar and Five Recyclable Plastic Wastes

Abstract

:1. Introduction

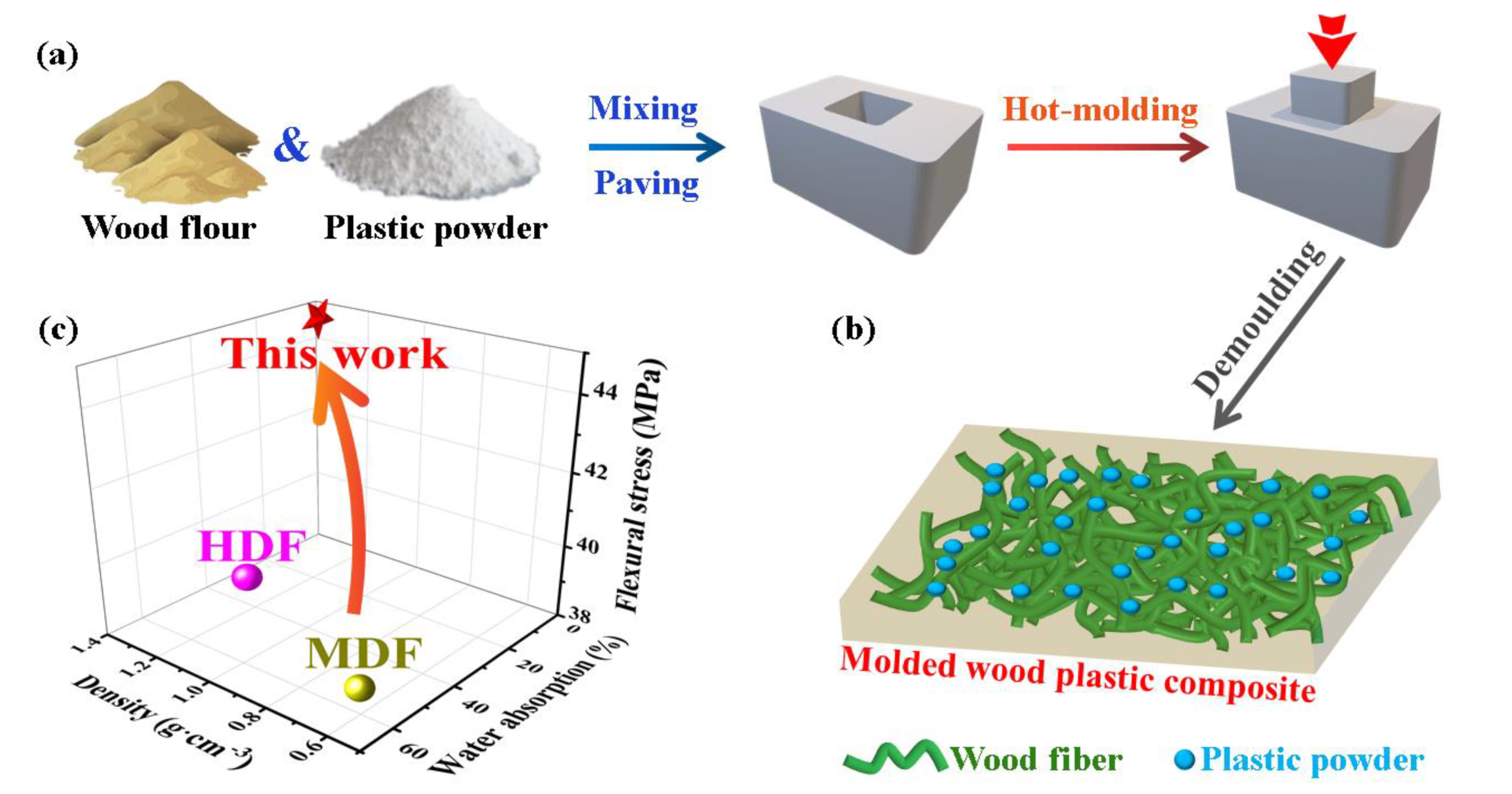

2. Materials and Methods

2.1. Materials Preparation

2.2. Physical Properties Measurement

2.3. Chemical Properties and Composition Determination

3. Results and Discussion

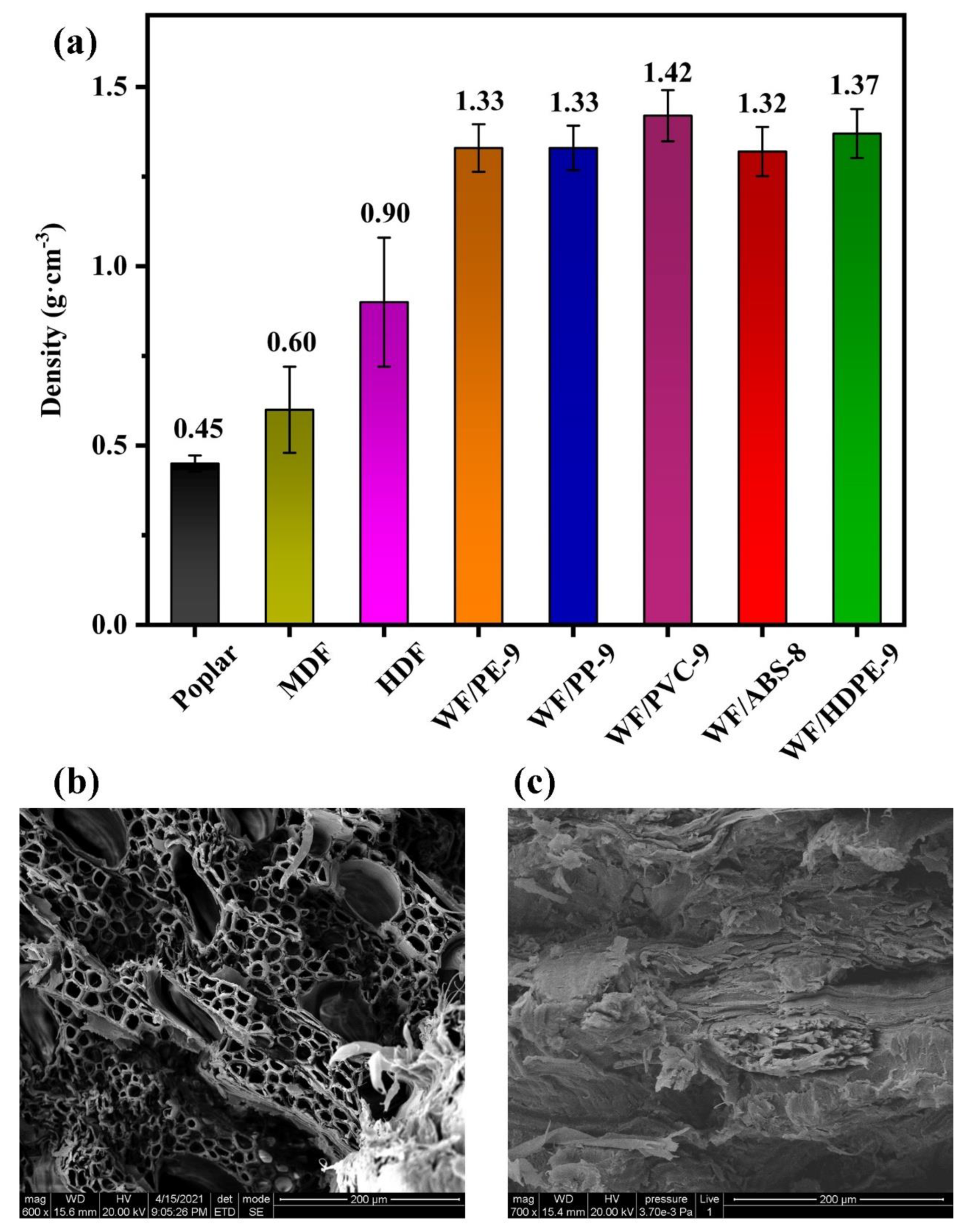

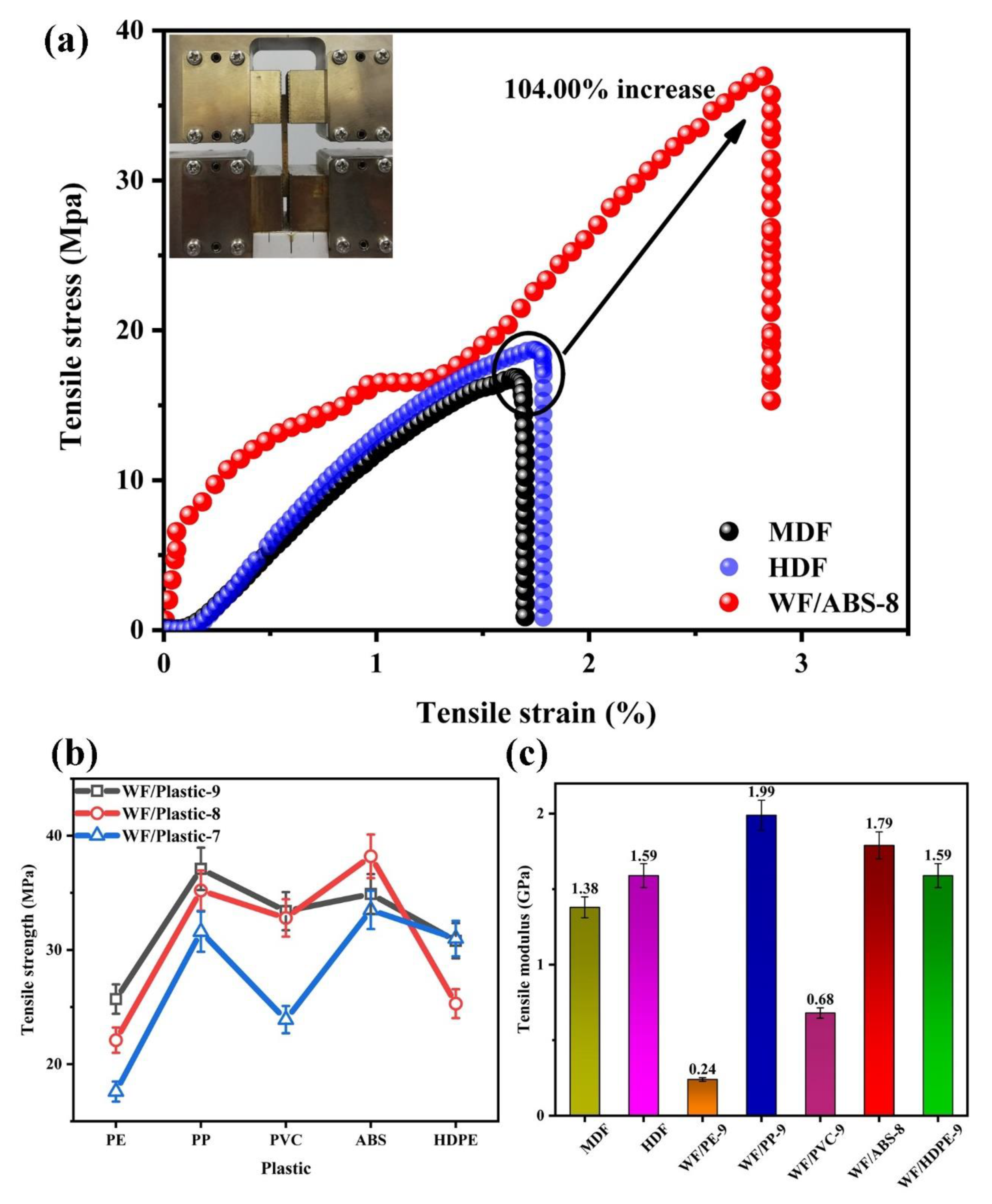

3.1. Physical Properties of WPC

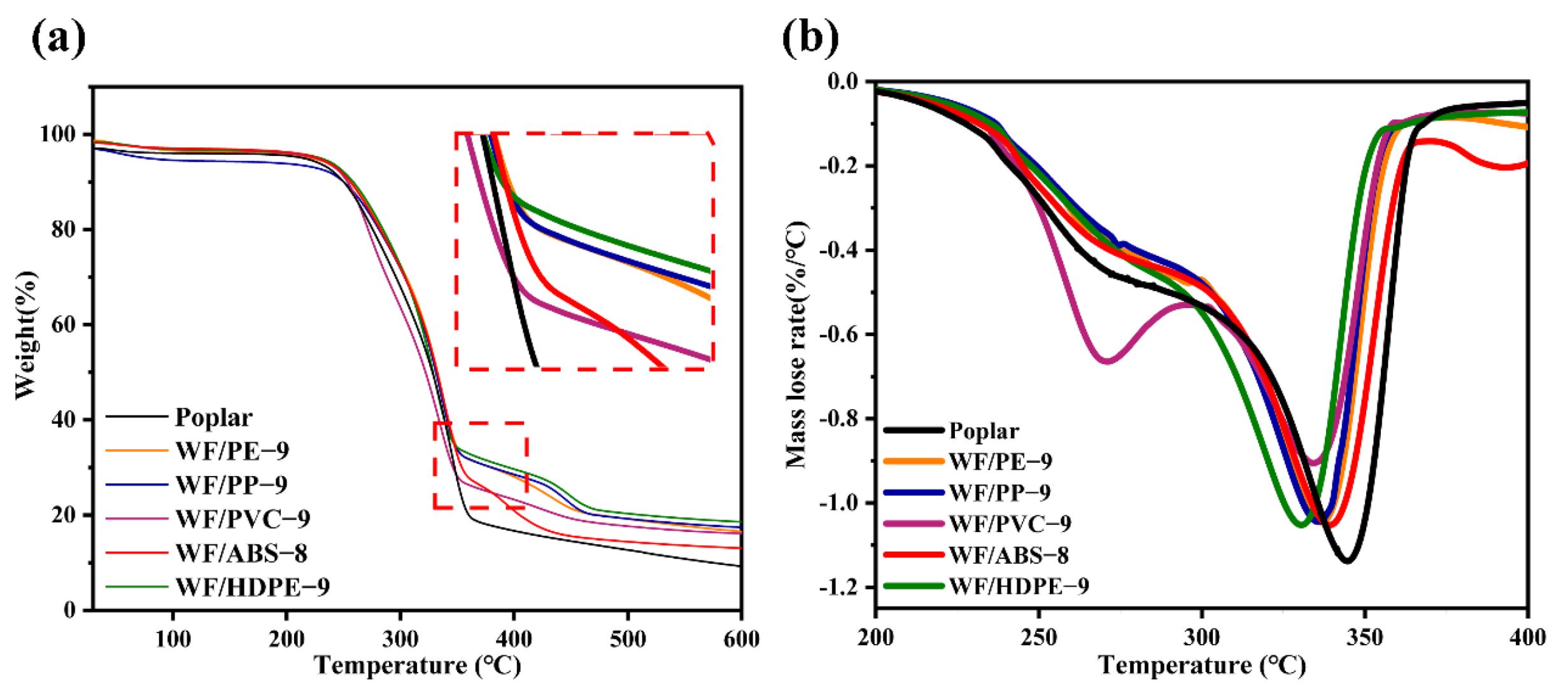

3.2. Dimensional Stability and Thermal Stability

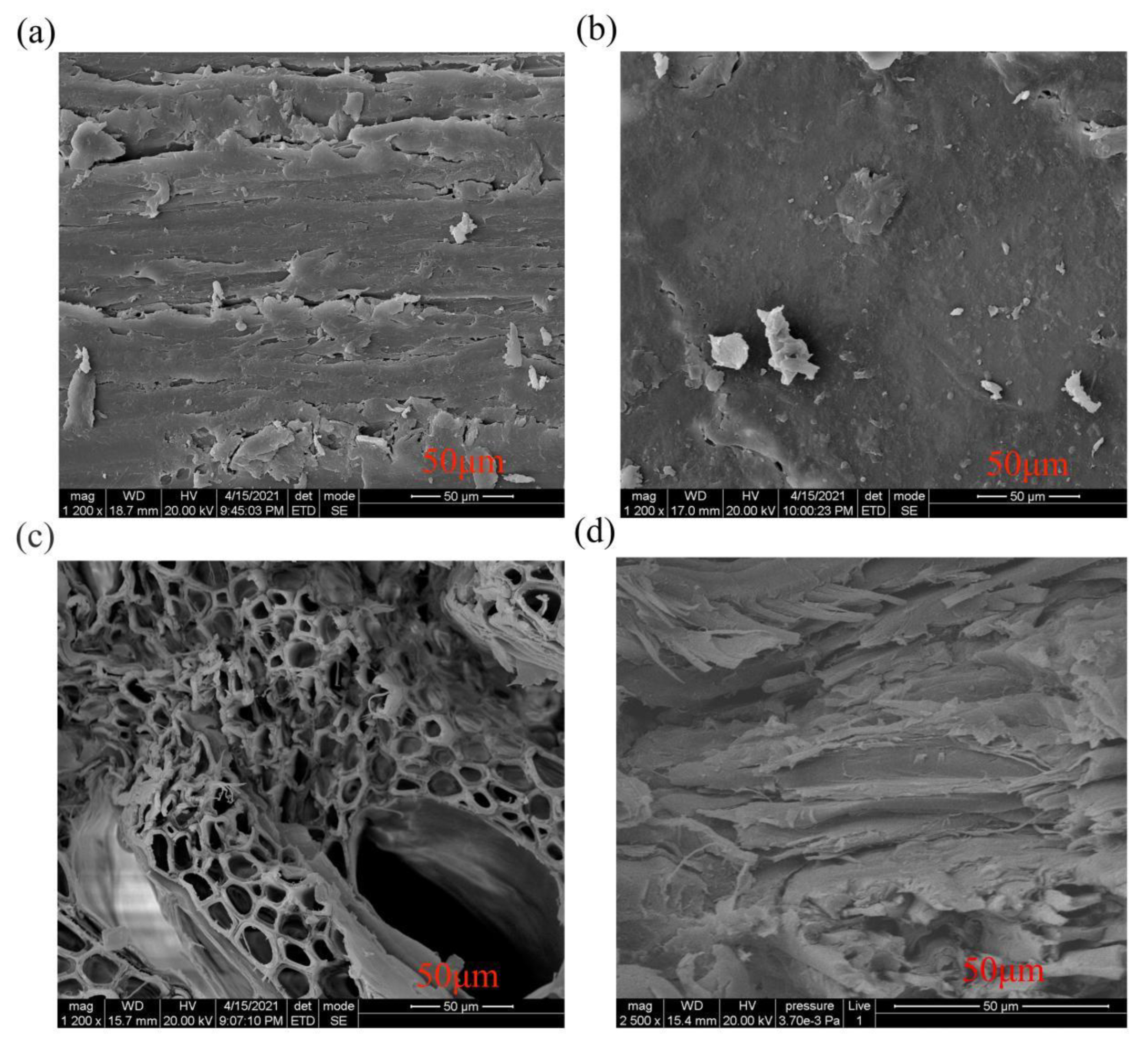

3.3. Micromorphological Analysis

3.4. Chemical Properties of WPC

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, X.; Ling, T.-C.; Mo, K.H. Functions and impacts of plastic/rubber wastes as eco-friendly aggregate in concrete—A review. Constr. Build. Mater. 2020, 240, 117869. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [Green Version]

- Almeshal, I.; Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Mohamed, A.M. Eco-friendly concrete containing recycled plastic as partial replacement for sand. J. Mater. Res. Technol. 2020, 9, 4631–4643. [Google Scholar] [CrossRef]

- Lin, T.A.; Lin, J.-H.; Bao, L. Polypropylene/thermoplastic polyurethane blends: Mechanical characterizations, recyclability and sustainable development of thermoplastic materials. J. Mater. Res. Technol. 2020, 9, 5304–5312. [Google Scholar] [CrossRef]

- Wu, Y.; Ge, S.; Xia, C.; Mei, C.; Kim, K.-H.; Cai, L.; Smith, L.M.; Lee, J.; Shi, S.Q. Application of intermittent ball milling to enzymatic hydrolysis for efficient conversion of lignocellulosic biomass into glucose. Renew. Sustain. Energy Rev. 2021, 136, 110442. [Google Scholar] [CrossRef]

- Nampoothiri, K.M.; Nair, N.R.; John, R.P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef]

- Wu, Y.; Xia, C.; Cai, L.; Garcia, A.C.; Shi, S.Q. Development of natural fiber-reinforced composite with comparable mechanical properties and reduced energy consumption and environmental impacts for replacing automotive glass-fiber sheet molding compound. J. Clean. Prod. 2018, 184, 92–100. [Google Scholar] [CrossRef]

- Wu, Y.; Xia, C.; Cai, L.; Shi, S.Q.; Cheng, J. Water-resistant hemp fiber-reinforced composites: In-situ surface protection by polyethylene film. Ind. Crop. Prod. 2018, 112, 210–216. [Google Scholar] [CrossRef]

- Xia, C.; Wu, Y.; Qiu, Y.; Cai, L.; Smith, L.M.; Tu, M.; Zhao, W.; Shao, D.; Mei, C.; Nie, X.; et al. Processing high-performance woody materials by means of vacuum-assisted resin infusion technology. J. Clean. Prod. 2019, 241, 118340. [Google Scholar] [CrossRef]

- Ge, S.; Foong, S.Y.; Ma, N.L.; Liew, R.K.; Mahari, W.A.W.; Xia, C.; Yek, P.N.Y.; Peng, W.; Nam, W.L.; Lim, X.Y.; et al. Vacuum pyrolysis incorporating microwave heating and base mixture modification: An integrated approach to transform biowaste into eco-friendly bioenergy products. Renew. Sustain. Energy Rev. 2020, 127, 109871. [Google Scholar] [CrossRef]

- Ge, S.; Wu, Y.; Peng, W.; Xia, C.; Mei, C.; Cai, L.; Shi, S.; Sonne, C.; Lam, S.S.; Tsang, Y.F. High-pressure CO2 hydrothermal pretreatment of peanut shells for enzymatic hydrolysis conversion into glucose. Chem. Eng. J. 2020, 385, 123949. [Google Scholar] [CrossRef]

- Adhikary, K.B.; Pang, S.; Staiger, M. Dimensional stability and mechanical behaviour of wood–plastic composites based on recycled and virgin high-density polyethylene (HDPE). Compos. Part B Eng. 2008, 39, 807–815. [Google Scholar] [CrossRef]

- Gardner, D.J.; Han, Y.; Wang, L. Wood–Plastic Composite Technology. Curr. For. Rep. 2015, 1, 139–150. [Google Scholar] [CrossRef] [Green Version]

- Ge, S.; Yek, P.N.Y.; Cheng, Y.W.; Xia, C.; Mahari, W.A.W.; Liew, R.K.; Peng, W.; Yuan, T.-Q.; Tabatabaei, M.; Aghbashlo, M.; et al. Progress in microwave pyrolysis conversion of agricultural waste to value-added biofuels: A batch to continuous approach. Renew. Sustain. Energy Rev. 2021, 135, 110148. [Google Scholar] [CrossRef]

- Xia, C.; Garcia, A.C.; Shi, S.Q.; Qiu, Y.; Warner, N.; Wu, Y.; Cai, L.; Rizvi, H.R.; D’Souza, N.A.; Nie, X. Hybrid boron nitride-natural fiber composites for enhanced thermal conductivity. Sci. Rep. 2016, 6, 1–8. [Google Scholar] [CrossRef]

- Najafi, S.K. Use of recycled plastics in wood plastic composites—A review. Waste Manag. 2013, 33, 1898–1905. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kaymakci, A. Fast growing biomass as reinforcing filler in thermoplastic composites: Paulownia elongata wood. Ind. Crop. Prod. 2013, 43, 457–464. [Google Scholar] [CrossRef]

- Ge, S.; Zuo, S.; Zhang, M.; Luo, Y.; Yang, R.; Wu, Y.; Zhang, Y.; Li, J.; Xia, C. Utilization of decayed wood for polyvinyl chloride/wood flour composites. J. Mater. Res. Technol. 2021, 12, 862–869. [Google Scholar] [CrossRef]

- Nourbakhsh, A.; Ashori, A. Preparation and Properties of Wood Plastic Composites Made of Recycled High-density Polyethylene. J. Compos. Mater. 2009, 43, 877–883. [Google Scholar] [CrossRef]

- Camlibel, O. Effect of calcite addition on technical properties and reduction of formaldehyde emissions of medium density fiberboard. BioResources 2021, 16, 3718–3733. [Google Scholar] [CrossRef]

- Yang, Y.S.; Shen, H.J.; Wang, X.; Qiu, J. Preparation of Nanolignocellulose/Chitin Composites with Superior Mechanical Property and Thermal Stability. J. Bioresour. Bioprod. 2019, 4, 251–259. [Google Scholar] [CrossRef]

- Ez-Zahraoui, S.; Kassab, Z.; Ablouh, E.; Sehaqui, H.; Bouhfid, R.; Alami, J.; El Achaby, M.; Qaiss, A.E.K. Effect of fly ash and coupling agent on the structural, morphological, thermal, and mechanical properties of polyamide 6/ acrylonitrile-butadiene-styrene blend. Polym. Compos. 2021, 1–21. [Google Scholar] [CrossRef]

- Gürgen, A.; Ustaömer, D.; Yildiz, S. Application of artificial neural network to predict the effect of paraffin addition on water absorption and thickness swelling of MDF. Drv. Ind. 2019, 70, 247–255. [Google Scholar] [CrossRef] [Green Version]

- Akdeniz, G.; Yahsi, U.; Tav, C. Viscous behavior of PS, PP, and ABS in terms of temperature and pressure-dependent hole fraction. J. Appl. Polym. Sci. 2010, 117, 110–113. [Google Scholar] [CrossRef]

- Vural, D.; Smith, J.C.J.C.; Petridis, L. Dynamics of the lignin glass transition. Phys. Chem. Chem. Phys. 2018, 20, 20504–20512. [Google Scholar] [CrossRef]

- Ewulonu, C.M.; Liu, X.; Wu, M.; Yong, H. Lignin-Containing Cellulose Nanomaterials: A Promising New Nanomaterial for Numerous Applications. J. Bioresour. Bioprod. 2019, 4, 3–10. [Google Scholar] [CrossRef]

- Yoo, J.J.; Yong, D.K.; Lee, H.K.; Kim, D.S.; Lee, H.I.; Kim, S.H.; Lee, K.Y.; Lee, S.G. Thermal Decomposition and Mechanical Properties of Polycarbonate/ABS Blends Prepared by High Shear Rate Processing. Polym. Korea 2014, 38, 471–476. [Google Scholar] [CrossRef] [Green Version]

- Fernandes, E.M.; Correlo, V.M.; Chagas, J.A.; Mano, J.F.; Reis, R.L. Properties of new cork–polymer composites: Advantages and drawbacks as compared with commercially available fibreboard materials. Compos. Struct. 2011, 93, 3120–3129. [Google Scholar] [CrossRef] [Green Version]

- Medved, S.; Tomec, D.K.; Balzano, A.; Merela, M. Alien Wood Species as a Resource for Wood-Plastic Composites. Appl. Sci. 2020, 11, 44. [Google Scholar] [CrossRef]

- Ge, S.; Ma, N.L.; Jiang, S.; Ok, Y.S.; Lam, S.S.; Li, C.; Shi, S.Q.; Nie, X.; Qiu, Y.; Li, D.; et al. Processed Bamboo as a Novel Formaldehyde-Free High-Performance Furniture Biocomposite. ACS Appl. Mater. Interfaces 2020, 12, 30824–30832. [Google Scholar] [CrossRef]

- Kartal, S.N.; Aysal, S.; Terzi, E.; Yilgör, N.; Yoshimura, T.; Tsunoda, K. Wood and Bamboo-PP Composites: Fungal and Termite Resistance, Water Absorption, and FT-IR Analyses. Bioresources 2012, 8, 1222–1244. [Google Scholar] [CrossRef] [Green Version]

- Burgada, F.; Fages, E.; Quiles-Carrillo, L.; Lascano, D.; Ivorra-Martinez, J.; Arrieta, M.; Fenollar, O. Upgrading Recycled Polypropylene from Textile Wastes in Wood Plastic Composites with Short Hemp Fiber. Polymers 2021, 13, 1248. [Google Scholar] [CrossRef] [PubMed]

| Different Kinds of WPCs | F-Value | p-Value | F Crit |

|---|---|---|---|

| WF/PE | 33.05 | 0.001 | 5.14 |

| WF/PP | 4.27 | 0.071 | 5.14 |

| WF/PVC | 1.38 | 0.321 | 5.14 |

| WF/ABS | 1.84 | 0.238 | 5.14 |

| WF/HDPE | 8.41 | 0.018 | 5.14 |

| Different Kinds of WPCs | F-Value | p-Value | F Crit |

|---|---|---|---|

| WF/PE | 66.39 | 0.000 | 5.14 |

| WF/PP | 84.47 | 0.000 | 5.14 |

| WF/PVC | 17.35 | 0.003 | 5.14 |

| WF/ABS | 6.78 | 0.029 | 5.14 |

| WF/HDPE | 32.87 | 0.001 | 5.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Q.; Wang, Y.; Ye, H.; Sheng, Y.; Shi, Y.; Zhang, M.; Fan, W.; Yang, R.; Xia, C.; Ge, S. Preparation and Properties of Wood Plastic Composites with Desirable Features Using Poplar and Five Recyclable Plastic Wastes. Appl. Sci. 2021, 11, 6838. https://doi.org/10.3390/app11156838

Yu Q, Wang Y, Ye H, Sheng Y, Shi Y, Zhang M, Fan W, Yang R, Xia C, Ge S. Preparation and Properties of Wood Plastic Composites with Desirable Features Using Poplar and Five Recyclable Plastic Wastes. Applied Sciences. 2021; 11(15):6838. https://doi.org/10.3390/app11156838

Chicago/Turabian StyleYu, Qinghan, Yang Wang, Haoran Ye, Yequan Sheng, Yang Shi, Minglong Zhang, Wei Fan, Rui Yang, Changlei Xia, and Shengbo Ge. 2021. "Preparation and Properties of Wood Plastic Composites with Desirable Features Using Poplar and Five Recyclable Plastic Wastes" Applied Sciences 11, no. 15: 6838. https://doi.org/10.3390/app11156838

APA StyleYu, Q., Wang, Y., Ye, H., Sheng, Y., Shi, Y., Zhang, M., Fan, W., Yang, R., Xia, C., & Ge, S. (2021). Preparation and Properties of Wood Plastic Composites with Desirable Features Using Poplar and Five Recyclable Plastic Wastes. Applied Sciences, 11(15), 6838. https://doi.org/10.3390/app11156838