The Potential of the Biodigester as a Useful Tool in Coffee Farms

Abstract

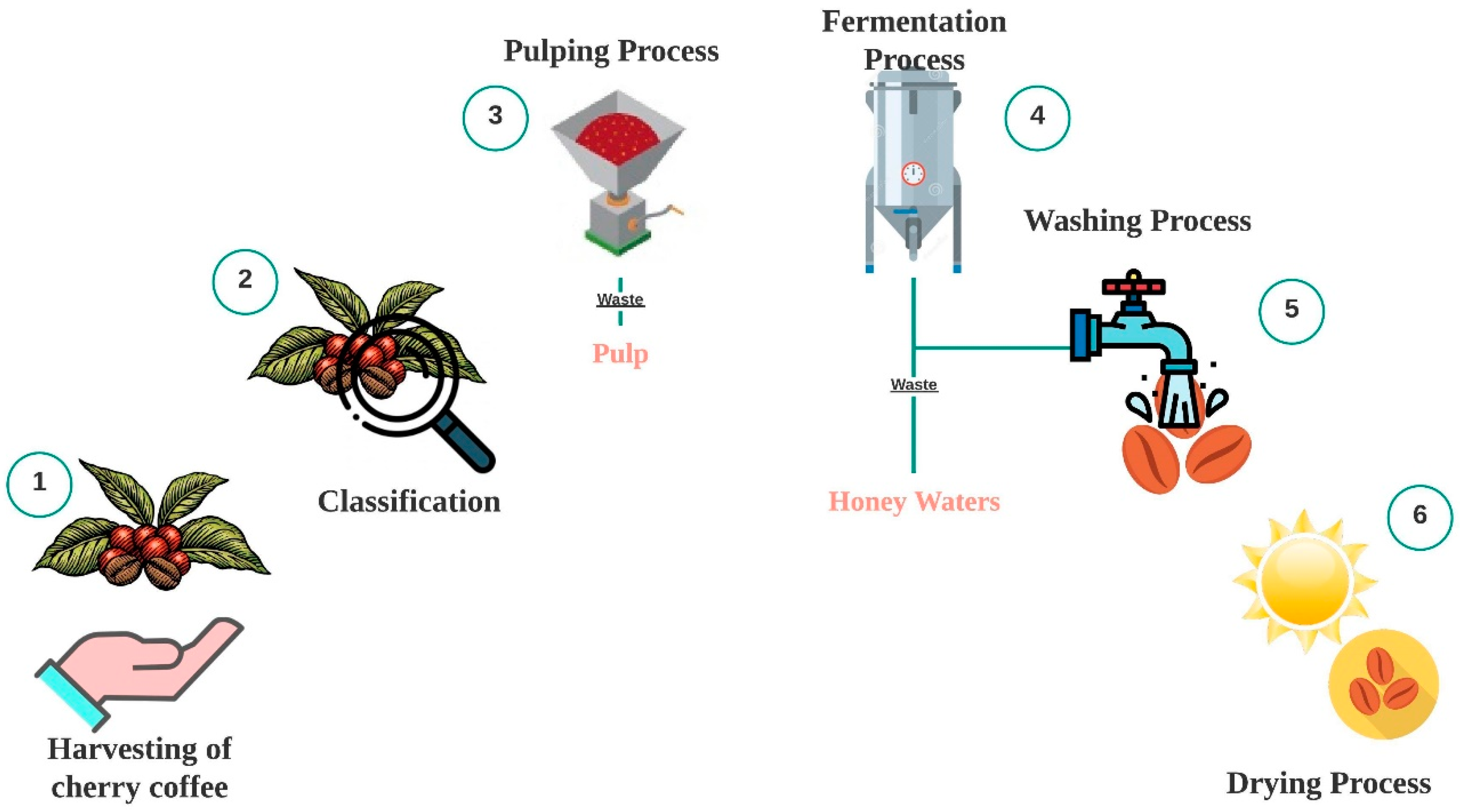

:1. Introduction

2. Materials and Methods

2.1. Preliminary Studies on the Status of the Use of Biodigesters in Coffee Farms

2.2. Substrate Characterization

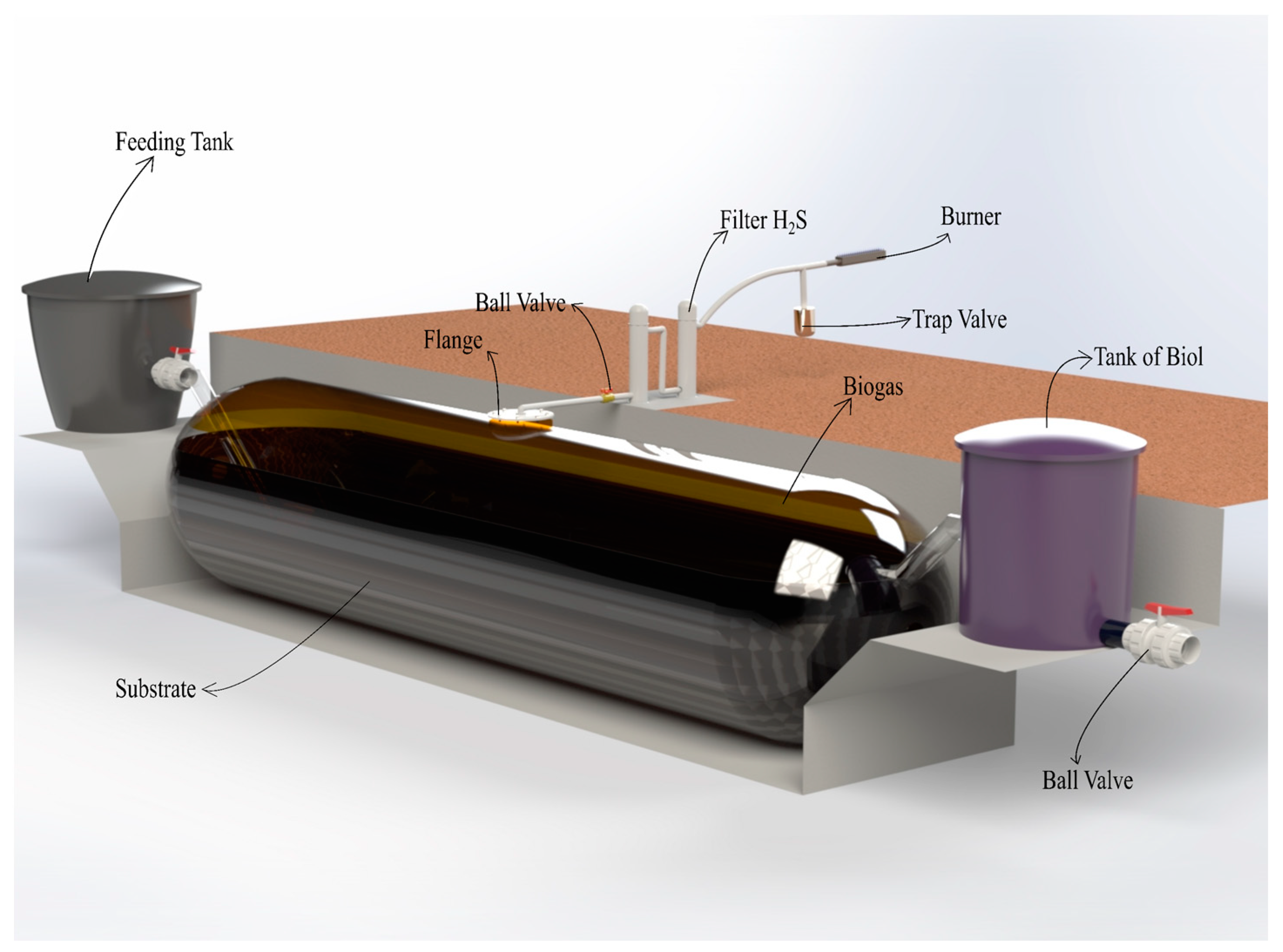

2.3. Biodigester

2.3.1. Biogas

2.3.2. Hydrogen Sulfide Filter

2.4. Aspects of Economic Analysis

3. Results and Discussion

3.1. Biogas Concentration

3.2. Energetic Application

3.3. Biogas Assisted Coffee Drying Process

3.4. Operational Analysis of the Biodigester

3.5. Biogas Concentration and Biol

3.6. Economic Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Federación Nacional de Cafeteros de Colombia Informe de Gestión 2019. Available online: https://cdn.flipsnack.com/widget/v2/widget.html?hash=dpazs597t9 (accessed on 23 July 2021).

- MinAgricultura Colombia; Federación Nacional de Cafeteros. Área Sembrada y Área Cosechada del Cultivo de Producción y Rendimiento del Cultivo de Café 2007–2017. Available online: https://www.agronet.gov.co/Documents/1-CAFÉ_2017.pdf (accessed on 23 July 2021).

- Federación Nacional de Cafeteros de Colombia Estadísticas Cafeteras. Available online: https://federaciondecafeteros.org/wp/estadisticas-cafeteras/ (accessed on 23 July 2021).

- Romero Loaiza, R.; Mamani Paro, R. Obtención de biogás como fuente de energía renovable a partir de los subproductos del café. Rev. Investig. Altoandinas 2013, 15, 241–252. [Google Scholar] [CrossRef]

- Rattan, S.; Parande, A.K.; Nagaraju, V.D.; Ghiwari, G.K. A comprehensive review on utilization of wastewater from coffee processing. Environ. Sci. Pollut. Res. 2015, 22, 6461–6472. [Google Scholar] [CrossRef]

- Dadi, D.; Mengistie, E.; Terefe, G.; Getahun, T.; Haddis, A.; Birke, W.; Beyene, A.; Luis, P.; Van der Bruggen, B. Assessment of the effluent quality of wet coffee processing wastewater and its influence on downstream water quality. Ecohydrol. Hydrobiol. 2018, 18, 201–211. [Google Scholar] [CrossRef]

- Chinappi Ciccolella, I.; Jerez Carrizo, A. Biodigestión anaeróbica de la pulpa de café. Propuesta de saneamiento ambiental y ahorro energético. Rev. Acad. 2008, 13, 75–83. [Google Scholar]

- Ijanu, E.M.; Kamaruddin, M.A.; Norashiddin, F.A. Coffee processing wastewater treatment: A critical review on current treatment technologies with a proposed alternative. Appl. Water Sci. 2019, 10, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Sengupta, B.; Priyadarshinee, R.; Roy, A.; Banerjee, A.; Malaviya, A.; Singha, S.; Mandal, T.; Kumar, A. Toward sustainable and eco-friendly production of coffee: Abatement of wastewater and evaluation of its potential valorization. Clean Technol. Environ. Policy 2020, 22, 995–1014. [Google Scholar] [CrossRef]

- Corro, G.; Pal, U.; Bañuelos, F.; Rosas, M. Generation of biogas from coffee-pulp and cow-dung co-digestion: Infrared studies of postcombustion emissions. Energy Convers. Manag. 2013, 74, 471–481. [Google Scholar] [CrossRef]

- Zambrano, D.; Rodríguez, N.; López, U.; Orozco, P.; Zambrano, A. Tratamiento Anaerobio de las Aguas Mieles del Café; CENICAFÉ: Chinchiná, Colombia, 2006. [Google Scholar]

- Rodríguez, S.; Pérez, R.; Boizán, M. Estudio de la biodegradabilidad anaerobia de las aguas residuales del beneficio húmedo del café. Interciencia 2000, 25, 386–390. [Google Scholar]

- Bermeo-Andrade, H.; Bahamón-Monje, A.F.; Aragón-Calderón, R.; Beltrán-Vargas, Y.; Gutiérrez-Guzmán, N. Is coffee (Coffea arabica l.) quality related to a combined farmer–farm profile? Sustainability 2020, 12, 9518. [Google Scholar] [CrossRef]

- Chen, C.; Zheng, D.; Liu, G.J.; Deng, L.W.; Long, Y.; Fan, Z.H. Continuous dry fermentation of swine manure for biogas production. Waste Manag. 2015, 38, 436–442. [Google Scholar] [CrossRef]

- Wijesinghe, D.T.N.; Suter, H.C.; Scales, P.J.; Chen, D. Lignite addition during anaerobic digestion of ammonium rich swine manure enhances biogas production. J. Environ. Chem. Eng. 2021, 9, 104669. [Google Scholar] [CrossRef]

- Manyi-Loh, C.; Mamphweli, S.; Meyer, E.; Okoh, A. Characterizing bacteria and methanogens in a balloon-type digester fed with dairy cattle manure for anaerobic mono-digestion. Polish J. Environ. Stud. 2019, 28, 1287–1293. [Google Scholar] [CrossRef]

- Franco, R.T.; Buffière, P.; Bayard, R. Cattle manure for biogas production. Does ensiling and wheat straw addition enhance preservation of biomass and methane potential? Biofuels 2017, 11, 671–682. [Google Scholar] [CrossRef] [Green Version]

- López Martínez, G.; Buriticá Arboleda, C.; Silva Lora, E. La biomasa residual pecuaria como recurso energético en Colombia. Visión Electron. 2018, 12, 180–188. [Google Scholar] [CrossRef] [Green Version]

- Acarley, F.; Quipuzco, L. Producción de metano mediante digestión anaerobia de aguamiel, subproducto del beneficio húmedo del café. Agroind. Sci. 2020, 10, 7–16. [Google Scholar] [CrossRef]

- Fluker Puscan, R.S.; Meléndez Mori, J.B.; Leiva Tafur, D.; Chávez Ortiz, J.; Rascón, J. Impacto del vertimiento de aguas mieles sobre la quebrada El Mito en el caserío El Mito, Distrito San Nicolás (Rodríguez de Mendoza–Amazonas). Rev. Investig. Agroproducción Sustentable 2018, 2, 57. [Google Scholar] [CrossRef]

- Los Barbosa, F.J.; Cabral, A.R.; Capanema, M.A.; Schirmer, W.N. Biogas generation potential of anaerobic co-digestion of municipal solid wastes and livestock manures. J. Solid Waste Technol. Manag. 2018, 44, 248–258. [Google Scholar] [CrossRef]

- Im, S.; Petersen, S.O.; Lee, D.; Kim, D.H. Effects of storage temperature on CH4 emissions from cattle manure and subsequent biogas production potential. Waste Manag. 2020, 101, 35–43. [Google Scholar] [CrossRef]

- Abbas, Y.; Jamil, F.; Rafiq, S.; Ghauri, M.; Khurram, M.S.; Aslam, M.; Bokhari, A.; Faisal, A.; Rashid, U.; Yun, S.; et al. Valorization of solid waste biomass by inoculation for the enhanced yield of biogas. Clean Technol. Environ. Policy 2020, 22, 513–522. [Google Scholar] [CrossRef]

- Budiyono, B.; Widiasa, I.N.; Johari, S.; Sunarso, S. Increasing Biogas Production Rate from Cattle Manure Using Rumen Fluid as Inoculums. Int. J. Sci. Eng. 2014, 6, 31–38. [Google Scholar] [CrossRef] [Green Version]

- Gutiérrez Guzmán, N.; Valencia Granada, E.; Aragon Calderon, R.A. Eficiencia de Remoción en Sistemas de Tratamiento de Aguas Residuales del Beneficio de Café (Coffea arabica). Colomb. For. 2014, 17, 151. [Google Scholar] [CrossRef] [Green Version]

- Cárdenas Garzón, R.C.; Ortíz Prieto, J.E. Manejo Integrado del Recurso Agua en el Beneficio Húmedo del Café, para la Asociación de Productores de Café “Acafeto” en el Municipio de Fresno, Departamento del Tolima. Available online: https://ridum.umanizales.edu.co/xmlui/handle/20.500.12746/1265 (accessed on 23 July 2021).

- Torres-Valenzuela, L.S.; Sanín-Villarrea, A.; Arango-Ramírez, A.; Serna-Jiménez, J.A. Caracterización fisicoquímica y microbiológica de aguas mieles del beneficio del café. Rev. ION 2019, 32, 59–66. [Google Scholar] [CrossRef]

- Valencia, N.; Castañeda, S.; Osorio, A.; Quintero, L. Dispositivos para el Óptimo Funcionamiento Hidráulico de los Sistemas Modulares de Tratamiento Anaerobio (SMTA); Comité Edi.; Cenicafé: Manizales, Colombia, 2019. [Google Scholar]

- Kafle, G.K.; Chen, L. Comparison on batch anaerobic digestion of five different livestock manures and prediction of biochemical methane potential (BMP) using different statistical models. Waste Manag. 2016, 48, 492–502. [Google Scholar] [CrossRef] [Green Version]

- Rice, E.W.; Baird, R.B.; Eaton, A.D. Standard Methods for the Examination of Water and Wastewater, 23rd ed.; American Public Health Association, American Water Works Association, Water Environment Federation: Washington, DC, USA, 2017; ISBN 9780875532875. [Google Scholar]

- Pérez-Espejo, R.; Cervantes-Hernández, G. Estrategias de mitigación. El programa de biodigestores en Yucatán, México. Península 2018, 13, 235–262. [Google Scholar]

- Saavedra, R.; Alamo, M.; Marcelo, M. Diseño de un Biodigestor Tubular para Zonas Rurales de la Región Piura. In Proceedings of the XXIV Simposio Peruano de Energía Solar y del Ambiente (XXIV-SPES), Huaraz, Peru, 13–17 November 2017. [Google Scholar]

- Ramirez-Perez, J.C. A Comparison of Performance between Two Anaerobic Biodigesters Configurations for Biogas Production. Rev. Técnica Energía 2018, 13, 213–223. [Google Scholar]

- Martí-Herrero, J. Biodigestores Familiares: Guía de Diseño y Manual de Instalación; Cooperación Tecnica Alemana GZT: La Paz, Bolivia, 2008; Volume 53, ISBN 978-99954-0-339-3. [Google Scholar]

- Battista, F.; Fino, D.; Mancini, G. Optimization of biogas production from coffee production waste. Bioresour. Technol. 2016, 200, 884–890. [Google Scholar] [CrossRef] [PubMed]

- Widjaja, T.; Nurkhamidah, S.; Altway, A.; Iswanto, T.; Gusdyarto, B.; Ilham, F.F. Performance of biogas production from coffee pulp waste using semi-continuous anaerobic reactor. IOP Conf. Ser. Mater. Sci. Eng. 2019, 673, 012003. [Google Scholar] [CrossRef]

- Laperrière, W.; Barry, B.; Torrijos, M.; Pechiné, B.; Bernet, N.; Steyer, J.P. Optimal conditions for flexible methane production in a demand-based operation of biogas plants. Bioresour. Technol. 2017, 245, 698–705. [Google Scholar] [CrossRef] [PubMed]

- Nsair, A.; Cinar, S.O.; Alassali, A.; Qdais, H.A.; Kuchta, K. Operational Parameters of Biogas Plants: A Review and Evaluation Study. Energies 2020, 13, 3761. [Google Scholar] [CrossRef]

- Paulauskas, R.; Martuzevičius, D.; Patel, R.B.; Pelders, J.E.H.; Nijdam, S.; Dam, N.J.; Tichonovas, M.; Striūgas, N.; Zakarauskas, K. Biogas combustion with various oxidizers in a nanosecond DBD microplasma burner. Exp. Therm. Fluid Sci. 2020, 118. [Google Scholar] [CrossRef]

- Zainol, N.I.; Osaka, Y.; Tsujiguchi, T.; Kumita, M.; Kodama, A. Separation and enrichment of CH 4 and CO 2 from a dry biogas using a thermally regenerative adsorbent-packed heat exchanger. Adsorpt. J. Int. Adsorpt. Soc. 2019, 25, 1159–1167. [Google Scholar] [CrossRef]

- Wang, X.; Yang, G.; Feng, Y.; Ren, G.; Han, X. Optimizing feeding composition and carbon-nitrogen ratios for improved methane yield during anaerobic co-digestion of dairy, chicken manure and wheat straw. Bioresour. Technol. 2012, 120, 78–83. [Google Scholar] [CrossRef] [PubMed]

- Acarley, F. Evaluación de la Producción de Metano a Partir de las Aguas Mieles del Beneficio Húmedo del Café Mediante Digestión Anaerobia; Universidad Nacional Agraria la Molina: Lima, Perú, 2018. [Google Scholar]

- Marchaim, U. Biogas Processes for Sustainable Development; Food and Agriculture Organization of the United Nations: Qiryat Shemona, Israel, 1992; ISBN 92-5-103126-6. [Google Scholar]

- Instituto Colombiano de Normas Técnicas y Certificación [ICONTEC] Norma Técnica Colombiana [NTC] 5167. Available online: https://tienda.icontec.org/gp-productos-para-la-industria-agricola-productos-organicos-usados-como-abonos-o-fertilizantes-y-enmiendas-o-acondicionadores-de-suelo-ntc5167-2011.html (accessed on 21 July 2021).

- Parra-Orobio, B.A.; Rotavisky-Sinisterra, M.P.; Pérez-Vidal, A.; Marmolejo-Rebellón, L.F.; Torres-Lozada, P. Physicochemical, microbiological characterization and phytotoxicity of digestates produced on single-stage and two-stage anaerobic digestion of food waste. Sustain. Environ. Res. 2021, 31. [Google Scholar] [CrossRef]

- Alfa, M.I.; Adie, D.B.; Igboro, S.B.; Oranusi, U.S.; Dahunsi, S.O.; Akali, D.M. Assessment of biofertilizer quality and health implications of anaerobic digestion effluent of cow dung and chicken droppings. Renew. Energy 2014, 63, 681–686. [Google Scholar] [CrossRef] [Green Version]

- Bonetta, S.; Bonetta, S.; Ferretti, E.; Fezia, G.; Gilli, G.; Carraro, E. Agricultural Reuse of the Digestate from Anaerobic Co-Digestion of Organic Waste: Microbiological Contamination, Metal Hazards and Fertilizing Performance. Water Air Soil Pollut. 2014, 225, 1–11. [Google Scholar] [CrossRef]

- Ndubuisi-Nnaji, U.U.; Ofon, U.A.; Ekponne, N.I.; Offiong, N.A.O. Improved biofertilizer properties of digestate from codigestion of brewer’s spent grain and palm oil mill effluent by manure supplementation. Sustain. Environ. Res. 2020, 30. [Google Scholar] [CrossRef]

- Kabyanga, M.; Balana, B.B.; Mugisha, J.; Walekhwa, P.N.; Smith, J.; Glenk, K. Economic potential of flexible balloon biogas digester among smallholder farmers: A case study from Uganda. Renew. Energy 2018, 120, 392–400. [Google Scholar] [CrossRef] [Green Version]

- Shiddiq, A.B.A.; Hermansyah, H.; Wijanarko, A.; Utami, T.S.; Sahlan, M. Analysis for the feasibility of portable biodigester to produce household scale energy. AIP Conf. Proc. 2020, 2255, 030048. [Google Scholar] [CrossRef]

| Characteristic | Swine Manure | Cattle Manure | Coffee’s Honey Waters | |||

|---|---|---|---|---|---|---|

| Literature * | Measured | Literature * | Measured | Literature * | Measured | |

| pH | 6.40–7.87 | 7.6–8.2 | 6.20–7.40 | 7.2–7.5 | 3.05–4.23 | 3.8–4.0 |

| Total solids (%) | 2.13–31.0 | 17–23 | 2.64–31.6 | 12–33 | - | - |

| Volatile solids (% TS) | 26.93–86.1 | 70–82 | 2.16–91.0 | 69–84 | - | - |

| Total Carbon (% TS) | 26.6–32.9 | - | - | - | - | - |

| CH4 production (%) | 21.84–65.0 | - | - | - | - | - |

| NH4+ N (mg/L) | 400–831 | - | - | - | - | - |

| TCOD (g/L) | - | - | 100.1–393 | - | - | - |

| COD (mg/L) | - | 5.2–6.8 × 103 | - | - | 500–1.29 × 105 | 1.35–1.63 × 104 |

| Total suspended solids (mg/L) | - | - | - | - | 52.6–14.75 × 103 | - |

| Suspended solids (mg/L) | - | - | - | - | 940–19 × 103 | - |

| Total nitrogen (mg/L) | - | - | - | - | 135 | 162–213 |

| Dissolved oxygen (mg/L) | - | - | - | - | 1.25 | - |

| Material | Diameter (θ) | Length | T.V. * | HRT | Outlet Valve | E.C. * |

|---|---|---|---|---|---|---|

| PVC 1005 geomembrane | 0.8 m | 8 m | 4 m3 | 35 days | ½′′ (12.7 mm) PVC | 6.2 kw |

| Municipality | Farm | Altitude (m.a.s.l.) | CH4 (Vol. %) | CO2 (Vol. %) | H2S (ppm) |

|---|---|---|---|---|---|

| Chaparral | El Mirador | 1710 | 49.1 ± 4.6 | 43.0 ± 3.9 | 68.0 ± 6.0 |

| Chaparral | El Desierto | 1525 | 58.1 ± 2.4 | 27.0 ± 2.8 | 35.0 ± 1.4 |

| Planadas | El Tesoro | 1500 | 55.8 ± 2.9 | 44.2 ± 2.6 | 53.2 ± 4.3 |

| Year | ||||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | |

| (+) Savings form LPG | - | 226 | 234 | 242 | 250 | 259 |

| (+) Savings form fertilizer | - | 851 | 881 | 912 | 944 | 977 |

| (−) Operational cost | - | 586 | 607 | 629 | 650 | 672 |

| (−) Maintenance cost | - | 28 | 29 | 30 | 31 | 32 |

| (−) Equipment depreciation | - | 21 | 21 | 21 | 21 | 21 |

| (=) Net cash | - | 442 | 458 | 475 | 492 | 511 |

| (+) Depreciation | - | 21 | 21 | 21 | 21 | 21 |

| (+) Investment | −1.424 | - | - | - | - | - |

| Cash flow | −1.424 | 463 | 479 | 496 | 513 | 532 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández-Sarabia, M.; Sierra-Silva, J.; Delgadillo-Mirquez, L.; Ávila-Navarro, J.; Carranza, L. The Potential of the Biodigester as a Useful Tool in Coffee Farms. Appl. Sci. 2021, 11, 6884. https://doi.org/10.3390/app11156884

Hernández-Sarabia M, Sierra-Silva J, Delgadillo-Mirquez L, Ávila-Navarro J, Carranza L. The Potential of the Biodigester as a Useful Tool in Coffee Farms. Applied Sciences. 2021; 11(15):6884. https://doi.org/10.3390/app11156884

Chicago/Turabian StyleHernández-Sarabia, Mauricio, Juan Sierra-Silva, Liliana Delgadillo-Mirquez, Julián Ávila-Navarro, and Laura Carranza. 2021. "The Potential of the Biodigester as a Useful Tool in Coffee Farms" Applied Sciences 11, no. 15: 6884. https://doi.org/10.3390/app11156884

APA StyleHernández-Sarabia, M., Sierra-Silva, J., Delgadillo-Mirquez, L., Ávila-Navarro, J., & Carranza, L. (2021). The Potential of the Biodigester as a Useful Tool in Coffee Farms. Applied Sciences, 11(15), 6884. https://doi.org/10.3390/app11156884