Calibration of GA Parameters for Layout Design Optimization Problems Using Design of Experiments

Abstract

:1. Introduction

2. A Brief Literature Review

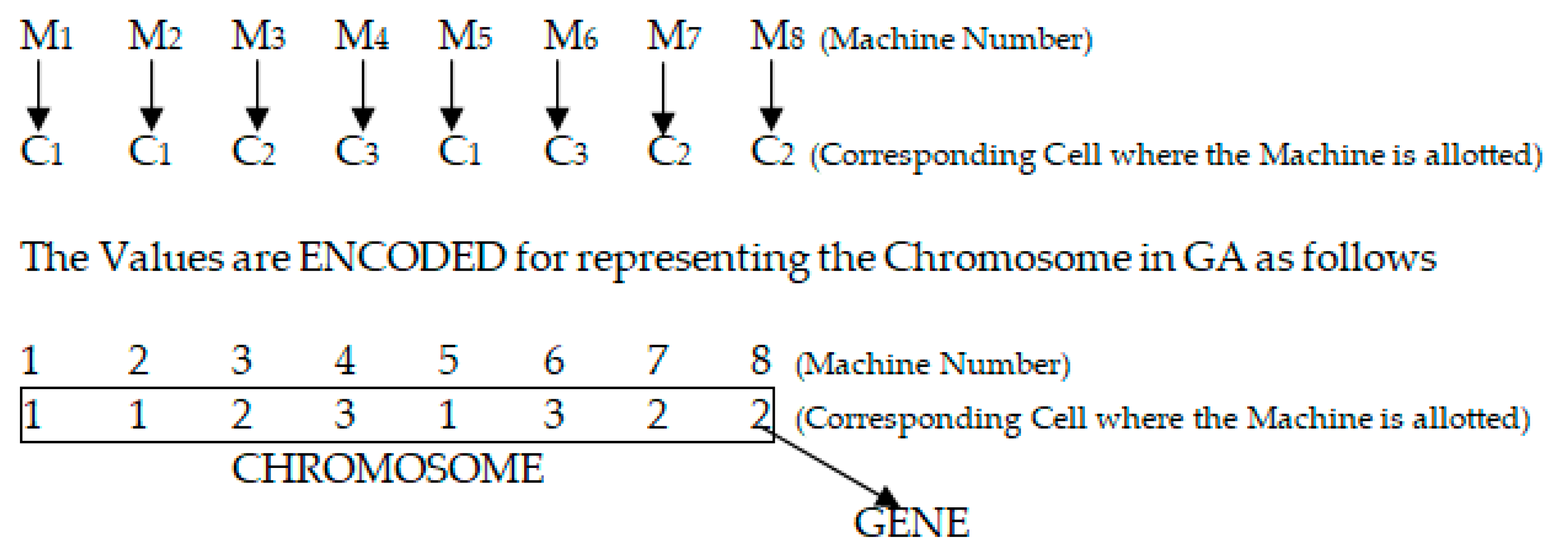

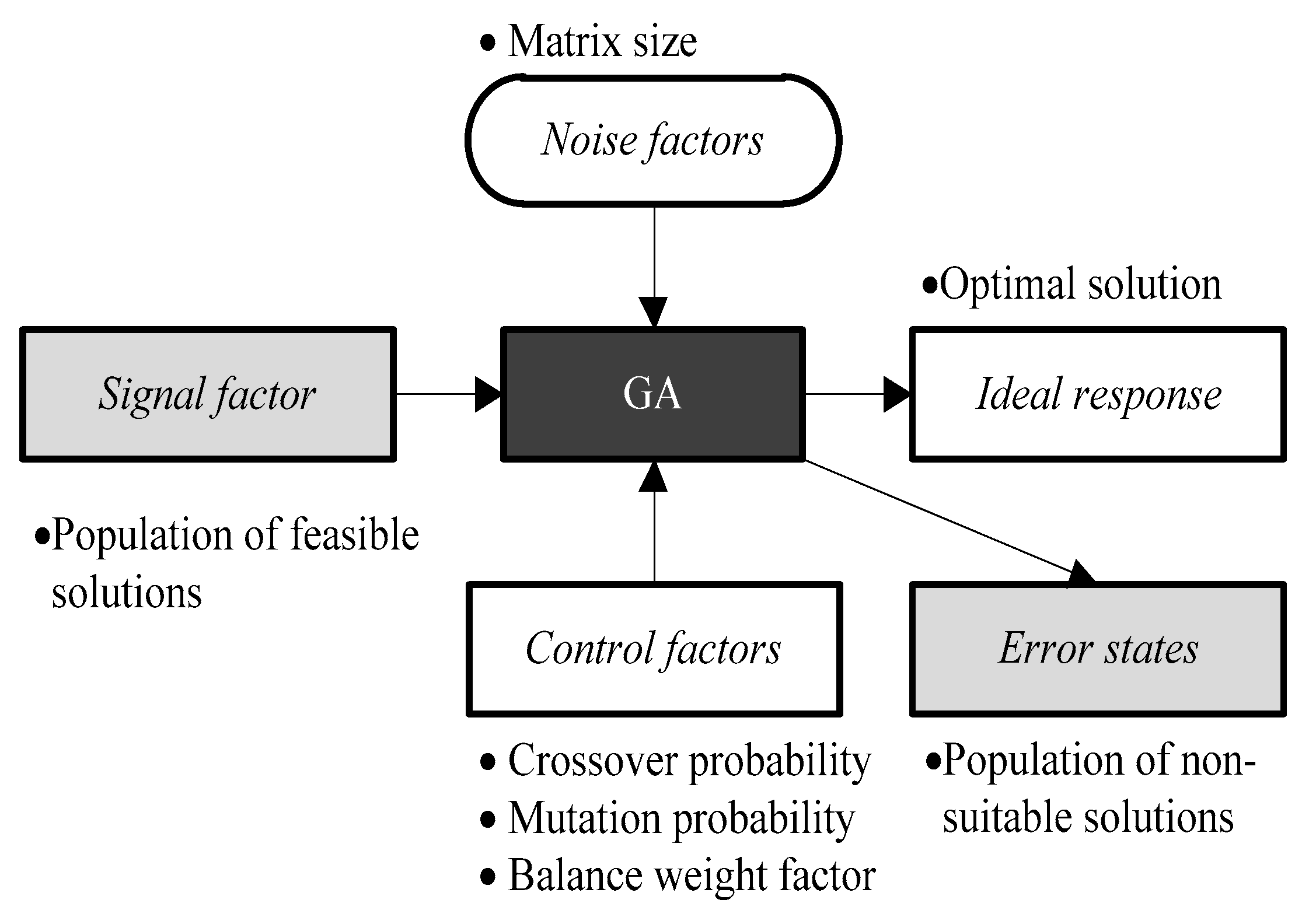

3. Structure of Genetic Algorithm

4. Mathematical Model of the Cell-Formation Problem

5. Case Study on Layout Design Optimization

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hosseini-Nasab, H.; Fereidouni, S.; Ghomi, S.M.T.F.; Fakhrzad, M.B. Classification of facility layout problems: A review study. Int. J. Adv. Manuf. Technol. 2018, 94, 957–977. [Google Scholar] [CrossRef]

- Azadivar, F.; Wang, J. Facility layout optimization using simulation and genetic algorithms. Int. J. Prod. Res. 2000, 38, 4369–4383. [Google Scholar] [CrossRef]

- Hamamoto, S.; Yie, Y.; Salvendy, G. Development and Validation of Genetic Algorithm-Based Facility Layout-A Case Study in the Pharmaceutical Industry. Int. J. Prod. Res. 1999, 37, 749–768. [Google Scholar] [CrossRef]

- Li, X.; Fung, R.Y.K. Optimal K-unit cycle scheduling of two-cluster tools with residency constraints and general robot moving times. J. Sched. 2016, 19, 165–176. [Google Scholar] [CrossRef]

- Selim, H.M.; Aal, R.M.A.; Mahdi, A.I. Formation of machine groups and part families: A modified SLC method and comparative study. Integr. Manuf. Syst. 2003, 14, 123–137. [Google Scholar] [CrossRef] [Green Version]

- Bidanda, B.; Ariyawongrat, P.; Needy, K.L.; Norman, B.A.; Tharmmaphornphilas, W. Human related issues in manufacturing cell design, implementation, and operation: A review and survey. Comput. Ind. Eng. 2005, 48, 507–523. [Google Scholar] [CrossRef]

- Modrak, V.; Pandian, R.S. Operations Management Research and Cellular Manufacturing Systems: Innovative Methods and Approaches; Business Science Reference: Hershey, PA, USA, 2012. [Google Scholar]

- Hertz, A.; Jaumard, B.; Ribeiro, C.C.; Filho, W.P.F. A multi-criteria tabu search approach to cell formation problems in group technology with multiple objectives. RAIRO-Oper. Res. 1994, 28, 303–328. [Google Scholar] [CrossRef]

- Süer, G.A.; Vazquez, R.; Cortes, M. A hybrid approach of genetic algorithms and local optimizers in cell loading. Comput. Ind. Eng. 2005, 48, 625–641. [Google Scholar] [CrossRef]

- Semančo, P.; Modrák, V. Hybrid GA-Based Improvement Heuristic with Makespan Criterion for Flow-Shop Scheduling Problems. Commun. Comput. Inf. Sci. 2011, 220, 11–18. [Google Scholar] [CrossRef]

- Herroelen, W.; De Reyck, B.; Demeulemeester, E. Resource-constrained project scheduling: A survey of recent developments. Comput. Oper. Res. 1998, 25, 279–302. [Google Scholar] [CrossRef]

- Kolisch, R.; Hartmann, S. Experimental investigation of heuristics for resource-constrained project scheduling: An update. Eur. J. Oper. Res. 2006, 174, 23–37. [Google Scholar] [CrossRef]

- Holland, J.H. Adaptation in Natural and Artificial Systems; The MIT Press: Cambridge, MA, USA, 1992. [Google Scholar]

- Venugopal, V.; Narendran, T. A genetic algorithm approach to the machine-component grouping problem with multiple objectives. Comput. Ind. Eng. 1992, 22, 469–480. [Google Scholar] [CrossRef]

- Joines, J.A.; Houck, C.R. On the use of non-stationary penalty functions to solve constrained optimization problems with genetic algorithms. In Proceedings of the IEEE International Symposium EC, Orlando, FL, USA, 27–29 June 1994; pp. 579–584. [Google Scholar]

- Gupta, Y.P.; Gupta, M.C.; Kumar, A.; Sundaram, C.A. A genetic algorithm-based approach to cell composition and layout design problems. Int. J. Prod. Res. 1996, 34, 447–482. [Google Scholar] [CrossRef]

- Alsultan, K.S.; Fedjki, C.A. A genetic algorithm for the part family formation problem. Prod. Plan. Conotrol 1997, 8, 788–796. [Google Scholar] [CrossRef]

- Gravel, M.; Nsakanda, A.L.; Price, W. Efficient solutions to the cell-formation problem with multiple routings via a double-loop genetic algorithm. Eur. J. Oper. Res. 1998, 109, 286–298. [Google Scholar] [CrossRef]

- Moon, C.; Gen, M. A genetic algorithm-based approach for design of independent manufacturing cells. Int. J. Prod. Econ. 1999, 60/61, 421–426. [Google Scholar] [CrossRef]

- Mak, K.L.; Wong, Y.S.; Wang, X.X. An Adaptive Genetic Algorithm for Manufacturing Cell Formation. Int. J. Adv. Manuf. Technol. 2000, 16, 491–497. [Google Scholar] [CrossRef]

- Zhao, C.W.; Wu, Z.M. A genetic algorithm for manufacturing cell formation with multiple routes and multiple objectives. Int. J. Prod. Res. 2000, 38, 385–395. [Google Scholar] [CrossRef]

- Arzi, Y.; Bukchin, J.; Masin, M. An efficiency frontier approach for the design of cellular manufacturing systems in a lumpy demand environment. Eur. J. Oper. Res. 2001, 134, 346–364. [Google Scholar] [CrossRef]

- Zolfaghari, S.; Liang, M. A new genetic algorithm for the machine/part grouping problem involving processing times and lot sizes. Comput. Ind. Eng. 2003, 45, 713–731. [Google Scholar] [CrossRef]

- Hu, L.; Yin, Y. A grouping genetic algorithm for the multi-objective cell formation problem. Int. J. Prod. Res. 2005, 43, 829–853. [Google Scholar] [CrossRef]

- Farahani, M.H.; Hosseini, L. An Ant ColonyOptimization Approach for the Machine–Part Cell Formation Problem. Int. J. Comput. Intell. Syst. 2011, 4, 486–496. [Google Scholar] [CrossRef] [Green Version]

- Mohammadi, M.; Forghani, K. A novel approach for considering layout problem in cellular manufacturing systems with alternative processing routings and subcontracting approach. Appl. Math. Model. 2014, 38, 3624–3640. [Google Scholar] [CrossRef]

- Dmytryshyn, T.; Ismail, M.; Rashwan, O. A novelmodeling approach for solving the cell formation problem. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), Pittsburgh, PA, USA, 9–15 November 2018; Volume 2. [Google Scholar]

- Kamalakannan, R.; Sudhakara Pandian, R.; Sivakumar, P. A simulated annealing for the cell formation problemwith ratio level data. Int. J. Enterp. Netw. Manag. 2019, 10, 78–90. [Google Scholar]

- Shashikumar, S.; Raut, R.D.; Narwane, V.S.; Gardas, B.B.; Narkhede, B.E.; Awasthi, A. A novel approach to determine the cell formation using heuristics approach. OPSEARCH 2019, 56, 628–656. [Google Scholar] [CrossRef]

- Sharma, V.; Gidwani, B.D.; Sharma, V.; Meena, M.L. Implementation model for cellular manufacturing system using AHP and ANP approach. Benchmark. Int. J. 2019, 26, 1605–1630. [Google Scholar] [CrossRef]

- Ramos-Figueroa, O.; Quiroz-Castellanos, M.; Mezura-Montes, E.; Schütze, O. Metaheuristics to solve grouping problems: A review and a case study. Swarm Evol. Comput. 2020, 53, 100643. [Google Scholar] [CrossRef]

- Mourtzis, D.; Siatras, V.; Synodinos, G.; Angelopoulos, J.; Panopoulos, N. A framework for adaptive scheduling incellular manufacturing systems. Proced. CIRP 2020, 93, 989–994. [Google Scholar] [CrossRef]

- Firouzian, S.; Mahdavi, I.; Paydar, M.M.; Saadat, M. Simulated annealing and artificial immune system algorithms for cell formation with part family clustering. J. Ind. Eng. Manag. Stud. 2020, 7, 191–219. [Google Scholar]

- Vitayasak, S.; Pongcharoen, P.; Hicks, C.; Hicks, C. Robust machine layout design under dynamic environment: Dynamic customer demand and machine maintenance. Expert Syst. Appl. X 2019, 3, 1–17. [Google Scholar] [CrossRef]

- Dolgui, A.; Ivanov, D.; Sokolov, B. Reconfigurable supp.ly chain: The X-network. Int. J. Prod. Res. 2020, 58, 4138–4163. [Google Scholar] [CrossRef]

- Bucki, R.; Suchánek, P. Comparative Simulation Analysis of the Performance of the Logistics Manufacturing System at the Operative Level. Complexity 2019, 2019, 7237585. [Google Scholar] [CrossRef]

- Boulif, M.; Atif, K. A new branch-&-bound-enhanced genetic algorithm for the manufacturing cell formation problem. Comput. Oper. Res. 2006, 33, 2219–2245. [Google Scholar] [CrossRef]

- Mahdavi, I.; Paydar, M.M.; Solimanpur, M.; Heidarzade, A. Genetic algorithm approach for solving a cell formation problem in cellular manufacturing. Expert Syst. Appl. 2009, 36, 6598–6604. [Google Scholar] [CrossRef]

- Deljoo, V.; Al-E-Hashem, S.M.; Deljoo, F.; Aryanezhad, M. Using genetic algorithm to solve dynamic cell formation problem. Appl. Math. Model. 2010, 34, 1078–1092. [Google Scholar] [CrossRef]

- Arkat, J.; Farahani, M.H.; Ahmadizar, F. Multi-objective genetic algorithm for cell formation problem considering cellular layout and operations scheduling. Int. J. Comput. Integr. Manuf. 2012, 25, 625–635. [Google Scholar] [CrossRef]

- Modrák, V.; Pandian, R.S. Flow shop scheduling algorithm to minimize completion time for n-jobs m-machines problem. Tehnički vjesnik 2010, 17, 273–278. [Google Scholar]

- Rafiei, H.; Rabbani, M.; Gholizadeh, H.; Dashti, H. A novel hybrid SA/GA algorithm for solving an integrated cell formation–job scheduling problem with sequence-dependent set-up times. Int. J. Manag. Sci. Eng. Manag. 2015, 11, 1–9. [Google Scholar] [CrossRef]

- Semanco, P.; Modrak, V. A comparison of constructive heuristics with the objective of minimizing makespan in the flow-shop scheduling problem. Acta Polytech. Hungarica 2012, 9, 177–190. [Google Scholar]

- Goli, A.; Tirkolaee, E.B.; Aydin, N.S. Fuzzy Integrated Cell Formation and Production Scheduling considering Automated Guided Vehicles and Human Factors. IEEE Trans. Fuzzy Syst. 2021, 1. [Google Scholar] [CrossRef]

- Li, M.-L. A novel algorithm of cell formation with alternative machines and multiple-operation-type machines. Comput. Ind. Eng. 2021, 154, 107172. [Google Scholar] [CrossRef]

- Boulif, M. A New Cut-Based Genetic Algorithm for Graph Partitioning Applied to Cell Formation. In Heuristics for Optimization and Learning; Springer Science and Business Media LLC: Berlin, Germany, 2021; pp. 269–284. [Google Scholar]

- Zhang, J.; Chung, H.; Lo, W.-L. Clustering-Based Adaptive Crossover and Mutation Probabilities for Genetic Algorithms. IEEE Trans. Evol. Comput. 2007, 11, 326–335. [Google Scholar] [CrossRef]

- Man, K.F.; Tang, K.S.; Kwong, S. Genetic Algorithms: Concepts and Designs; Springer Science & Business Media: Berlin, Germany, 2001. [Google Scholar]

- Fan, S.-K.S.; Jen, C.-H. An Enhanced Partial Search to Particle Swarm Optimization for Unconstrained Optimization. Mathematics 2019, 7, 357. [Google Scholar] [CrossRef] [Green Version]

- Goldberg, D.E. Genetic Algorithms in Search Optimization, and Machine Learning, Reading; Addison-Wesley Press: Boston, MA, USA, 1989. [Google Scholar]

- Zolfaghari, S.; Liang, M. Comparative study of simulated annealing, genetic algorithms and tabu search for solving binary and comprehensive machine-grouping problems. Int. J. Prod. Res. 2002, 40, 2141–2158. [Google Scholar] [CrossRef]

- Phadke, M.S. Quality Engineering Using Robust Design; Prentice-Hall: Hoboken, NJ, USA, 1989. [Google Scholar]

- Cao, Y.J.; Wu, Q.H. Optimization of control parameters in genetic algorithms: A stochastic approach. Int. J. Syst. Sci. 1999, 30, 551–559. [Google Scholar] [CrossRef]

- Taguchi, G.; Chowdhury, S.; Wu, Y. Taguchi’s Quality Engineering Handbook; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Zupan, H.; Herakovic, N.; Starbek, M. Hybrid Algorithm Based on Priority Rules for Simulation of Workshop Production. Int. J. Simul. Model. 2016, 15, 29–41. [Google Scholar] [CrossRef]

| Control Factors | Description | Levels | ||

|---|---|---|---|---|

| − | 0 | + | ||

| A | Probability of crossover (Pc) | 0.3 | 0.6 | 0.8 |

| B | Probability of mutation (Pm) | 0.01 | 0.05 | 0.1 |

| C | Balance weight factor (α) | 0.4 | 0.6 | 0.8 |

| # | Factors | D | 24 × 16 | 24 × 40 | 30 × 16 | 30 × 40 | Results | ||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | 1 | 2 | 3 | 4 | MSD | SNR | |

| 1 | − | − | − | 12 | 6 | 19 | 13 | 12.5 | −22.49 |

| 2 | − | 0 | 0 | 15 | 5 | 21 | 5 | 11.5 | −22.53 |

| 3 | − | + | + | 13 | 3 | 26 | 7 | 12.25 | −23.54 |

| 4 | 0 | − | 0 | 11 | 0 | 12 | 4 | 6.75 | −18.47 |

| 5 | 0 | 0 | + | 27 | 6 | 25 | 6 | 16 | −25.52 |

| 6 | 0 | + | − | 11 | 0 | 9 | 4 | 6 | −17.36 |

| 7 | + | − | + | 15 | 6 | 19 | 9 | 12.25 | −22.45 |

| 8 | + | 0 | − | 12 | 3 | 17 | 7 | 9.75 | −20.89 |

| 9 | + | + | 0 | 10 | 0 | 7 | 4 | 5.25 | −16.15 |

| # | Factors | D | 7 × 5 | 8 × 6 | 10 × 10 | 11 × 7 | 18 × 5 | 12 × 8 | 15 × 10 | 20 × 8 | 20 × 20 | 20 × 23 | 23 × 14 | 24 × 14 | 24 × 16 | 24 × 40 | 30 × 16 | 35 × 20 | 30 × 40 | 40 × 24 | 41 × 30 | Results | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | MSD | SNR | |

| 1 | − | − | − | 2 | 2 | 1 | 3 | 5 | 1 | 0 | 5 | 20 | 8 | 0 | 0 | 12 | 6 | 19 | 0 | 13 | 2 | 2 | 65.84 | −18.19 |

| 2 | − | 0 | 0 | 2 | 2 | 0 | 3 | 5 | 1 | 0 | 9 | 17 | 4 | 0 | 0 | 15 | 5 | 21 | 0 | 5 | 0 | 3 | 60.74 | −17.83 |

| 3 | − | + | + | 2 | 2 | 0 | 3 | 5 | 1 | 0 | 5 | 19 | 13 | 0 | 0 | 13 | 3 | 26 | 0 | 7 | 0 | 3 | 79.47 | −19.00 |

| 4 | 0 | − | 0 | 2 | 2 | 0 | 3 | 5 | 1 | 0 | 12 | 24 | 10 | 0 | 0 | 11 | 0 | 12 | 0 | 4 | 0 | 3 | 60.68 | −17.83 |

| 5 | 0 | 0 | + | 2 | 2 | 0 | 3 | 5 | 1 | 0 | 9 | 17 | 12 | 0 | 0 | 27 | 6 | 25 | 0 | 6 | 0 | 3 | 104.84 | −20.21 |

| 6 | 0 | + | − | 2 | 2 | 0 | 3 | 5 | 1 | 0 | 27 | 32 | 14 | 0 | 0 | 11 | 0 | 9 | 0 | 4 | 0 | 3 | 116.79 | −20.67 |

| 7 | + | − | + | 2 | 2 | 0 | 3 | 5 | 1 | 0 | 27 | 17 | 22 | 0 | 0 | 15 | 6 | 19 | 0 | 9 | 0 | 3 | 118.79 | −20.75 |

| 8 | + | 0 | − | 2 | 2 | 0 | 3 | 5 | 1 | 0 | 9 | 19 | 8 | 0 | 0 | 12 | 3 | 17 | 0 | 7 | 0 | 3 | 55.21 | −17.42 |

| 9 | + | + | 0 | 2 | 2 | 0 | 3 | 5 | 1 | 0 | 9 | 15 | 10 | 0 | 0 | 10 | 0 | 7 | 0 | 4 | 0 | 3 | 32.79 | −15.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Modrak, V.; Pandian, R.S.; Semanco, P. Calibration of GA Parameters for Layout Design Optimization Problems Using Design of Experiments. Appl. Sci. 2021, 11, 6940. https://doi.org/10.3390/app11156940

Modrak V, Pandian RS, Semanco P. Calibration of GA Parameters for Layout Design Optimization Problems Using Design of Experiments. Applied Sciences. 2021; 11(15):6940. https://doi.org/10.3390/app11156940

Chicago/Turabian StyleModrak, Vladimir, Ranjitharamasamy Sudhakara Pandian, and Pavol Semanco. 2021. "Calibration of GA Parameters for Layout Design Optimization Problems Using Design of Experiments" Applied Sciences 11, no. 15: 6940. https://doi.org/10.3390/app11156940

APA StyleModrak, V., Pandian, R. S., & Semanco, P. (2021). Calibration of GA Parameters for Layout Design Optimization Problems Using Design of Experiments. Applied Sciences, 11(15), 6940. https://doi.org/10.3390/app11156940