Influence of Far Infrared TiO2 and Multi-Walled Carbon Nanotubes Coatings on the Performance of a Hot Water Heater

Abstract

:1. Introduction

2. Related Theories and Sample Preparation

2.1. Wien’s Displacement Law

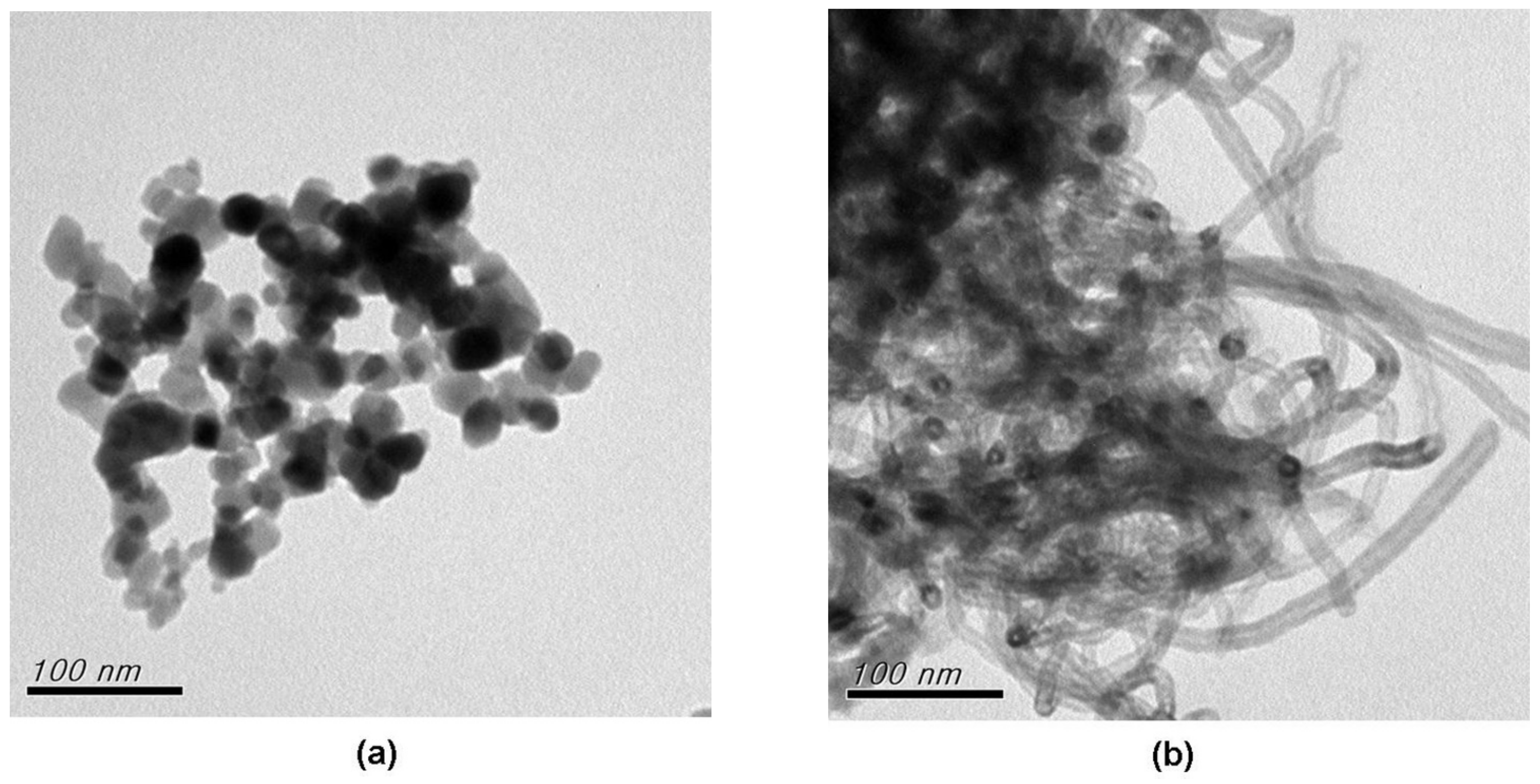

2.2. Preparation of FIRCs

3. Experimental Design and Procedures

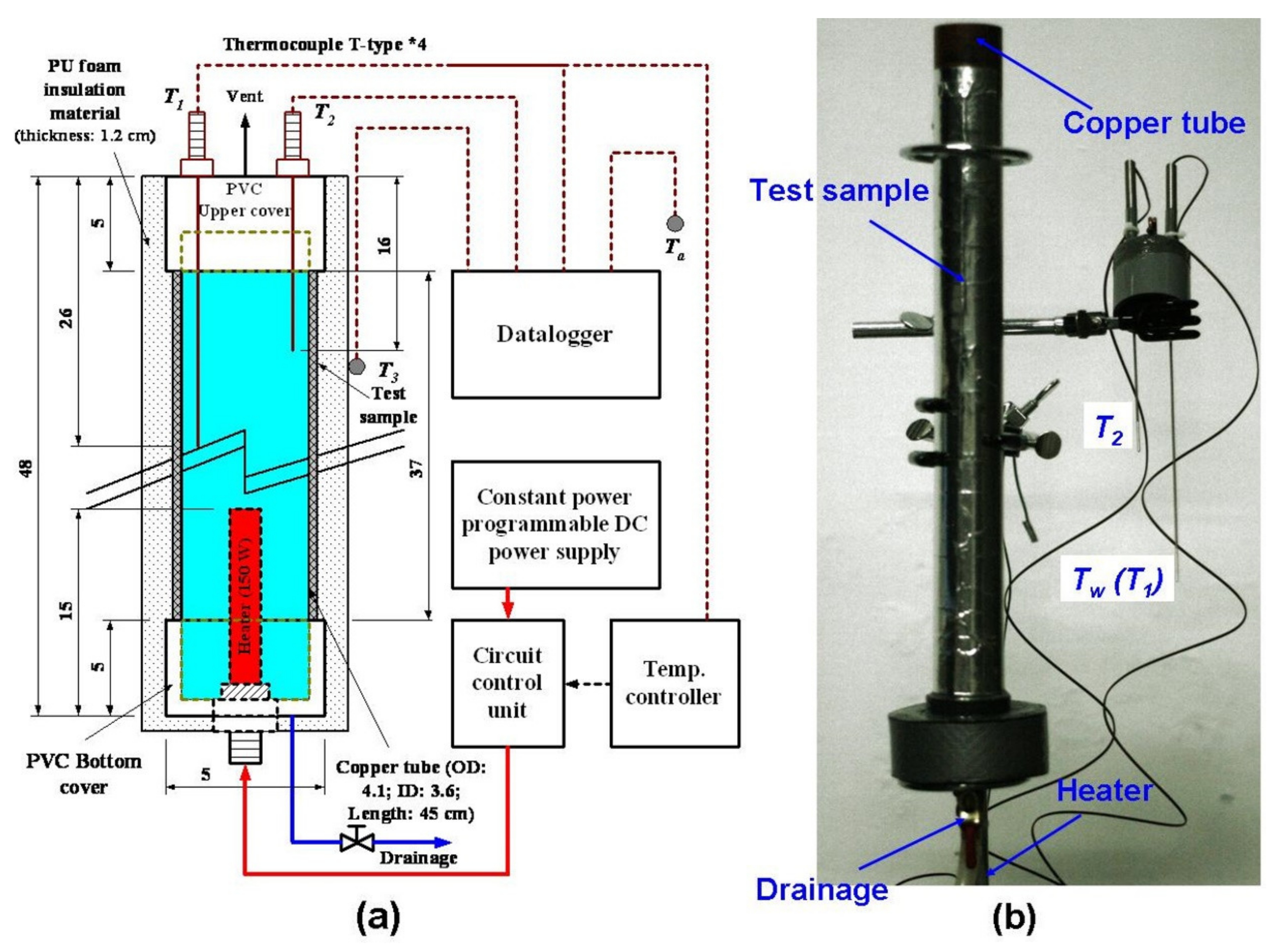

3.1. Experiment Apparatus

3.2. Experimental Procedure and Calculation

3.3. Uncertainty and Data Analysis

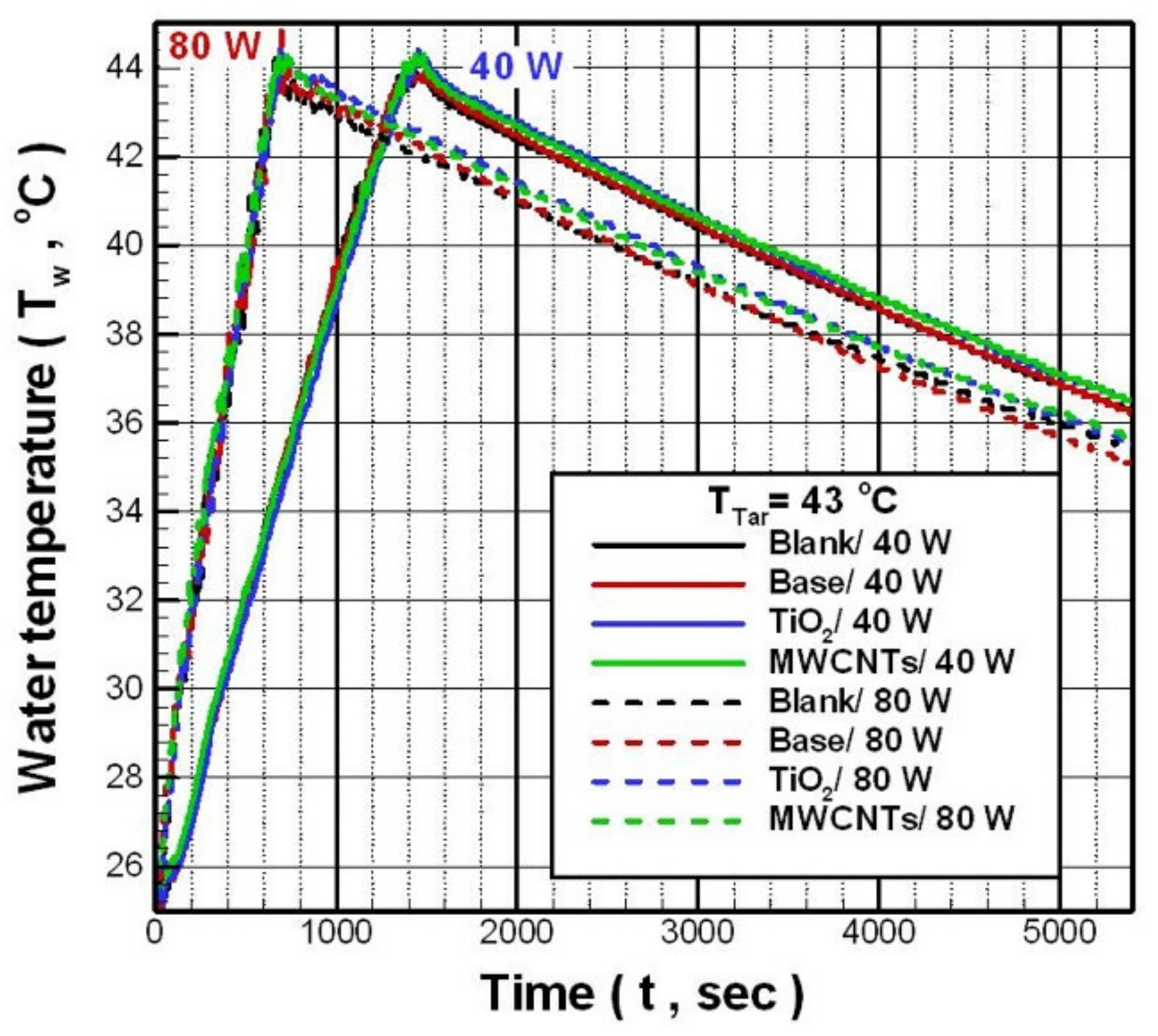

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| ε | emissivity (dimensionless) |

| λmax | Wavelength of the maximum radiation energy of the black body (μm) |

| k | Thermal conductivity (W/m-K) |

| T | Temperature (K) |

| Tmax | Maximum water temperature (°C) |

| T1 | Center water temperature (°C) |

| T2 | Upper water temperature (°C) |

| Tw | Water temperature (°C) |

| b | Wien’s displacement constant (≅2897 μm·K) |

| Str | Heating rate (°C/s) |

| TTar | Target temperature setting (°C) |

| Tla10 | Average water temperature in the last 10 min (°C) |

| STDdTw | Standard deviations of the temperature difference between the upper and the center water temperature |

| m | Measurement deviations (%) |

| um | Maximum relative uncertainty (%) |

| R | Change ratio (%) |

| ED | Experimental data |

| dTTar | Temperature difference between the Tmax and the TTar (°C) |

References

- Dover, J.S.; Phillips, T.J.; Arndt, K.A. Cutaneous effects and therapeutic uses of heat with emphasis on infrared radiation. J. Am. Acad. Dermatol. 1989, 20, 278–286. [Google Scholar] [CrossRef]

- Choi, S.J.; Cho, E.H.; Jo, H.M.; Min, C.; Ji, Y.S.; Park, M.Y.; Kim, J.K.; Hwang, S.D. Clinical utility of far-infrared therapy for improvement of vascular access blood flow and pain control in hemodialysis patients. Kidney Res. Clin. Pract. 2016, 35, 35–41. [Google Scholar] [CrossRef] [Green Version]

- Ishimaru, K.; Nakajima, T.; Namiki, Y.; Ryotokuji, K. Influences of pinpoint plantar long-wavelength infrared light irradiation (stress-free therapy) on chorioretinal hemodynamics, atherosclerosis factors, and vascular endothelial growth factor. Integr. Med. Res. 2018, 7, 103–107. [Google Scholar] [CrossRef]

- Io, H.; Nakata, J.; Aoyama, R.; Inoshita, H.; Nakano, T.; Ishizaka, M.; Fukui, M.; Tomino, Y.; Suzuki, Y. Far-infrared therapy for secondary vascular access patency of hemodialysis patients. Ren. Replace. Ther. 2019, 5, 31. [Google Scholar] [CrossRef]

- Chen, T.Y.; Yang, Y.C.; Sha, Y.N.; Chou, J.R.; Liu, B.S. Far-infrared therapy promotes nerve repair following end-to-end neurorrhaphy in rat models of sciatic nerve injury. Evid. Based Complement. Altern. Med. 2015, 2015, 207245. [Google Scholar] [CrossRef]

- Ou, S.M.; Hu, F.H.; Yang, W.C.; Lin, C.C. Far-infrared therapy as a novel treatment for encapsulating peritoneal sclerosis. Am. J. Gastroenterol. 2014, 109, 1957–1959. [Google Scholar] [CrossRef]

- Khan, I.; Pathan, S.; Li, X.A.; Leong, W.K.; Liao, W.L.; Wong, V.; Hsiao, W.L.W. Far infrared radiation induces changes in gut microbiota and activates GPCRs in mice. J. Adv. Res. 2020, 22, 145–152. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Hwang, S.H.; Hong, S.K.; Seo, J.K.; Sung, H.S.; Park, S.W.; Shin, J.H. The clinical efficacy, safety and functionality of anion textile in the treatment of atopic dermatitis. Ann. Dermatol. 2012, 24, 438–443. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hamada, Y.; Teraoka, F.; Matsumoto, T.; Madachi, A.; Toki, F.; Uda, E.; Hase, R.; Takahashi, J.; Matsuura, N. Effects of far infrared ray on Hela cells and WI-38 cells. Int. Congr. Ser. 2003, 1255, 339–341. [Google Scholar] [CrossRef]

- Cristiano, L. Use of infrared as a complementary treatment approach in medicine and aesthetic medicine. Asp. J. Biomed. Clin. Case Rep. 2019, 2, 77–81. [Google Scholar]

- Wikipedia. Emissivity. 2020. Available online: https://en.wikipedia.org/wiki/Emissivity (accessed on 6 December 2020).

- Heynderickx, G.J.; Nozawa, M. High-emissivity coatings on reactor tubes and furnace walls in steam cracking furnaces. Chem. Eng. Sci. 2004, 59, 5657–5662. [Google Scholar] [CrossRef]

- Zhu, D.; Ding, Y.; Wang, L.; Liang, G.; Wang, Y. Effect of rare earth composite ceramic materials on oil combustion of oil-burning boiler. J. Rare Earths 2006, 24, 244–247. [Google Scholar]

- Li, F.; Liang, J.; Meng, J.; Ding, Y.; Liang, G.; Xue, G.; Liu, L. Effect of tourmaline/resin composite materials on the combustion of diesel oil for oil-burning boiler. J. Chin. Ceram. Soc. 2007, 35, 517–521. [Google Scholar]

- Zhu, D.; Liang, J.; Liang, G.; Ding, Y.; Xue, G.; Liu, L. Effects on combustion of liquefied petroleum gas of porous ceramic doped with rare earth elements. J. Rare Earths 2007, 25, 212–215. [Google Scholar]

- Liang, J.; Zhu, D.; Meng, J.; Wang, L.; Li, F.; Liu, Z.; Ding, Y.; Liu, L.; Liang, G. Performance and application of far infrared rays emitted from rare earth mineral composite materials. J. Nanosci. Nanotechnol. 2008, 8, 1203–1210. [Google Scholar] [CrossRef]

- Lan, H.L. Research Some Questions of High Temperature Infrared Radiant Coating during the Application. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2012. [Google Scholar]

- Chen, T.Y.; Cho, H.P.; Jwo, C.S.; Hung, M.H.; Lee, W.S. Analyzing how the ZrO2 far infrared material affects the performance of smooth tube heat exchangers. J. Nanomater. 2015, 2015, 124632. [Google Scholar]

- Maznoy, A.; Kirdyashkin, A.; Pichugin, N.; Zambalov, S.; Petrov, D. Development of a new infrared heater based on an annular cylindrical radiant burner for direct heating applications. Energy 2020, 204, 117965. [Google Scholar] [CrossRef]

- Qiu, K.; Elhassan, A.; Tian, T.; Yin, X.; Yu, J.; Li, Z.; Ding, B. Highly flexible, efficient, and sandwich-structured infrared radiation heating fabric. ACS Appl. Mater. Interfaces 2020, 12, 11016–11025. [Google Scholar] [CrossRef] [PubMed]

- Xue, G.; Wu, X.M.; Liang, J.S.; Ding, Y.; Liu, L.H. Effect of mineral composite materials with far infrared radiation on diesel oil combustion. Adv. Mater. Res. 2008, 58, 47–53. [Google Scholar] [CrossRef]

- Wey, A.C.T. Infrared-Emitting Ceramics for Fuel Activation. U.S. Patent US20110186010 A1, 4 August 2011. [Google Scholar]

- Qin, X.L.; Yang, R.; Wang, Y.F.; Luo, L.; Qiao, S.F. Study of the effect of negative ions on energy efficiency of diesel engines. For. Mach. Wood. Equip. 2013, 41, 29–30. Available online: http://en.cnki.com.cn/Article_en/CJFDTOTAL-LJMG201303007.htm (accessed on 7 July 2020).

- Das, R. Wavelength- and frequency-dependent formulations of Wien’s displacement law. J. Chem. Edu. 2015, 92, 1130–1134. [Google Scholar] [CrossRef]

- NIST. CODATA Value: Wien wavelength displacement law constant. In The NIST Reference on Constants, Units, and Uncertainty; U.S. National Institute of Standards and Technology: Gaithersburg, MA, USA, 2011. [Google Scholar]

| TTar (°C) | Item | 40 W | 80 W | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Blank | Base | TiO2 | MWCNTs | Blank | Base | TiO2 | MWCNTs | ||

| 43 | Str (°C/s) | 0.01491 | 0.01482 | 0.01453 | 0.01404 | 0.02829 | 0.02745 | 0.02775 | 0.02804 |

| RStr (%) | 0.00 | −0.60 | −2.60 | −5.84 | 0.00 | −2.96 | −1.89 | −0.87 | |

| Tla10 (°C) | 36.69 | 36.70 | 36.92 | 36.93 | 35.80 | 35.52 | 35.97 | 36.06 | |

| RTla10 (%) | 0.00 | 0.00 | 0.62 | 0.65 | 0.00 | −0.78 | 0.48 | 0.73 | |

| STDdTw | 0.43 | 0.48 | 0.41 | 0.42 | 0.68 | 0.74 | 0.62 | 0.66 | |

| RSTDdTw (%) | 0.00 | 10.94 | −5.66 | −3.95 | 0.00 | 8.83 | −8.54 | −2.14 | |

| 53 | Str (°C/s) | 0.01327 | 0.01317 | 0.01312 | 0.01331 | 0.02652 | 0.02625 | 0.02654 | 0.02658 |

| RStr (%) | 0.00 | −0.78 | −1.14 | 0.32 | 0.00 | −1.02 | 0.06 | 0.22 | |

| Tla10 (°C) | 45.08 | 45.06 | 45.03 | 45.34 | 42.15 | 42.11 | 42.43 | 42.20 | |

| RTla10 (%) | 0.00 | −0.05 | −0.12 | 0.57 | 0.00 | −0.09 | 0.67 | 0.12 | |

| STDdTw | 0.74 | 0.71 | 0.61 | 0.64 | 0.92 | 0.85 | 0.84 | 0.83 | |

| RSTDdTw (%) | 0.00 | −4.52 | −17.27 | −13.21 | 0.00 | −7.06 | −8.87 | −9.51 | |

| 63 | Str (°C/s) | 0.01209 | 0.01219 | 0.01215 | 0.01180 | 0.02584 | 0.02584 | 0.02621 | 0.02589 |

| RStr (%) | 0.00 | 0.81 | 0.54 | −2.40 | 0.00 | 0.02 | 1.43 | 0.19 | |

| Tla10 (°C) | 56.22 | 55.79 | 55.68 | 56.29 | 49.40 | 49.25 | 49.44 | 49.16 | |

| RTla10 (%) | 0.00 | −0.76 | −0.95 | 0.13 | 0.00 | −0.29 | 0.10 | −0.49 | |

| STDdTw | 0.85 | 0.83 | 0.79 | 0.81 | 1.07 | 1.05 | 0.95 | 0.97 | |

| RSTDdTw (%) | 0.00 | −3.01 | −7.72 | −4.50 | 0.00 | −1.28 | −11.08 | −9.44 | |

| Rank | 4 | 3 | 2 | 1 | 3 | 4 | 1 | 2 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teng, T.-P.; Yu, S.-P.; Lue, Y.-F.; Xie, Q.-L.; Hsieh, H.-K.; Huang, C.-C. Influence of Far Infrared TiO2 and Multi-Walled Carbon Nanotubes Coatings on the Performance of a Hot Water Heater. Appl. Sci. 2021, 11, 7043. https://doi.org/10.3390/app11157043

Teng T-P, Yu S-P, Lue Y-F, Xie Q-L, Hsieh H-K, Huang C-C. Influence of Far Infrared TiO2 and Multi-Walled Carbon Nanotubes Coatings on the Performance of a Hot Water Heater. Applied Sciences. 2021; 11(15):7043. https://doi.org/10.3390/app11157043

Chicago/Turabian StyleTeng, Tun-Ping, Shang-Pang Yu, Yeou-Feng Lue, Qi-Lin Xie, Hsiang-Kai Hsieh, and Chia-Cing Huang. 2021. "Influence of Far Infrared TiO2 and Multi-Walled Carbon Nanotubes Coatings on the Performance of a Hot Water Heater" Applied Sciences 11, no. 15: 7043. https://doi.org/10.3390/app11157043