Design and Switching Characteristics of Flip-Chip GaN Half-Bridge Modules Integrated with Drivers

Abstract

:Featured Application

Abstract

1. Introduction

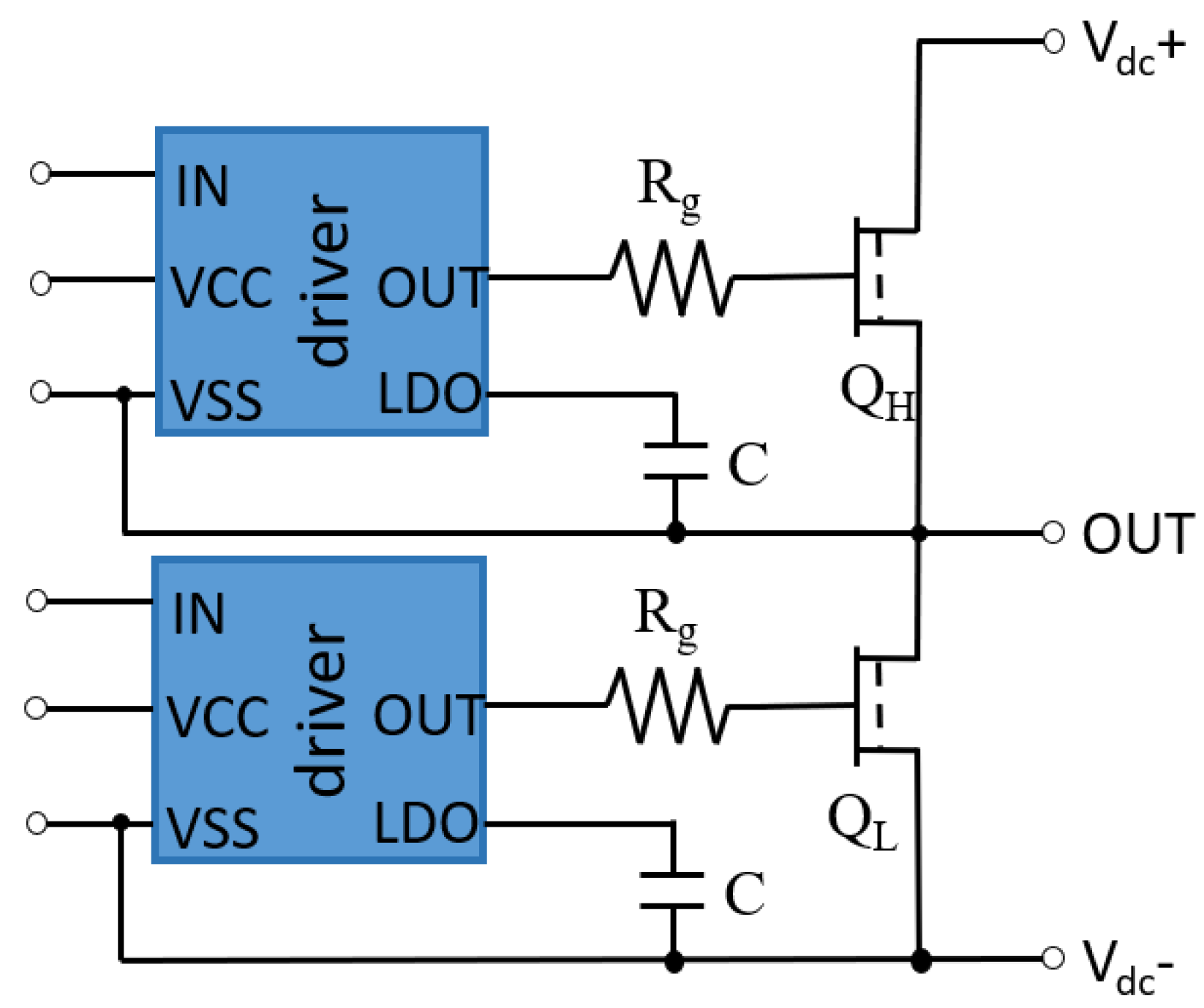

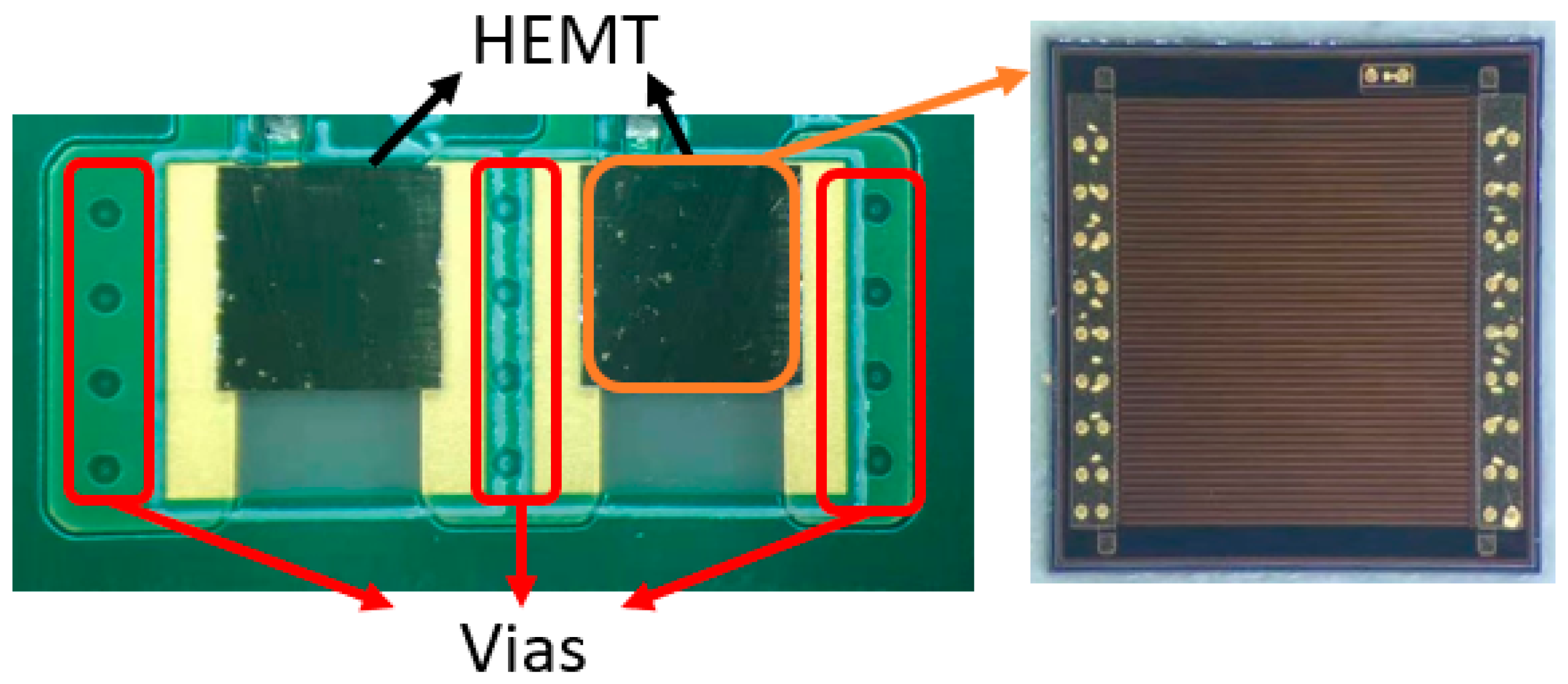

2. Module Design and Fabrication

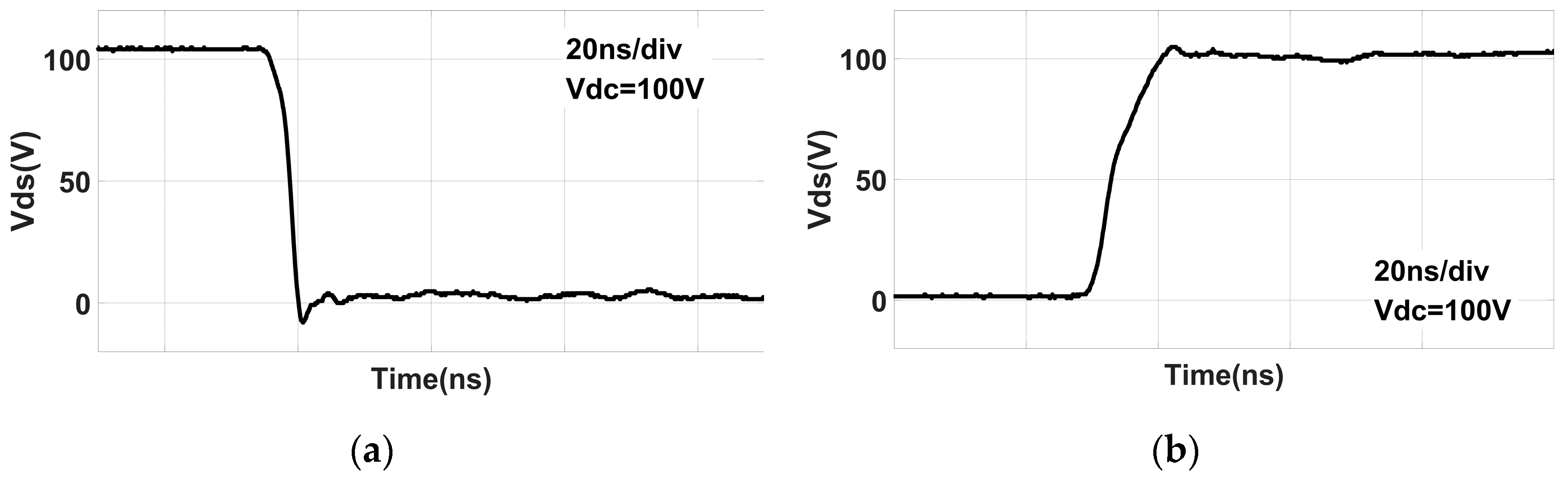

3. Switching Characteristics

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Niloufar, K.; Deqiang, W.; Bharat, A.; Ruoyu, H.; Ali, E. Current Status and Future Trends of GaN HEMTs in Electrified Transportation. IEEE Access 2020, 8, 70553–70571. [Google Scholar]

- Joshin, K.; Kikkawa, T.; Masuda, S.; Watanabe, K. Outlook for GaN HEMT Technology. Fujitsu Sci. Tech. J. 2014, 50, 138–143. [Google Scholar]

- Fletcher, A.S.A.; Nirmal, D. A survey of Gallium Nitride HEMT for RF and high power applications. Superlattices Microstruct. 2017, 109, 519–537. [Google Scholar] [CrossRef]

- De Santi, C.; Meneghini, M.; Meneghesso, G.; Zanoni, E. Review of dynamic effects and reliability of depletion and enhancement GaN HEMTs for power switching applications. Iet Power Electron. 2018, 11, 668–674. [Google Scholar] [CrossRef]

- Luo, F.; Liang, L.; Huitink, D.; Spiesshoefer, S. Advanced Power Module Packaging and Integration Structures for High Frequency Power Conversion: From Silicon to GaN. Power Electron. 2018, 52, 9–18. [Google Scholar]

- Lautner, J.; Piepenbreier, B. Analysis of GaN HEMT Switching Behavior. In Proceedings of the 2015 9th International Conference on Power Electronics and Ecce Asia, Seoul, Korea, 1–5 June 2015; pp. 567–574. [Google Scholar]

- Reusch, D.; Strydom, J. Understanding the Effect of PCB Layout on Circuit Performance in a High-Frequency Gallium-Nitride-Based Point of Load Converter. IEEE Trans. Power Electron. 2014, 29, 2008–2015. [Google Scholar] [CrossRef]

- Kuring, C.; Wolf, M.; Geng, X.; Hilt, O.; Bocker, J.; Wieczorek, N.; Wurfl, J.; Dieckerhoff, S. Evaluation of a GaN HEMT Half-Bridge embedded to a Multilayer Aluminum Nitride Substrate. In Proceedings of the CIPS 2020; 11th International Conference on Integrated Power Electronics Systems. VDE, Berlin, Germany, 24–26 March 2020; pp. 1–6. [Google Scholar]

- Liu, W.; Mei, Y.; Xie, Y.; Wang, M.; Li, X.; Lu, G.-Q. Design and Characterizations of a Planar Multichip Half-Bridge Power Module by Pressureless Sintering of Nanosilver Paste. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 7, 1627–1636. [Google Scholar] [CrossRef]

- Chen, C.; Chen, Y.; Li, Y.; Huang, Z.; Liu, T.; Kang, Y. An SiC-Based Half-Bridge Module with an Improved Hybrid Packaging Method for High Power Density Applications. IEEE Trans. Ind. Electron. 2017, 64, 8980–8991. [Google Scholar] [CrossRef]

- Chen, C.; Huang, Z.; Chen, L.; Tan, Y.; Kang, Y.; Luo, F. Flexible PCB-Based 3-D Integrated SiC Half-Bridge Power Module With Three-Sided Cooling Using Ultralow Inductive Hybrid Packaging Structure. IEEE Trans. Power Electron. 2019, 34, 5579–5593. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, L.; Lei, Y.; Li, X.; Xue, F.; Yu, W.; Huang, A.Q. 3.38 Mhz Operation of 1.2kV SiC MOSFET With Integrated Ultra-Fast Gate Drive. In Proceedings of the Wipda 2015 3rd Ieee Workshop on Wide Bandgap Power Devices and Applications, Blacksburg, VA, USA, 2–4 November 2015; pp. 390–395. [Google Scholar]

- Zhao, X.; Gao, B.; Zhang, L.; Hopkins, D.C.; Huang, A.Q. Performance Optimization of A 1.2kV SiC High Density Half Bridge Power Module in 3D Package. In Proceedings of the Thirty-Third Annual Ieee Applied Power Electronics Conference and Exposition, San Antonio, TX, USA, 4–8 March 2018; pp. 1266–1271. [Google Scholar]

- Chen, J.; Xie, Y.; Trombley, D.; Murugan, R. System Co-design of a 600V GaN FET Power Stage with Integrated Driver in a QFN System-in-Package (QFN-SiP). In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; pp. 1221–1226. [Google Scholar]

- Seal, S.; Wallace, A.K.; Dearien, A.M.; Farnell, C.; Mantooth, H.A. A Wire Bondless SiC Switching Cell With a Vertically Integrated Gate Driver. IEEE Trans. Power Electron. 2020, 35, 9690–9699. [Google Scholar] [CrossRef]

- Seal, S.; Glover, M.D.; Mantooth, H.A. 3-D Wire Bondless Switching Cell Using Flip-Chip-Bonded Silicon Carbide Power Devices. IEEE Trans. Power Electron. 2018, 33, 8553–8564. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Cheng, Z.; Yu, Z.-G.; Lin, D.-F.; Liu, Z.; Jia, L.-F.; Zhang, Y. Design and Switching Characteristics of Flip-Chip GaN Half-Bridge Modules Integrated with Drivers. Appl. Sci. 2021, 11, 7057. https://doi.org/10.3390/app11157057

Wang L, Cheng Z, Yu Z-G, Lin D-F, Liu Z, Jia L-F, Zhang Y. Design and Switching Characteristics of Flip-Chip GaN Half-Bridge Modules Integrated with Drivers. Applied Sciences. 2021; 11(15):7057. https://doi.org/10.3390/app11157057

Chicago/Turabian StyleWang, Lin, Zhe Cheng, Zhi-Guo Yu, De-Feng Lin, Zhe Liu, Li-Fang Jia, and Yun Zhang. 2021. "Design and Switching Characteristics of Flip-Chip GaN Half-Bridge Modules Integrated with Drivers" Applied Sciences 11, no. 15: 7057. https://doi.org/10.3390/app11157057

APA StyleWang, L., Cheng, Z., Yu, Z.-G., Lin, D.-F., Liu, Z., Jia, L.-F., & Zhang, Y. (2021). Design and Switching Characteristics of Flip-Chip GaN Half-Bridge Modules Integrated with Drivers. Applied Sciences, 11(15), 7057. https://doi.org/10.3390/app11157057