Development of Wireless and Passive SAW Temperature Sensor with Very High Accuracy

Abstract

:1. Introduction

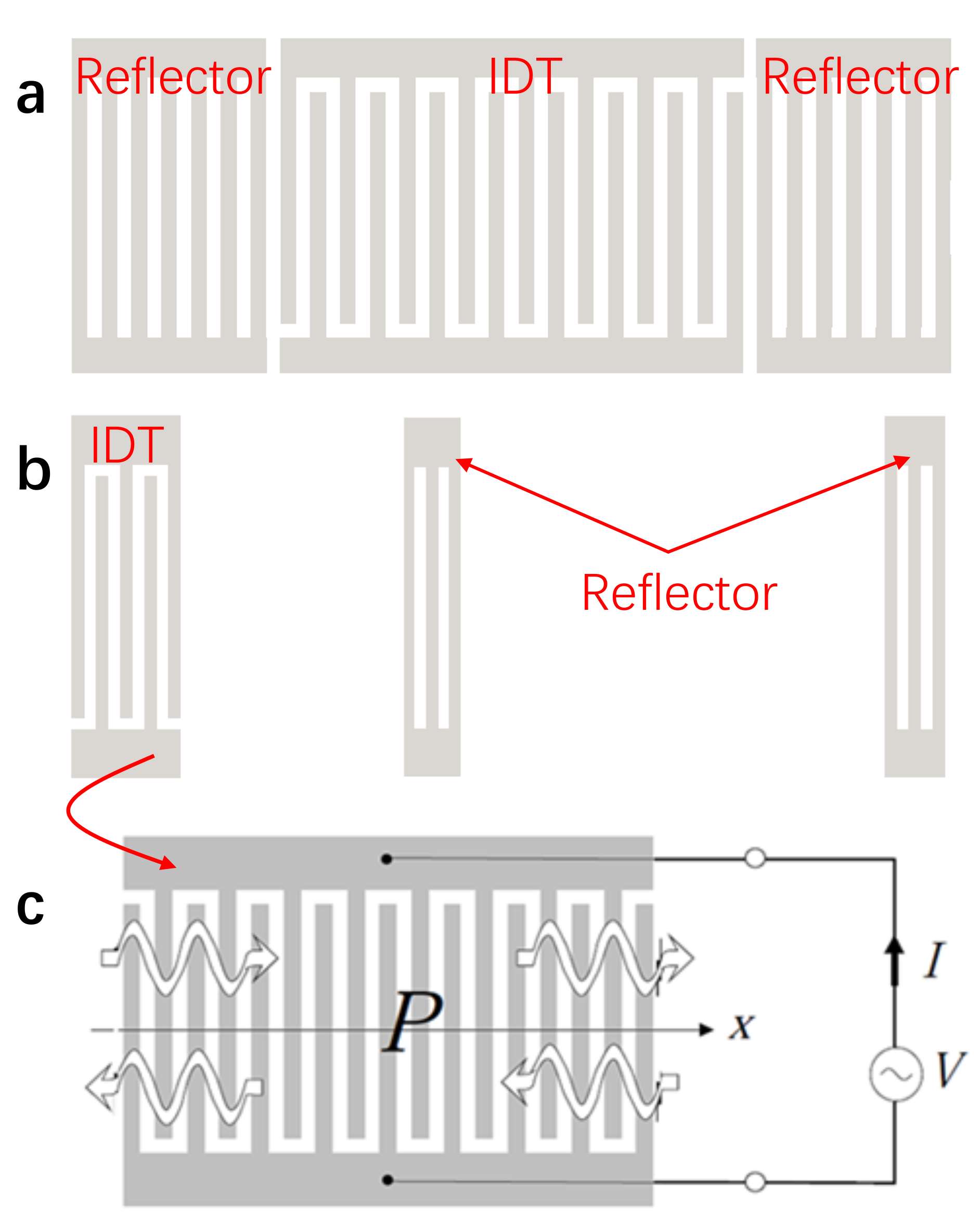

2. COM Simulation for Sensing Device

3. Technique Realizations

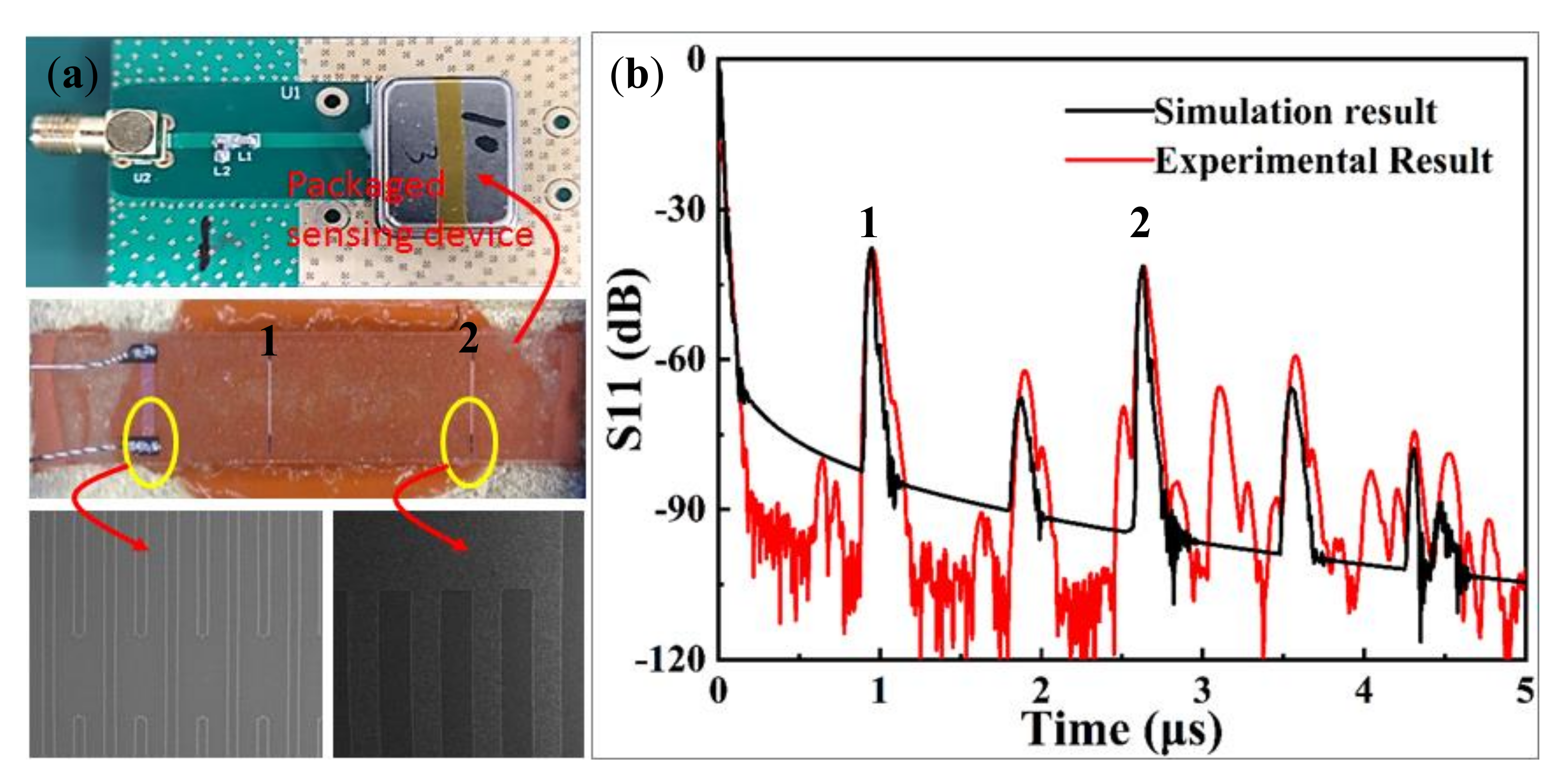

3.1. SAW Sensing Device

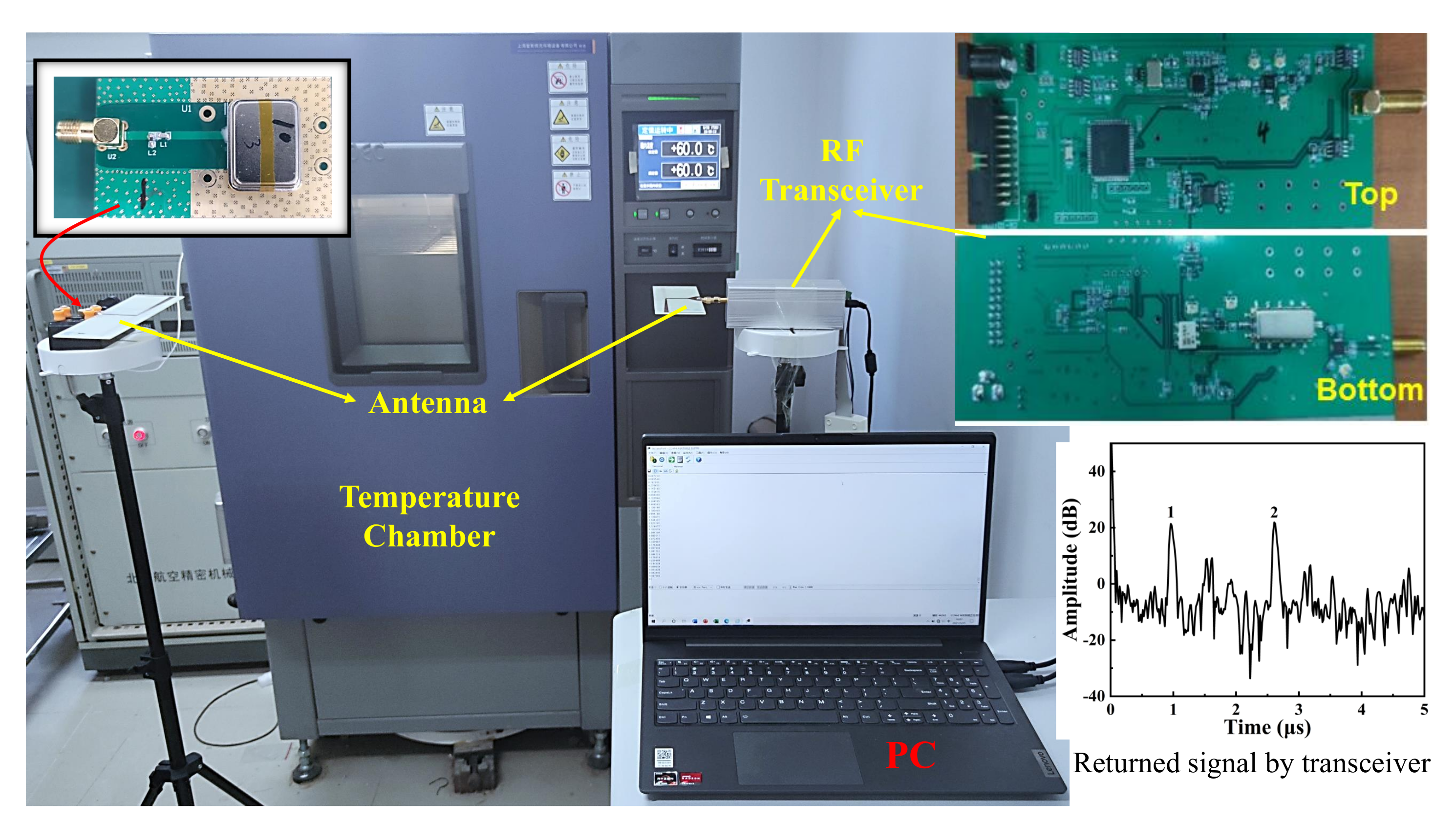

3.2. Wireless System

4. Signal Processing Method

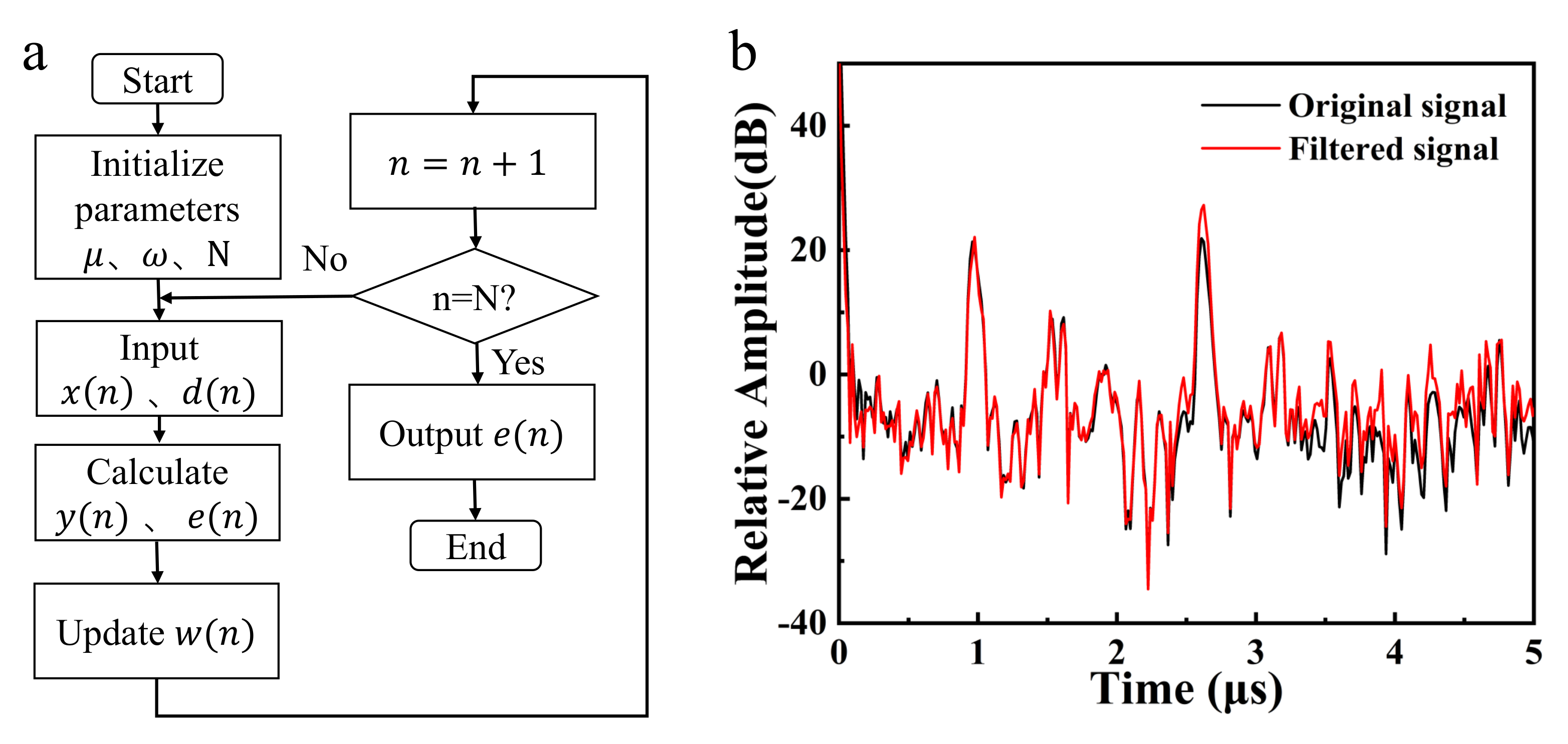

4.1. Adaptive LMS Algorithm

4.2. Multi-Point Parabola Approximation and Moving Average Algorithm

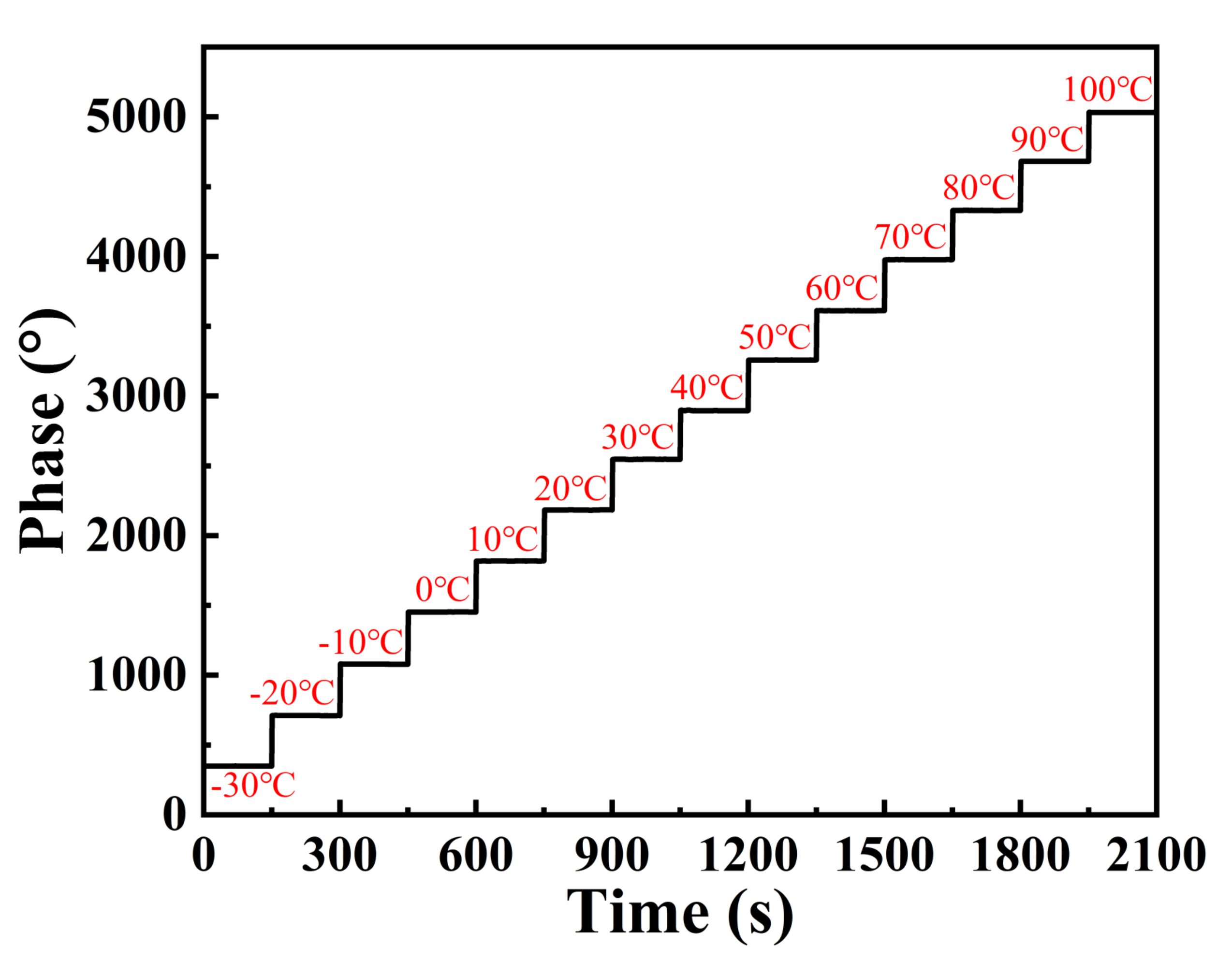

5. Sensing Experiment and Discussions

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ming, W.W.; Yao, Z.; Wen, Q.G.; Li, Q.H.; Qin, J.L. Design of the Chemical Reaction Tank Temperature Acquisition System Based on Wireless Sensor Networks. Adv. Mater. Res. 2014, 945–949, 1982–1986. [Google Scholar] [CrossRef]

- Zhang, X.; Xuehui, H.U.; Zhai, Y.; Qin, C. The Design and Experimental Study of High Precise Temperature Acquisition System Based on PT100. Chuangan Jishu Xuebao 2010, 23, 812–815. [Google Scholar]

- Tan, Q.; Luo, T.; Wei, T.; Liu, J.; Lin, L.; Xiong, J. A Wireless Passive Pressure and Temperature Sensor via a Dual LC Resonant Circuit in Harsh Environments. J. Microelectromech. Syst. 2017, 26, 351–356. [Google Scholar] [CrossRef]

- Yan, D.; Yang, Y.; Hong, Y.; Liang, T.; Yao, Z.; Chen, X.; Xiong, J. Low-Cost Wireless Temperature Measurement: Design, Manufacture, and Testing of a PCB-Based Wireless Passive Temperature Sensor. Sensors 2018, 18, 532. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yan, D.; Yong, Y.; Hong, Y.; Liang, T.; Yao, Z.; Chen, X.; Xiong, J. AlN-Based Ceramic Patch Antenna-Type Wireless Passive High-Temperature Sensor. Micromachines 2017, 8, 301. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Xue, X.; Fan, S.; Liu, M.; Lu, M. Development of a wireless and passive temperature-compensated SAW strain sensor. Sens. Actuators A 2020, 308, 112015. [Google Scholar] [CrossRef]

- Paquit, M.; Arapan, L.; Feng, W.; Friedt, J.M. Long Range Passive RADAR Interrogation of Subsurface Acoustic Passive Wireless Sensors Using Terrestrial Television Signals. IEEE Sens. J. 2020, 20, 7156–7160. [Google Scholar] [CrossRef]

- Devkota, J.; Greve, D.W.; Hong, T.; Kim, K.J.; Ohodnicki, P.R. An 860 MHz Wireless Surface Acoustic Wave Sensor with a Metal-Organic Framework Sensing Layer for CO2 and CH4. IEEE Sens. J. 2020, 20, 9740–9747. [Google Scholar] [CrossRef]

- Rabus, D.; Friedt, J.M.; Arapan, L.; Lamare, S.; Cherioux, F. Sub-surface H2S detection by a Surface Acoustic Wave passive wireless sensor interrogated with a ground penetrating radar. ACS Sens. 2020, 5, 1075–1081. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Yassine, O.; Kosel, J. A Surface Acoustic Wave Passive and Wireless Sensor for Magnetic Fields, Temperature, and Humidity. IEEE Sens. J. 2014, 15, 453–462. [Google Scholar] [CrossRef]

- Pan, Y.; Qin, M.; Guo, T.; Zhang, L.; Xue, X. Wireless passive surface acoustic wave (SAW) technology in gas sensing. Sens. Rev. 2021, 41, 135–143. [Google Scholar] [CrossRef]

- Bao, X.Q.; Burkhard, W.; Varadan, V.V.; Varadan, V.K. SAW Temperature Sensor and Remote Reading System. In Proceedings of the IEEE 1987 Ultrasonics Symposium, Denver, CO, USA, 14–16 October 1987; pp. 583–586. [Google Scholar] [CrossRef]

- Xu, F.Q.; Wang, W.; Xue, X.F.; Hu, H.L.; Liu, X.L.; Yong, P. Development of a Wireless and Passive SAW-Based Chemical Sensor for Organophosphorous Compound Detection. Sensors 2015, 15, 30187–30198. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kuypers, J.H.; Reindl, L.M.; Tanaka, S.; Esashi, M. Maximum accuracy evaluation scheme for wireless saw delay line sensors. IEEE Trans. Sonics Ultrason. 2008, 55, 1640–1652. [Google Scholar] [CrossRef] [PubMed]

- Yudytskiy, M.; Fachberger, R. Continuous temperature monitoring algorithm for SAW sensors. IEEE Int. Ultrason. Symp. 2015, 1–4. [Google Scholar] [CrossRef]

- Kim, J.; Luis, R.; Smith, M.S.; Figueroa, J.A.; Malocha, D.; Nam, B.H. Concrete temperature monitoring using passive wireless surface acoustic wave sensor system. Sens. Actuators A 2015, 224, 131–139. [Google Scholar] [CrossRef]

- Kalinin, V. Passive wireless strain and temperature sensors based on SAW devices. In Proceedings of the 2004 IEEE Radio and Wireless Conference, Atlanta, GA, USA, 22 September 2004; pp. 187–190. [Google Scholar] [CrossRef]

- Fachberger, R.; Bruckner, G.; Hauser, R.; Reindl, L. Wireless SAW based high-temperature measurement systems. In Proceedings of the 2006 IEEE International Frequency Control Symposium and Exposition, Miami, FL, USA, 4–7 June 2006; pp. 358–367. [Google Scholar] [CrossRef]

- Wang, W.; Xue, X.; Shao, X.; Wang, J.; Liang, Y. Development of a surface acoustic wave wireless and passive temperature sensor incorporating reflective delay line. Chin. J. Acous. 2014, 39, 473–478. [Google Scholar] [CrossRef]

- Tang, Z.; Wu, W.; Gao, J.; Luo, J.; Xu, L. A Multi-Iteration Enhanced 2P-SMA Method for Improved Error Reduction on a WP-SAW Water Temperature and Pressure Sensor. IEEE Access 2021, 9, 48236–48243. [Google Scholar] [CrossRef]

- Huang, D.; Li, T. Design of RF temperature measurement system of delay linear SAW temperature sensor based on FPGA. In Proceedings of the 2020 International Conference on Computer Engineering and Application (ICCEA), Guangzhou, China, 18–20 March 2020; pp. 520–524. [Google Scholar] [CrossRef]

- Rodriguez, L.M.; Gallagher, D.R.; Gallagher, M.W.; Fisher, B.H.; Humphries, J.R.; Malocha, D.C. Wireless SAW Sensor Temperature Extraction Precision. IEEE Sens. J. 2014, 14, 3830–3837. [Google Scholar] [CrossRef]

- Wen, W.; Lee, K.; Woo, I.; Park, I.; Yang, S. Optimal design on SAW sensor for wireless pressure measurement based on reflective delay line. Sens. Actuators A 2007, 139, 2–6. [Google Scholar] [CrossRef]

- Lee, K.; Wang, W.; Kim, T.; Yang, S. A novel 440 MHz wireless SAW microsensor integrated with pressure–temperature sensors and ID tag. J. Micromech. Microeng. 2007, 17, 515–523. [Google Scholar] [CrossRef]

- Hashimoto, K.Y. Surface Acoustic Wave Devices in Telecommunications. In Modelling and Simulation; Springer: Berlin/Heidelberg, Germany, 2000. [Google Scholar]

- Bulst, W.E.; Fischerauer, G.; Reindl, L. State of the art in wireless sensing with surface acoustic waves. IEEE Trans. Ind. Electron. Control Instrum. 2001, 48, 265–271. [Google Scholar] [CrossRef]

- Liu, B.; Han, T.; Zhang, C. Error Correction Method for Passive and Wireless Resonant SAW Temperature Sensor. IEEE Sens. J. 2015, 15, 3608–3614. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, R.; Li, S.; Qi, S. Temperature Sensor Denoising Algorithm Based on Curve Fitting and Compound Kalman Filtering. Sensors 2020, 20, 1959. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Widrow, B.; Hoff, M.E. Adaptive switching circuits. Neurocomputing 1960, 4, 126–134. [Google Scholar]

- Reindl, L.; Shrena, I.; Kenshil, S.; Peter, R. Wireless measurement of temperature using surface acoustic waves sensors. In Proceedings of the IEEE International Frequency Control Symposium and PDA Exhibition Jointly with the 17th European Frequency and Time Forum, Tampa, FL, USA, 4–8 May 2003; pp. 935–941. [Google Scholar] [CrossRef]

| Piezoelectric substrate crystal | YZ LiNbO |

| Operation frequency | 433 MHz |

| IDT type | Bidirectional structure |

| Electrodes number in IDT | 20 |

| Aperture | 100 times of the acoustic wavelength |

| Electrodes number in reflectors | 8 |

| Electrode material and thickness | Aluminum (AL), 300 nm |

| Position of two reflectors | 1 s, 2.6 s |

| Frequency of the Reflective SAW Delay Line Device | Temperature Detection Range | Accuracy | References |

|---|---|---|---|

| 2.45 GHz | 30 C∼200 C | ±0.5 C | [10] |

| 434 MHz | 15 C∼90 C | ±0.8 C | [11] |

| 433 MHz | 40 C∼60 C | ±0.15% | [12] |

| 429.2 MHz | 25 C∼130 C | ±0.6 C | [13] |

| 2.4 GHz | 25 C∼200 C | ±0.6 C | [22] |

| 433 MHz | −30 C∼100 C | ±0.2 C | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, X.; Cheng, L.; Xue, X.; Zhai, S.; Liang, Y.; Wang, W.; Liu, M.; Zhu, J.; Li, Z. Development of Wireless and Passive SAW Temperature Sensor with Very High Accuracy. Appl. Sci. 2021, 11, 7422. https://doi.org/10.3390/app11167422

Gao X, Cheng L, Xue X, Zhai S, Liang Y, Wang W, Liu M, Zhu J, Li Z. Development of Wireless and Passive SAW Temperature Sensor with Very High Accuracy. Applied Sciences. 2021; 11(16):7422. https://doi.org/10.3390/app11167422

Chicago/Turabian StyleGao, Xu, Lina Cheng, Xufeng Xue, Shoupei Zhai, Yong Liang, Wen Wang, Mengwei Liu, Jialiang Zhu, and Zhuoyue Li. 2021. "Development of Wireless and Passive SAW Temperature Sensor with Very High Accuracy" Applied Sciences 11, no. 16: 7422. https://doi.org/10.3390/app11167422