Variability of Gravel Pavement Roughness: An Analysis of the Impact on Vehicle Dynamic Response and Driving Comfort

Abstract

:Featured Application

Abstract

1. Introduction

2. Related Works

3. Indexes for Gravel Road Quality Assessment

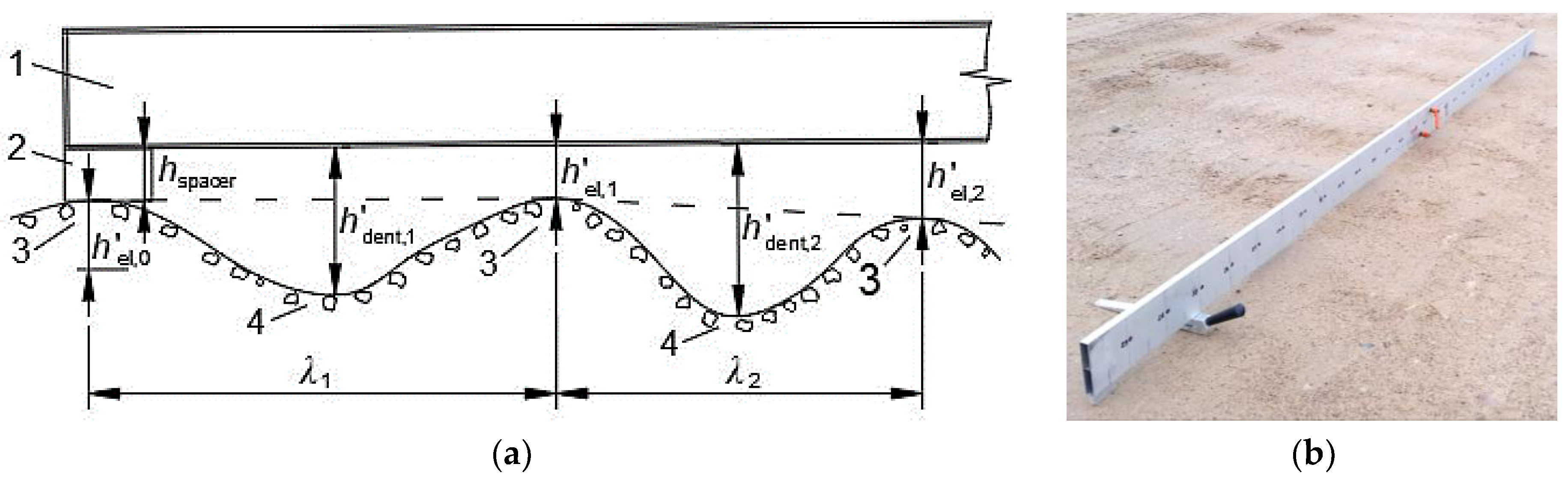

4. Roughness Measurement Using a Straightedge

5. Results

5.1. The IRI Approach for Gravel Pavement

5.2. Vehicle Response to the Pavement Surface State

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Horiuchi, S.; Tsuda, A.; Kobayashi, H.; Redding, C.A.; Prochaska, J.O. Sustainable transportation pros, cons, and self-efficacy as predictors of 6-month stage transitions in a Chinese sample. J. Transp. Health 2017, 6, 481–489. [Google Scholar] [CrossRef]

- Obeng, D.A.; Tuffour, Y.A. Prospects of alternative funding sourcing for maintenance of road networks in developing countries. Transp. Res. Interdiscip. Perspect. 2020, 8, 100225. [Google Scholar] [CrossRef]

- Pasindu, H.R.; Gamage, D.E.; Bandara, J.M.S.J. Framework for selecting pavement type for low volume roads. Transp. Res. Proc. 2020, 48, 3924–3938. [Google Scholar] [CrossRef]

- Petkevičius, K.; Maskeliūnaitė, L.; Sivilevičius, H. Determining travel conditions on motorways for automobile transport based on the case study for Lithuanian highways. Transport 2019, 34, 89–102. [Google Scholar] [CrossRef] [Green Version]

- Ziyadi, M.; Ozer, H.; Kang, S.; Al-Qadi, I.L. Vehicle energy consumption and an environmental impact calculation model for the transportation infrastructure systems. J. Clean Prod. 2018, 174, 424–436. [Google Scholar] [CrossRef]

- Gleave, S.D.; Frisoni, R.; Dionori, F.; Casullo, L.; Vollath, C.; Devenish, L.; Spano, F.; Sawicki, T.; Carl, S.; Lidia, R.; et al. EU Road Surfaces: Economic and Safety Impact of the Lack of Regular Road Maintenance. European Parliament—Directorate General for Internal Policies, Policy Department B: Structural and Cohesion Policies, Transport and Tourism. 2014. Available online: https://www.europarl.europa.eu/RegData/etudes/STUD/2014/529059/IPOL_STU(2014)529059_EN.pdf (accessed on 16 August 2021).

- Mamčic, S.; Sivilevičius, H. The analysis of traffic accidents on Lithuanian regional gravel roads. Transport 2013, 28, 108–115. [Google Scholar] [CrossRef]

- Pretagostini, F.; Ferranti, L.; Berardo, G.; Ivanov, V.; Shyrokau, B. Survey on Wheel Slip Control Design Strategies, Evaluation and Application to Antilock Braking Systems. IEEE Access 2020, 8, 10951–10970. [Google Scholar] [CrossRef]

- Van der Merwe, N.A.; Els, P.S.; Žuraulis, V. ABS braking on rough terrain. J. Terramech. 2018, 80, 49–57. [Google Scholar] [CrossRef] [Green Version]

- Cao, D.; Song, X.; Ahmadian, M. Editors’ perspectives: Road vehicle suspension design, dynamics, and control. Veh. Syst. Dyn. 2011, 49, 3–28. [Google Scholar] [CrossRef] [Green Version]

- Hamersma, H.A.; Els, P.S. Improving the braking performance of a vehicle with ABS and a semi-active suspension system on a rough road. J. Terramech. 2014, 56, 91–101. [Google Scholar] [CrossRef] [Green Version]

- Šabanovič, E.; Žuraulis, V.; Prentkovskis, O.; Skrickij, V. Identification of Road-Surface Type Using Deep Neural Networks for Friction Coefficient Estimation. Sensors 2020, 20, 612. [Google Scholar] [CrossRef] [Green Version]

- Žuraulis, V.; Surblys, V.; Šabanovič, E. Technological measures of forefront road identification for vehicle comfort and safety improvement. Transport 2019, 34, 363–372. [Google Scholar] [CrossRef] [Green Version]

- Savitski, D.; Ivanov, V.; Shyrokau, B.; De Smet, J.; Theunissen, J. Experimental study on continuous ABS operation in pure regenerative mode for full electric vehicle. SAE Int. J. Passeng. Cars Mech. Syst. 2015, 8, 364–369. [Google Scholar] [CrossRef]

- Gao, H.; Jézéquel, L.; Cabrol, E.; Vitry, B. Chassis durability and comfort trade-off at early stage of project by virtual proving ground simulation. Veh. Syst. Dyn. 2021, 5–20. [Google Scholar] [CrossRef]

- Fauriat, W.; Mattrand, C.; Gayton, N.; Bekou, A.; Cembrzynski, T. Estimation of road profile variability from measured vehicle responses. Veh. Syst. Dyn. 2016, 54, 585–605. [Google Scholar] [CrossRef]

- Kerst, S.; Shyrokau, B.; Holweg, E. Anti-lock braking control based on bearing load sensing. In Proceedings of the EuroBrake, Dresden, Germany, 4–6 May 2015; pp. 4–6. [Google Scholar]

- Vantsevich, V.V.; Shyrokau, B.N. Autonomously operated power-dividing unit for driveline modeling and AWD vehicle dynamics control. Dyn. Syst. Control Conf. 2008, 43352, 891–898. [Google Scholar] [CrossRef]

- Bitelli, G.; Simone, A.; Girardi, F.; Lantieri, C. Laser Scanning on Road Pavements: A New Approach for Characterizing Surface Texture. Sensors 2012, 12, 9110–9128. [Google Scholar] [CrossRef] [PubMed]

- ISO 13473-2: 2002. Characterisation of Pavement Texture by Use of Surface Profiles–Part 2: Terminology and Basic Requirements Related to Pavement Texture Profile Analysis; International Standardization Organization: Geneva, Switzerland, 2002. [Google Scholar]

- Walker, D.; Entine, L.; Kummer, S. Pavement Surface Evaluation and Rating (PASER) Manual; Wisconsin Transportation Information Center, University of Wisconsin-Madison: Madison, WI, USA, 2002. [Google Scholar]

- Kropáč, O.; Múčka, P. Deterioration Model of Longitudinal Road Unevenness Based on its Power Spectral Density Indices. Road Mater. Pavement Des. 2008, 9, 389–420. [Google Scholar] [CrossRef]

- Taberlet, N.; Morris, S.W.; McElwaine, J.N. Washboard Road: The dynamics of granular ripples formed by rolling wheels. Phys. Rev. Lett. 2007, 99, 068003. [Google Scholar] [CrossRef] [Green Version]

- Both, J.A.; Hong, D.C.; Kurtze, D.A. Corrugation of roads. Phys. A Stat. Mech. Appl. 2001, 301, 545–559. [Google Scholar] [CrossRef] [Green Version]

- Mahgoub, H.; Bennett, C.; Selim, A. Analysis of factors causing corrugation of gravel roads. Transp. Res. Rec. 2011, 2204, 3–10. [Google Scholar] [CrossRef]

- Edvardsson, K.; Magnusson, R. Monitoring of dust emission on gravel roads: Development of a mobile methodology and examination of horizontal diffusion. Atmos. Environ. 2009, 43, 889–896. [Google Scholar] [CrossRef]

- Zhu, D.; Gillies, J.A.; Etyemezian, V.; Nikolich, G.; Shaw, W.J. Evaluation of the surface roughness effect on suspended particle deposition near unpaved roads. Atmos. Environ. 2015, 122, 541–551. [Google Scholar] [CrossRef]

- McClelland, D.E.; Foltz, R.B.; Falter, M.C.; Wilson, W.D.; Cundy, T.; Schuster, R.L.; Saurbier, J.; Rabe, C.; Heinemann, R. Relative Effects on a Low-Volume Road System of Landslides Resulting from Episodic Storms in Northern Idaho. Transp. Res. Rec. Transp. Res. Board 1999, 1652, 235–243. [Google Scholar] [CrossRef]

- Uys, P.E.; Els, P.S.; Thoresson, M. Suspension settings for optimal ride comfort of off-road vehicles travelling on roads with different roughness and speeds. J. Terramech. 2007, 44, 163–175. [Google Scholar] [CrossRef] [Green Version]

- Scholtz, O.; Els, P.S. Tyre rubber friction on a rough road. J. Terramech. 2021, 93, 41–50. [Google Scholar] [CrossRef]

- Farrahi, G.H.; Ahmadi, A.; Kasyzadeh, K.R. Simulation of vehicle body spot weld failures due to fatigue by considering road roughness and vehicle velocity. Simul. Model. Pract. Theory 2020, 105, 102168. [Google Scholar] [CrossRef]

- Raslavičius, L.; Pakalnis, A.; Keršys, A.; Skvireckas, R.; Juodvalkis, D. Investigation of asphalt texture roughness on friction evolution for wheeled vehicles. Transport 2016, 31, 133–141. [Google Scholar] [CrossRef] [Green Version]

- Van Zyl, G. Blading optimisation Reverting from Theory to Practice. Transp. Res. Rec. 2011, 2204, 11–20. [Google Scholar] [CrossRef]

- Žilionienė, D.; Čygas, D.; Juzėnas, A.A.; Jurgaitis, A. Improvement of functional designation of low-volume roads by dust abatement in Lithuania. Transp. Res. Rec. Transp. Res. Board 2007, 1989, 293–298. [Google Scholar] [CrossRef]

- Jurkevičius, M.; Puodžiukas, V.; Laurinavičius, L. Implementation of Road Performance Calculation Models Used in Strategic Planning Systems for Lithuania Conditions. Balt. J. Road Bridge Eng. 2020, 15, 146–165. [Google Scholar] [CrossRef]

- Archondo-Callao, R. HDM-4 Road User Cost Model Documentation; Version 1.20; User’s Guide; The World Bank: Washington, DC, USA, 2009. [Google Scholar]

- Yunusov, A.; Eshkabilov, S.; Riskaliev, D.; Abdukarimov, N. Estimation and evaluation of road roughness via different tools and methods. In Proceedings of the Transport Problems 2019, XI International Scientific Conference, Silesian University of Technology Faculty of Transport, Silesia, Poland, 26–28 June 2019; pp. 770–784. [Google Scholar]

- Tomiyama, K.; Kawamura, A. Application of lifting wavelet transform for pavement surface monitoring by use of a mobile profilometer. Int. J. Pavement Res. Technol. 2016, 9, 345–353. [Google Scholar] [CrossRef] [Green Version]

- Sayers, M.W.; Karamihas, S.M. The Little Book of Profiling; University of Michigan: Ann Arbor, MI, USA, 1998. [Google Scholar]

- Rajkamal, K.; Reddy, T.D.; Rohith, D.; Chowdary, V.; Prasad, C.S.R.K. Performance Evaluation of Gravel Road Sections Sealed with Surface Dressing. Transp. Res. Proc. 2019, 17, 81–89. [Google Scholar] [CrossRef]

- Abulizi, N.; Kawamura, A.; Tomiyama, K.; Fujita, S. Measuring and evaluating of road roughness conditions with a compact road profiler and ArcGIS. J. Traffic Transp. Eng. 2016, 3, 398–411. [Google Scholar] [CrossRef] [Green Version]

- Bidgoli, A.M.; Galroo, A.; Nadjar, H.S.; Rashidabad, A.G.; Ganji, M.R. Road Roughness measurement using a cost-effective sensor-based monitoring system. Autom Constr. 2019, 104, 140–152. [Google Scholar] [CrossRef]

- Du, Y.; Liu, C.; Wu, D.; Jiang, S. Measurement of International Roughness Index by Using 𝑍-Axis Accelerometers and GPS, Hindawi Publishing Corporation. Math. Probl. Eng. 2014, 2014, 928980. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eshkabilov, S.; Yunusov, A. Measuring and Assessing Road Profile by Employing Accelerometers and IRI Assessment Tools. Am. J. Traffic Transp. Eng. 2018, 3, 24–40. [Google Scholar] [CrossRef] [Green Version]

- Leitner, B.; Decký, M.; Kováč, M. Road pavement longitudinal evenness quantification as stationary stochastic process. Transport 2019, 34, 195–203. [Google Scholar] [CrossRef] [Green Version]

- Pawar, P.R.; Mathew, A.T.; Saraf, M.R. IRI (International Roughness Index): An Indicator of Vehicle Response. Mater. Today Proc. 2018, 5, 11738–11750. [Google Scholar] [CrossRef]

- Žuraulis, V.; Levulytė, L.; Sokolovskij, E. The impact of road roughness on the duration of contact between a vehicle wheel and road surface. Transport 2014, 29, 431–439. [Google Scholar] [CrossRef] [Green Version]

- Shtayat, A.; Moridpour, S.; Best, B.; Shroff, A.; Raol, D. A review of monitoring systems of pavement condition in paved and unpaved roads. J. Traffic Transp. Eng. 2020, 7, 629–638. [Google Scholar] [CrossRef]

- Becker, C.M.; Els, P.S. Profiling of rough terrain. Int. J. Veh. Des. 2014, 64, 240–261. [Google Scholar] [CrossRef]

- Souza, V.M.A. Asphalt pavement classification using smartphone accelerometer and Complexity Invariant Distance. Eng. Appl. Artif. Intell. 2018, 74, 198–211. [Google Scholar] [CrossRef]

- Botha, T.R.; Els, P.S. Rough terrain profiling using digital image correlation. J. Terramech. 2015, 59, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Kerst, S.; Shyrokau, B.; Holweg, E. Reconstruction of wheel forces using an intelligent bearing. SAE Int. J. Passeng. Cars Electron. Electr. Syst. 2016, 9, 196–203. [Google Scholar] [CrossRef]

- Kerst, S.; Shyrokau, B.; Holweg, E. A Model-based approach for the estimation of bearing forces and moments using outer ring deformation. IEEE Trans. Ind. Electron. 2019, 67, 461–470. [Google Scholar] [CrossRef]

- Múčka, P. Current approaches to quantify the longitudinal road roughness. Int. J. Pavement Eng. 2016, 17, 659–679. [Google Scholar] [CrossRef]

- Loprencipe, G.; Zoccali, P. Ride Quality Doe to Road Surface Irregularities: Comparison of Different Methods Applied on a Set of Real Road Profiles. Coatings 2017, 7, 59. [Google Scholar] [CrossRef] [Green Version]

- ISO 2631-1: 1997. Mechanical Vibration and Shock—Evaluation of Human Response to Whole-Body Vibration. Part I: General Requirements; International Standardization Organization: Geneva, Switzerland, 1997. [Google Scholar]

- Gurmail, L.; Kiss, P. A comparative study of destructive effects resulting from road profile acting on off-road towed vehicles. J. Terramech. 2019, 81, 57–65. [Google Scholar] [CrossRef]

- Kropáč, O.; Múčka, P. Be careful when using the International Roughness Index as an indicator of road unevenness. J. Sound Vib. 2005, 287, 989–1003. [Google Scholar] [CrossRef]

- Fichera, G.; Scionti, M.; Garescì, F. Experimental correlation between the road roughness and the comfort perceived in bus cabins. SAE Tech. Pap. 2007, 116, 39–49. [Google Scholar] [CrossRef]

- Sayers, M.W.; Gillespie, T.D.; Queiroz, C.A.V. International Road Roughness Experiment: Establishing Correlation and a Calibration Standard for Measurements; Technical Report, World Bank Technical Paper 1986, No. WTP 45; World Bank Group: Washington, DC, USA.

- Gillespie, T.D.; Paterson, W.D.O.; Sayers, M.W. Guidelines for Conducting and Calibrating Road Roughness Measurements; World Bank Technical Paper 1986, No. WTP 46; World Bank Group: Washington, DC, USA. (In English)

- Sidess, A.; Ravina, A.; Oged, E. A model for predicting the deterioration of the international roughness index. Int. J. Pavement Eng. 2020. [Google Scholar] [CrossRef]

- Pérez-Acebo, H.; Gonzalo-Orden, H.; Findley, D.J.; Rojí, E. Modeling the international roughness index performance on semi-rigid pavements in single carriageway roads. Constr. Build. Mater. 2021, 272, 121665. [Google Scholar] [CrossRef]

- Yamany, M.S.; Abraham, D.M. Hybrid approach to incorporate preventive maintenance effectiveness into probabilistic pavement performance models. J. Transp. Eng. Part. B Pavements 2021, 147, 04020077. [Google Scholar] [CrossRef]

- Yamany, M.S.; Abraham, D.M.; Labi, S. Comparative analysis of Markovian methodologies for modeling infrastructure system performance. J. Infrastruct. Syst. 2021, 27, 04021003. [Google Scholar] [CrossRef]

- Mirtabar, Z.; Golroo, A.; Mahmoudzadeh, A.; Barazandeh, F. Development of a crowdsourcing-based system for computing the international roughness index. Int. J. Pavement Eng. 2020. [Google Scholar] [CrossRef]

- Pérez-Acebo, H.; Mindra, N.; Railean, A.; Rojí, E. Rigid pavement performance models by means of Markov Chains with half-year step time. Int. J. Pavement Eng. 2019, 20, 830–843. [Google Scholar] [CrossRef]

- Obunguta, F.; Matsushima, K. Optimal pavement management strategy development with a stochastic model and its practical application to Ugandan national roads. Int. J. Pavement Eng. 2020, 1–15. [Google Scholar] [CrossRef]

- ISO 8608: 2016. Mechanical Vibrations—Road Surface Profiles—Reported of Measured Data; International Standardization Organization: Geneva, Switzerland, 2016. [Google Scholar]

- Goenaga, B.; Fuentes, L.; Mora, O. Evaluation of the methodologies used to generate random pavement profiles based on the power spectral density: An approach based on the International Roughness Index. Ing. E Investig. 2017, 37, 49–57. [Google Scholar] [CrossRef] [Green Version]

- Múčka, P. Road waviness and the dynamic tyre force. Int. J. Veh. Des. 2004, 36, 216–232. [Google Scholar] [CrossRef]

- Els, P.S.; Theron, N.J.; Uys, P.E.; Thoresson, M.J. The ride comfort vs. handling compromise for off-road vehicles. J. Terramech. 2007, 44, 303–317. [Google Scholar] [CrossRef] [Green Version]

- Ngwangwa, H.M.; Heyns, P.S.; Breytenbach, H.G.A.; Els, S. Reconstruction of road defects and road roughness classification using Artificial Neural Networks simulation and vehicle dynamic responses: Application to experimental data. J. Terramech. 2014, 53, 1–18. [Google Scholar] [CrossRef] [Green Version]

- ISO/TS 13473-4: 2008. Characterisation of Pavement Texture by Use of Surface Profiles—Part 4: Spectral Analysis of Surface Profiles; Technical Specification; International Standardization Organization: Geneva, Switzerland, 2008. [Google Scholar]

- Múčka, P.; Stein, G.J.; Tobolka, P. Whole-body vibration and vertical road profile displacement power spectral density. Veh. Syst. Dyn. 2020, 58, 630–656. [Google Scholar] [CrossRef]

- Rill, G. Road Vehicle Dynamics: Fundamentals and Modeling; CRC Press LLC: New York, NY, USA, 2020. [Google Scholar]

- Tyan, F.; Hong, Y.F.; Tu, S.H.; Jeng, W.S. Generation of random road profiles. J. Adv. Eng. 2009, 4, 373–1378. [Google Scholar]

- Reza-Kashyzadeh, R.; Ostad-Ahmad-Ghorabi, M.J.; Arghavan, A. Investigating the effect of road roughness on automotive component. Eng. Fail. Anal. 2014, 41, 96–107. [Google Scholar] [CrossRef]

- Sayers, M.W. On the calculation of international roughness index from longitudinal road profile. Transp. Res. Rec 1995, 1501, 1–12. [Google Scholar]

- ASTM E1926-98. Standard Practice for Computing International Roughness Index for Roads from Longitudinal Profile Measurement; ASTM E 1926–98 ASTM International: West Conshohocken, PA, USA, 1998. [Google Scholar] [CrossRef]

- Cebon, D. Handbook of Vehicle-Road Interaction; CRC Press: Lisse, The Netherlands, 1999. [Google Scholar]

- Múčka, P. Simulated Road Profiles According to ISO 8608 in Vibration Analysis. J. Test. Eval. 2018, 46, 405–418. [Google Scholar] [CrossRef]

- Buhari, R.; Rohani, M.M.; Abdullah, M.E. Dynamic Load Coefficient of Tyre Forces from Truck Axles. Appl. Mech. Mater. 2013, 405–408, 1900–1911. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Falchetto, A.C.; Goeke, M.; Wang, W.; Li, T.; Wistuba, M.P. Influence of computation algorithm on the accuracy of rut depth measurement. J. Traffic Transp. Eng. 2017, 4, 156–164. [Google Scholar] [CrossRef]

- Lakušić, S.; Brčić, D.; Tkalčević Lakušić, V. Analysis of Vehicle Vibrations—New Approach to Rating Pavement Condition of Urban Roads. Promet Traffic Transp. 2012, 23, 485–494. [Google Scholar] [CrossRef] [Green Version]

- Seimas, L.R. Dėl Lietuvos Respublikos Vyriausybės 2002 m. Gruodžio 11 d. Nutarimo Nr. 1950 „Dėl Kelių Eismo Taisyklių Patvirtinimo“ Pakeitimo. Available online: https://e-seimas.lrs.lt/portal/legalAct/lt/TAD/2a948a80506e11e485f39f55fd139d01 (accessed on 6 August 2021).

- Múčka, P. Road Roughness Limit Values Based on Measured Vehicle Vibration. J. Infrastruct. Syst. 2016, 23, 04016029. [Google Scholar] [CrossRef]

- Múčka, P. Proposal of Road Unevenness Classification Based on Road Elevation Spectrum Parameters. J. Test. Eval. 2016, 44, 930–944. [Google Scholar] [CrossRef]

- Xu, Y.; Ahmadian, M. Improving the capacity of tire normal force via variable stiffness and damping suspension system. J. Terramech. 2013, 50, 121–132. [Google Scholar] [CrossRef]

| Pavement State | IRI, m/km | Velocity RMS, m/s | |

|---|---|---|---|

| SM | USM | ||

| PS-1 | 6.33 | 0.0283 | 0.1821 |

| PS-2 | 7.28 | 0.0313 | 0.2303 |

| PS-3 | 5.51 | 0.0378 | 0.1530 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Žuraulis, V.; Sivilevičius, H.; Šabanovič, E.; Ivanov, V.; Skrickij, V. Variability of Gravel Pavement Roughness: An Analysis of the Impact on Vehicle Dynamic Response and Driving Comfort. Appl. Sci. 2021, 11, 7582. https://doi.org/10.3390/app11167582

Žuraulis V, Sivilevičius H, Šabanovič E, Ivanov V, Skrickij V. Variability of Gravel Pavement Roughness: An Analysis of the Impact on Vehicle Dynamic Response and Driving Comfort. Applied Sciences. 2021; 11(16):7582. https://doi.org/10.3390/app11167582

Chicago/Turabian StyleŽuraulis, Vidas, Henrikas Sivilevičius, Eldar Šabanovič, Valentin Ivanov, and Viktor Skrickij. 2021. "Variability of Gravel Pavement Roughness: An Analysis of the Impact on Vehicle Dynamic Response and Driving Comfort" Applied Sciences 11, no. 16: 7582. https://doi.org/10.3390/app11167582