Determination of the Loading of a Flat Rack Container during Operating Modes

Abstract

1. Introduction

2. Analysis of Literature Data and Problem Statement

3. The Purpose and Tasks of the Research

- to suggest measures for improving the bearing structure of a container;

- to determine the dynamic loading of a container in the vertical plane;

- to determine the dynamic loading of a container in the longitudinal plane; and

- to determine the strength characteristics of the bearing structure of a flat car.

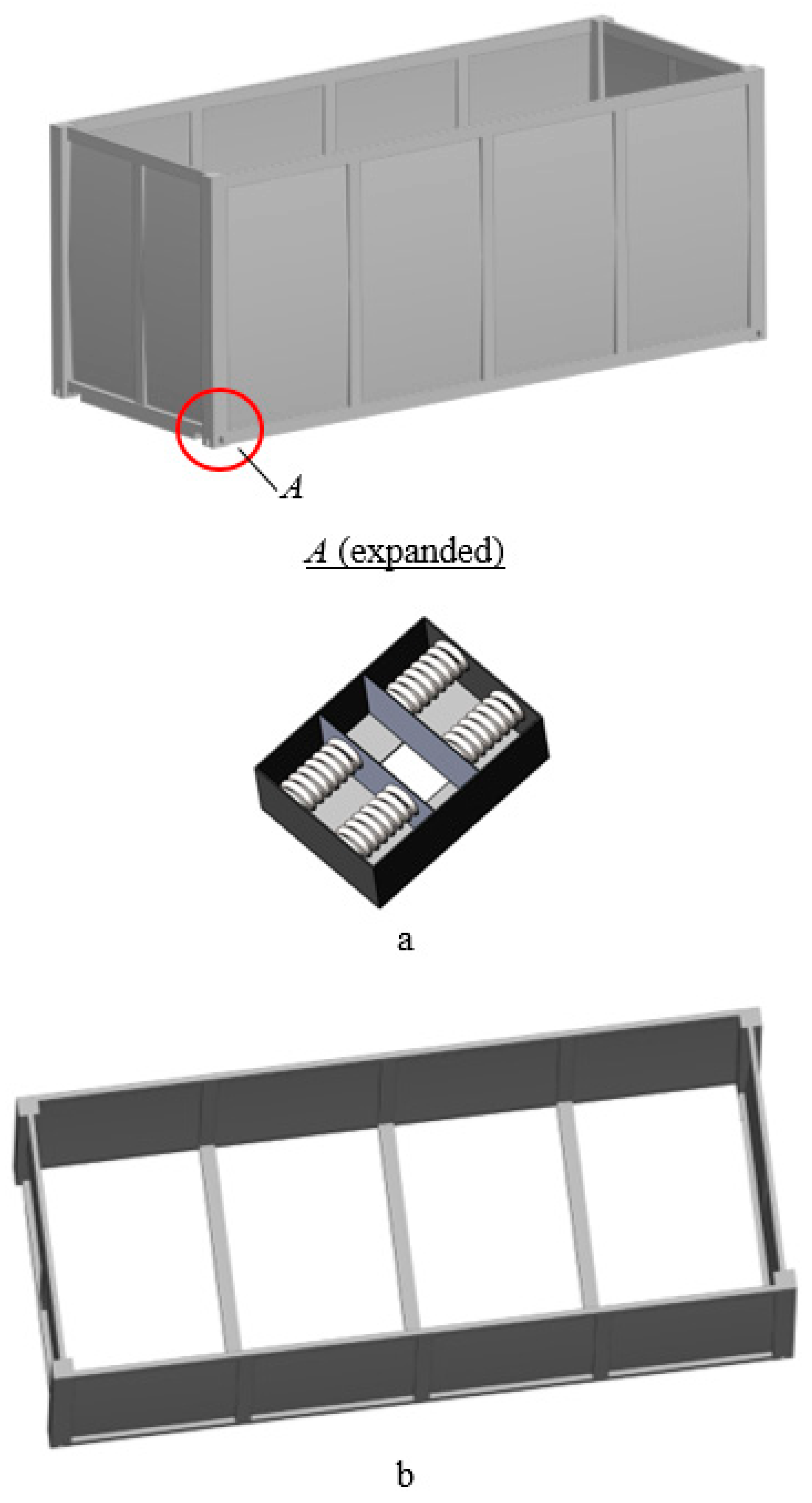

4. Improvements in the Bearing Structure of a Container

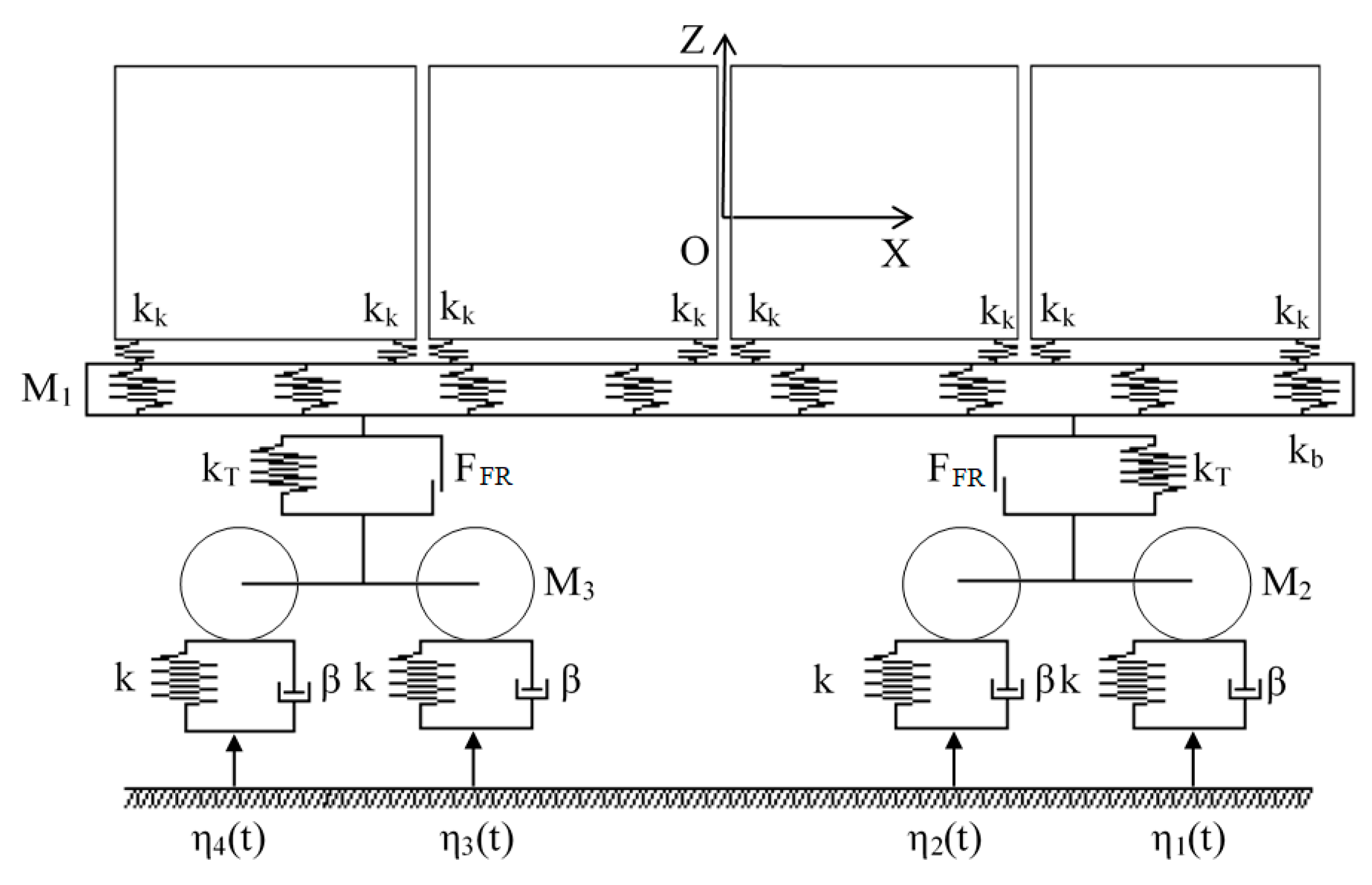

5. Determination of the Dynamic Loading of a Container in the Vertical Plane

6. Determination of the Dynamic Loading of a Container in the Longitudinal Plane

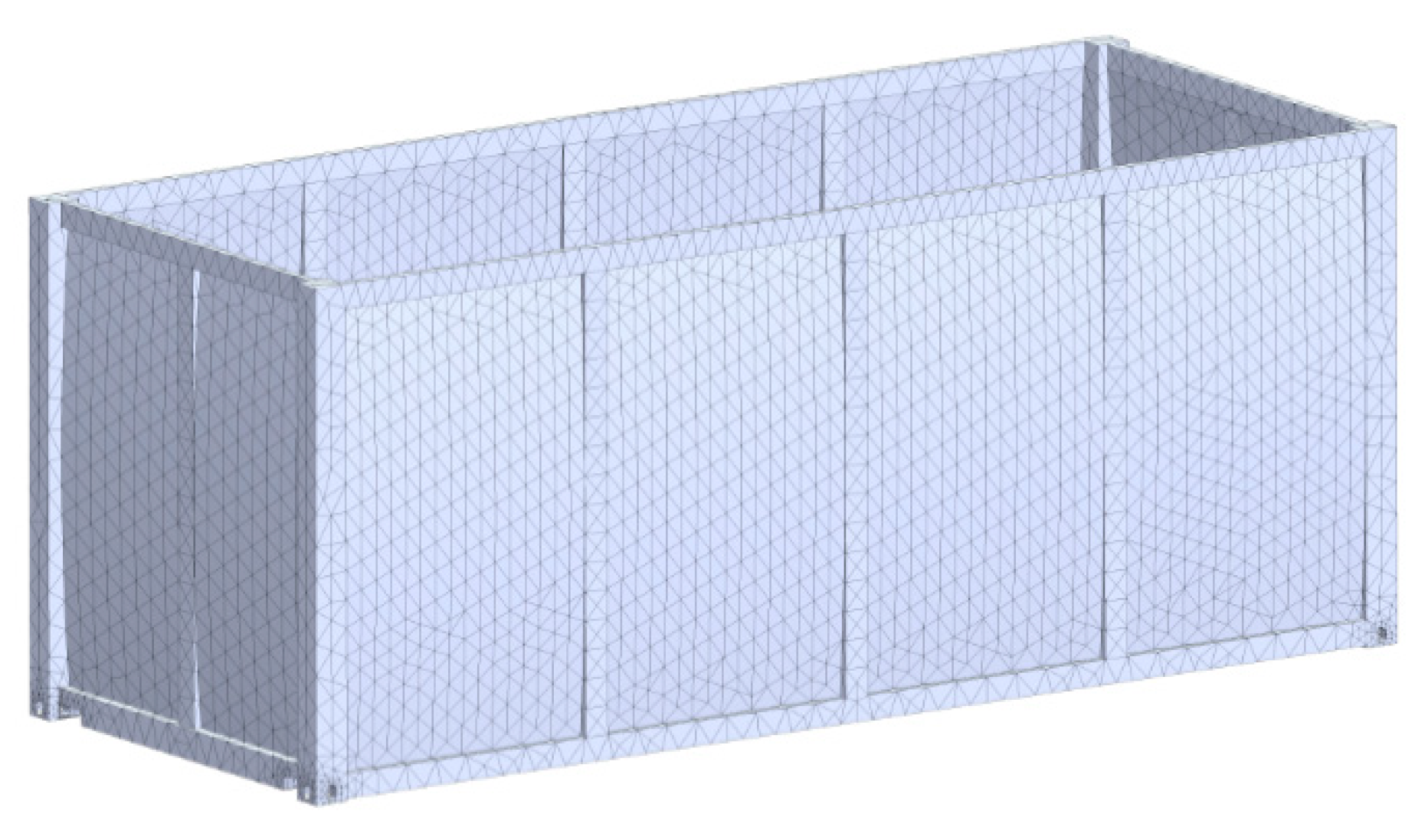

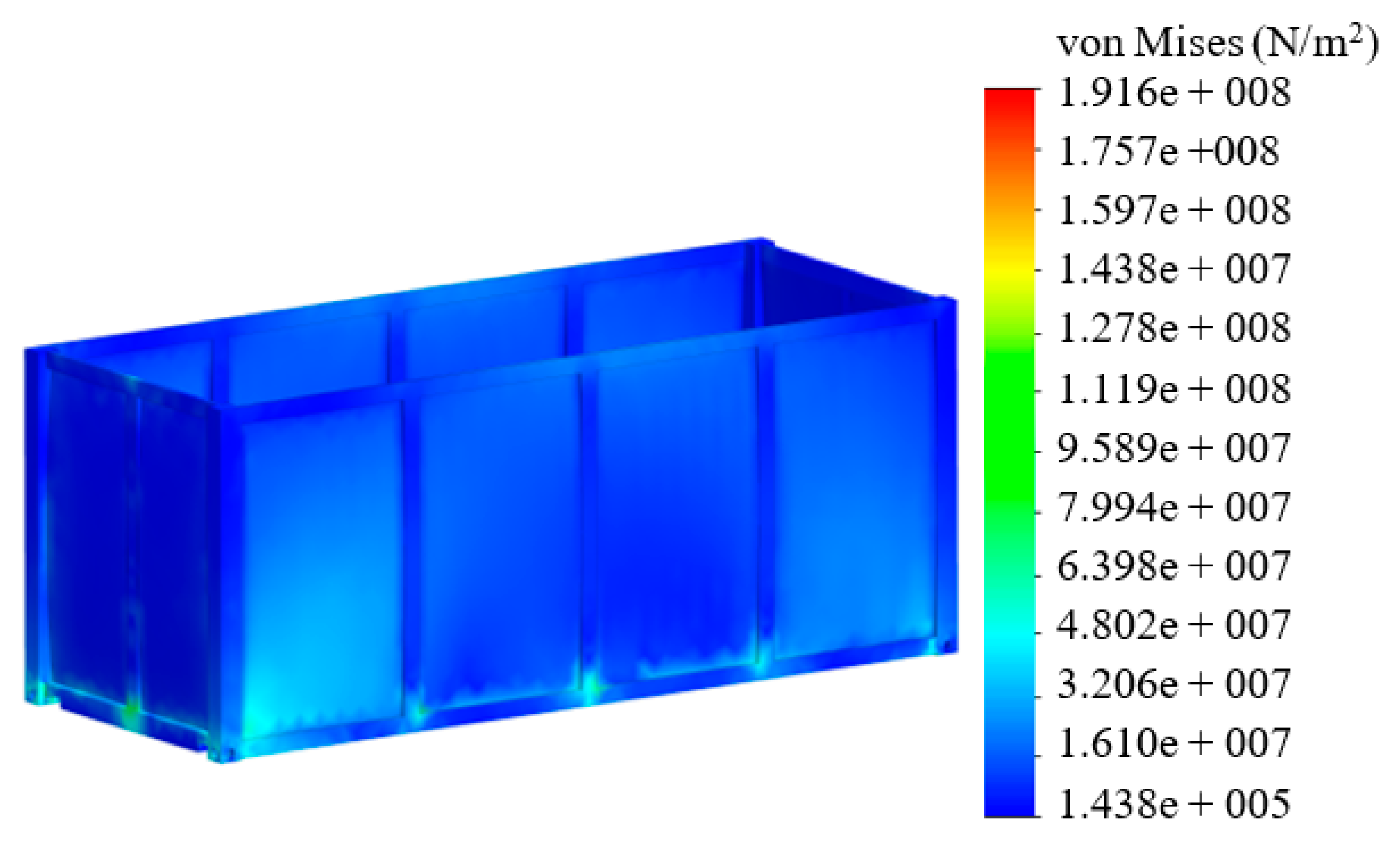

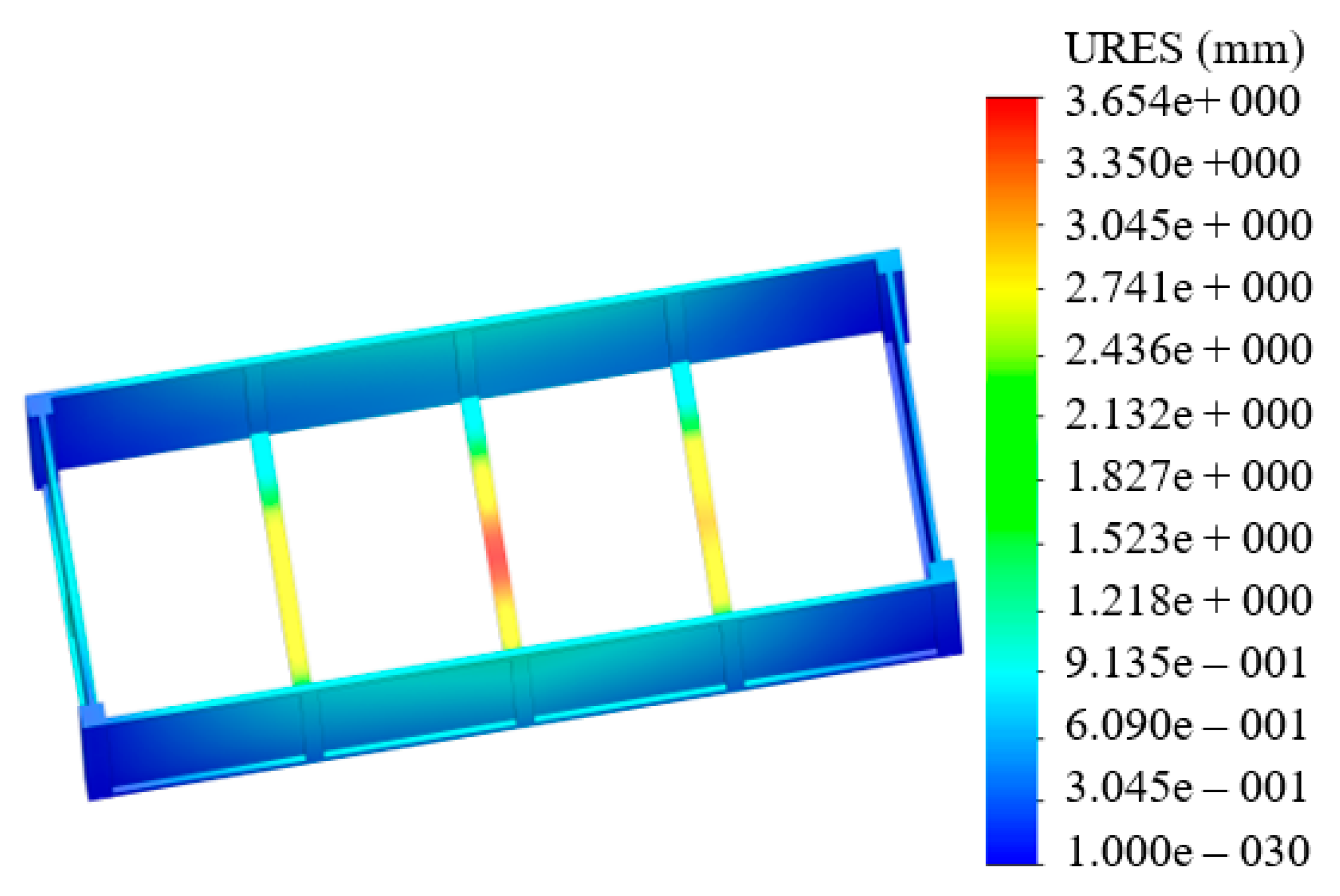

7. Determination of the Strength Characteristics of the Bearing Structure of a Container

8. Discussion of the Loading Values of a Container Obtained during Operating Modes

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Šťastniak, P.; Kurčík, P.; Pavlík, A. Design of a new railway wagon for intermodal transport with the adaptable loading platform. MATEC Web Conf. 2018, 235, 00030. [Google Scholar] [CrossRef][Green Version]

- Dižo, J.; Steišunas, S.; Blatnický, M. Simulation analysis of the effects of a rail vehicle running with wheel flat. Manuf. Technol. 2016, 16, 889–896. [Google Scholar] [CrossRef]

- Fomin, O.; Kulbovskiy, I.; Sorochinska, E.; Sapronova, S.; Bambura, O. Experimental confirmation of the theory of implementation of the coupled design of center girder of the hopper wagons for iron ore pellets. Eastern-Eur. J. Enterp. Technol. 2017, 5/1, 11–19. [Google Scholar] [CrossRef][Green Version]

- Boronenko, Y.P.; Dauksha, A.S. The prospects of railroad cars with increased carrying swap bodies implementation. Proc. Petersburg Transp. Univ. 2017, 3, 437–451. (In Russian) [Google Scholar]

- Boronenko, Y.P.; Dauksha, A.S. The prospects of railroad cars with increased carrying swap bodies implementation. Transp. Russ. Federation. J. Sci. Pract. Econ. 2017, 3, 29–32. (In Russian) [Google Scholar]

- Chuanjin, O.U.; Bingtao, L.I. Research and application of new multimodal transport equipment-swap bodies in China. E3S WebofConferences 2020, 145, 02001. [Google Scholar] [CrossRef]

- Rzeczycki, A.; Wisnicki, B. Strength analysis of shipping container floor with gooseneck tunnel under heavy cargo load. Solid State Phenom. 2016, 252, 81–90. [Google Scholar] [CrossRef]

- Berescu, C.; Fratila, C.; Axinte, T.; Diaconu, M.; Cojocaru, R. The mechanism’s study of fixing a container on a freight wagon type Rgs. IOP Conf. Ser. Mater. Sci. Eng. 2020, 916, 012010. [Google Scholar] [CrossRef]

- Lovska, A.; Fomin, O.; Píštěk, V.; Kučera, P. Dynamic load modelling with in combined transport trains during transportationon a railway ferry. Appl. Sci. 2020, 10, 5710. [Google Scholar] [CrossRef]

- Fomin, O.; Lovska, A.; Píštek, V.; Kucera, P. Dynamic load effect on the transportation safety of tank containers as part of combined trains on railway ferries. Vibroeng. Procedia 2019, 29, 124–129. [Google Scholar] [CrossRef]

- Lovska, A.; Fomin, O. A new fastener to ensure the reliability of a passenger coach car body on a railway ferry. Acta Polytech. 2020, 60, 478–485. [Google Scholar] [CrossRef]

- Mishuta, D.V. Simplified methods for measuring the stress-strain state of a container body of variable volume. Instrum. Methods Meas. 2012, 2, 100–103. (In Russian) [Google Scholar]

- Mishuta, D.V.; Algin, V.B.; Mikhailov, V.G. Assessment of the stress-strain state of a container body of variable volume. Bull. Belarusian-Russ. Univ. 2012, 4, 61–68. (In Russian) [Google Scholar]

- Eremin, V.; Semennikova, L. Investigation of the stress-strain state of a container body using the AWM WinMachine software package. CAD Graph. 2004, 7, 23–28. (In Russian) [Google Scholar]

- Ibragimov, N.N.; Rakhimov, R.V.; Khadzhimukhamedova, M.A. Development of a container design for transportation of fruits and vegetables. Young Sci. 2015, 21, 168–173. (In Russian) [Google Scholar]

- Bogomaz, G.I.; Mekhov, D.D.; Pilipchenko, O.P.; Chernomashentseva, Y.G. Loading of tank containers located on a railway flat wagon when impact into an automatic coupler. Dyn. Control Motion Mech. Syst. 1992, 1, 87–95. (In Russian) [Google Scholar]

- DSTU 7598:2014. Freight Wagons. General Requirements for Calculations and Design of New and Modernized Wagons of 1520 mm Track (Non-Self-Propelled); UkrNDNTS: Kiev, Ukraine, 2015; 162p. (In Ukrainian) [Google Scholar]

- GOST 33211-2014. Freight Wagons. Requirements for Strength and Dynamic Properties; FGUP “STANDARTINFORM”: Moskow, Russia, 2016; 54p. (In Russian) [Google Scholar]

- Tiernan, S.; Fahy, M. Dynamic fea modelling of iso tank containers. J. Mater. Process. Technol. 2002, 124, 126–132. [Google Scholar] [CrossRef]

- Makeiev, S.V.; Builenkov, P.M. Features of Calculating the Stress-Strain State of a Tank-Container Taking into Account the Actual Loading in Operation. SCIENCE-EDUCATION-PRODUCTION: Experience and Development Prospects: A Collection of Materials from the XIV International Scientific and Technical Conference Dedicated to the Memory of Doctor of Technical Sciences; Zudov, E.G., Ed.; Gorgo-Metallurgical Production. Mechanical Engineering and Metalworking; NTI (Branch) UrFU: Nizhny Tagil, Russia, 2018; Volume 1, pp. 174–184. [Google Scholar]

- Martin, S.; Martin, J.; Lai, P. International container design regulations and ISO standards: Are they fit for purpose? Marit. Policy Manag. 2018. [Google Scholar] [CrossRef]

- Kardas-Cinal, E. Selected problems in railway vehicle dynamics related to running safety. Arch. Transp. 2014, 31, 37–45. [Google Scholar] [CrossRef]

- Yildiz, T. Design and Analysis of a Lightweight Composite Shipping Container Made of Carbon Fiber Laminates. Logistics 2019, 3, 18. [Google Scholar] [CrossRef]

- Andriankaja, H.; Vallet, F.; Le Duigou, J.; Eynard, B. A method to ecodesign structural parts in the transport sector based on product life cycle management. J. Clean. Prod. 2015, 94, 165–176. [Google Scholar] [CrossRef]

- Acanfora, M.; Montewka, J.; Hinz, T.; Matusiak, J. On the estimation of the design loads on container stacks due to excessive acceleration in adverse weather conditions. Mar. Struct. 2017, 53, 105–123. [Google Scholar] [CrossRef]

- Panasenko, N.N.; Yakovlev, P.V. Design of containers for sea transportation of long pipes. Bull. Astrakhan State Tech. Univ. Ser. Mar. Eng. Technol. 2014, 3, 97–107. (In Russian) [Google Scholar]

- Nikitchenko, A.; Artiukh, V.; Shevchenko, D.; Prakash, R. Evaluation of Interaction Between Flat Car and Container at Dynamic Coupling of Flat Cars. MATEC Web Conf. 2016, 73, 04008. [Google Scholar] [CrossRef]

- Fomin, O.; Lovska, A. Establishing patterns in determining the dynamics and strength of a covered freight car, which exhausted its resource. East. Eur. J. Enterp. Technol. 2020, 6, 21–29. [Google Scholar]

- Fomin, O. Modern requirements to carrying systems of railway general-purpose gondola cars. Sci. Tech. J. Metall. Min. Ind. 2014, 5, 31–43. [Google Scholar]

- Goolak, S.; Gubarevych, O.; Yermolenko, E.; Slobodyanyuk, M.; Gorobchenko, O. Mathematical Modeling of an Induction Motor for Vehicles. East. Eur. J. Enterp. Technol. 2020, 2, 25–34. [Google Scholar] [CrossRef]

- Dyomin, Y.V.; Chernyak, G.Y. Fundamentals of Car Dynamics; QUETT: Kyiv, Ukraine, 2019. (In Ukrainian) [Google Scholar]

- Kiryanov, D.V. Mathcad 13; BHV. Petersburg: Saint Petersburg, Russia, 2006. (In Russian) [Google Scholar]

- Dyakonov, V. MATHCAD 8/2000: A Special Reference Book; Piter: Saint Petersburg, Russia, 2000. (In Russian) [Google Scholar]

- Lovska, A. Simulation of Loads on the Carrying Structure of an Articulated Flat Car in Combined Transportation. Int. J. Eng. Technol. 2018, 7, 140–146. [Google Scholar] [CrossRef]

- Kondratiev, A.; Gaidachuk, V.; Nabokina, T.; Tsaritsynskyi, A. New possibilities in creating of effective composite size-stable honeycomb structures designed for space purposes. Adv. Intell. Syst. Comput. 2020, 1113, 45–59. [Google Scholar]

- Kelrykh, M.; Fomin, O. Perspective directions of planning carrying systems of gondolas. Metall. Min. Ind. 2014, 6, 64–67. [Google Scholar]

- Lovska, A.A. Peculiarities of computer modeling of strength of body bearing construction of gondola car during transportation by ferry-bridge. Metall. Min. Ind. 2015, 1, 49–54. [Google Scholar]

- Kuric, I.; Gorobchenko, O.; Litikova, O.; Gritsuk, I.; Mateichyk, V.; Bulgakov, M.; Klackova, I. Research of vehicle control informative functioning capacity. Pap. Presented IOP Conf. Ser. Mater. Sci. Eng. 2020, 776, 012036. [Google Scholar] [CrossRef]

- Alyamovsky, A.A. SolidWorks/COSMOSWorks 2006–2007. In Engineering Analysis by the Finite Element Method; DMK Press: Moscow, Russia, 2007. (In Russian) [Google Scholar]

- Alyamovsky, A.A. COSMOSWorks. In Fundamentals of Structural Strength Analysis in the SolidWorks Environment; DMK Press: Moscow, Russia, 2010. (In Russian) [Google Scholar]

- Vatulia, G.; Komagorova, S.; Pavliuchenkov, M. Optimization of the truss beam. Verification of the calculation results. MATEC Web Conf. 2018, 230, 02037. [Google Scholar] [CrossRef]

- Vatulia, G.L.; Lobiak, O.V.; Deryzemlia, S.V.; Verevicheva, M.A.; Orel, Y.F. Rationalization of cross-sections of the composite reinforced concrete span structure of bridges with a monolithic reinforced concrete roadway slab. IOP Conf. Ser. Mater. Sci. Eng. 2019, 664, 012014. [Google Scholar] [CrossRef]

- EN 12663–2. Railway Applications—Structural Requirements of Railway Vehicle Bodies—Part 2: Freight Wagons. B.; BDS: Sofia, Bulgaria, 2010; 54p. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fomin, O.; Gerlici, J.; Vatulia, G.; Lovska, A.; Kravchenko, K. Determination of the Loading of a Flat Rack Container during Operating Modes. Appl. Sci. 2021, 11, 7623. https://doi.org/10.3390/app11167623

Fomin O, Gerlici J, Vatulia G, Lovska A, Kravchenko K. Determination of the Loading of a Flat Rack Container during Operating Modes. Applied Sciences. 2021; 11(16):7623. https://doi.org/10.3390/app11167623

Chicago/Turabian StyleFomin, Oleksij, Juraj Gerlici, Glib Vatulia, Alyona Lovska, and Kateryna Kravchenko. 2021. "Determination of the Loading of a Flat Rack Container during Operating Modes" Applied Sciences 11, no. 16: 7623. https://doi.org/10.3390/app11167623

APA StyleFomin, O., Gerlici, J., Vatulia, G., Lovska, A., & Kravchenko, K. (2021). Determination of the Loading of a Flat Rack Container during Operating Modes. Applied Sciences, 11(16), 7623. https://doi.org/10.3390/app11167623