1. Introduction

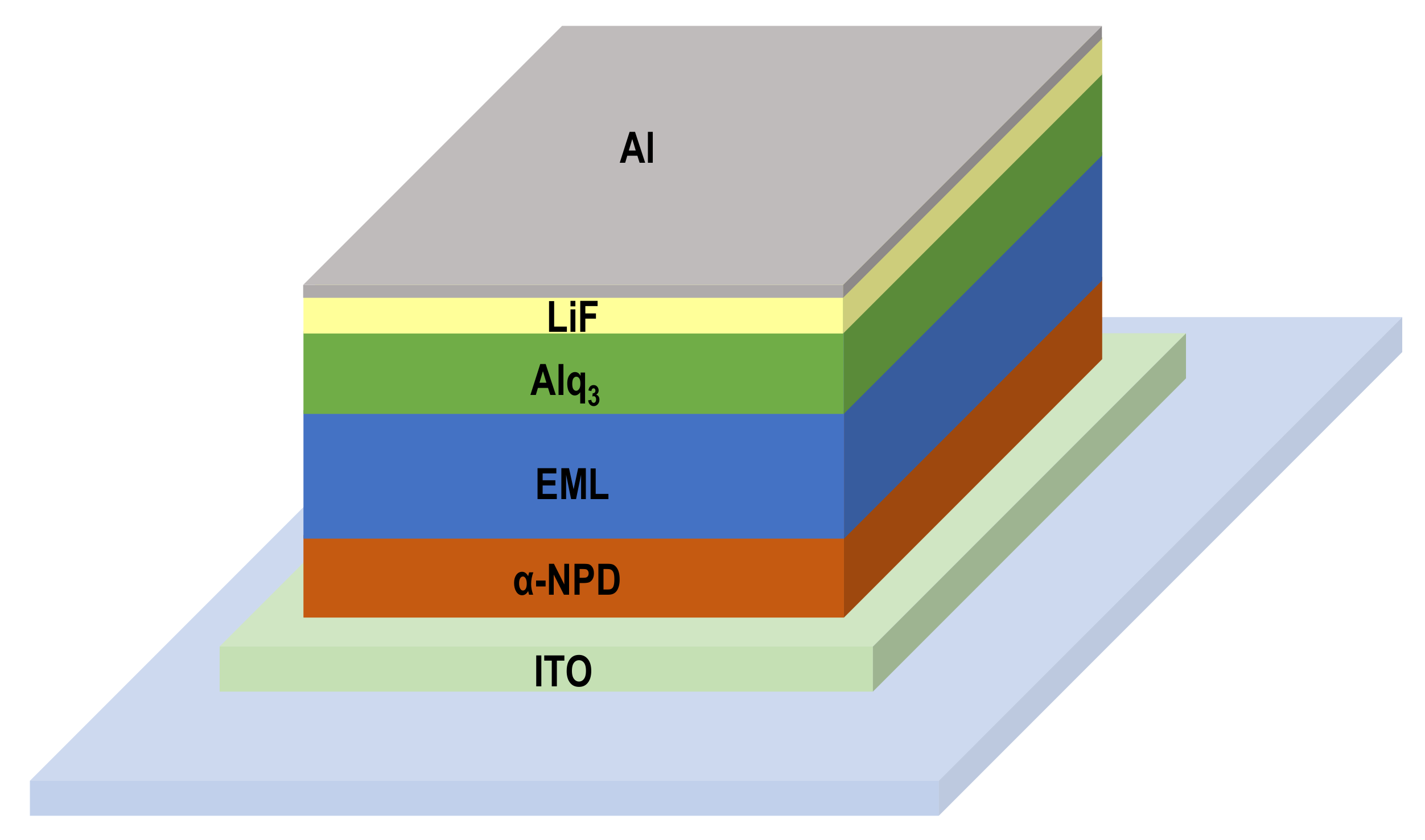

Since the development of multi-layer organic light-emitting diodes (OLEDs) in 1987 [

1], the device performance has been improved tremendously over the past decades. Owing to the merits of organic materials and improvements of their efficiencies, the application of OLEDs is widespread and anticipated to be expanded even further [

2,

3]. Despite the advantages compared with inorganic counterparts, however, the utilization of OLEDs is sometimes limited by their reliabilities. Especially, OLEDs are vulnerable to environments such as water vapor and oxygen [

4]. Hence, remedies to enhance the storage lifetime shortened by the external factors have been pursued intensely and a significant progress has been made [

5]. With the strict standards, the encapsulation of OLEDs has now become quite reliable for harsh environments. Thus, the degradation during the device operation requires more attention to improve the device reliability further.

In general, the monitoring of luminance reduction is used to evaluate how fast the device degrades [

6]. The degradation curve is empirically fitted with a stretched exponential decay function [

7]. The device lifetime, which is defined, for example, as the elapsed time when the luminance is decreased to the half of its initial value, follows the power law depending on the aging current [

6]. This method can be applied universally as there is no assumption involved for the test. However, physical foundation on the properties of the luminance decay is not considered sufficient. Moreover, the dominant cause of the device degradation cannot be determined from this empirical evaluation.

The chemical analyses to clarify the OLED degradations have also been used popularly [

8,

9]. These methods examine the chemical products after the acceleration test. By investigating the chemical products inside the device, one can guess a chemical reaction involved during the device operation. However, these analyses require destructive probings after which the device does not function any longer. Also, they take additional time as the OLED devices contain many different kinds of chemicals from the deposition of multi-layer structures.

Taken together, the methods described above can give a clue why the device has degraded. However, characterization and understanding of the performance degradation from the device point of view is necessary and beneficial in industry. The device analyses and modeling based on the physical mechanisms can give more insights into how the device degrades than the conventional chemical reaction or decomposition suggests. For this purpose, introducing quantitative factors from the electrical and optical properties of OLEDs [

10,

11] is essential in evaluating how the device degradation progresses. From the analyses, the direction for further enhancing the device performance can also be determined, which leads to save resources and time.

In this paper, we analyze the transient behavior of the OLED device characteristics under electrical stress, where both the current and luminance at a given voltage initially increase before the degradation occurs. The quantitative factors are used to characterize how the device behaves under electrical stress and a model that can explain this observation is presented.

3. Results and Discussion

In

Figure 2, the current density-voltage (

J-

V) curves of devices under electrical stress are shown. For the stress level of 2.5 ×

JD, the device characteristics seem to be almost unchanged during 168 h. On the other hand, the current variation under high current stress (15 ×

JD) increases at a fixed voltage, which shows the typical device degradation. More variation under higher stress level can also be found in the

L-

J curve depicted in

Figure 3. However, simple

L-

J-

V curves alone are not sufficient for analyzing the degradation phenomena in detail.

In

Figure 4, the current density at the operating voltage (

VD) for each experiment is selected and plotted as a function of operation time. Commonly, the variation in current density can be divided roughly into two regions. In case of the stress test at 2.5 ×

JD (

Figure 4a), the overall trend shows that the current density at

VD increases up to 96 h after an initial decrease in the current density at

VD (region 1). After 96 h, the device degradation of decreasing current density with the operation time is observed (region 2). The similar tendency is observed for the stress test at 15 ×

JD (

Figure 4b). Due to the higher stress condition, the device begins to degrade earlier (after 48 h) than the case shown in

Figure 4a. Although the intervals collecting the device degradation data are different for each experiment, the overall trends are clear. Furthermore, the reliability tests for 168 h seem to be sufficient for observing the degradation behaviors shown in

Figure 4.

To investigate the electrical properties further, the ideality factors,

nideal, defined as

are plotted as a function of operation time in

Figure 5. Here,

q is the elementary charge,

kB is the Boltzmann constant, and

T is the absolute temperature. As seen in

Figure 2, one can deduce that the overall shapes of

J-

V curves during the device operation are quite similar since

nideal is related to the slope of ln

J vs.

V curve.

Furthermore, the value and tendency of

nideal give clues about dominant carrier recombination and transport mechanisms [

12,

13]. At low current density (<10

−3 mA/cm

2), it is seen that

nideal is ~2, which indicates that the Shockley-Read-Hall (SRH) recombination inside the emissive layer (EML) is dominant in the device [

13]. In general, it is known that the mobility for the hole transport is much higher than that for the electron transport in organic semiconductors [

14]. Thus, the dominant recombination mechanism would be the SRH recombination by the electron capture in this region. As the current increases,

nideal is seen to increase due to the additional voltage drop caused by the series resistance in the layers outside the EML. From

nideal in the driving current region (indicated by a dotted line marked by

JD), the device resistance in

Figure 5a seems almost constant under electrical stress, as indicated by overlapping curves. However,

nideal at

JD for the higher current stress shown in

Figure 5a is slightly increased due to the effect of rapid device degradation.

For further analysis, the change in luminance at

JD as a function of operation time is shown in

Figure 6. In region 1, for the case of 2.5 ×

JD device operation, which is depicted in

Figure 6a, the overall luminance increases whereas the applied voltage decreases with respect to the operation time. After 96 h, the luminance is almost saturated. This trend in device degradation is more pronounced under higher electrical stress (

Figure 6b). The device efficiency is investigated next to identify why the luminance of the sample varies under electrical stress.

The external quantum efficiencies (EQE,

ηEQE) of the degrading devices under electrical stress are shown in

Figure 7. It is noted in

Figure 7 that there is little change in shape except the minute changes at very low current densities (~10

−2 mA/cm

2), which reflects the initial current variation before 24 h in

Figure 4. For the case of the stress test at 2.5 ×

JD (

Figure 7a), the EQE is almost the same during device operation up to 168 h, which shows the same tendencies as the current and luminance variation.

In order to investigate further, the EQE curves are shown in

Figure 8 after normalizing with respect to respective peaks. The reason why the normalized EQEs show this trend can be explained by considering the factors constituting the EQE. It is known that the EQE can be divided into the internal quantum efficiency (IQE,

ηIQE) and the outcoupling efficiency (

ηout) [

15]:

ηIQE is defined as the ratio of the number of generated photons per unit time inside the EML to the number of injected electrons per unit time.

ηout indicates a fraction of photons escaping from the EML to free space. In general,

ηout can be predominantly affected by the device structure. Many researchers have attempted to increase

ηout by modifying the layer structure with such things as the layer grating, the microlens array, and the inserted scattering particles [

16]. Since the device structure was not changed during the operation in this case, the variation of the efficiency curve is not attributable to

ηout.

The analysis above implies that the variation of the efficiency curve should be caused by the change in

ηIQE. The IQE of an OLED device can be expressed as the product of three factors [

15]:

where

γ is the charge-carrier balancing factor,

ηS/T is the spin singlet/triplet factor, and

qeff is the effective radiative efficiency. First of all,

ηS/T is determined by how the EML layer forms excitons. In our experiments,

ηS/T can be regarded as constant as the fluorescent light-emission process for our device is not changed [

17]. Furthermore, the shape of the efficiency curve is the result of the competition between the radiative and nonradiative recombinations, which is related to

qeff. As we can see in

Figure 8, the shape does not change during the operation after the initial 24 h, indicating that

qeff has not been hampered under the electrical stress. In other words, the effect of electrical stress is outside the EML, i.e., in cladding layers. Therefore, it is thought that the change in cladding layers has caused the variation in

γ, relating to the observed transient behavior.

As deduced from the analysis of the efficiency curves, one can ask what triggers this phenomenon. While each chemical should be stable enough to have a minimal impact on the device performance, it has been reported that the reaction between LiF/Al and Alq

3 is possible during deposition [

18], as supported by the electron energy-loss spectroscopy. As a result of the reaction, the dissociated Li ions can migrate into the EML as the device is operated. Then the states of the migrated Li ions can be formed in the vicinity of the LiF/Al:Alq

3 interface. In this case, the migrated Li ions can play an important role in the observed transient behavior as shown in

Figure 9. For the EML, it can act as defects, which degrades the device’s lifetime. However, the reason why both the current density at

VD and the luminance at

JD increase (region 1) by the migration of Li ions should be deduced from the nature of organic semiconductors.

The bonding strength between organic molecules is dominated by the weak dipole interaction, also known as the van der Waals interaction [

17]. Thus, the carrier transport based on the band theory may not be applicable because the band formation in organic solids is weak. In a disordered system, the main charge transfer mechanism is the hopping process via quantum-mechanical tunneling [

19]. The injected charges may hop by emitting or absorbing phonons. In this phonon-assisted hopping, the hopping transition rate,

Wij, from an initial state in a position

with an energy

Ei to a final state in a position

with an energy

Ej is given by the Miller–Abraham formulation [

19]:

where

ν0 is the hopping frequency,

α is the inverse of the decay length,

is the distance between the states. The states induced by the migrated Li ions can lead to the interstate distance shortened, which would enhance the electron injection. Moreover, the work function of Li is ~2.3 eV, lower than the lowest unoccupied molecular orbital of Alq

3 [

20,

21,

22]. Due to this nature of the work function, electron hopping assisted by Li ions can be facilitated. Consequently, the

γ factor would increase owing to the enhanced electron transport as schematically described in

Figure 9.

However, once Li ions migrate further into the EML, the effect of transport enhancement ceases to exist, thus reducing the current conduction as seen in region 2 in

Figure 4. Although the migrated Li ions can assist the electron injection initially, excessive migration with further stress would eventually degrade the EML, thus detrimental to the device as illustrated in

Figure 10.

As shown in

Figure 4, the operation time when the current and luminance increase initially are shortened under higher stress current. It indicates that the rate of Li migration increases with the level of stress current. Although the effect of Li migration on the reliability of OLED may seem trivial, this effect is rather pronounced at the low-current operation. This investigation suggests that by optimizing the LiF layer or applying a more stable EIL, the lifetime of an OLED device could be extended further.