Development of Crack Width Prediction Models for RC Beam-Column Joint Subjected to Lateral Cyclic Loading Using Machine Learning

Abstract

1. Introduction

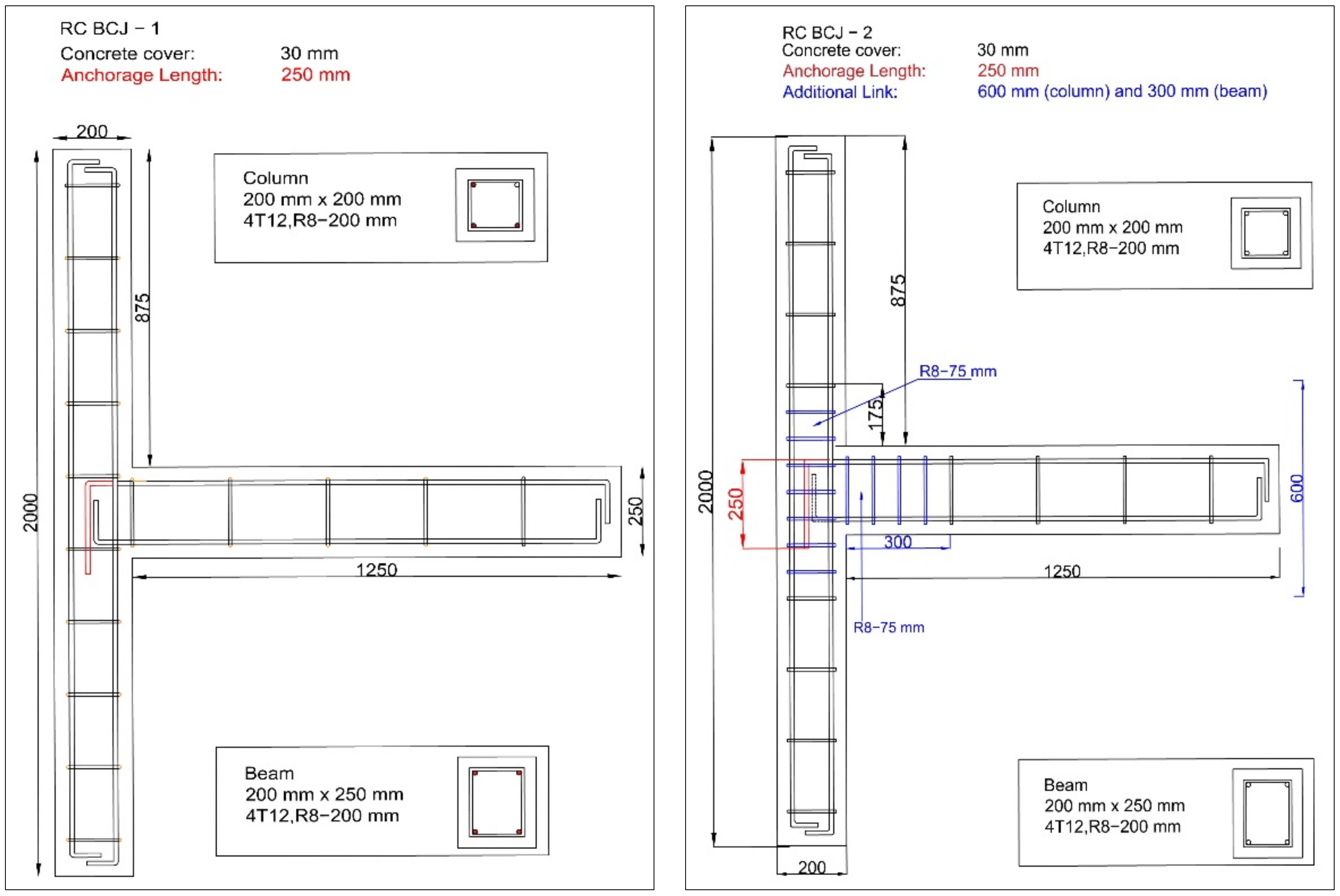

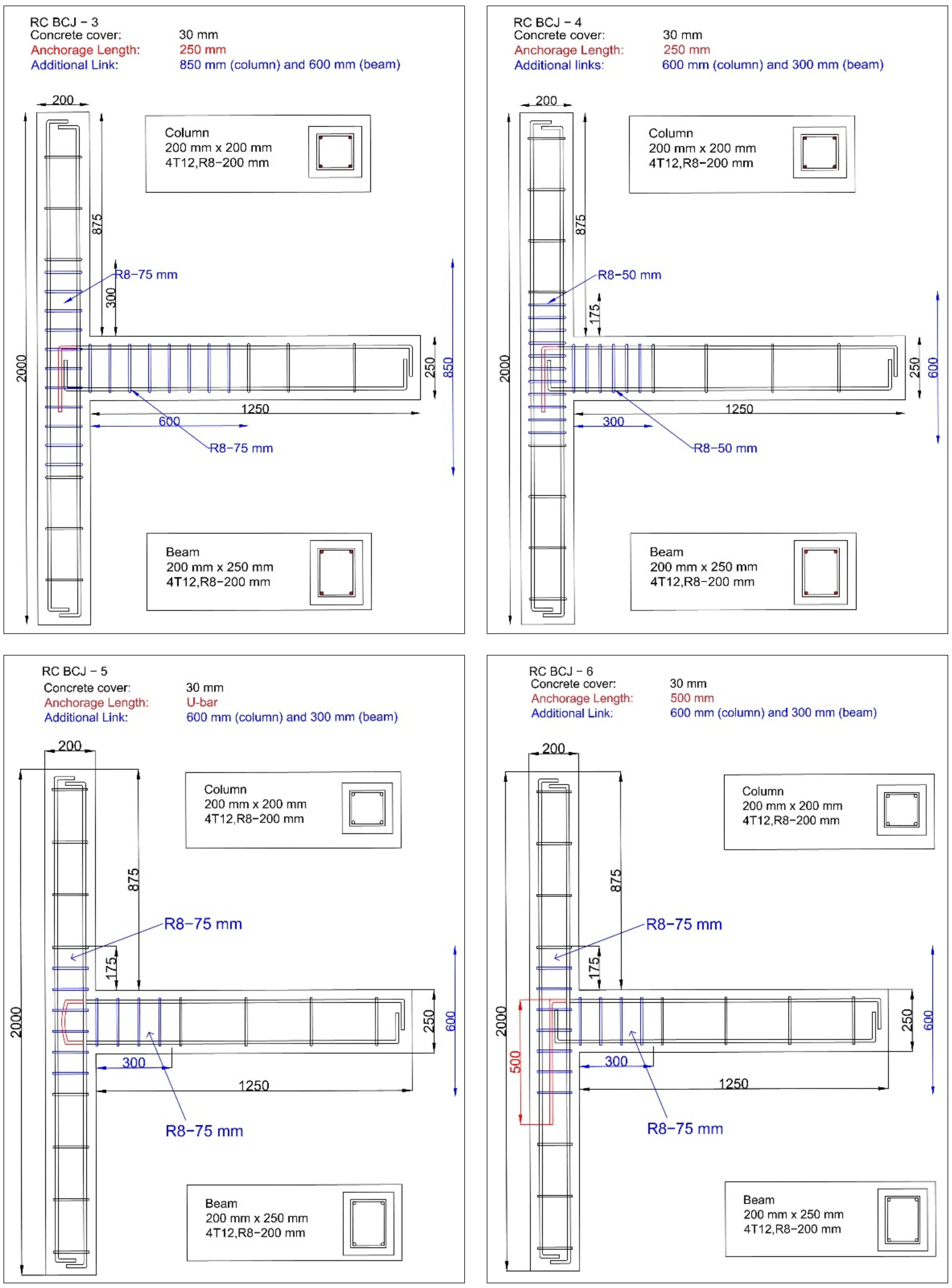

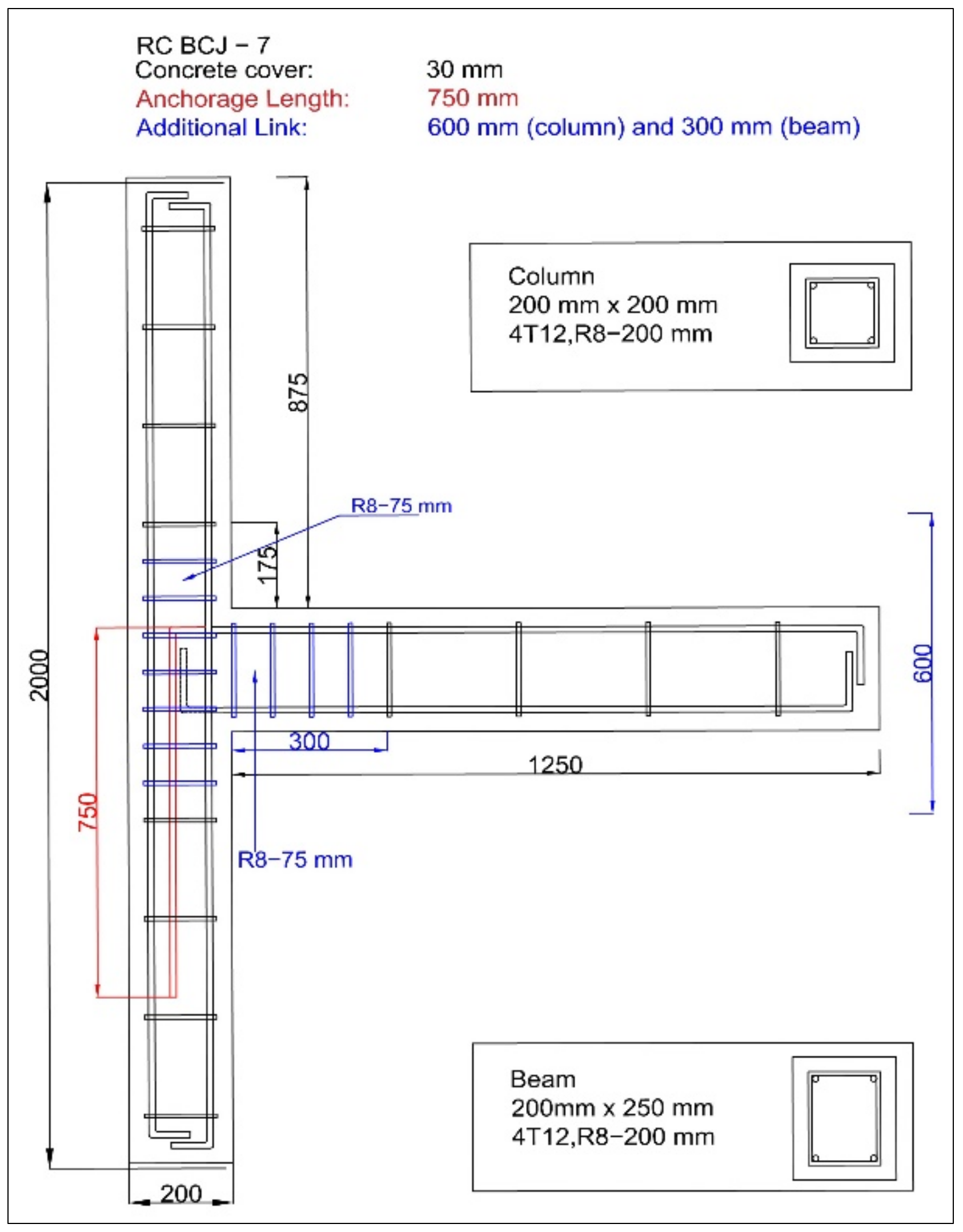

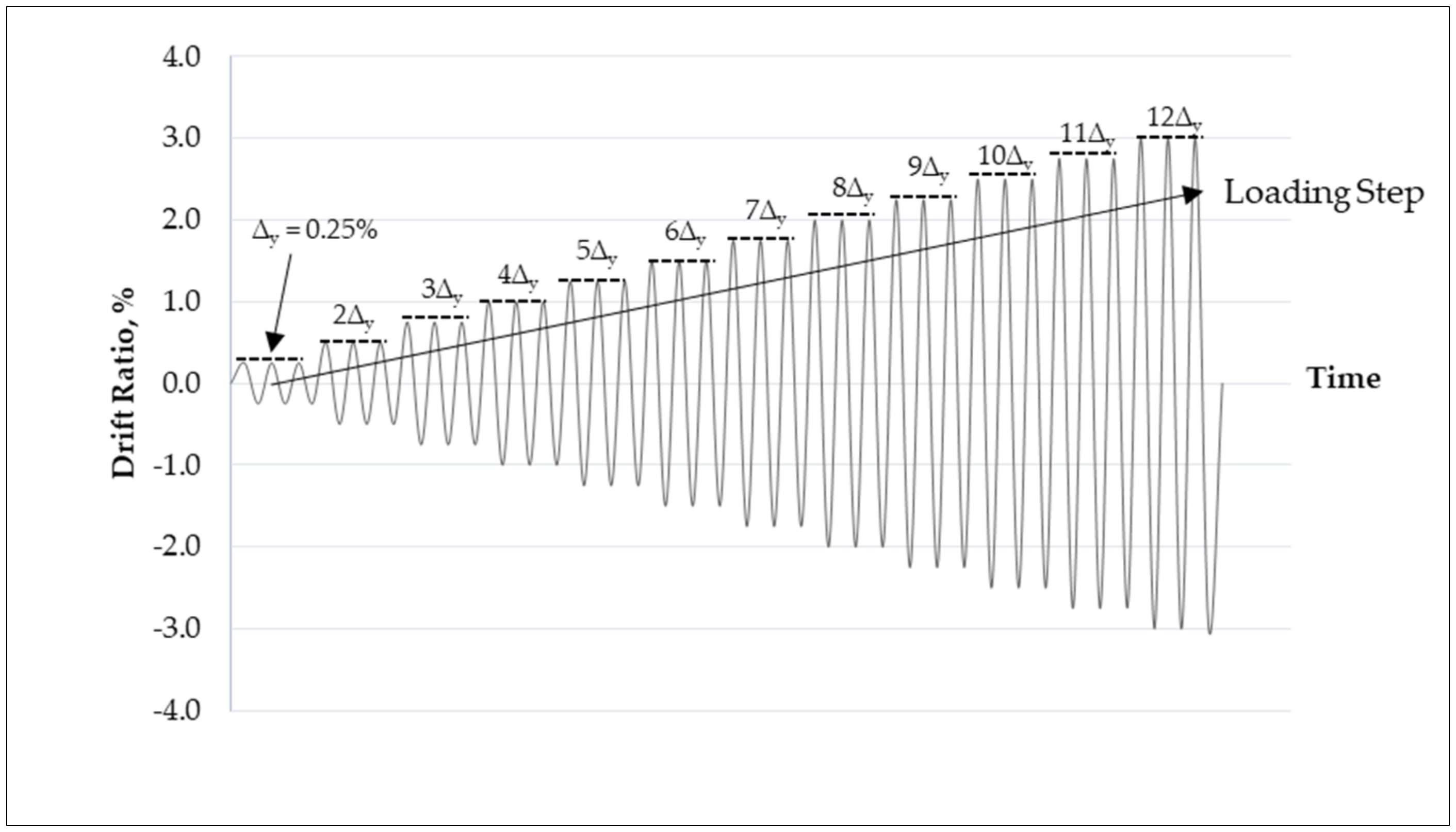

2. Experimental Specimen Test

3. Experimental Testing Results

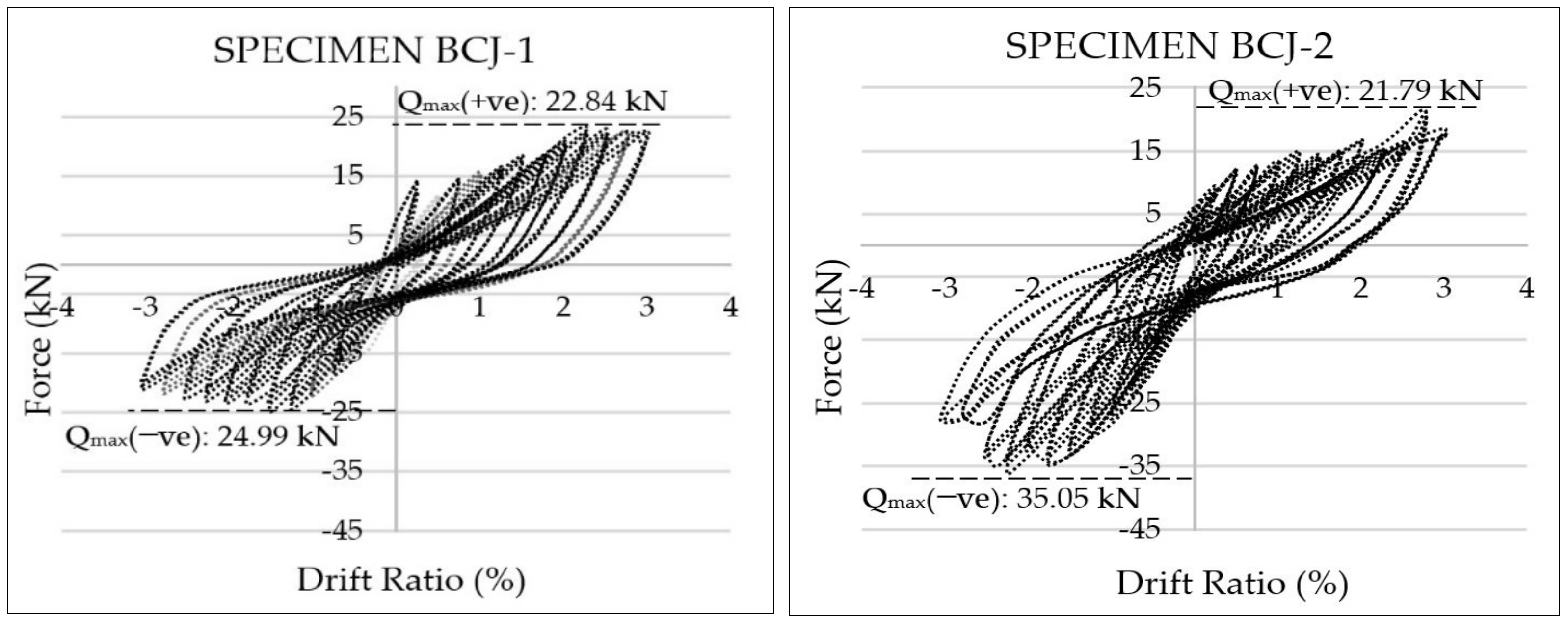

3.1. Hysteretic Graph of Specimens

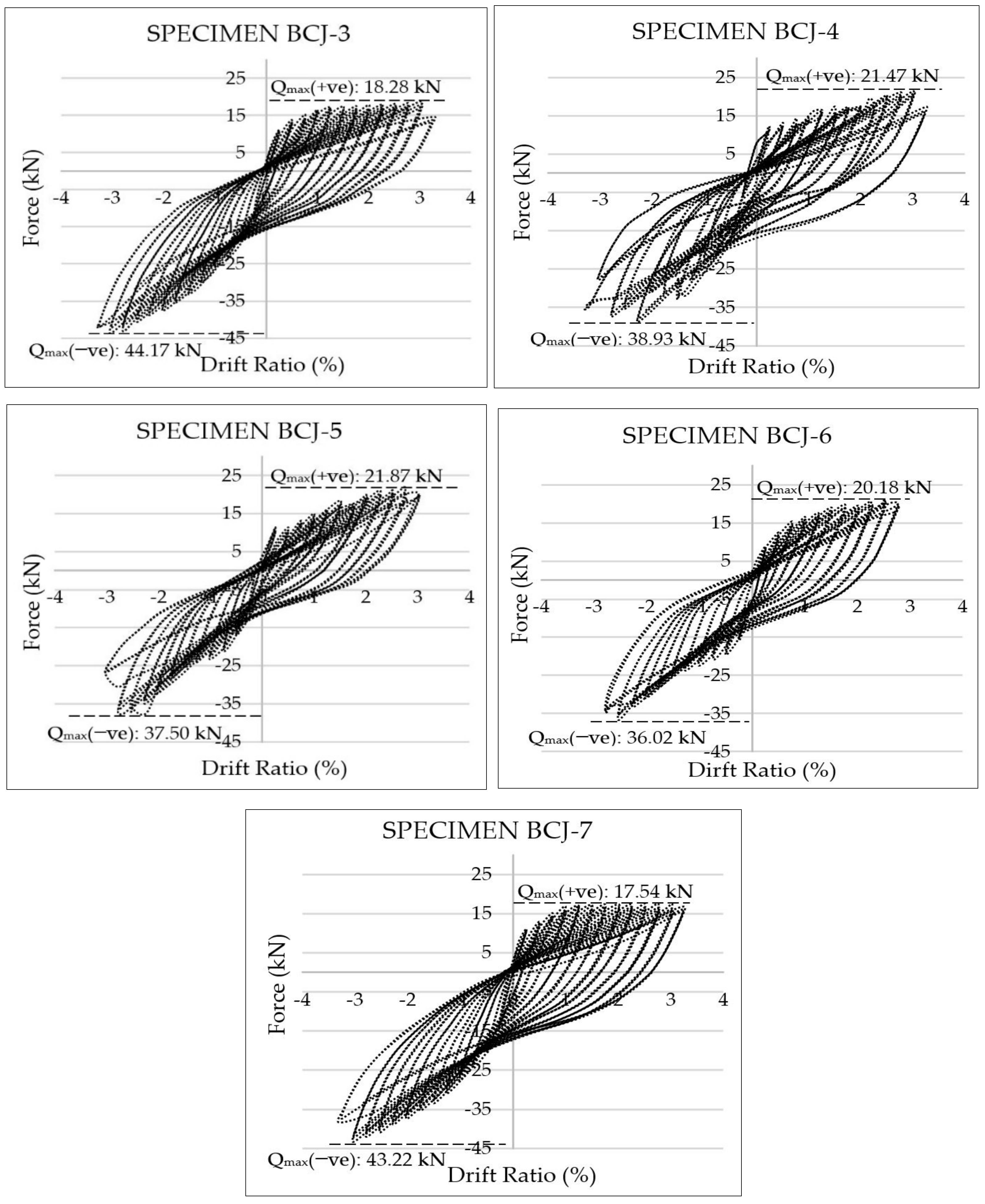

3.2. Crack Formation of Specimens

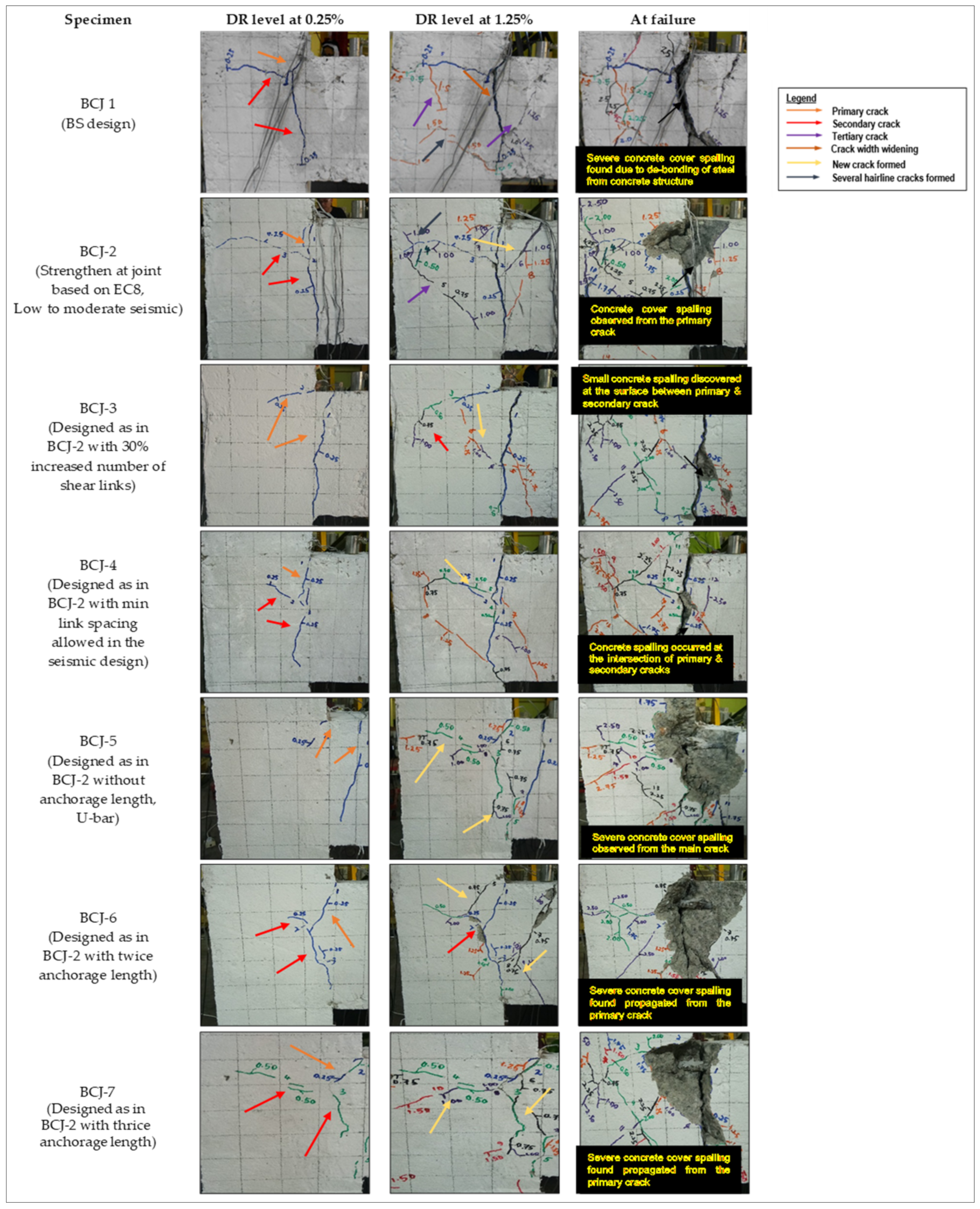

4. The Neural Network Configuration

4.1. Application of Deep Learning (DL) and Support Vector Machine (SVM) in Engineering Practice

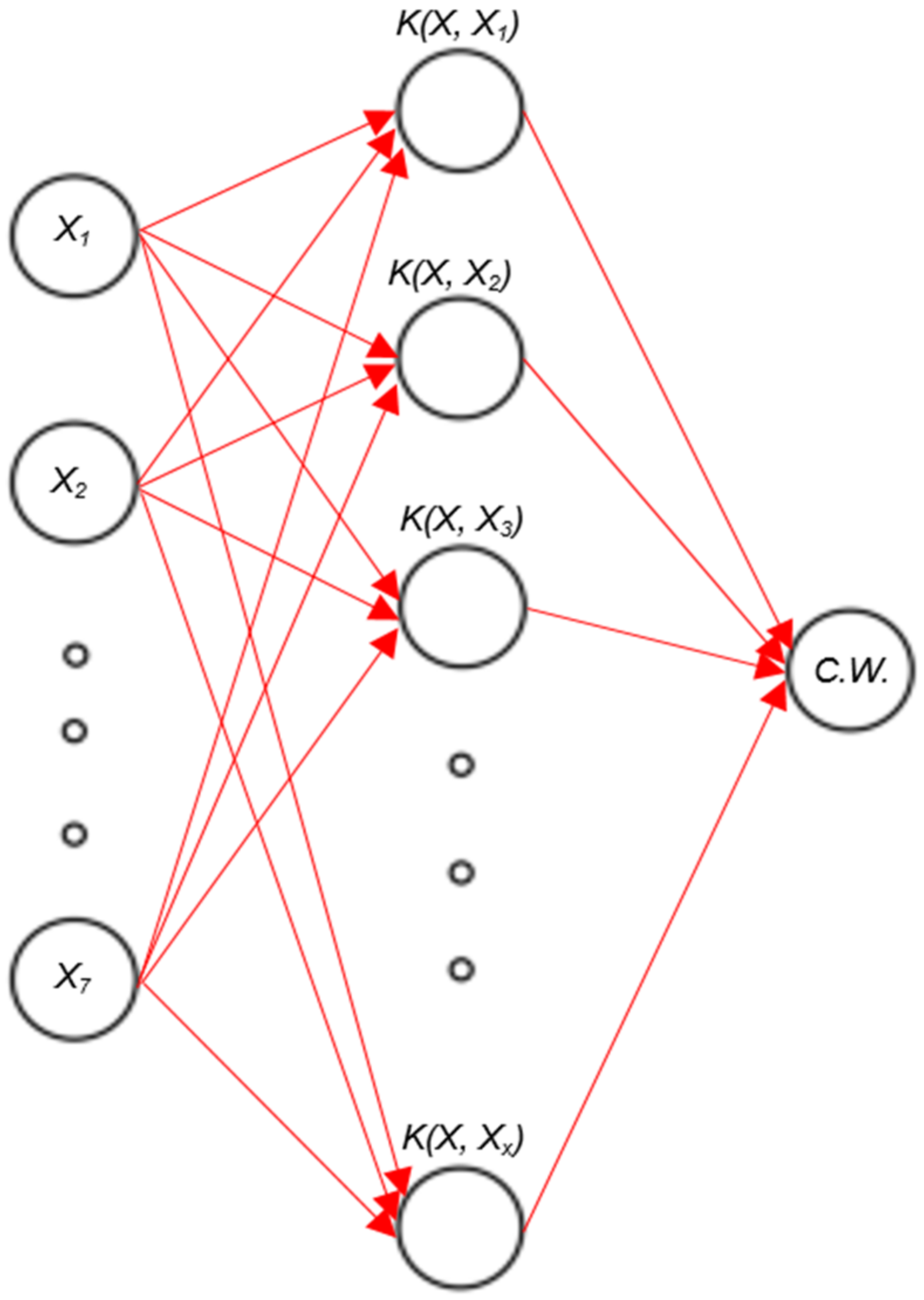

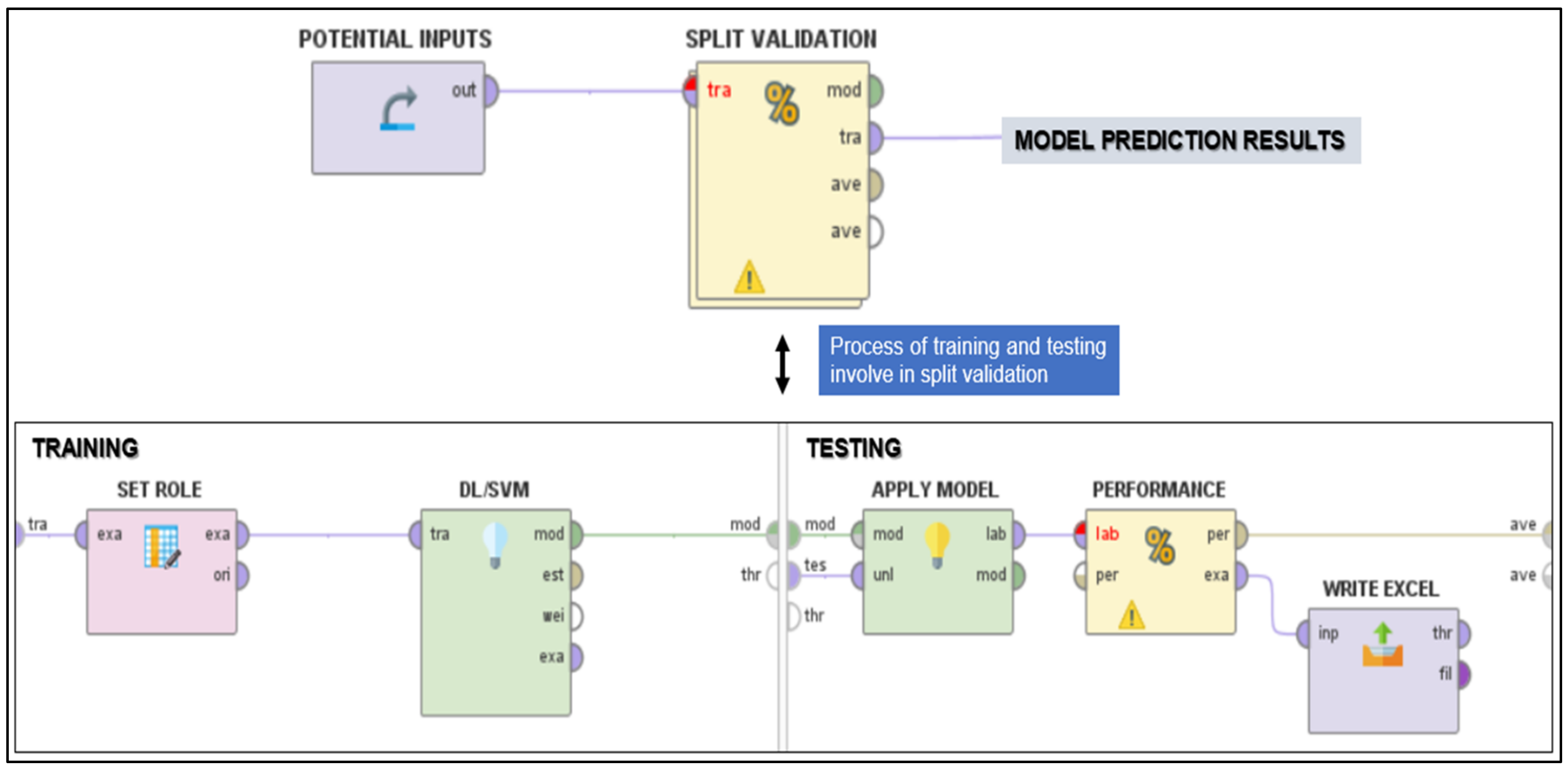

4.2. Framework Model of Deep Learning (DL) and Support Vector Machine (SVM)

5. Results and Discussion

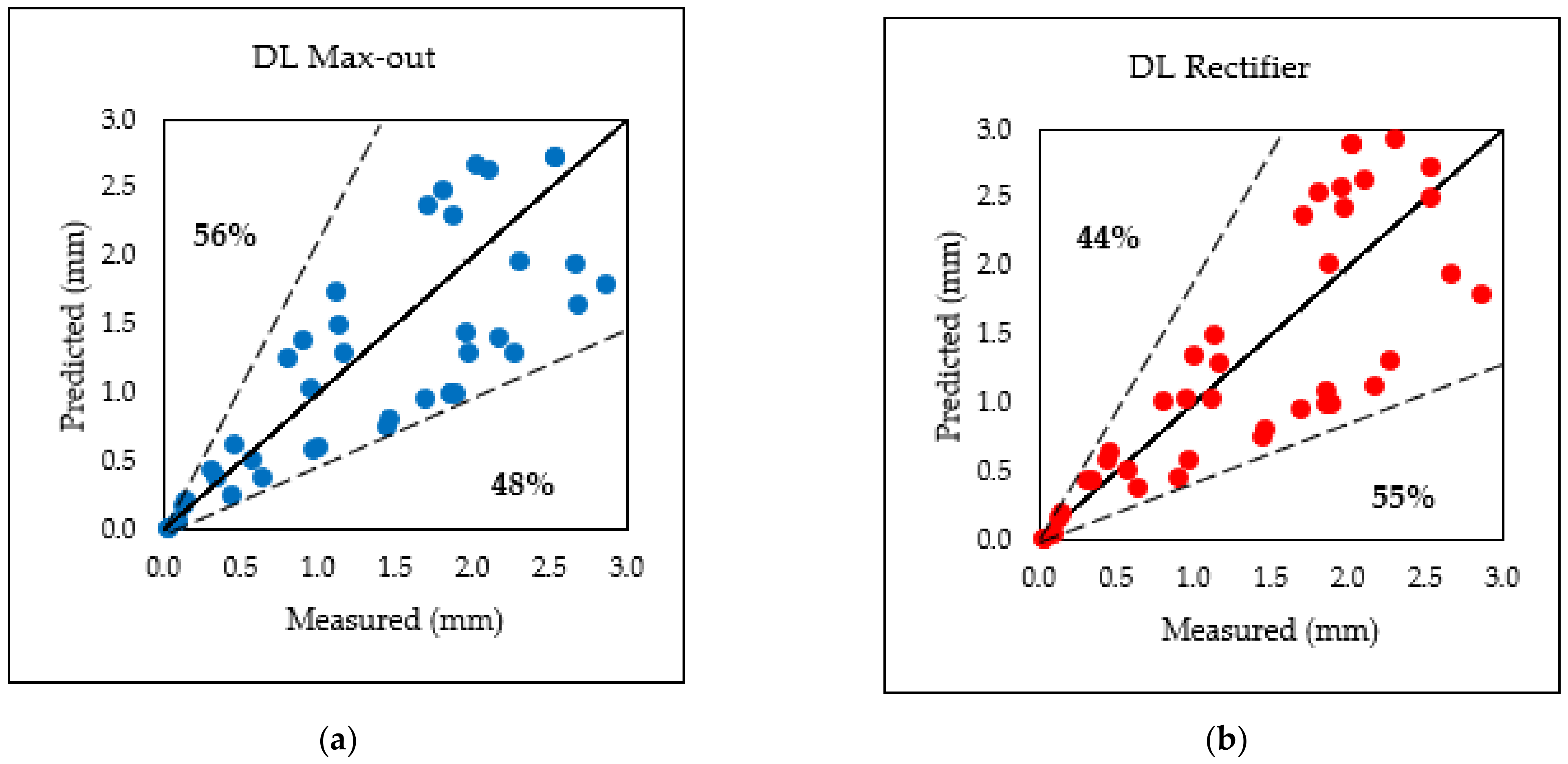

5.1. Comparison of Prediction Models from Rapidminer

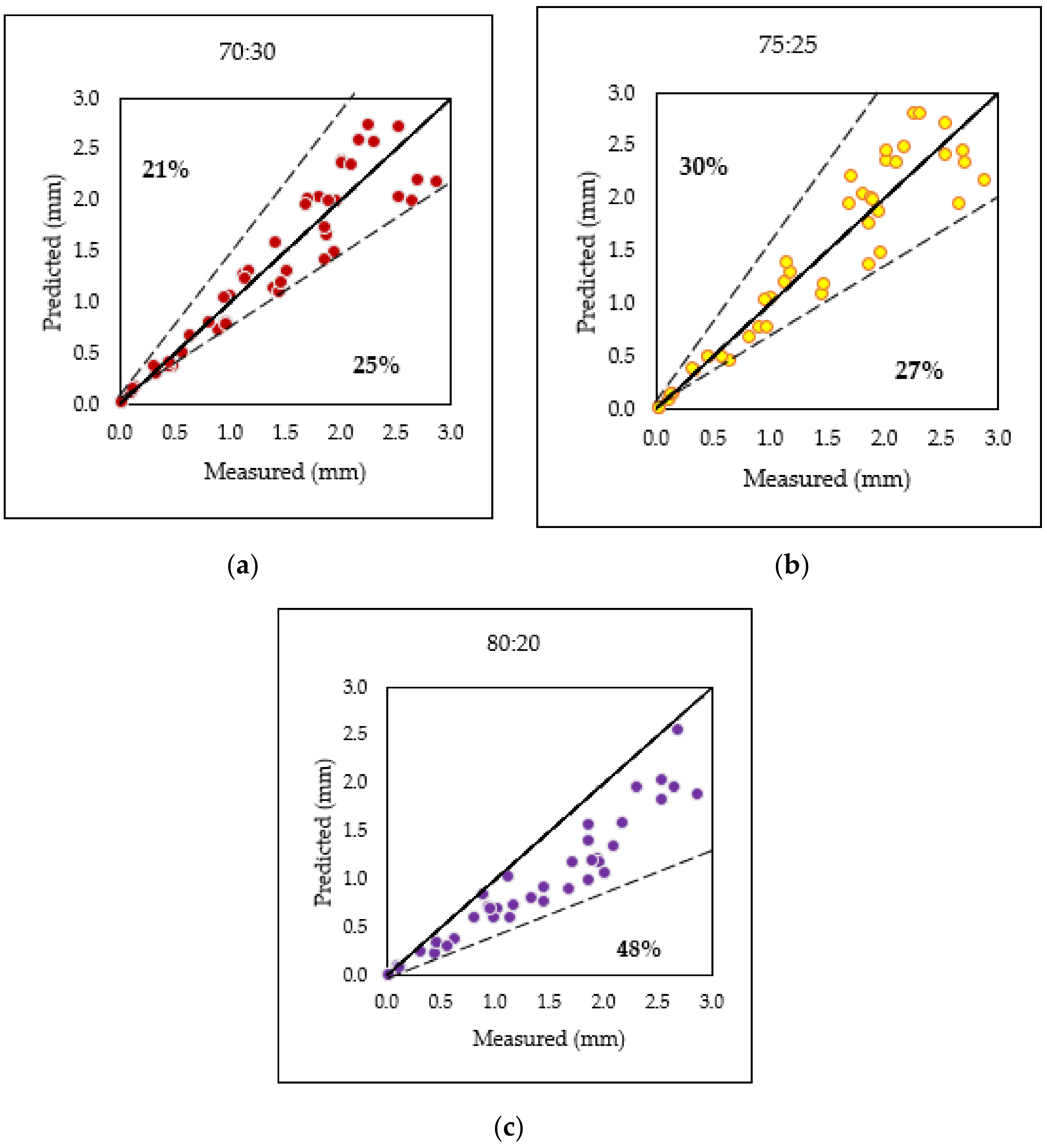

5.2. Data Splitting Ratio Analysis in SVM—Dot Model

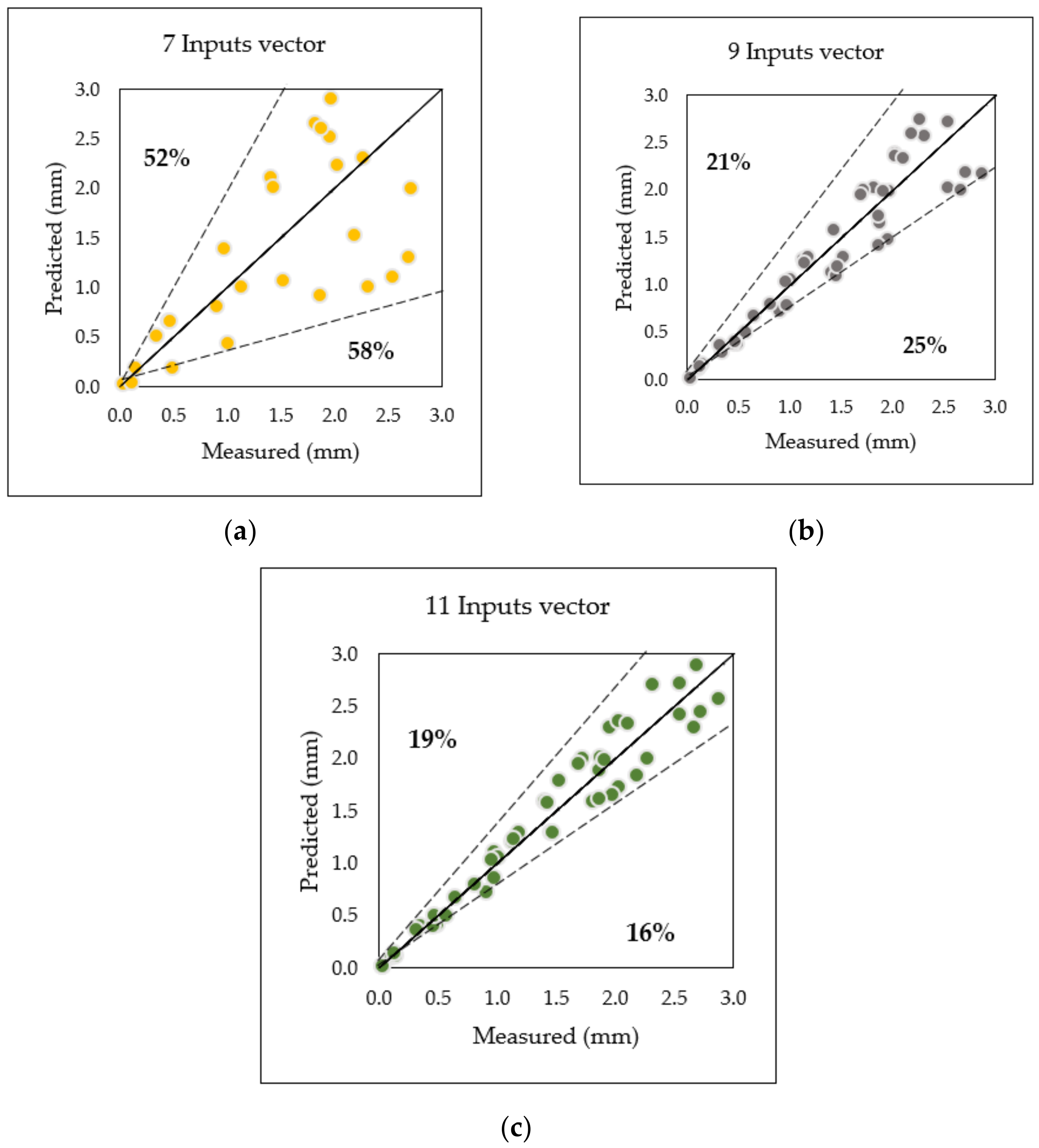

5.3. Analysis on Input Parameters Selection for SVM—Dot Model

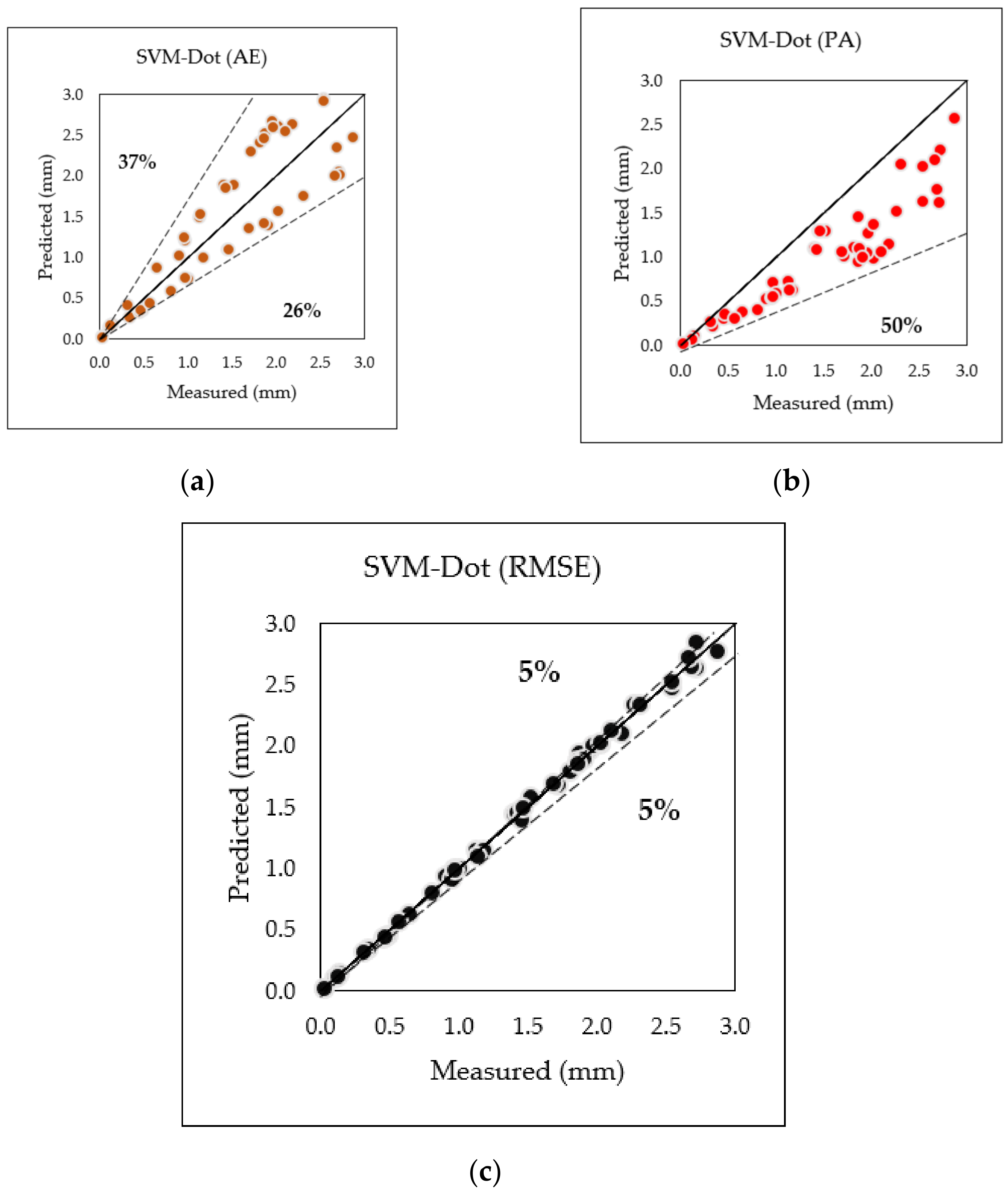

5.4. Analysis on Performance Indexes (Regression) Supported in SVM—Dot Model

6. Conclusions

- SVM—dot kernel prediction model exhibited 30% fewer discrepancy values between measured and predicted crack width compared to DL—max-out (56%), DL—rectifier (55%), and SVM—neural (48%) and was therefore chosen.

- For the data splitting ratio, 70:30 split of testing and training smaller number dataset was comparable to the experimental range, thus being a decent and reasonable choice in this research.

- The higher number of input variables (eleven inputs) being pre-processed by the SVM—dot model was recommended, where the small dataset for this research with an increased number of inter-related inputs parameter presented errors less than 20% consistency of predicted points varied along the reference lines compared to over-fitting result found in seven inputs (52–58%) and less under-fit found in nine inputs (21–25%), respectively.

- Finally, based on conclusion (2) and (3), further optimization was made where the root mean square error (RMSE) performance index was adapted, and the SVM—dot prediction model further reduced the error between measured and predicted crack width up to 5% compared to absolute error (AE), 37%, and prediction average (PA), 50%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Elshafey, A.A.; Dawood, N.; Marzouk, H.; Haddara, M. Crack width in concrete using artificial neural networks. Eng. Struct. 2013, 52, 676–686. [Google Scholar] [CrossRef]

- Allam, S.M.; Shoukry, M.S.; Rashad, G.E.; Hassan, A.S. Crack width evaluation for flexural RC members. Alex. Eng. J. 2012, 51, 211–220. [Google Scholar] [CrossRef]

- Pancic, A.; Milasinovica, D.D.; Golesb, D. Crack propagation in flexural fatigue of concrete using rheological-dynamical theory. Comput. Concr. 2021, 27, 055. [Google Scholar]

- Haeri, H.; Sarfarazi, V.; Zhu, Z. Effect of normal load on the crack propagation from pre-existing joints using Particle Flow Code (PFC). Comput. Concr. 2017, 19, 99–110. [Google Scholar] [CrossRef]

- Haeri, H.; Sarfarazi, V.; Shemirani, A.B. Experimental and numerical study of shear crack propagation in concrete specimens. Comput Concr. 2017, 20, 57–63. [Google Scholar]

- Hull, D. Fractography: Observing, Measuring and Interpreting Fracture Surface Topography; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Shah, S.P. Size-effect method for determining fracture energy and process zone size of concrete. Mater. Struct. 1990, 23, 461. [Google Scholar] [CrossRef]

- Souza, J.C. What Do the Cracks in Concrete Structures Mean? Available online: https://www.archdaily.com/879953/what-do-the-cracks-in-concrete-structures-mean/ (accessed on 28 July 2019).

- British Standards Institution. BS 8110-2: 1985: Structural Use of Concrete—Part 2: Code of Practice for Special Circumstances; British Standards Institution: London, UK, 1985. [Google Scholar]

- ACI. ACI 224R-01: Control of Cracking in Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2001. [Google Scholar]

- Normalisation, C.E. Eurocode 2: Design of Concrete Structures: Part 1-1: General Rules and Rules for Buildings; British Standards Institution: London, UK, 2004. [Google Scholar]

- Shinmura, A.; Saouma, V.E. Fluid fracture interaction in pressurized reinforced concrete vessels. Mater. Struct. 1997, 30, 72–80. [Google Scholar] [CrossRef]

- Goszczyńska, B.; Trąmpczyński, W.; Tworzewska, J. Analysis of Crack Width Development in Reinforced Concrete Beams. Materials 2021, 14, 3043. [Google Scholar] [CrossRef] [PubMed]

- Beeby, A.W. The influence of the parameter ϕ/ρ eff on crack widths. Struct. Concr. 2005, 6, 155–165. [Google Scholar] [CrossRef]

- Edwards, A.D.; Picard, A. Theory of cracking in concrete members. J. Struct. Div. 1972, 98, 2687–2700. [Google Scholar] [CrossRef]

- Base, G.; Murray, M. A new look at shrinkage cracking. In Proceedings of the Symposium on Concrete 1981, Adelaide, Australia, 2 June 1981. [Google Scholar]

- Carino, N.J. Prediction of Cracking in Reinforced Concrete Structures; US Department of Commerce, National Institute of Standards and Technology: Gaithersburg, MD, USA, 1995.

- Gilbert, R.I. Shrinkage cracking in fully restrained concrete members. Struct. J. 1992, 89, 141–149. [Google Scholar]

- Liebold, F.; Maas, H.-G. Strategy for Crack Width Measurement of Multiple Crack Patterns in Civil Engineering Material Testing Using a Monocular Image Sequence Analysis. J. Photogramm. Remote Sens. Geoinf. Sci. 2020, 1–20. [Google Scholar] [CrossRef]

- Ramanauskas, R.; Kaklauskas, G.; Sokolov, A. Estimating the primary crack spacing of reinforced concrete structures: Predictions by neural network versus the innovative strain compliance approach. Mech. Adv. Mater. Struct. 2020, 1–17. [Google Scholar] [CrossRef]

- González, J.; Martin, U.; Gaona-Tiburcio, C.; Nunez-Jaquez, R.; Almeraya-Calderon, F.; Bastidas, J.M.; Bastidas, D.M. Modeling Steel Corrosion Failure in Reinforced Concrete by Cover Crack Width 3d FEM Analysis. FrMat 2020, 7, 41. [Google Scholar]

- Nogales, A.; Fuente, A. Crack width design approach for fibre reinforced concrete tunnel segments for TBM thrust loads. Tunn. Undergr. Space Technol. 2020, 98, 103342. [Google Scholar] [CrossRef]

- Islam, A. Computer aided failure prediction of reinforced concrete beam. Comput. Concr. 2020, 25, 67–73. [Google Scholar]

- Theriault, M.; Benmokrane, B. Effects of FRP reinforcement ratio and concrete strength on flexural behavior of concrete beams. J. Compos. Constr. 1998, 2, 7–16. [Google Scholar] [CrossRef]

- Zomorodian, M.; Yang, G.; Belarbi, A.; Ayoub, A. Cracking behavior and crack width predictions of FRP strengthened RC members under tension. Eng. Struct. 2016, 125, 313–324. [Google Scholar] [CrossRef]

- Li, C.Q.; Yang, S. Prediction of concrete crack width under combined reinforcement corrosion and applied load. J. Eng. Mech. 2011, 137, 722–731. [Google Scholar] [CrossRef]

- Xu, L.Y.; Nie, X.; Zhou, M.; Tao, M.X. Whole-process crack width prediction of reinforced concrete structures considering bonding deterioration. Eng. Struct. 2017, 142, 240–254. [Google Scholar] [CrossRef]

- BSI. BS EN 12390-3: 2009: Testing Hardened Concrete. Compressive Strength of Test Specimens; British Standards Institution: London, UK, 2009. [Google Scholar]

- BSI. 10002-1: 2001. Tensile Testing of Metallic Materials. Method of Test at Ambient Temperature; British Standards Institution: London, UK, 2001. [Google Scholar]

- Fardis, M.N.; Carvalho, E.C.; Fajfar, P.; Pecker, A. Seismic Design of Concrete Buildings to Eurocode 8; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Standards Malaysia. Malaysia National Annex to Eurocode 8: Design of Structures for Earthquake Resistance—Part 1: General Rules, Seismic Actions and Rules for Buildings; Standards Malaysia: Cyberjaya, Malaysia, 2017.

- Hee, M.; Lam, N.; Tsang, H.; Looi, D. Draft National Annex to Eurocode 8 for Malaysia and cost implication for residential buildings with thin size elements. In Proceedings of the Tenth Pacific Conference on Earthquake Engineering (PCEE2015), Building an Earthquake-Resilient Pacific, Australian Earthquake Engineering Society, Sydney, Australia, 6–8 November 2015; pp. 6–8. [Google Scholar]

- Allen, A. Reinforced Concrete Design to BS 8110 Simply Explained; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Scott, R.; Feltham, I.; Whittle, R. Reinforced concrete beam-column connections and BS 8110. Struct. Eng. 1994, 72, 55–60. [Google Scholar]

- Roy, B.; Laskar, A.I. Cyclic Performance of Beam-Column Subassemblies with Construction Joint in Column Retrofitted with GFRP. Structures 2018, 14, 290–300. [Google Scholar] [CrossRef]

- Ganasan, M.R.; Tan, D.C.G.; Ibrahim, D.Z.; Bunnori, D.N.M.; Nazri, D.F.M.; Nayaka, D.R.R. Crack assessment of RC beam-column joints subjected to cyclic lateral loading using Acoustic Emission (AE): The influence of shear links aspect. Can. J. Civil Eng. 2020, in press. [Google Scholar] [CrossRef]

- Truong, G.T.; Dinh, N.H.; Kim, J.C.; Choi, K.-K. Seismic Performance of Exterior RC Beam–Column Joints Retrofitted using Various Retrofit Solutions. Int. J. Concr. Struct. Mater. 2017, 11, 415–433. [Google Scholar] [CrossRef]

- Rahman, M.M.; Jumaat, M.Z.; Rahman, M.A.; Qeshta, I.M. Innovative hybrid bonding method for strengthening reinforced concrete beam in flexure. Constr. Build. Mater. 2015, 79, 370–378. [Google Scholar] [CrossRef]

- Huda, M.N.; Jumat, M.Z.B.; Islam, A.S. Flexural performance of reinforced oil palm shell & palm oil clinker concrete (PSCC) beam. Constr. Build. Mater. 2016, 127, 18–25. [Google Scholar]

- Akter Hosen, M.; Jumaat, M.Z.; Saiful Islam, A.; Obaydullah, M.; Darain, M.; Huda, N. Investigation on Energy Absorption Capacity of Reinforced Concrete Beams by the Near-Surface Mounted Technique Using Ductile Materials. Sci. Adv. Mater. 2016, 8, 1536–1546. [Google Scholar] [CrossRef]

- Borg, R.P.; Cuenca, E.; Gastaldo Brac, E.M.; Ferrara, L. Crack sealing capacity in chloride-rich environments of mortars containing different cement substitutes and crystalline admixtures. J. Sustain. Cem. Based Mater. 2018, 7, 141–159. [Google Scholar] [CrossRef]

- Hardwinarto, S.; Aipassa, M. Rainfall monthly prediction based on artificial neural network: A case study in Tenggarong Station, East Kalimantan-Indonesia. Procedia Comput. Sci. 2015, 59, 142–151. [Google Scholar]

- Amer, M.M.; Dahab, A.S.; El-Sayed, A.-A.H. An ROP predictive model in nile delta area using artificial neural networks. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 24–27 April 2017. [Google Scholar]

- Abbas, A.K.; Al-haideri, N.A.; Bashikh, A.A. Implementing artificial neural networks and support vector machines to predict lost circulation. Egypt. J. Pet. 2019, 28, 339–347. [Google Scholar] [CrossRef]

- Tokui, S.; Oono, K.; Hido, S.; Clayton, J. Chainer: A next-generation open source framework for deep learning. In Proceedings of the Workshop on Machine Learning Systems (LearningSys) in the Twenty-Ninth Annual Conference on Neural Information Processing Systems (NIPS), Montreal, QC, Canada, 7–12 December 2015; pp. 1–6. [Google Scholar]

- Abhishek, K.; Kumar, A.; Ranjan, R.; Kumar, S. A rainfall prediction model using artificial neural network. In Proceedings of the 2012 IEEE Control and System Graduate Research Colloquium, Shah Alam, Malaysia, 16–17 July 2012; pp. 82–87. [Google Scholar]

- Mall, S.; Chakraverty, S. Artificial Neural Network Based Solution of Fractional Vibration Model. In Recent Trends in Wave Mechanics and Vibrations; Springer: Berlin/Heidelberg, Germany, 2020; pp. 393–406. [Google Scholar]

- Geetha, A.; Nasira, G. Artificial neural networks’ application in weather forecasting–using RapidMiner. Int. J. Comput. Intell. Inform. 2014, 4, 177–182. [Google Scholar]

- Geetha, A.; Nasira, G. Data mining for meteorological applications: Decision trees for modeling rainfall prediction. In Proceedings of the 2014 IEEE International Conference on Computational Intelligence and Computing Research, Coimbatore, India, 18–20 December 2014; pp. 1–4. [Google Scholar]

- Yadav, A.K.; Malik, H.; Chandel, S. Application of rapid miner in ANN based prediction of solar radiation for assessment of solar energy resource potential of 76 sites in Northwestern India. Renew. Sustain. Energy Rev. 2015, 52, 1093–1106. [Google Scholar] [CrossRef]

- Brereton, R.G.; Lloyd, G.R. Support vector machines for classification and regression. Analyst 2010, 135, 230–267. [Google Scholar] [CrossRef] [PubMed]

- Almansour, N.A.; Syed, H.F.; Khayat, N.R.; Altheeb, R.K.; Juri, R.E.; Alhiyafi, J.; Alrashed, S.; Olatunji, S.O. Neural network and support vector machine for the prediction of chronic kidney disease: A comparative study. Comput. Biol. Med. 2019, 109, 101–111. [Google Scholar] [CrossRef] [PubMed]

- Rafiei, M.H.; Adeli, H. A novel unsupervised deep learning model for global and local health condition assessment of structures. Eng. Struct. 2018, 156, 598–607. [Google Scholar] [CrossRef]

- Bhatkande, S.S.; Hubballi, R.G. Weather Prediction Based on Decision Tree Algorithm Using Data Mining Techniques. Int. J. Adv. Res. Comput. Commun. Eng. 2016, 5, 483–487. [Google Scholar]

- Jayaprakash, J.; Pournasiri, E.; Choong, K.; Tan, C.; De’nan, F. External CFRP repairing of pretested beams reinforced using prestress rebars. J. Reinf. Plast. Compos. 2011, 30, 1753–1768. [Google Scholar] [CrossRef]

- Deng, L.; Yu, D. Deep learning: Methods and applications. Found. Trends® Signal Process. 2014, 7, 197–387. [Google Scholar] [CrossRef]

- Ahmad, J.; Farman, H.; Jan, Z. Deep learning methods and applications. In Deep Learning: Convergence to Big Data Analytics; Springer: Berlin/Heidelberg, Germany, 2019; pp. 31–42. [Google Scholar]

- Furey, T.S.; Cristianini, N.; Duffy, N.; Bednarski, D.W.; Schummer, M.; Haussler, D. Support vector machine classification and validation of cancer tissue samples using microarray expression data. Bioinformatics 2000, 16, 906–914. [Google Scholar] [CrossRef]

- Pavlidis, P.; Wapinski, I.; Noble, W.S. Support vector machine classification on the web. Bioinformatics 2004, 20, 586–587. [Google Scholar] [CrossRef]

- Ferreiro-Cabello, J.; Fraile-Garcia, E.; de Pison Ascacibar, E.M.; Martinez-de-Pison, F. Metamodel-based design optimization of structural one-way slabs based on deep learning neural networks to reduce environmental impact. Eng. Struct. 2018, 155, 91–101. [Google Scholar] [CrossRef]

- Wei, F.; Yao, G.; Yang, Y.; Sun, Y. Instance-level recognition and quantification for concrete surface bughole based on deep learning. Autom. Constr. 2019, 107, 102920. [Google Scholar] [CrossRef]

- Nazari, A.; Sanjayan, J.G. Modelling of compressive strength of geopolymer paste, mortar and concrete by optimized support vector machine. Ceram. Int. 2015, 41, 12164–12177. [Google Scholar] [CrossRef]

- Liu, J.; Yan, K.; Zhao, X.; Hu, Y. Prediction of autogenous shrinkage of concretes by support vector machine. Int. J. Pavement Res. Technol. 2016, 9, 169–177. [Google Scholar] [CrossRef]

- Labjar, H.; Cherif, W.; Nadir, S.; Digua, K.; Sallek, B.; Chaair, H. Support vector machines for modelling phosphocalcic hydroxyapatite by precipitation from a calcium carbonate solution and phosphoric acid solution. J. Taibah Univ. Sci. 2016, 10, 745–754. [Google Scholar] [CrossRef][Green Version]

- Todkar, S.S.; Le Bastard, C.; Baltazart, V.; Ihamouten, A.; Dérobert, X. Performance assessment of SVM-based classification techniques for the detection of artificial debondings within pavement structures from stepped-frequency A-scan radar data. NDT E Int. 2019, 107, 102128. [Google Scholar] [CrossRef]

- Hariri-Ardebili, M.A.; Pourkamali-Anaraki, F. Support vector machine based reliability analysis of concrete dams. Soil Dyn. Earthq. Eng. 2018, 104, 276–295. [Google Scholar] [CrossRef]

- Da Silva, I.N.; Spatti, D.H.; Flauzino, R.A.; Liboni, L.H.B.; dos Reis Alves, S.F. Artificial Neural Networks; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Schmidhuber, J. On learning to think: Algorithmic information theory for novel combinations of reinforcement learning controllers and recurrent neural world models. arXiv 2015, arXiv:1511.09249. [Google Scholar]

- Dechter, R. Learning While Searching in Constraint-Satisfaction Problems; University of California, Computer Science Department, Cognitive Systems: Los Angeles, CA, USA, 1986. [Google Scholar]

- Aizenberg, I.; Aizenberg, N.N.; Vandewalle, J.P. Multi-Valued and Universal Binary Neurons: Theory, Learning and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Gomez, F.J.; Schmidhuber, J. Co-evolving recurrent neurons learn deep memory POMDPs. In Proceedings of the 7th Annual Conference on Genetic and Evolutionary Computation, Washington, DC, USA, 25–29 June 2005; pp. 491–498. [Google Scholar]

- Raicea, R. Want to Know How Deep Learning Works? Here’s a Quick Guide for Everyone. Available online: https://www.freecodecamp.org/news/want-to-know-how-deep-learning-works-heres-a-quick-guide-for-everyone-1aedeca88076/ (accessed on 23 November 2019).

- West, M. An Introduction to Deep Learning. Available online: https://www.bouvet.no/bouvet-deler/an-introduction-to-deep-learning/ (accessed on 30 October 2019).

- Serrano, W. Smart Internet Search with Random Neural Networks. Eur. Rev. 2017, 25, 260–272. [Google Scholar] [CrossRef]

- Cortes, C.; Vapnik, V. Support-vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Adewumi, A.A.; Owolabi, T.O.; Alade, I.O.; Olatunji, S.O. Estimation of physical, mechanical and hydrological properties of permeable concrete using computational intelligence approach. Appl. Soft Comput. 2016, 42, 342–350. [Google Scholar] [CrossRef]

- Akande, K.O.; Olatunji, S.O.; Owolabi, T.O.; AbdulRaheem, A. Feature Selection-Based ANN for Improved Characterization of Carbonate Reservoir. In Proceedings of the SPE Saudi Arabia Section Annual Technical Symposium and Exhibition, Al-Khobar, Saudi Arabia, 21 April 2015. [Google Scholar]

- Gunn, S.R. Support vector machines for classification and regression. ISIS Tech. Rep. 1998, 14, 5–16. [Google Scholar]

- Vapnik, V. The Nature of Statistical Learning Theory; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Yang, L.; Dong, H. Robust support vector machine with generalized quantile loss for classification and regression. Appl. Soft Comput. 2019, 81, 105483. [Google Scholar] [CrossRef]

- Arabloo, M.; Ziaee, H.; Lee, M.; Bahadori, A. Prediction of the properties of brines using least squares support vector machine (LS-SVM) computational strategy. J. Taiwan Inst. Chem. Eng. 2015, 50, 123–130. [Google Scholar] [CrossRef]

- Reitermanova, Z. Data splitting. In Proceedings of the WDS, Prague, Czech Republic, 1–4 June 2010; pp. 31–36. [Google Scholar]

- May, R.J.; Maier, H.R.; Dandy, G.C. Data splitting for artificial neural networks using SOM-based stratified sampling. Neural Netw. 2010, 23, 283–294. [Google Scholar] [CrossRef] [PubMed]

- Hart, J.D.; Malloure, M. Prior-free Bayes Factors Based on Data Splitting. Int. Stat. Rev. 2019, 87, 419–442. [Google Scholar] [CrossRef]

- Torresani, L.; Lee, K.-C. Large margin component analysis. In Proceedings of the Advances in Neural Information Processing Systems, Vancouver, BC, Canada, 3–6 December 2007; pp. 1385–1392. [Google Scholar]

- Flores, A.C.; Icoy, R.I.; Peña, C.F.; Gorro, K.D. An Evaluation of SVM and Naive Bayes with SMOTE on Sentiment Analysis Data Set. In Proceedings of the 2018 International Conference on Engineering, Applied Sciences, and Technology (ICEAST), Phuket, Thailand, 4–7 July 2018; pp. 1–4. [Google Scholar]

- Murthy, A.K.; Suresha. XML URL Classification Based on their Semantic Structure Orientation for Web Mining Applications. Procedia Comput. Sci. 2015, 46, 143–150. [Google Scholar] [CrossRef]

- Suzuki, K. (Ed.) Artificial Neural Networks: Methodological Advances and Biomedical Applications; InTech: Rijeka, Croatia, 2011. [Google Scholar]

- May, R.; Dandy, G.; Maier, H. Review of input variable selection methods for artificial neural networks. Artif. Neural Netw. Methodol. Adv. Biomed. Appl. 2011, 10, 16004. [Google Scholar]

- Gevrey, M.; Dimopoulos, I.; Lek, S. Review and comparison of methods to study the contribution of variables in artificial neural network models. Ecol. Model. 2003, 160, 249–264. [Google Scholar] [CrossRef]

- Choudhury, S.; Ghosh, S.; Bhattacharya, A.; Fernandes, K.J.; Tiwari, M.K. A real time clustering and SVM based price-volatility prediction for optimal trading strategy. Neurocomputing 2014, 131, 419–426. [Google Scholar] [CrossRef]

- Shin, H.; Hou, T.; Park, K.; Park, C.-K.; Choi, S. Prediction of movement direction in crude oil prices based on semi-supervised learning. Decis. Support Syst. 2013, 55, 348–358. [Google Scholar] [CrossRef]

- Shynkevich, Y.; McGinnity, T.M.; Coleman, S.A.; Belatreche, A.; Li, Y. Forecasting price movements using technical indicators: Investigating the impact of varying input window length. Neurocomputing 2017, 264, 71–88. [Google Scholar] [CrossRef]

- Zhao, Y.P.; Wang, J.J.; Li, X.Y.; Peng, G.J.; Yang, Z. Extended least squares support vector machine with applications to fault diagnosis of aircraft engine. ISA Trans. 2019, 97, 189–201. [Google Scholar] [CrossRef]

| Specimen | Detailing | Remarks | ||||

|---|---|---|---|---|---|---|

| Column | Beam | At Joint | ||||

| Main Bar | Add. Shear Link Spacing (mm) | Main Bar | Add. Shear Link Spacing (mm) | Anchorage Length (mm) | ||

| BCJ-1 | 4T12 | - | 4T12 | - | 250 | Design based on British Standard [33,34] |

| BCJ-2 | 4T12 | R8-75 (600 *) | 4T12 | R8-75 (300) | 250 | Strengthen at joint based on EC8 (Low to moderate seismic) [30] |

| BCJ-3 | 4T12 | R8-75 (850) | 4T12 | R8-75 (600) | 250 | Designed as in BCJ-2 with a 30% increased number of shear links |

| BCJ-4 | 4T12 | R8-50 (600) | 4T12 | R8-50 (300) | 250 | Designed as in BCJ-2 with minimum link spacing allowed in the seismic design |

| BCJ-5 | 4T12 | R8-75 | 4T12 | R8-75 (300) | 180 | Designed as in BCJ-2 without anchorage length (U-bar) |

| BCJ-6 | 4T12 | R8-75 | 4T12 | R8-75 (300) | 500 | Designed as in BCJ-2 with twice anchorage length |

| BCJ-7 | 4T12 | R8-75 | 4T12 | R8-75 (300) | 750 | Designed as in BCJ-2 with thrice anchorage length |

| Num | Parameters Obtained before and after Experimental Testing | Abbrev. | Unit |

|---|---|---|---|

| 1. | Reinforcement area | As | mm2 |

| 2. | Shear link spacing at beam | SLB | mm |

| 3. | Shear link spacing at column | SLC | mm |

| 4. | Shear span for additional shear links at beam | SSLB | mm |

| 5. | Shear span for additional shear links at column | SSLC | mm |

| 6. | Anchorage length at joint | AL | mm |

| 7. | Concrete compression strength | Cc | MPa |

| 8. | Concrete tensile strength | Ct | MPa |

| 9. | Tensile bar strength | Tt | MPa |

| 10. | Drift ratio | DR | % |

| 11. | Maximum positive load-carrying capacity | Qmax(+ve) | kN |

| 12. | Maximum negative load-carrying capacity | Qmax(−ve) | kN |

| No | Model | Prediction Method |

|---|---|---|

| 1. | Deep learning (DL) | Max-out: Based on the maximum coordinate of the input vector. |

| 2. | Deep learning (DL) | Rectifier: Rectifier Linear Unit (RLU), which chooses the maximum of (0, x) where x is the input value. |

| 3. | Support Vector Machine (SVM) | Dot: The dot kernel is defined by k(x,y) = x × y, i.e., it is the inner product of x and y. |

| 4. | Support Vector Machine (SVM) | Neural: The neural kernel is defined by a two-layered neural net tanh (ax × y + b), where a is alpha and b is the intercept constant. These parameters can be adjusted using the kernel a and kernel b parameters. A common value for alpha is 1/N, where N is the data dimension. |

| List of Inputs | 7 Inputs Vector (X1–X7) | 9 Inputs Vector (Y1–Y9) | 11 Inputs Vector (Z1–Z11) |

|---|---|---|---|

| As | As | As | |

| OLB/C | OLB/C | OLB/C | |

| SSLB | SSLB | SSLB | |

| SSLC | SSLC | SSLC | |

| AL | AL | AL | |

| Cc | Cc | Cc | |

| DR | DR | Ct | |

| Qmax(+ve) | Tt | ||

| Qmax(−ve) | DR | ||

| Qmax(+ve) | |||

| Qmax(-ve) | |||

| Output | Crack width (C.W.) | ||

| No | Parameter | Description |

|---|---|---|

| 1. | Absolute error (AE) | AE is determined by adding the variance of all expected values from the label attribute’s actual values and dividing the amount by the total number of predictions. |

| 2. | Prediction average (PA) | PA is determined by adding all the real label values and dividing the total number of examples by this figure. |

| 3. | Root mean square error (RMSE) | RMSE is a quadratic scoring method calculating the error’s average magnitude. It is the cumulative square root of variations between predictive and real observation. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ganasan, R.; Tan, C.G.; Ibrahim, Z.; Nazri, F.M.; Sherif, M.M.; El-Shafie, A. Development of Crack Width Prediction Models for RC Beam-Column Joint Subjected to Lateral Cyclic Loading Using Machine Learning. Appl. Sci. 2021, 11, 7700. https://doi.org/10.3390/app11167700

Ganasan R, Tan CG, Ibrahim Z, Nazri FM, Sherif MM, El-Shafie A. Development of Crack Width Prediction Models for RC Beam-Column Joint Subjected to Lateral Cyclic Loading Using Machine Learning. Applied Sciences. 2021; 11(16):7700. https://doi.org/10.3390/app11167700

Chicago/Turabian StyleGanasan, Reventheran, Chee Ghuan Tan, Zainah Ibrahim, Fadzli Mohamed Nazri, Muhammad M. Sherif, and Ahmed El-Shafie. 2021. "Development of Crack Width Prediction Models for RC Beam-Column Joint Subjected to Lateral Cyclic Loading Using Machine Learning" Applied Sciences 11, no. 16: 7700. https://doi.org/10.3390/app11167700

APA StyleGanasan, R., Tan, C. G., Ibrahim, Z., Nazri, F. M., Sherif, M. M., & El-Shafie, A. (2021). Development of Crack Width Prediction Models for RC Beam-Column Joint Subjected to Lateral Cyclic Loading Using Machine Learning. Applied Sciences, 11(16), 7700. https://doi.org/10.3390/app11167700