Analysis of Nanoindentation Test Results of Asphalt Mixture with Different Gradations

Abstract

:1. Introduction

2. Experiment

2.1. Specimen Preparation

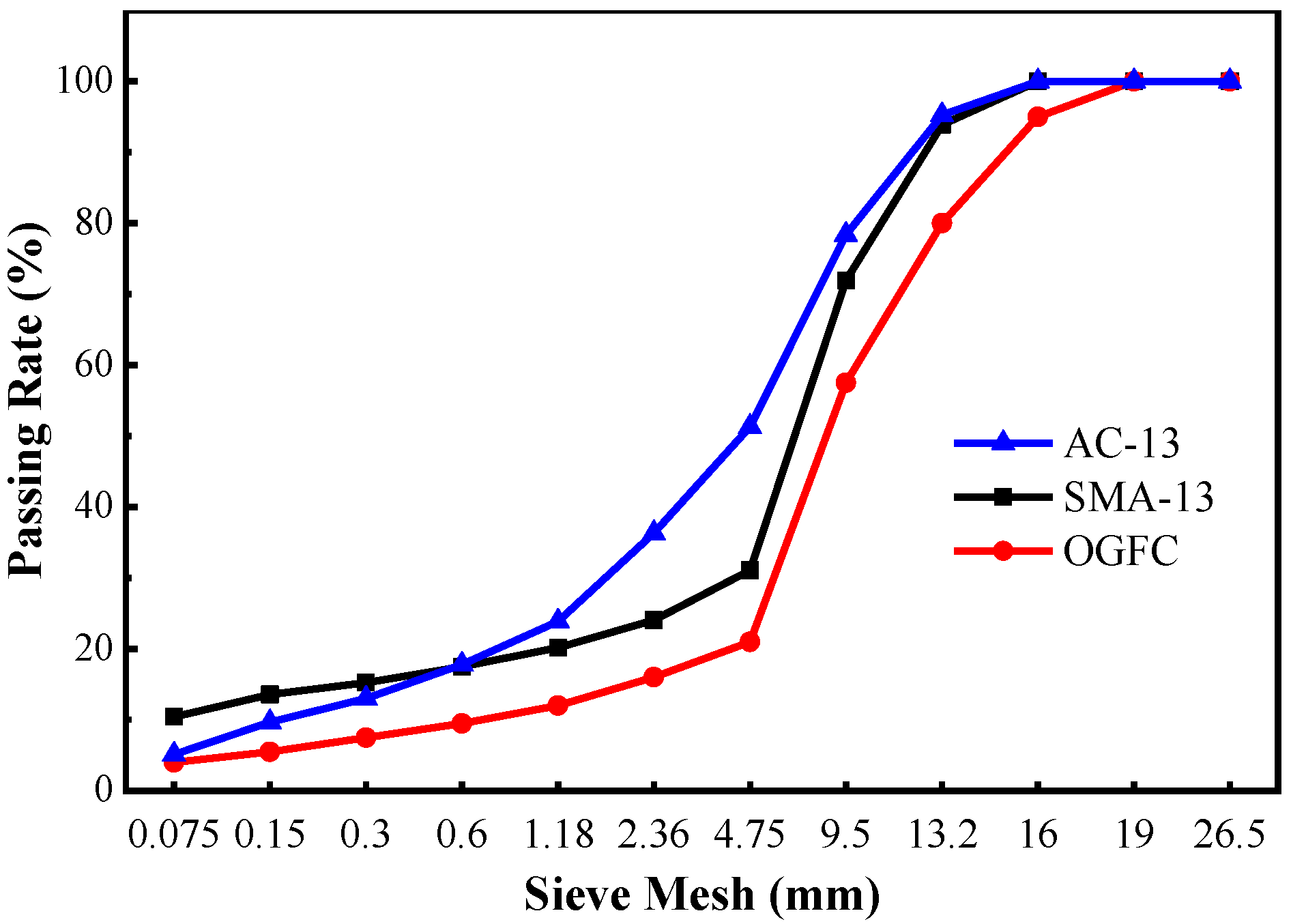

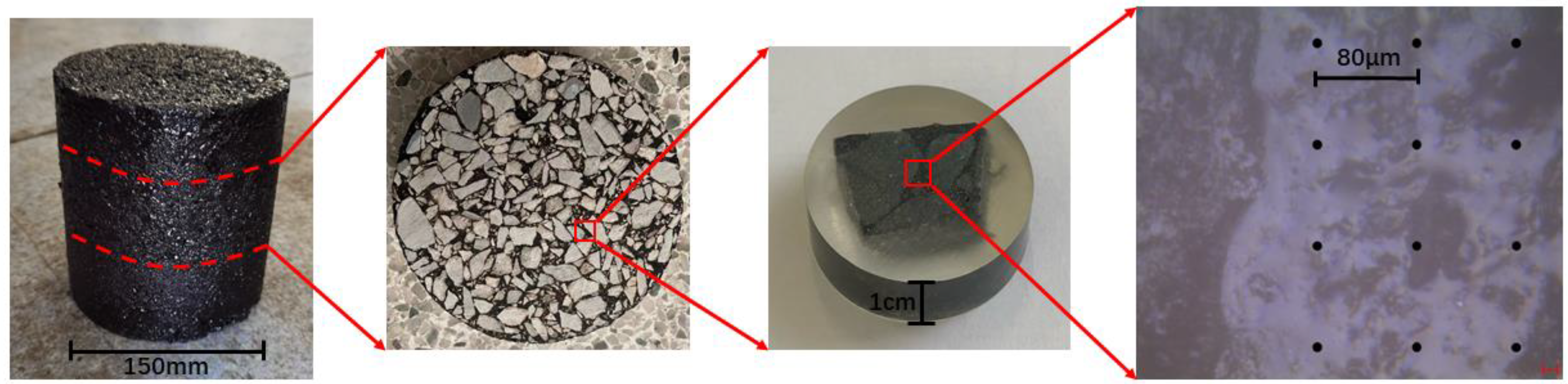

2.1.1. Asphalt Mixture Specimens

2.1.2. Asphalt Mastic Specimens

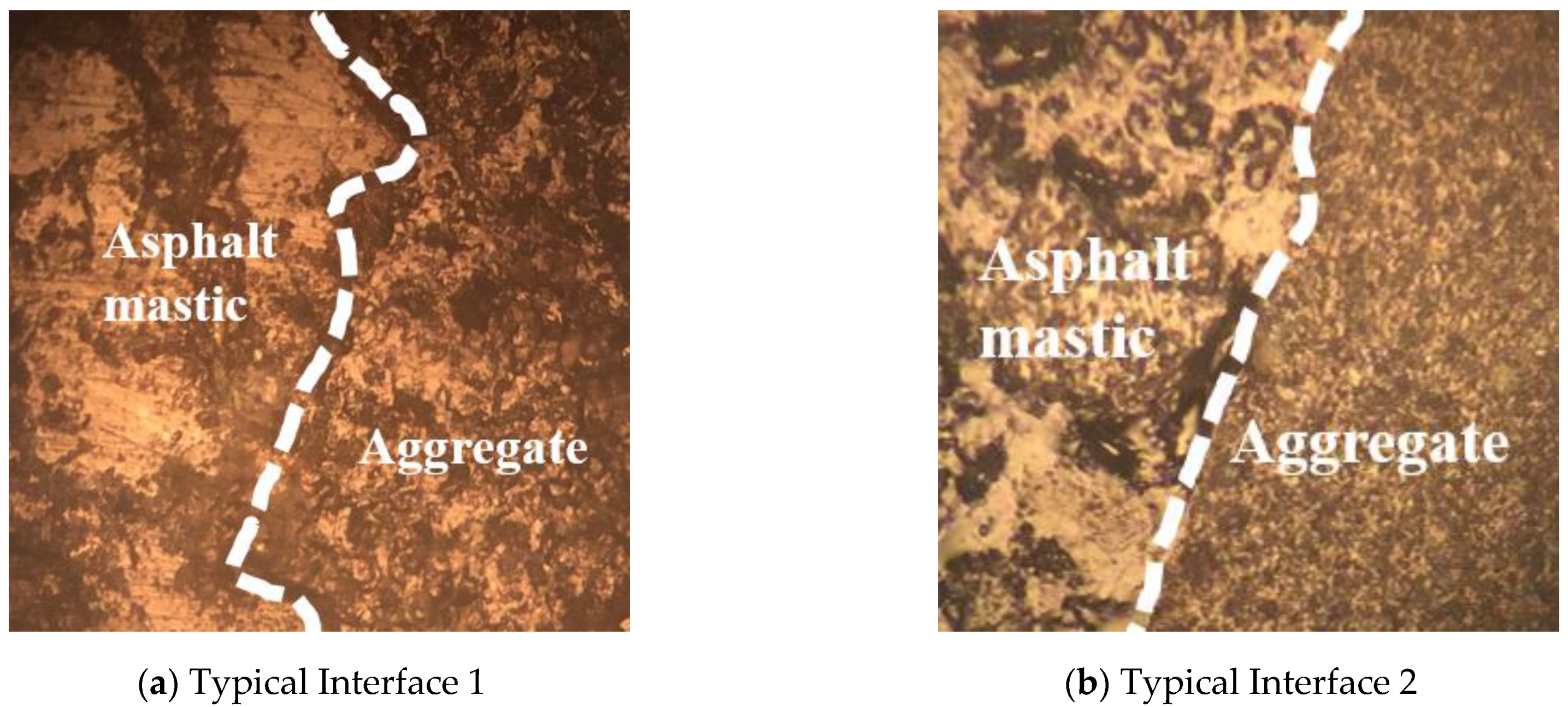

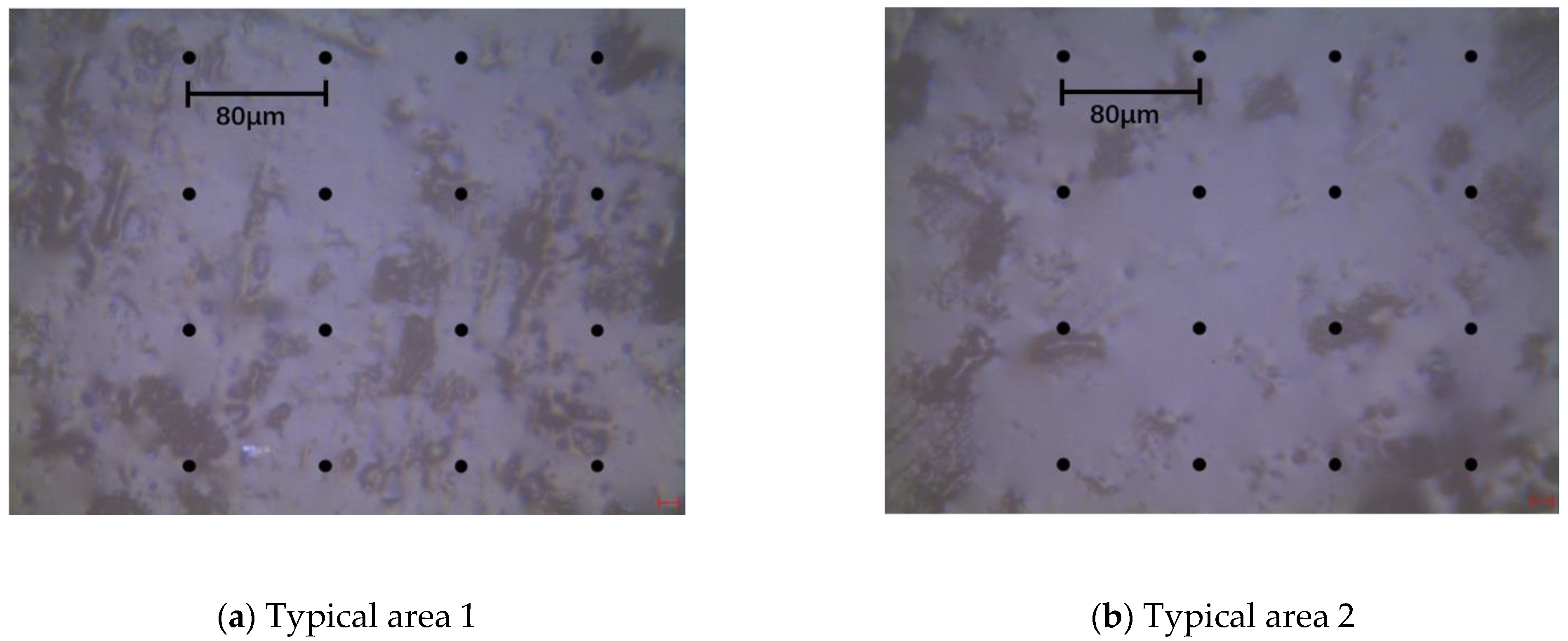

2.2. Test Method

3. Results and Discussion

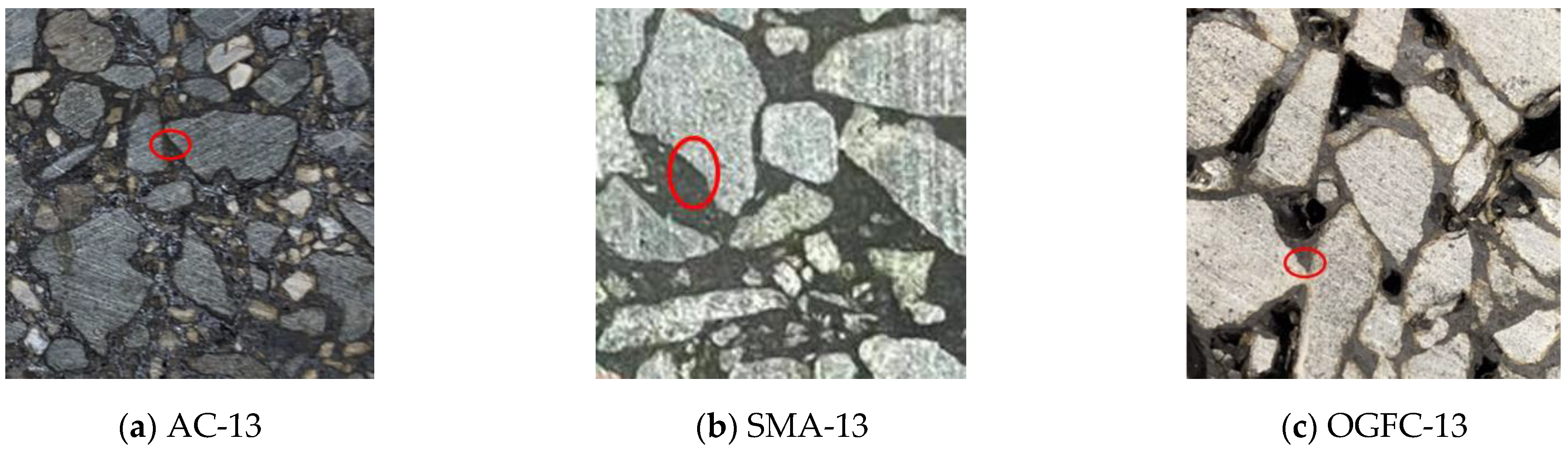

3.1. Analysis of the Three Gradations

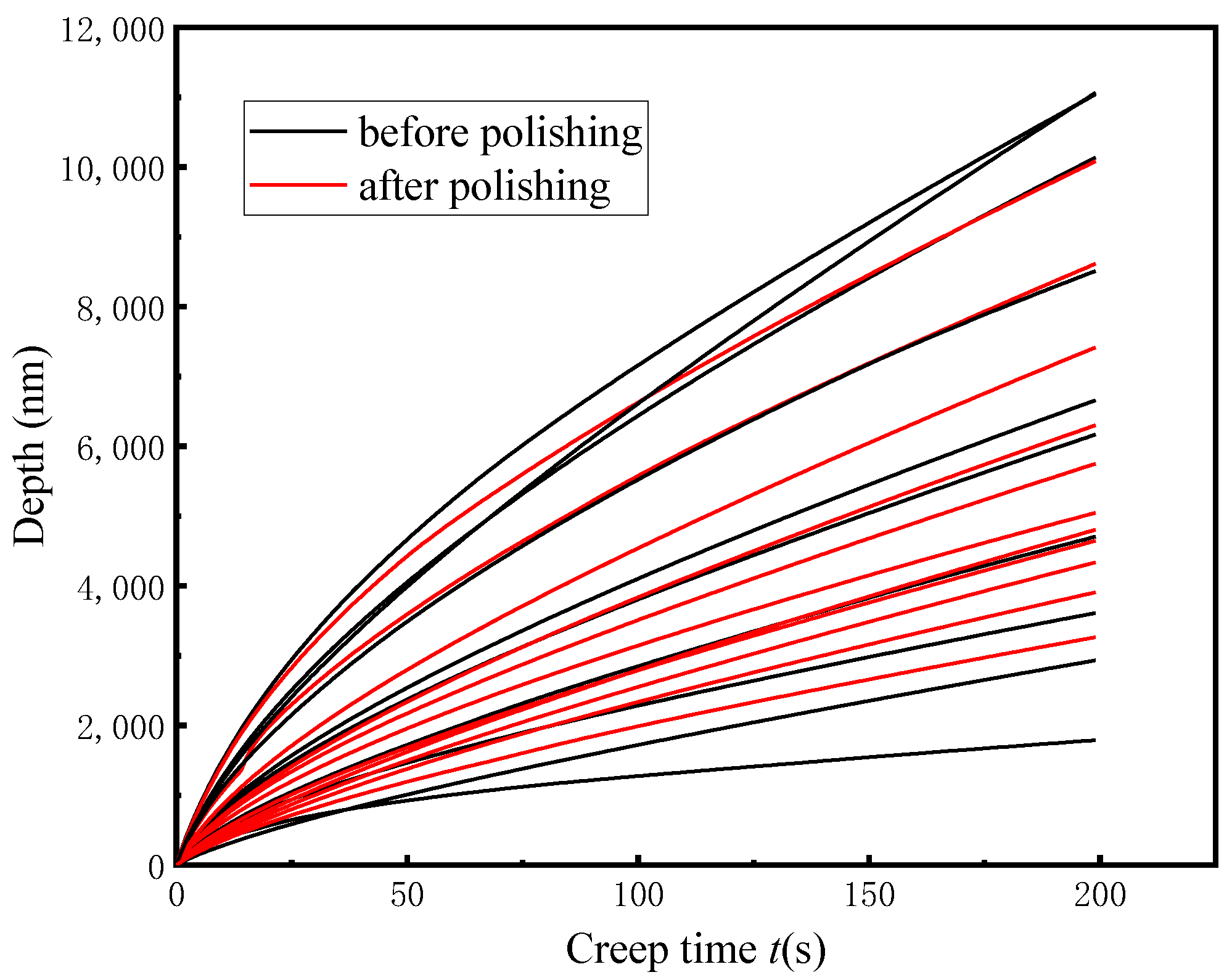

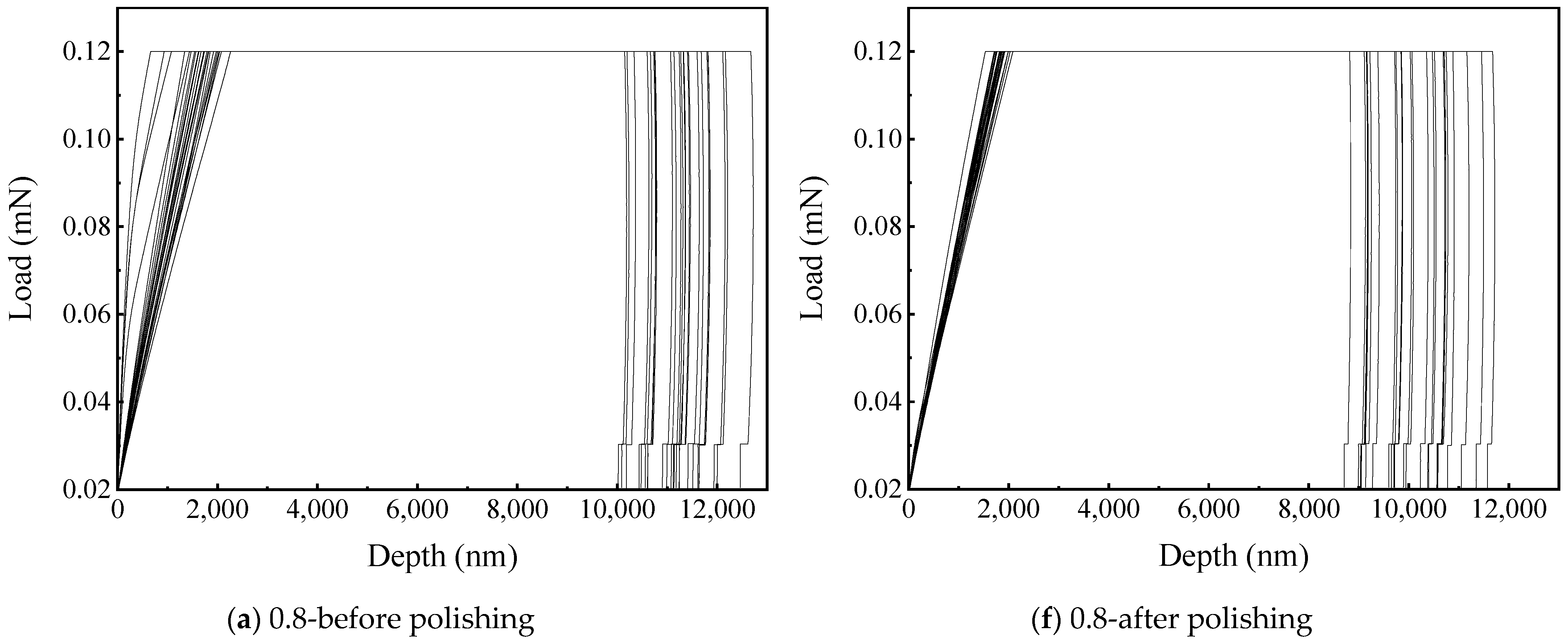

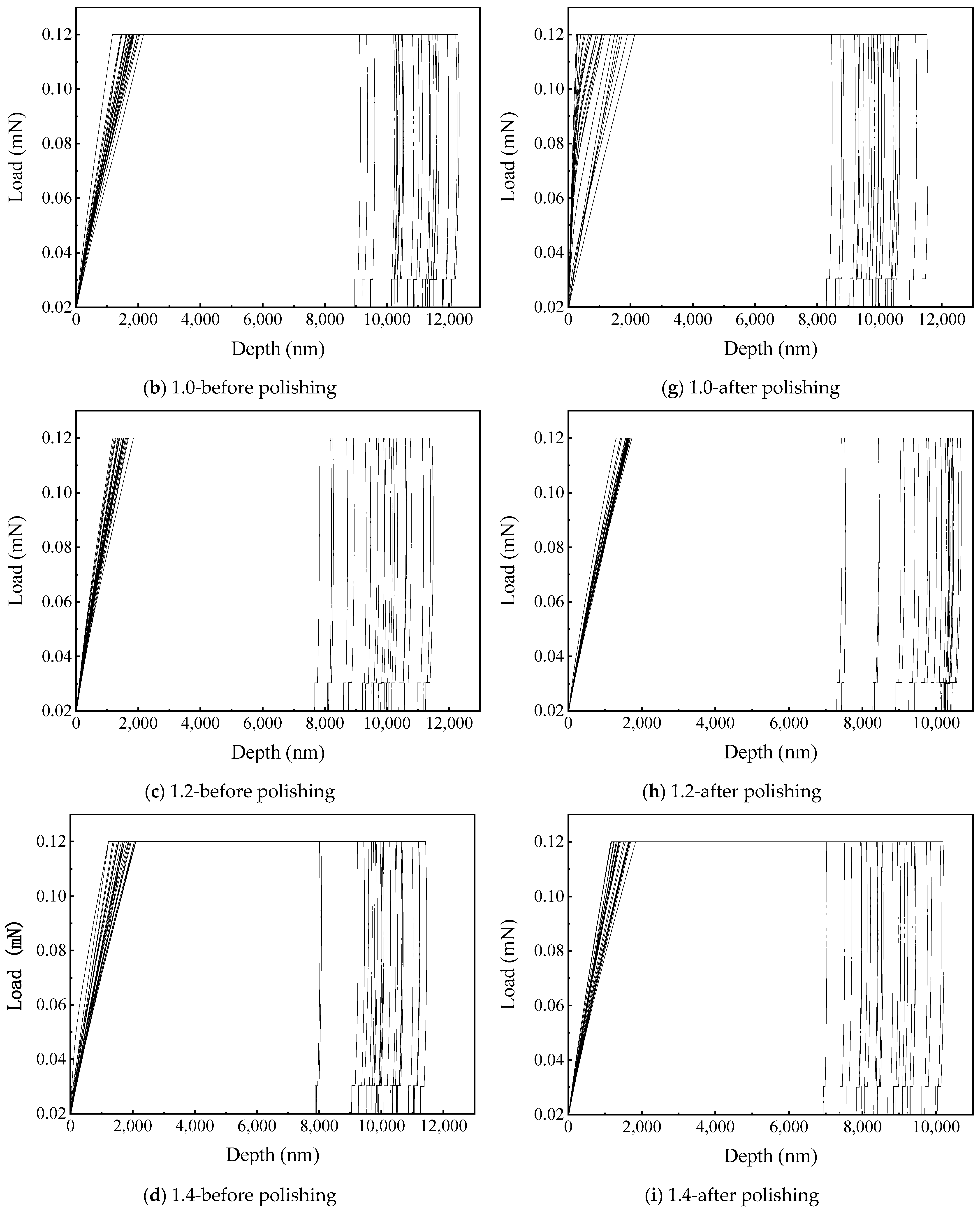

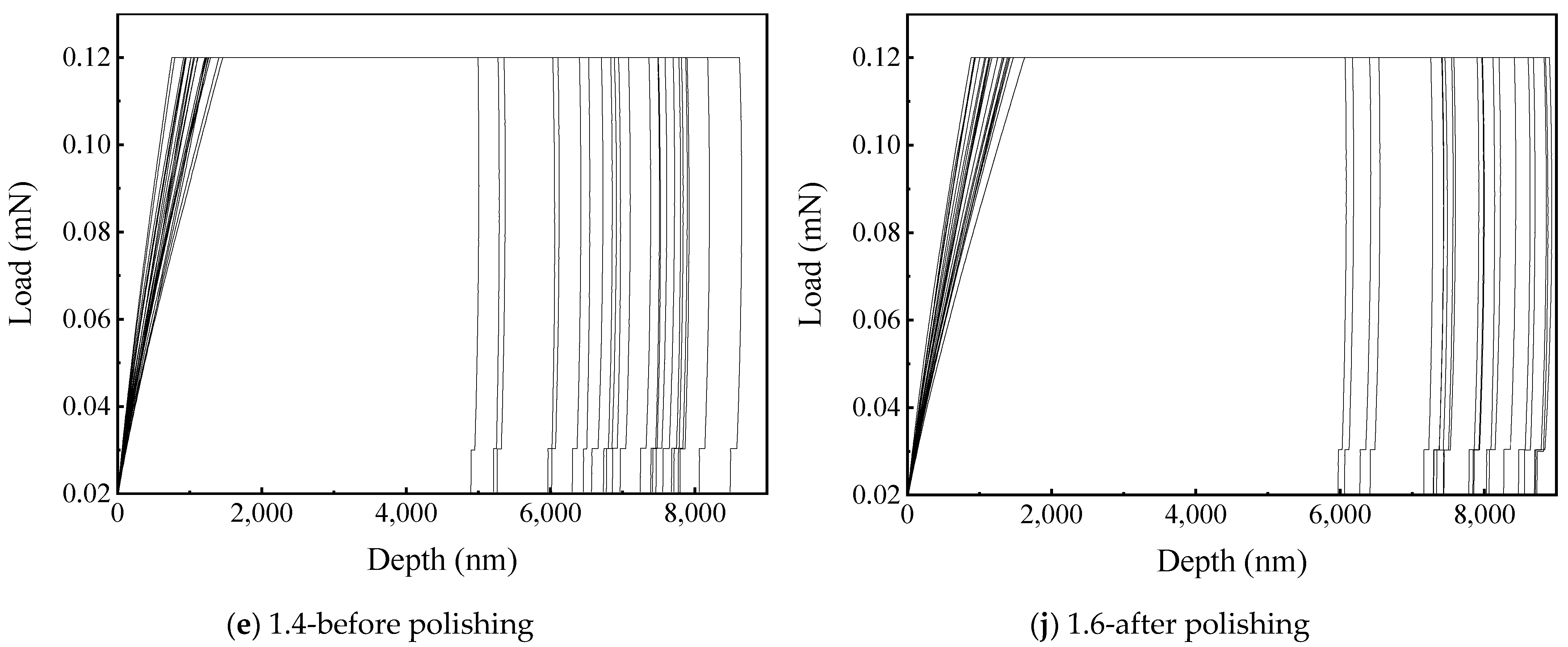

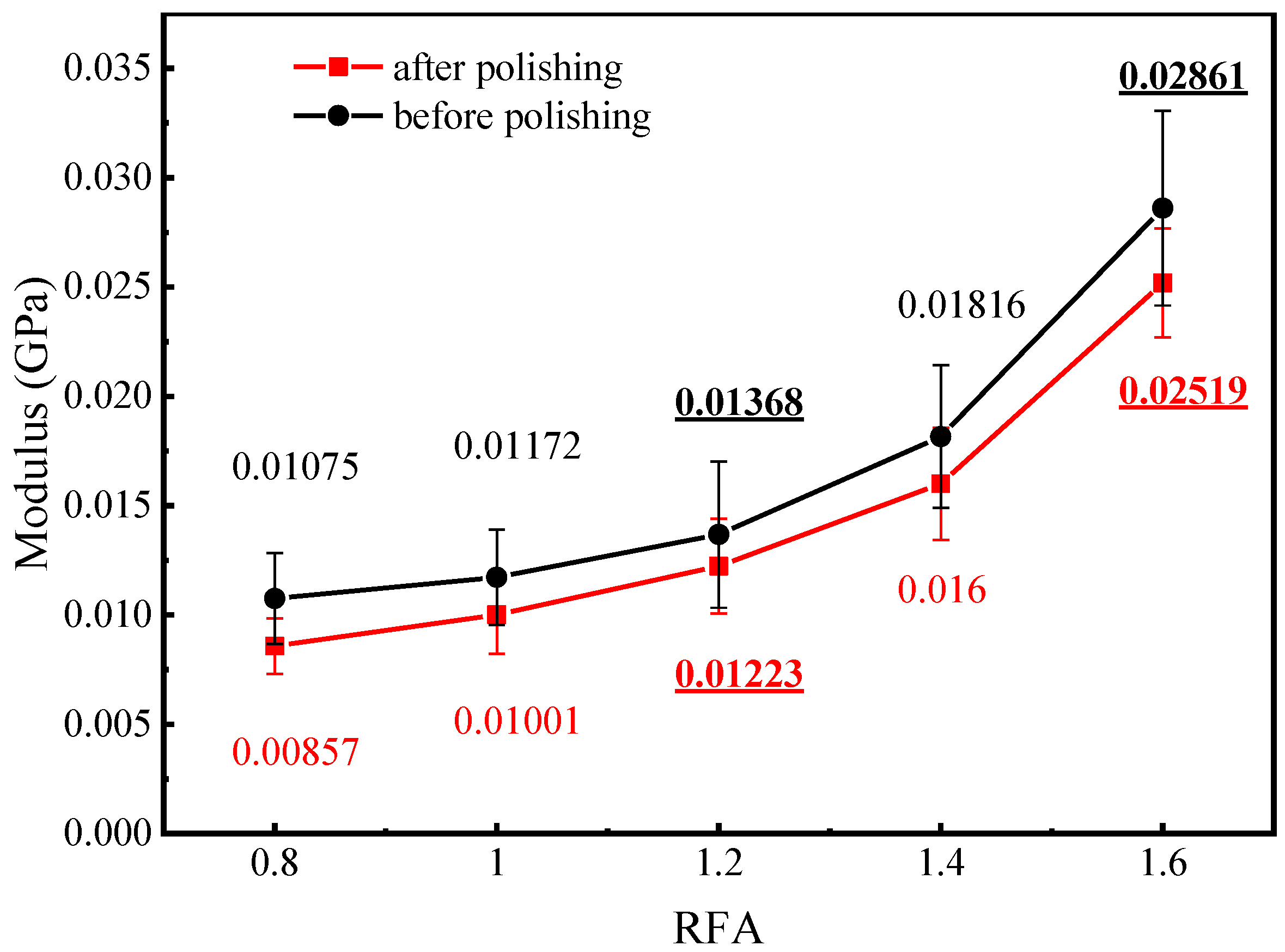

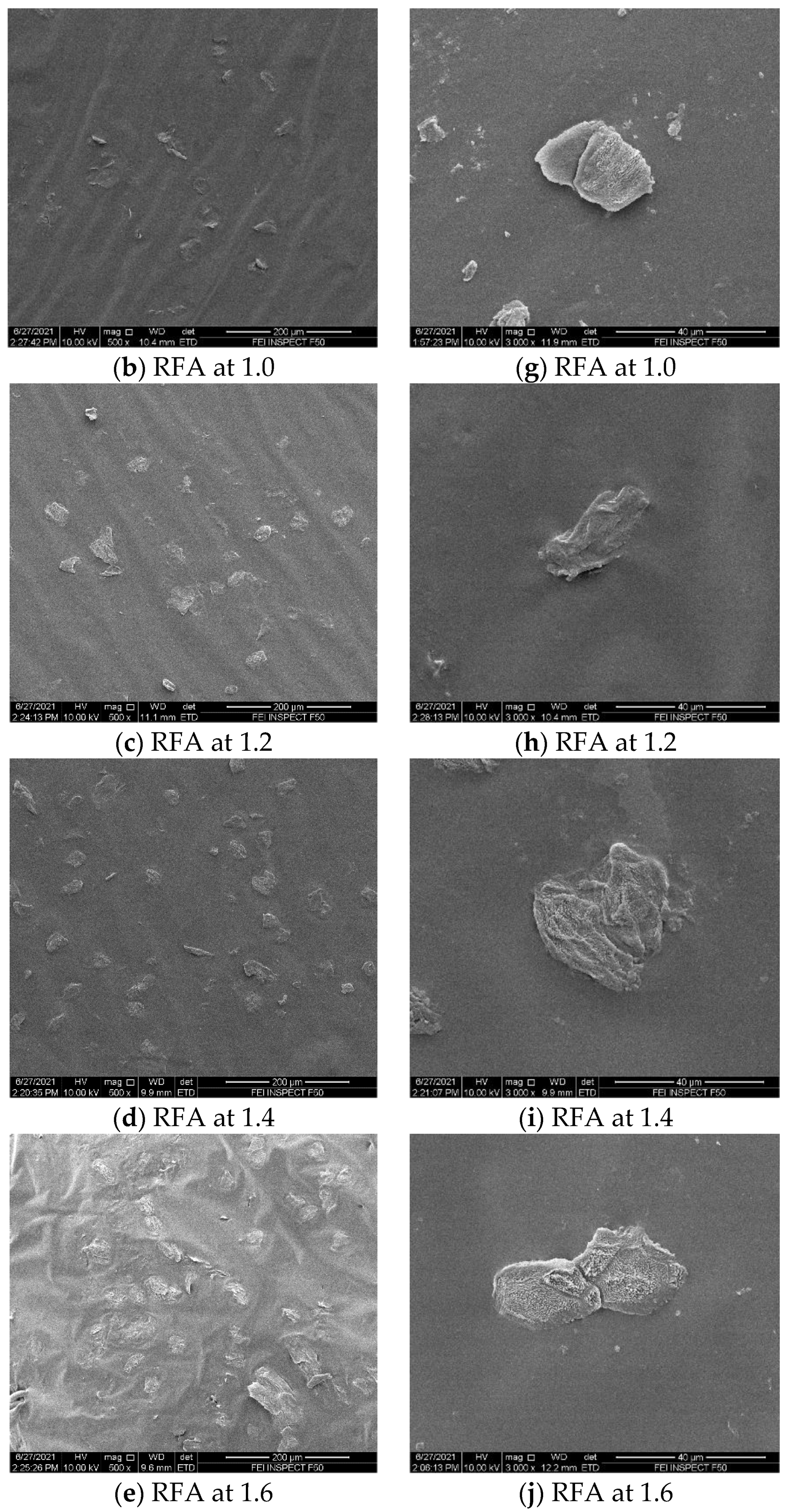

3.2. Effect of Different Rates of Filler and Asphalt

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Arimateia Almeida e Silva, J.; Rodrigues, J.K.G.; de Carvalho, M.W.; de Figueredo Lopes Lucena, L.C.; Cavalcante, E.H. Mechanical performance of asphalt mixtures using polymer-micronized PET-modified binder. Road Mater. Pavement Des. 2018, 19, 1001–1009. [Google Scholar]

- Morovatdar, A.; Ashtiani, R.S.; Licon, C.; Tirado, C.; Mahmoud, E. Novel Framework for the Quantification of Pavement Damages in the Overload Corridors. TRR 2020, 2674, 036119812092580. [Google Scholar] [CrossRef]

- Lu, J.; Gong, M.; Chen, J.; Zhang, D.; Liu, Z.J.C.; Materials, B. Study on the decay behavior of the stability of asphalt mixture under different dry-wet cycle conditions. Constr. Build. Mater. 2021, 296, 123307. [Google Scholar] [CrossRef]

- Polaczyk, P.; Ma, Y.; Xiao, R.; Hu, W.; Huang, B.J.R.M.; Design, P. Characterization of aggregate interlocking in hot mix asphalt by mechanistic performance tests. Road Mater. Pavement. 2021, 22, S498–S513. [Google Scholar] [CrossRef]

- Ghuzlan, K.A.; Al-Mistarehi, B.; Al-Momani, A.S.J.C.; Materials, B. Rutting performance of asphalt mixtures with gradations designed using Bailey and conventional Superpave methods. Constr. Build. Mater. 2020, 261, 119941. [Google Scholar] [CrossRef]

- Arifuzzaman, M. Nano-scale evaluation of moisture damage in asphalt. Ph.D. Thesis, The University of New Mexico, Albuquerque, NM, USA, 2010. [Google Scholar]

- Khorasani, S.; Masad, E.; Kassem, E.; Al-Rub, R.A. Nano-Mechanical Characterization of Mastic, Aggregate, and Interfacial Zone in Asphalt Composites. J. Test. Eval. 2013, 41, 924–932. [Google Scholar] [CrossRef]

- Tarefder, R.A.; Zaman, A.M.; Uddin, W. Determining Hardness and Elastic Modulus of Asphalt by Nanoindentation. Int. J. Geomech. 2010, 10, 106–116. [Google Scholar] [CrossRef]

- Ger, A.; Lackner, R.; Eberhardsteiner, J.J.M. Identification of viscoelastic properties by means of nanoindentation taking the real tip geometry into account. Meccanica 2007, 42, 293–306. [Google Scholar]

- Veytskin, Y.; Bobko, C.; Castorena, C. Nanoindentation investigation of asphalt binder and mastic viscoelasticity. Int. J. Pavement Eng. 2016, 17, 363–376. [Google Scholar] [CrossRef]

- Veytskin, Y.; Bobko, C.; Castorena, C. Nanoindentation and atomic force microscopy investigations of asphalt binder and mastic. J. Mater. Civ. Eng. 2016. [Google Scholar] [CrossRef]

- Fischer-Cripps, A.C. A simple phenomenological approach to nanoindentation creep. Mater. Sci. Eng. 2004, 385, 74–82. [Google Scholar] [CrossRef]

- Oyen, M.J. Spherical Indentation Creep Following Ramp Loading. J. Mater. Res. 2005, 20, 2094–2100. [Google Scholar] [CrossRef]

- Lu, H.; Wang, B.; Ma, J.; Huang, G.; Viswanathan, H.J. Measurement of Creep Compliance of Solid Polymers by Nanoindentation. Mech. Time-Depend. Mater. 2003, 7, 189–207. [Google Scholar] [CrossRef]

- Khan, Z.; Faisal, H.M.; Tarefder, R. Fracture Toughness Measurement of Asphalt Concrete by Nanoindentation. In Proceedings of the ASME 2017 International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2017. [Google Scholar]

- Yao, Z.; Zhu, H.; Gong, M.; Yang, J.; Xu, G.; Zhong, Y.J.C.; Materials, B. Characterization of asphalt materials’ moisture susceptibility using multiple methods. Constr. Build. Mater. 2017, 155, 286–295. [Google Scholar] [CrossRef]

- Abd, D.M.; Al-Khalid, H.; Akhtar, R.J.C.; Materials, B. An investigation into the impact of warm mix asphalt additives on asphalt mixture phases through a nano-mechanical approach. Constr. Build. Mater. 2018, 189, 296–306. [Google Scholar] [CrossRef]

- Zhu, X.; Ying, Y.; Li, L.; Du, Y.; Feng, L.J. Identification of interfacial transition zone in asphalt concrete based on nano-scale metrology techniques. Mater. Des. 2017, 129, 91–102. [Google Scholar] [CrossRef]

- Hu, J.; Huang, Q.; Lou, N.; Luo, S.J.M. Microstructural Characteristics of Interfacial Zone in Asphalt Mixture Considering the Influence of Aggregates Properties. Materials 2020, 13, 2558. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Qian, Z.; Hu, J.; Zheng, D.; Yu, J.J.C.; Materials, B. Investigation on the properties of aggregate-mastic interfacial transition zones (ITZs) in asphalt mixture containing recycled concrete aggregate. Constr. Build. Mater. 2020, 269, 121257. [Google Scholar] [CrossRef]

- Dan, Z. Research on Nanoindentation Response of Metallic Glasses via Molecular Dynamics Simulations. Ph.D. Thesis, Jilin University, Changchun, China, June 2020. [Google Scholar]

- Tarefder, R.A.; Faisal, H.J. Effects of Dwell Time and Loading Rate on the Nanoindentation Behavior of Asphaltic Materials. J. Nanomech. Micromech. 2013, 3, 17–23. [Google Scholar] [CrossRef]

- Zeheng, Y. Characterization of Micromechanical Propertires of Aged Asphalt Mixtures by Nanoindentation. Master’s Thesis, Southeast University, Nanjing, China, May 2019. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. An Improved Technique for Determining Hardness and Elastic-Modulus Using Load and Displacement Sensing Indentation Experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Na, W. Design of SMA Ratios and Road Performance of Southern Mountain Highways. Master’s Thesis, Chang’an University, Xi’an, China, June 2003. [Google Scholar]

- Lei, W. Study on OGFC Gradation Regulations and Pavement Performance. Master’s Thesis, Chang’an University, Xi’an, China, June 2009. [Google Scholar]

- Weinian, Z. Drainage asphalt mixture (OGFC-13) ratio design. J. Chang. Inst. Technol. 2013, 6, 39–43. [Google Scholar]

- Shao, X.Z.; Tan, Y.Q.; Sun, L.J. Research on Microstructure of Asphalt Mortar. Highway 2003, 105–109. [Google Scholar]

- Ma, X.Y.; Chen, C.J.; Yang, P.W. Fatigue life prediction of asphalt mastics based on simplified viscoelastic continuum damage model. J. Chang. Univ. (Nat. Sci. Ed.) 2019, 39, 35–43. [Google Scholar] [CrossRef]

| Gradation | Air Void Content | Number of Gyrations | Optimum Asphalt Content |

|---|---|---|---|

| AC-13 | 4% | 100 | 5.0% |

| SMA-13 | 4% | 100 | 6.0% |

| OGFC | 20% | 75 | 4.1% |

| Test | SBS Modified Asphalt |

|---|---|

| Penetration(25 °C, 100 g, 5 s)/0.1 mm | 55 |

| Softening point/°C | 87.7 |

| Ductility(10 °C, 5 cm/min)/cm | 41 |

| Mass change/% | 0.13 |

| Gradation | Modulus/GPa | Coefficient of Variation/% |

|---|---|---|

| AC-13 | 0.576 | 31.8% |

| SMA-13 | 0.028 | 16.3% |

| OGFC | 0.014 | 11.03% |

| RFA/Polish | Modulus/GPa | Coefficient of Variation/% | ||

|---|---|---|---|---|

| Before Polishing | After Polishing | Before Polishing | After Polishing | |

| 0.8 | 0.0108 | 0.0086 | 17.1% | 21.1% |

| 1.0 | 0.0117 | 0.0100 | 11.9% | 12.6% |

| 1.2 | 0.0137 | 0.0122 | 15.4% | 14.3% |

| 1.4 | 0.0181 | 0.0160 | 18.3% | 16.9% |

| 1.6 | 0.0286 | 0.0252 | 16.8% | 17.7% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Xu, G.; Wang, T.; Chen, H.; Wang, H.; Yang, J. Analysis of Nanoindentation Test Results of Asphalt Mixture with Different Gradations. Appl. Sci. 2021, 11, 7992. https://doi.org/10.3390/app11177992

Yu Y, Xu G, Wang T, Chen H, Wang H, Yang J. Analysis of Nanoindentation Test Results of Asphalt Mixture with Different Gradations. Applied Sciences. 2021; 11(17):7992. https://doi.org/10.3390/app11177992

Chicago/Turabian StyleYu, Yunhong, Gang Xu, Tianling Wang, Huimin Chen, Houzhi Wang, and Jun Yang. 2021. "Analysis of Nanoindentation Test Results of Asphalt Mixture with Different Gradations" Applied Sciences 11, no. 17: 7992. https://doi.org/10.3390/app11177992