Chloride Ion Diffusion and Durability Characteristics of Rural-Road Concrete Pavement of South Korea Using Air-Cooled Slag Aggregates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Proportions

2.3. Test Methods

2.3.1. Flexural Strength

2.3.2. Chloride Ion Diffusion

2.3.3. Repeated Wetting-Drying

2.3.4. Abrasion Resistance

2.3.5. Impact Resistance

2.3.6. Repeated Freezing and Thawing Resistance

3. Results

3.1. Flexural Strength

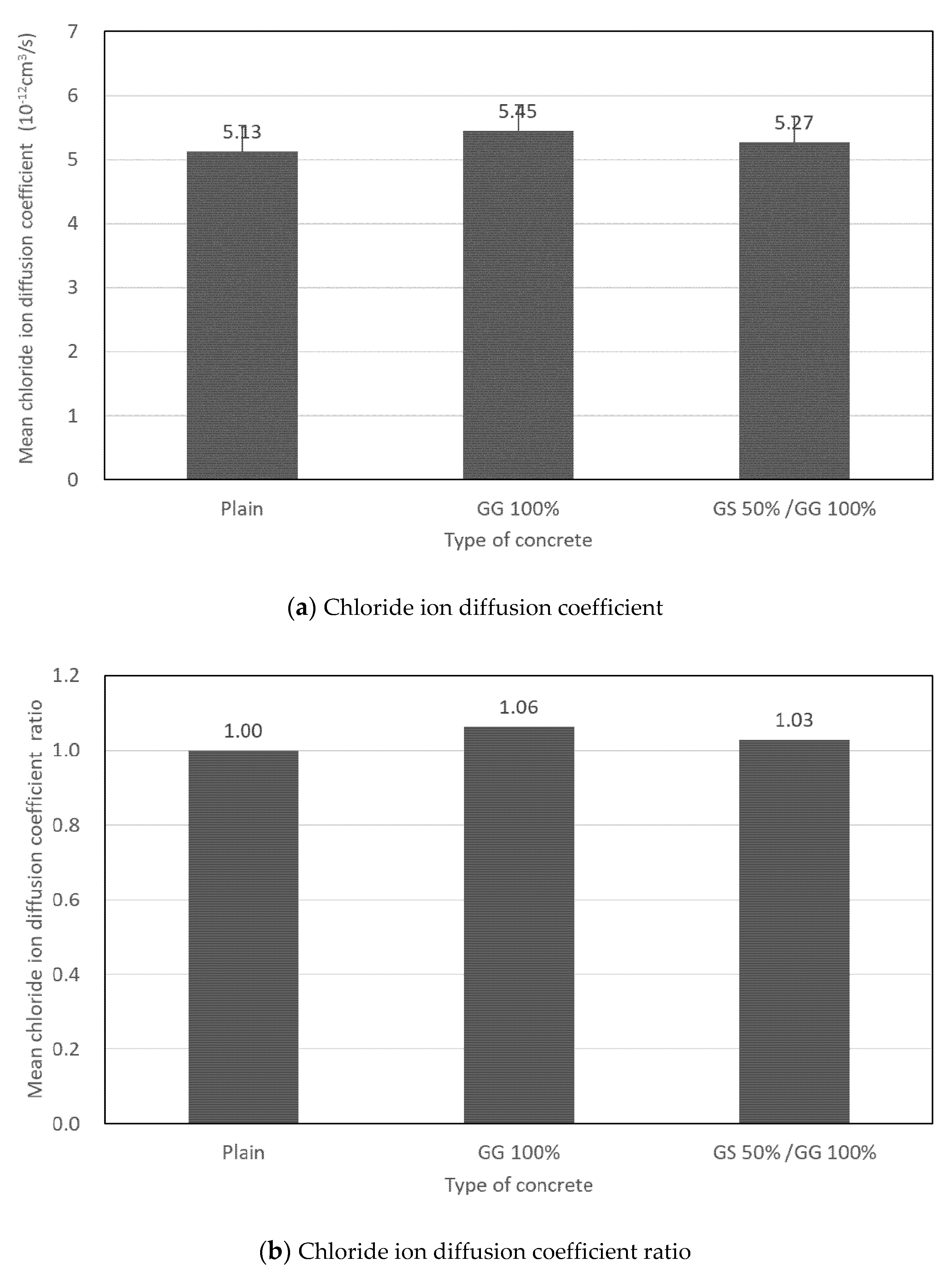

3.2. Chloride Ion Diffusion

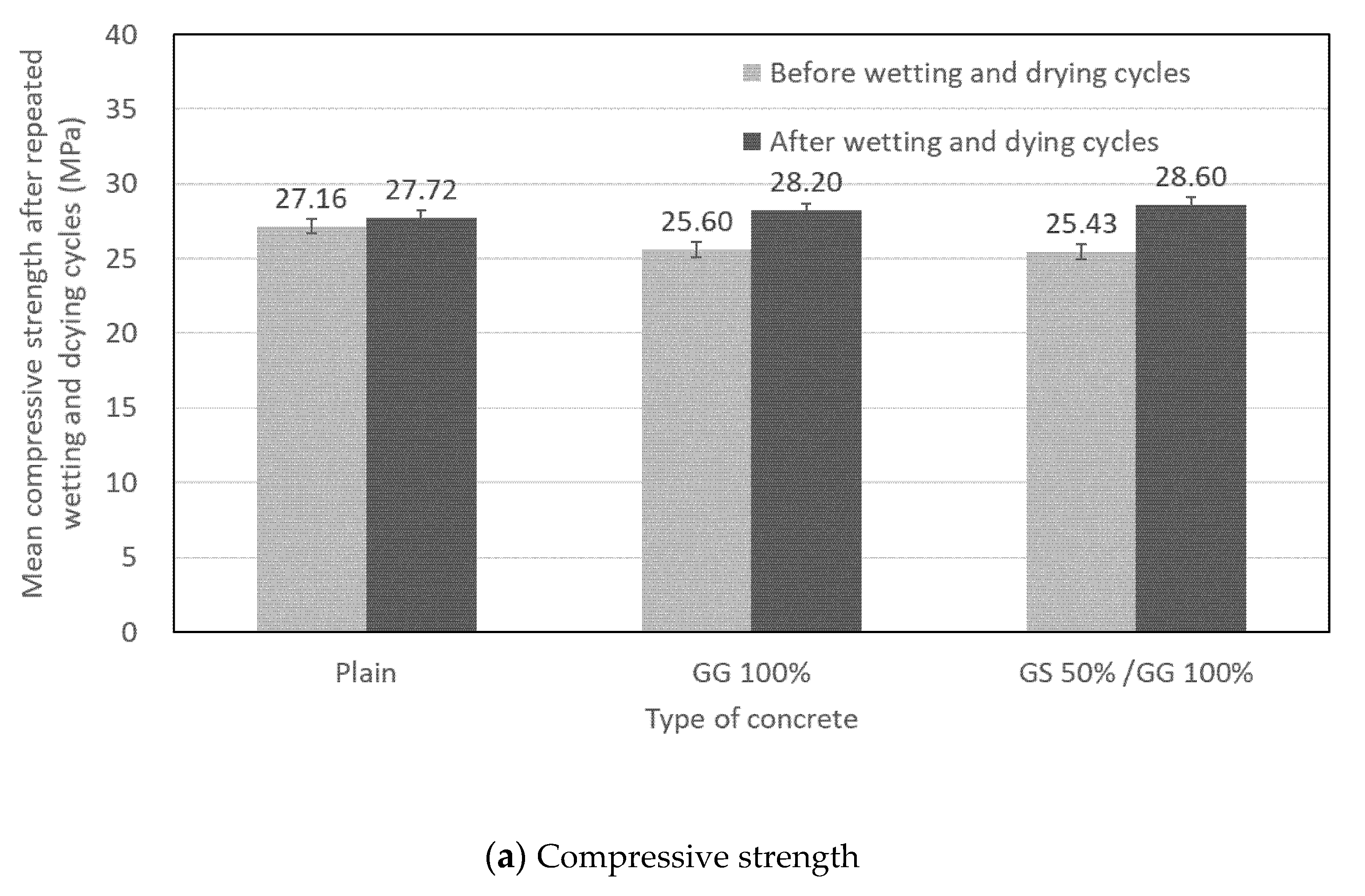

3.3. Repeated Wetting and Drying

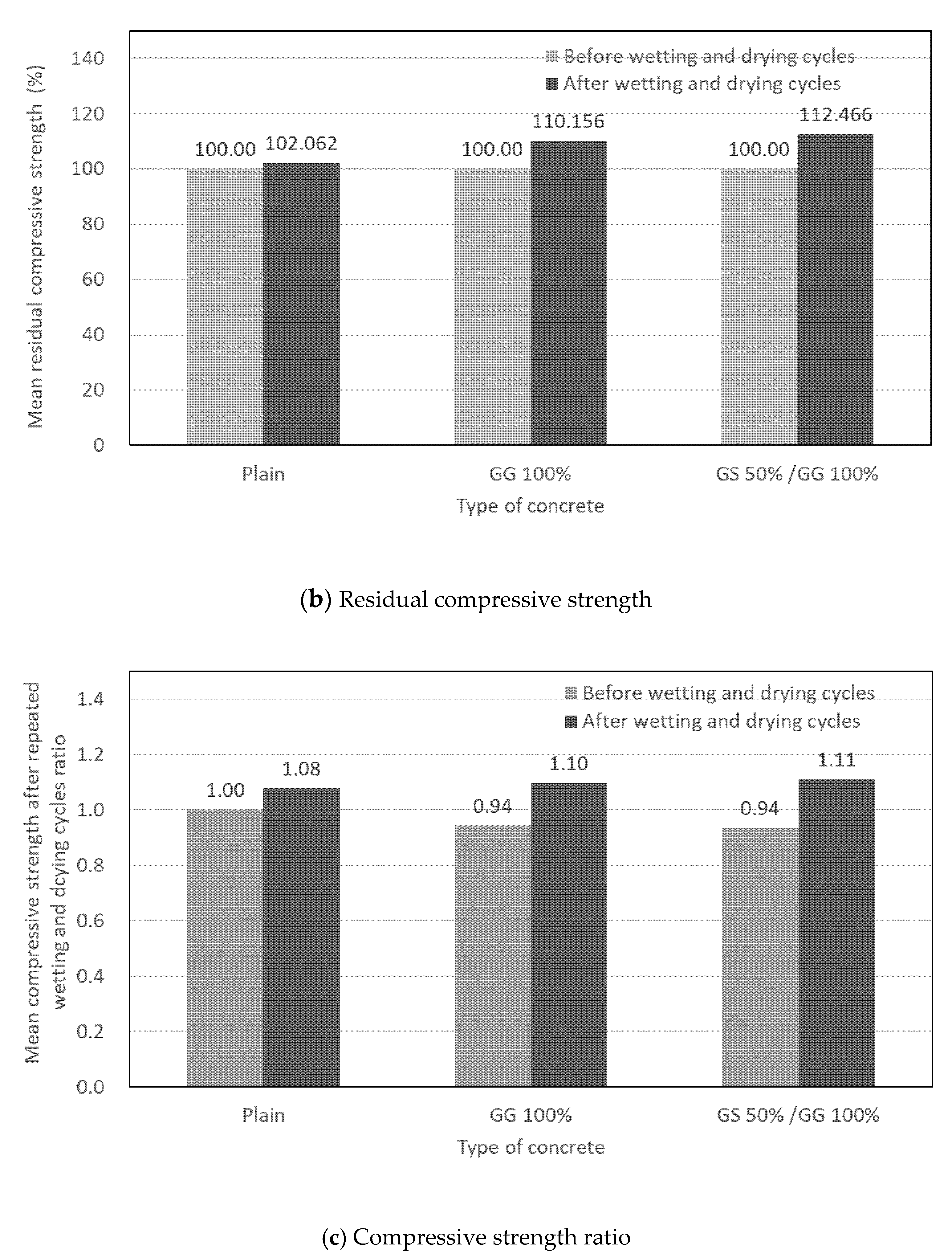

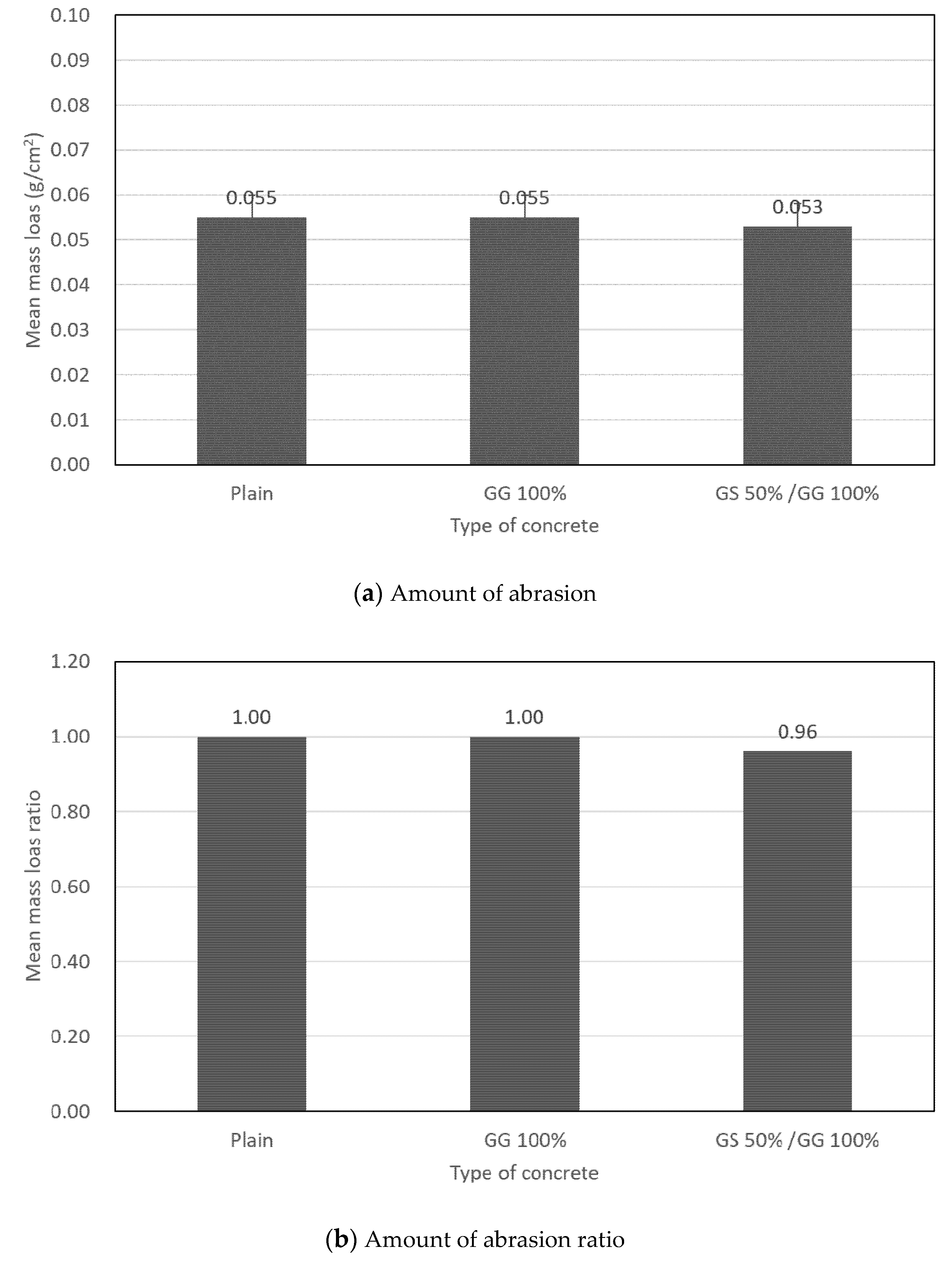

3.4. Abrasion Resistance

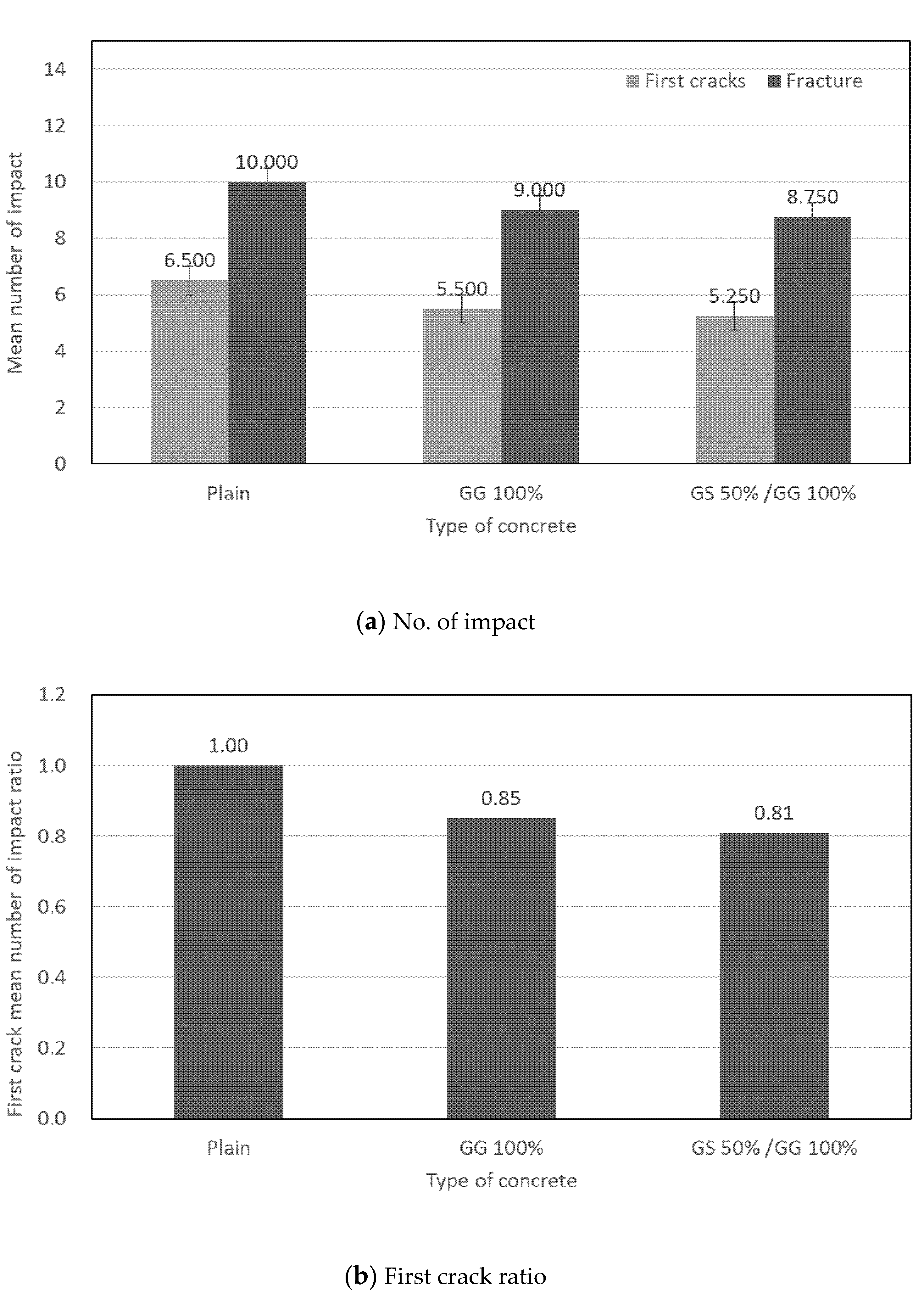

3.5. Impact Resistance

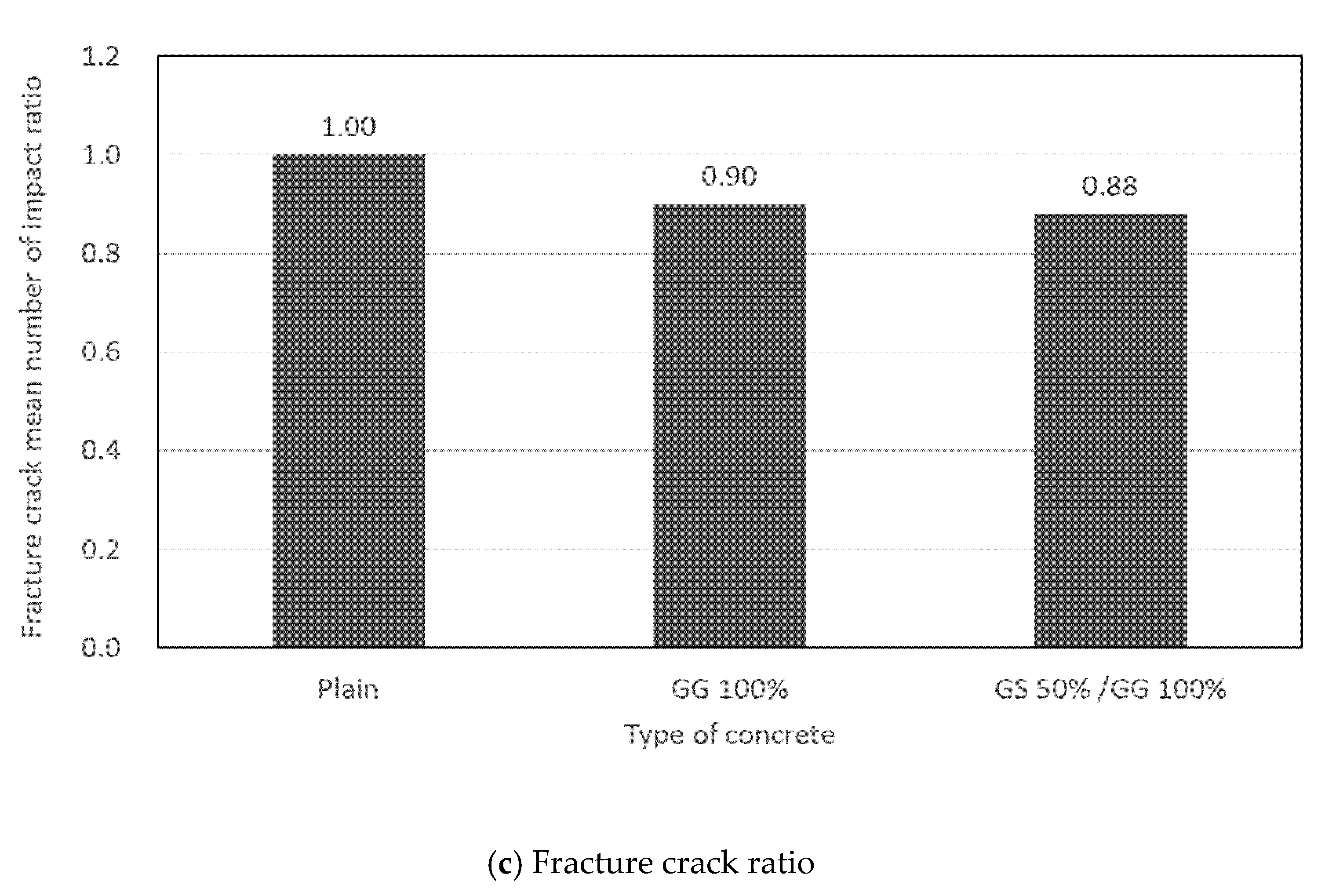

3.6. Repeated Freezing and Thawing Cycles

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, J.M.; Choi, H.K.; Yoo, T.J.; Kim, Y.M. Establishing a Resource Circulation Network through the Use of Blast Furnace Slag Ready-Mix Concrete Aggregate; EIP Report; Korea Industrial Complex Corporation: Dae-gu, Korea, 2017. [Google Scholar]

- Jeon, J.G.; Jin, S.J.; Kim, D.H. Present Status and Recycling Technology for Slag in Korea. J. Korean Recycl. Constr. Resour. Inst. 2013, 8, 8–10. [Google Scholar]

- Choi, S.W.; Kim, V.; Jang, W.S.; Kim, E.Y. The Present Situation of Production and Utilization of Steel Slag in Korea and Other Countries. Mag. Korea Concr. Inst. 2007, 19, 28–33. [Google Scholar]

- Korea Waste Association. Study on the Improvement of the Steel Slag Recycling System; Ministry of Environment: Sejong, Korea, 2011.

- Ryu, D.H.; Choi, S.W. The Prospect for Utilization of Blast Furnace Slag as Concrete’s Aggregate. J. Korean Recycl. Constr. Resour. Inst. 2010, 5, 24–32. [Google Scholar]

- Mun, H.Y.; Jeong, S.J.; Lim, N.K. Aggregate for concrete using industrial by-products and waste-blast furnace slag aggregate. Mag. Korea Concr. Inst. 1997, 9, 18–22. [Google Scholar]

- Ryu, C.S. Actual State of Recycled Aggregate Utilization & Improving Way of Construction Waste Recycle. J. Korean Recycl. Constr. Resour. Inst. 2007, 3, 23–26. [Google Scholar]

- Park, M.S.; Kim, Y.S. A Study on the Sulfate Attack Resistance of Concrete Using EAF Slag as Fine Aggregate. J. Korean Inst. Archit. Constr. 2009, 9, 81–87. [Google Scholar]

- Song, T.Y.; Lee, K.C.; Lee, W.P. Plan for Expanded Recycling of Recycled Aggregates as Construction Materials. J. Korean Recycl. Constr. Resour. Inst. 2016, 11, 14–17. [Google Scholar]

- Yoo, Y.S.; Choi, H.B.; Bang, J.H.; Chae, S.C.; Kim, J.W.; Kim, J.M.; Lee, S.W. CO2 Sequestration and Utilization of Calcium-extracted Slag Using Air-cooled Blast Furnace Slag and Convert Slag. Appl. Chem. Eng. 2017, 28, 101–111. [Google Scholar]

- Lee, D.G.; Min, G.H.; Jeong, Y.W. A Study on the Reduction of Drying Shrinkage of Mortar and Concrete Using the Expandability of Rapidly Cooled Slag Fine Aggregate. J. Korea Acad.-Ind. Coop. Soc. 2015, 16, 3511–3517. [Google Scholar]

- Lee, S.T.; Park, G.P. Mechanical Properties and Durability of Concrete Incorporating Air-Cooled Slag. J. Korea Acad.-Ind. Coop. Soc. 2017, 18, 356–363. [Google Scholar]

- Lim, H.S.; Lee, H.S. Experimental Study on Evaluation on Volume Stability of the Electric Arc Furnace Oxidizing Slag Aggregate. J. Korea Inst. Struct. Maint. Insp. 2017, 21, 78–86. [Google Scholar]

- Jeong, W.K.; Kim, Y.S.; Bae, J.O. Development and application examples of high-performance concrete pavement repair materials using fine aggregates of oxidized slag of an electric furnace, a by-product of the steel industry. Korean Soc. Road Eng. Road 2012, 14, 39–50. [Google Scholar]

- de Matos, P.R.; Oliveira, J.C.; Medina, T.M.; Magalhaes, D.C.; Gleize, P.J.; Schankoski, R.A.; Pilar, R. Use of air-cooled blast furnace slag as supplementary cementitious material for self-compacting concrete production. Constr. Build. Mater. 2020, 262, 102–120. [Google Scholar] [CrossRef]

- Verian, K.P.; Behnood, A. Effects of deicers on the performance of concrete pavements containing air-cooled blast furnace slag and supplementary cementitious materials. Cem. Concr. Compos. 2018, 90, 27–41. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Gu, L.; Pour, A.F. Normal- and high-strength concretes incorporating air-cooled blast furnace slag coarse aggregates: Effect of slag size and content on the behavior. Constr. Build. Mater. 2016, 126, 138–146. [Google Scholar] [CrossRef]

- Abdel-Ghani, N.T.; El-Sayed, H.A.; El-Habak, A.A. Utilization of by-pass cement kiln dust and air-cooled blast-furnace steel slag in the production of some “green” cement products. HBRC J. 2018, 14, 408–414. [Google Scholar] [CrossRef] [Green Version]

- Smith, K.D.; Morian, D.A.; van Dam, T.J. Use of Air-Cooled Blast Furnace Slag as Coarse Aggregate in Concrete Pavements—A Guide to Best Practice; FHWA-HIF-009; Federal Highway Administration: Washington, DC, USA, 2012.

- Min, K.S.; Park, Y.K.; Lee, J.H.; Kim, H.W.; Jeong, K.Y.; Yoon, K.W. A Study on Application of PHC Pile Concrete of Aggregate using Air-cooled Blast Furnace Slag Aggregate. In Proceedings of the Korea Concrete Institute 2014 Spring Conference, Seoul, Korea, 16 May 2014; Volume 26, pp. 341–342. [Google Scholar]

- Park, S.B. Construction Materials; Muneundang: Seoul, Korea, 2010. [Google Scholar]

- Shin, K.S.; Lee, B.K.; Kim, K.Y. Durability of Concrete Using Blast Furnace Slag Powder. J. Korean Recycl. Constr. Resour. Inst. 2012, 7, 13–17. [Google Scholar]

- Lee, H.J.; Se, J.I.; Ryu, S.W. Bond Behavior of Concrete According to Replacement Ratio of Fly Ash and Compressive Strength of Concrete. J. Korean Recycl. Constr. Resour. Inst. 2016, 4, 19–24. [Google Scholar]

- Ahn, B.H.; Lee, S.J.; Park, C.G. Physical and Mechanical Properties of Rural-Road Pavement Concrete in South Korea Containing Air-Cooled Blast-Furnace Slag Aggregates. Appl. Sci. 2021, 11, 5645. [Google Scholar] [CrossRef]

- Korea Ministry of Agriculture, Food and Rural Affairs. Agricultural Production Infrastructure Maintenance Business Plan’s Design Criteria; Korea Ministry of Agriculture, Food and Rural Affairs: Sejong, Korea, 2007.

- Korea Expressway Corporation. Construction Material Quality and Standard for Highway Construction; Korea Expressway Corporation: Kimcheon, Korea, 2005. [Google Scholar]

- KSL 2405, Fly Ash; Korea Standards Association: Seoul, Korea, 2016.

- ASTM C78/C78M, Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); American Society for Testing and Materials: Philadelphia, PA, USA, 2021.

- NT BUILD 492, Concrete, Mortar and Cement-Based Repair Materials: Chloride Migration Coefficient from Non-Steady State Migration Experiments; Nordtest: Espoo, Finland, 1999.

- Park, S.K.; Won, J.P.; Park, C.G. Evaluation of Diffusion Property of Latex Modified Concrete. J. Korean Soc. Agric. Eng. 2008, 50, 27–37. [Google Scholar] [CrossRef]

- Tang, L.; Nilsson, L.O. Rapid Determination of the Chloride Diffusivity in Concrete by Applying an Electrical Field. ACI Mater. J. 1992, 89, 49–53. [Google Scholar]

- Won, J.P.; Jeon, W.J.; Park, C.G.; Jeong, I.S. Effect of Polypropylene Fiber on Reduction of Shrinkage Crack and Improvement of Durability of Rural Road Concrete Pavement. J. Korean Soc. Agric. Eng. 2002, 44, 134–141. [Google Scholar]

- ASTM C39/C39M, Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; American Society for Testing and Materials: Philadelphia, PA, USA, 2017.

- ASTM. ASTM C944. Standard Test Method for Abrasion Resistance of Concrete or Mortar Surfaces by the Rotating-Cutter Method; American Society for Testing and Materials: Philadelphia, PA, USA, 2012. [Google Scholar]

- ACI Committee. 544.2R-89: Measurement of Properties of Fiber Reinforced concrete. ACI Mater. J. 1998, 85, 583–593. [Google Scholar]

- ASTM C666/C666M. Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing; American Society for Testing and Materials: Philadelphia, PA, USA, 2015. [Google Scholar]

| Type of Cement | Fineness (cm2/g) | Specific Gravity | Stability (%) | Setting Time (min) | Compressive Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|

| Initial | Final | 3 Days | 7 Days | 28 Days | ||||

| Type I | 3200 | 3.15 | 0.02 | 220 | 400 | 20.3 | 30.2 | 38.7 |

| Density (g/mm3) | Fineness (cm2/g) | Absorption (%) | LOI * (%) | ||||

|---|---|---|---|---|---|---|---|

| 2.14 | 3400 | 0.13 | 3.28 | ||||

| Chemical Composition (%) | |||||||

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | TiO2 |

| 58.12 | 23.56 | 7.69 | 2.59 | 1.12 | 0.31 | 1.42 | 1.05 |

| Density (g/mm3) | Fineness (cm2/g) | LOI (%) | |||||

|---|---|---|---|---|---|---|---|

| 2.8 | 4000∼6000 | 3.0 | |||||

| Chemical Composition (%) | |||||||

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | MnO | TiO | S |

| 33.1 | 13.9 | 0.29 | 42.4 | 6.1 | 0.4 | 0.96 | 0.66 |

| Fineness Modulus | Density (g/mm3) | Water Absorption Ratio (%) | 0.08 nm Pass Efficiency |

|---|---|---|---|

| 2.72 | 2.58 | 1.58 | 6.9 |

| Type of Aggregate | Density (g/mm3) | Absorption (%) | F.M | ||

|---|---|---|---|---|---|

| Bulk | Bulk (SSD) | Apparent | |||

| Crushed coarse aggregate | 2.80 | 2.65 | 2.83 | 0.35 | 6.92 |

| Type of Aggregate | Absolute Dry Density | Water Absorption Ratio | Unit Volume Weight |

|---|---|---|---|

| Fine aggregate | 2.77 | 1.57 | 1.70 |

| Coarse aggregate | 2.49 | 4.28 | 1.41 |

| Chemical Composition (%) | |||

| CaO | S | SO3 | FeO |

| 40.81 | 0.00 | 0.39 | 1.19 |

| Type | Color | Solids (%) | Density (g/mm3) | pH |

|---|---|---|---|---|

| Liquid | Light brown | ≥40 | 1.10 ∼ 1.20 | 4.0 ∼ 7.5 |

| Type of Mix | W/B 1 (%) | S 2/a 3 (%) | Unit Weight (kg/m3) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W 4 | C 5 | BFS 6 | FA 7 | CS 8 | SS 9 | GS 10 | G 11 | GG 12 | HRWA 13 | |||

| Plain | 55.5 | 49.6 | 161 | 173 | 73 | 44 | 458 | 452 | - | 926 | - | 2.03 |

| GG 100% | 161 | 173 | 73 | 44 | 458 | 452 | - | - | 926 | 2.03 | ||

| GS 50%/GG 100% | 161 | 173 | 73 | 44 | 229 | 226 | 455 | - | 926 | 2.03 | ||

| Initial Current I30V (with 30 V) (mA) | Applied Voltage U (After Adjustment) (V) | Possible New Initial Current I0 (mA) | Test Duration t (hours) |

|---|---|---|---|

| I0 < 5 | 60 | I0 < 5 | 96 |

| 5 ≤ I0 < 10 | 60 | 10 ≤ I0 < 20 | 48 |

| 10 ≤ I0 < 15 | 60 | 20 ≤ I0 < 30 | 24 |

| 15 ≤ I0 < 20 | 50 | 25 ≤ I0 < 35 | 24 |

| 25 ≤ I0 < 30 | 40 | 25 ≤ I0 < 40 | 24 |

| 30 ≤ I0 < 40 | 35 | 35 ≤ I0 < 50 | 24 |

| 40 ≤ I0 < 60 | 30 | 40 ≤ I0 < 60 | 24 |

| 60 ≤ I0 < 90 | 25 | 50 ≤ I0 < 75 | 24 |

| 90 ≤ I0 < 120 | 20 | 60 ≤ I0 < 80 | 24 |

| 120 ≤ I0 < 180 | 15 | 60 ≤ I0 < 90 | 24 |

| 180 ≤ I0 < 360 | 10 | 60 ≤ I0 < 120 | 24 |

| 360 ≤ I0 | 10 | 120 ≤ I0 | 6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, B.-H.; Lee, S.-J.; Park, C.-G. Chloride Ion Diffusion and Durability Characteristics of Rural-Road Concrete Pavement of South Korea Using Air-Cooled Slag Aggregates. Appl. Sci. 2021, 11, 8215. https://doi.org/10.3390/app11178215

Ahn B-H, Lee S-J, Park C-G. Chloride Ion Diffusion and Durability Characteristics of Rural-Road Concrete Pavement of South Korea Using Air-Cooled Slag Aggregates. Applied Sciences. 2021; 11(17):8215. https://doi.org/10.3390/app11178215

Chicago/Turabian StyleAhn, Byung-Hwan, Su-Jin Lee, and Chan-Gi Park. 2021. "Chloride Ion Diffusion and Durability Characteristics of Rural-Road Concrete Pavement of South Korea Using Air-Cooled Slag Aggregates" Applied Sciences 11, no. 17: 8215. https://doi.org/10.3390/app11178215

APA StyleAhn, B.-H., Lee, S.-J., & Park, C.-G. (2021). Chloride Ion Diffusion and Durability Characteristics of Rural-Road Concrete Pavement of South Korea Using Air-Cooled Slag Aggregates. Applied Sciences, 11(17), 8215. https://doi.org/10.3390/app11178215