Developing a Recommendation Model for the Smart Factory System

Abstract

:1. Introduction

2. Literature Review

2.1. Smart Factory

2.2. Recommendation Systems

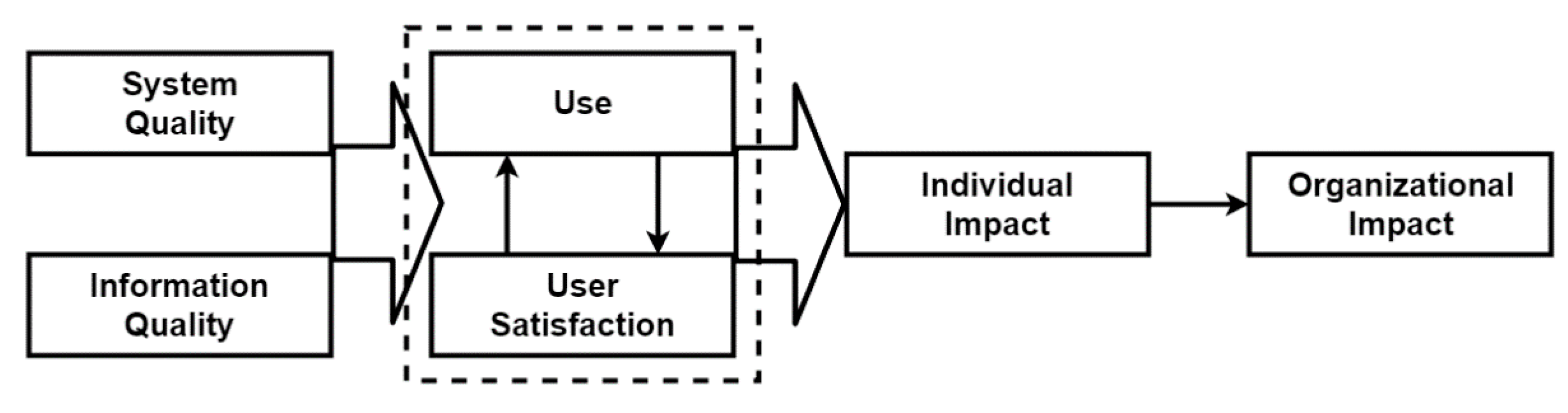

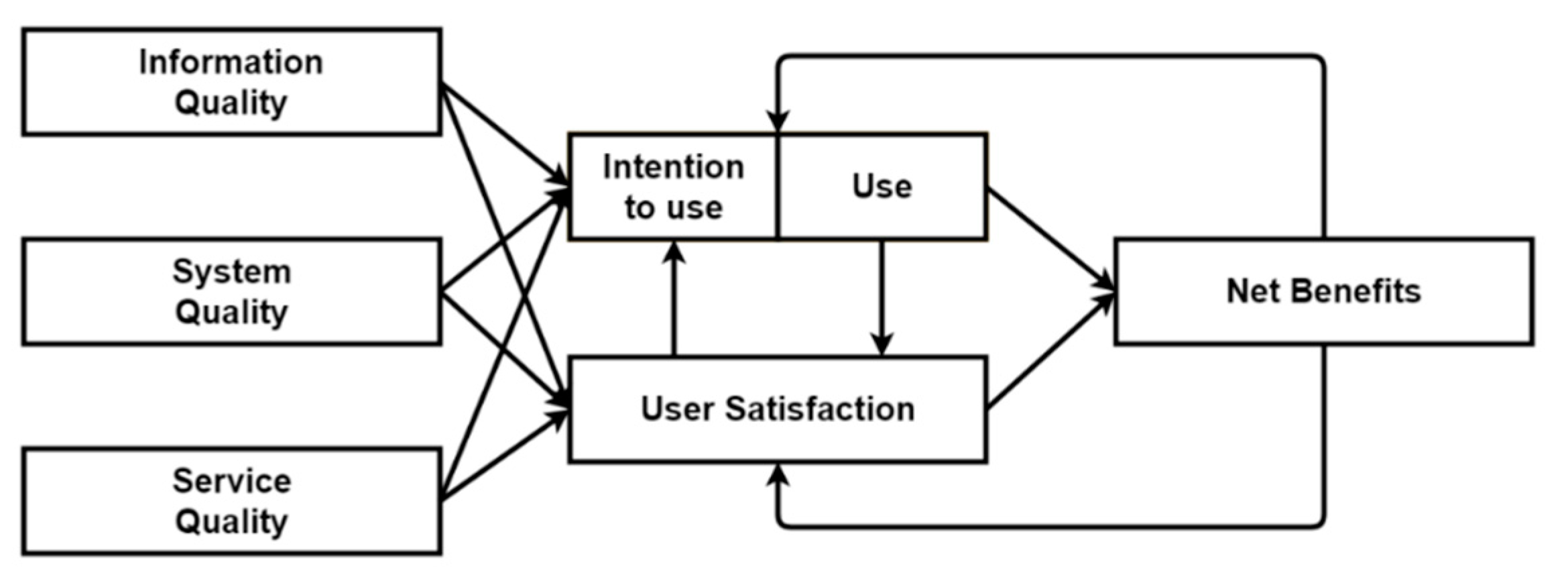

2.3. Updated Information System Success Model

3. Methodology

3.1. EKB Model

3.2. Modified Delphi Method

3.3. ELECTRE II Method

4. Result of SFRS Development

4.1. Driving Recommendation Model

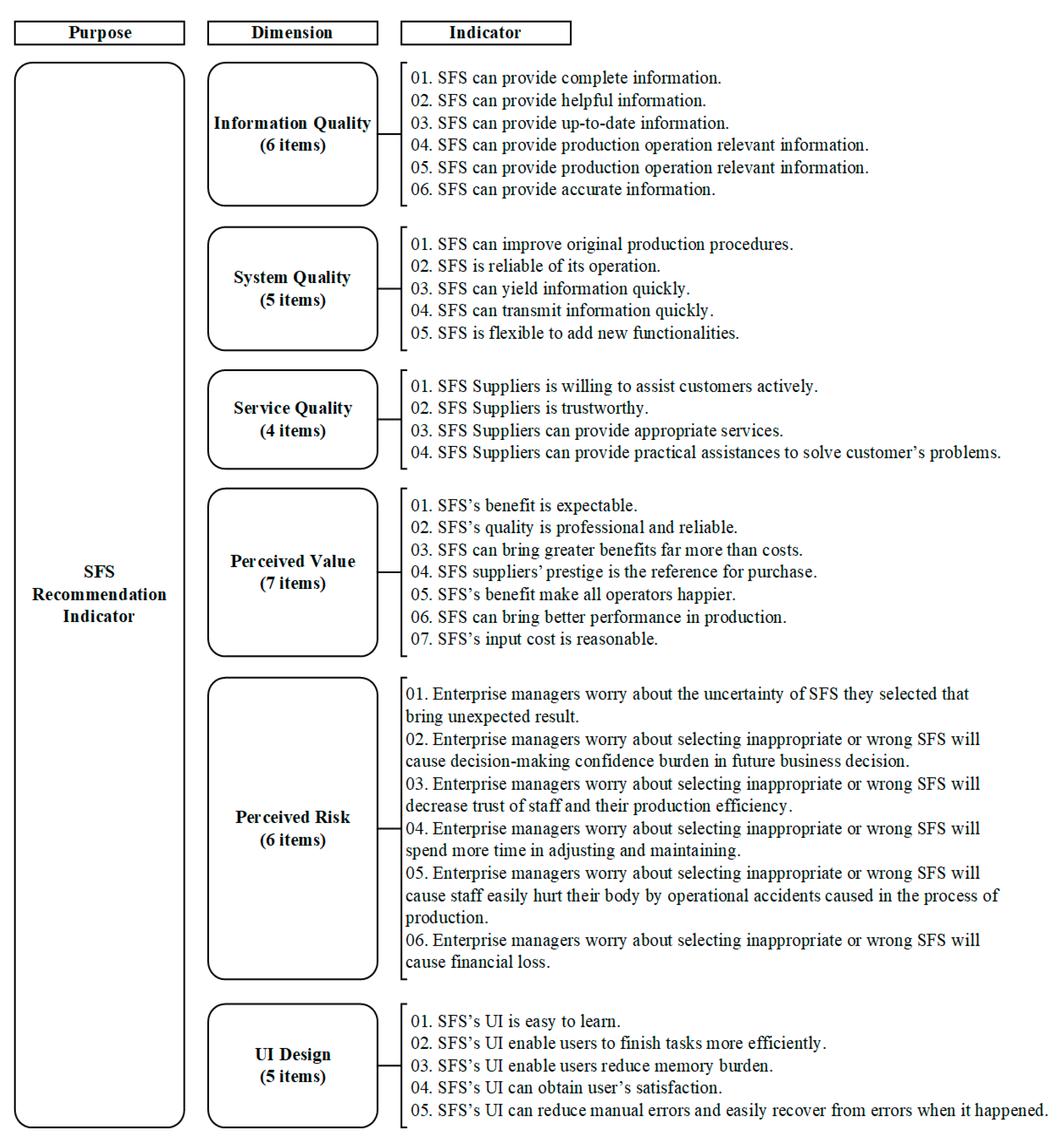

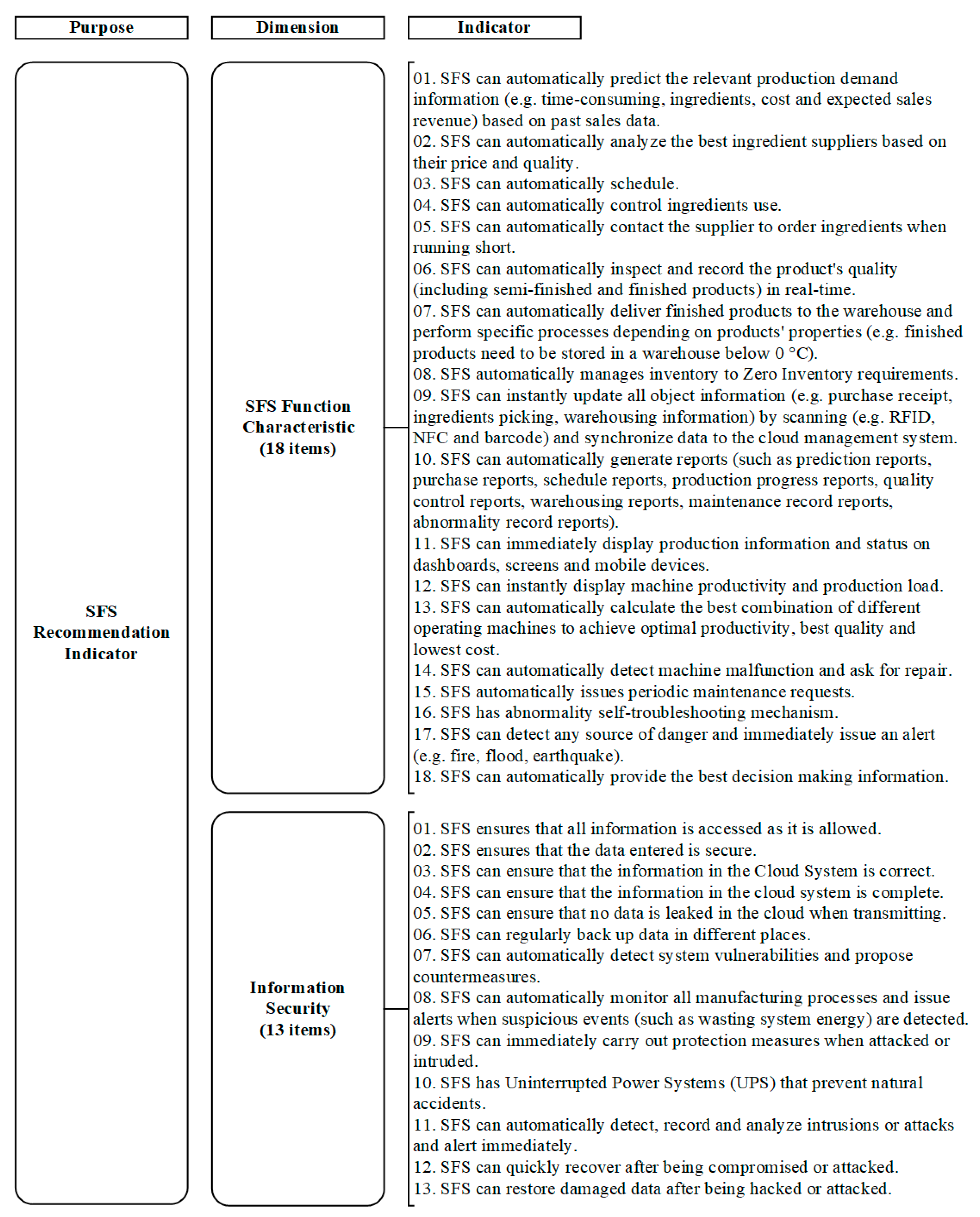

4.2. Constructing Prototype Indicator

4.3. Result of Prototype Indicators with Amendment and Simplification

4.3.1. First Round of Modified Delphi Method

4.3.2. Second Round of Modified Delphi Method

4.4. Result of Analyzing Alternatives Evaluation of SFS by Indicator Weight

4.4.1. Factors Construction

4.4.2. Weights Construction

- (1)

- “Information Quality”

- (2)

- “System Quality”

- (3)

- ”Service Quality”

- (4)

- “SFS Function characteristics”

- (5)

- “Information Security”

- (6)

- “Perceived Value”

- (7)

- “Perceived Risk”

- (8)

- “UI Design”

4.4.3. ELECTRE II Method Evaluation Set Construction

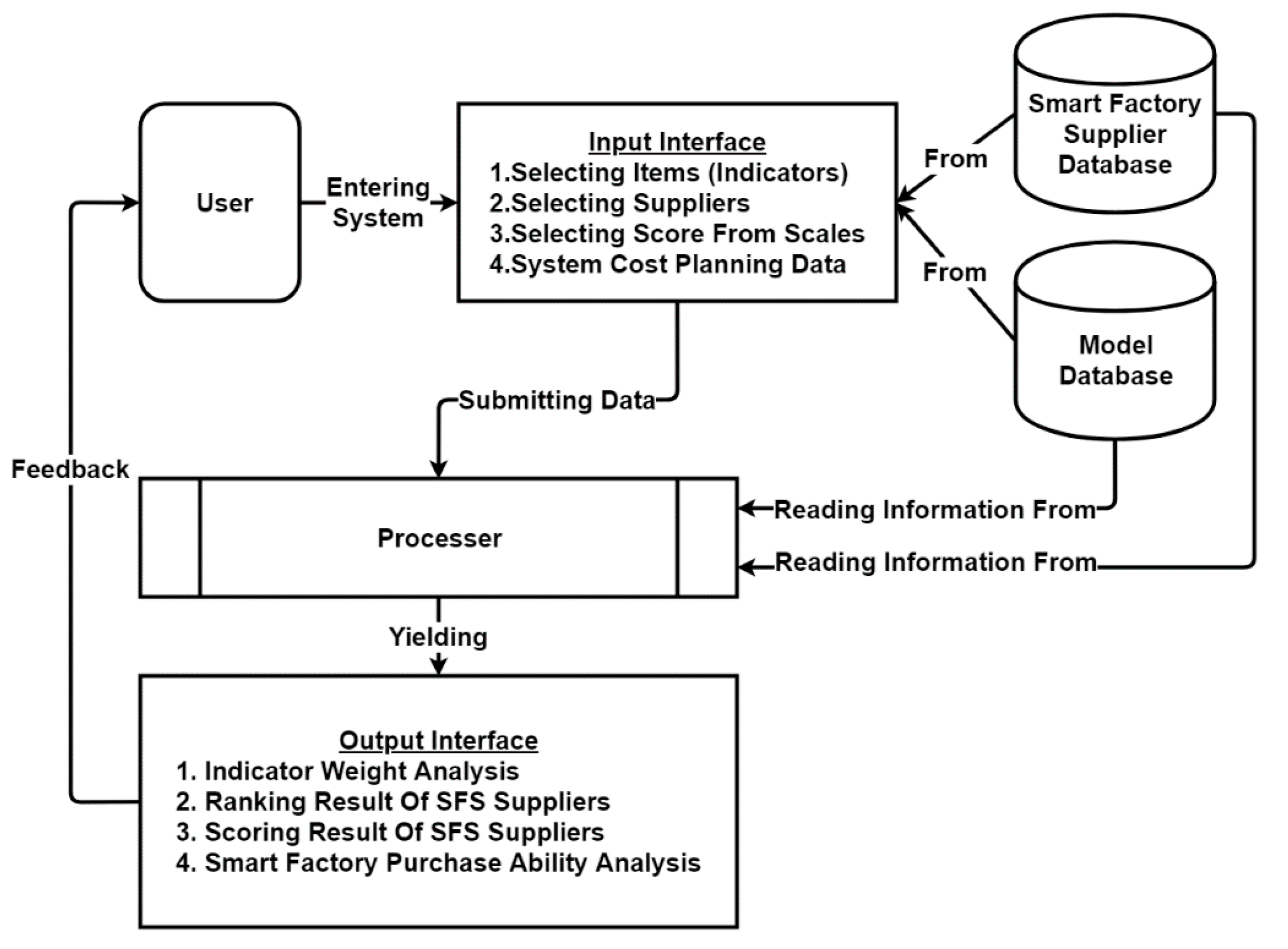

4.5. Result of Recommendation System Development

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, H.; Yoo, S.; Kim, Y.W. An energy management framework for smart factory based on context-awareness. In Proceedings of the 18th International Conference on Advanced Communication Technology (ICACT), PyeongChang, Korea, 31 January–3 February 2016; pp. 685–688. [Google Scholar]

- Radziwon, A.; Bilberg, A.; Bogers, M.; Madsen, E.S. The Smart Factory: Exploring Adaptive and Flexible Manufacturing Solutions. Procedia Eng. 2014, 69, 1184–1190. [Google Scholar] [CrossRef] [Green Version]

- Heng, S. Industry 4.0 Upgrading of Germany’s Industrial Capabilities on the Horizon, Deutsche Bank (DB) Research. 2014, pp. 1–16. Available online: file:///C:/Users/MDPI/AppData/Local/Temp/Industry_4_0%20_Upgrading_of_Germany%25u2019s_industrial_ca.pdf (accessed on 12 September 2021).

- Raynor, M.; Cotteleer, M. The More Things Change: Value Creation, Value capture, and the Internet of Things. In Deloitte Review; Deloitte University Press: Deloitte, CA, USA, 2015; Volume 17, pp. 49–65. [Google Scholar]

- Ahuett-Garza, H.; Kurfess, T. A Brief Discussion on the Trends of Habilitating Technologies for Industry 4.0 and Smart Manufacturing. Manuf. Lett. 2018, 15, 60–63. [Google Scholar] [CrossRef]

- Ting, S.L.; Tsang, A.H.C.; Tse, Y.K. A Framework for the implementation of RFID systems. Int. J. Bus. Manag. 2013, 5, 1–16. [Google Scholar] [CrossRef]

- Schallock, B.; Rybski, C.; Jochem, R.; Kohl, H. Learning Factory for Industry 4.0 to Provide Future Skills beyond Technical training. Procedia Manuf. 2018, 23, 27–32. [Google Scholar] [CrossRef]

- Mourtzis, D.; Vlachou, E.; Dimitrakopoulos, G.; Zogopoulos, V. Cyber-Physical Systems and Education 4.0—The Teaching Factory 4.0 cCncept. Procedia Manuf. 2018, 23, 129–134. [Google Scholar] [CrossRef]

- Al-Fadhli, A.A.; Othman, M.; Ali, N.; Al-Jamrh, B.A. Understanding Health Professionals Intention to Use Telehealth in Yemen Using the DeLone and McLean IS Success Model, International Conference of Reliable Information and Communication Technology. Lect. Notes Data Eng. Commun. Technol. 2018, 5, 627–638. [Google Scholar]

- Shariatzadeh, N.; Lundholm, T.; Lindberg, L.; Sivard, G. Integration of Digital Factory with Smart Factory Based on Internet of Things. Procedia CIRP 2016, 50, 512–517. [Google Scholar] [CrossRef]

- Lechner, J.; Ascher, A.; Nosovic, S.; Günthner, W.A. Concept for an Intelligent UHF RFID Reader According to the Ideas of Industry 4.0. In Proceedings of the Smart SysTech 2016, European Conference on Smart Objects, Systems and Technologies, Duisburg, Germany, 7–8 July 2016; pp. 1–5. [Google Scholar]

- Rana, N.P.; Dwivedi, Y.K.; Williams, M.D.; Weerakkody, V. Investigating Success of an e-Government Initiative Validation of an Integrated IS Success Model. Inf. Syst. Front. 2015, 17, 127–142. [Google Scholar] [CrossRef] [Green Version]

- Wong, Y.S. Developing a Selection Support System for Smart Factory System. Master’s Thesis, National Kaohsiung University of Applied Sciences, Kaohsiung, Taiwan, 2017, unpublished. [Google Scholar]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Lee, J. Smart factory systems. Inform. Spektrum 2015, 38, 230–235. [Google Scholar] [CrossRef]

- Mabkhot, M.M.; Al-Ahmari, A.M.; Salah, B.; Alkhalefah, H. Requirements of the smart factory system: A survey and perspective. Machines 2018, 6, 23. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing smart factory of industries 4.0: An outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 686–695. [Google Scholar]

- Sjödin, D.R.; Parida, V.; Leksell, M.; Petrovic, A. Smart factory implementation and process innovation. Res.-Technol. Manag. 2018, 61, 22–31. [Google Scholar] [CrossRef] [Green Version]

- Moeuf, A.; Lamouri, S.; Pellerin, R.; Tamayo-Giraldo, S.; Tobon-Valencia, E.; Eburdy, R. Identification of critical success factors, risks and opportunities of Industry 4.0 in SMEs. Int. J. Prod. Res. 2020, 58, 1384–1400. [Google Scholar] [CrossRef]

- Hameed, B.; Khan, I.; Durr, F.; Rothermel, K. An RFID based consistency management framework for production monitoring in a smart real-time factory. In Proceedings of the Internet of Things (IOT) 2010, Tokyo, Japan, 29 November–1 December 2010; pp. 1–8. [Google Scholar]

- Murofushi, R.H.; Tavares, J.J. Towards Fourth Industrial Revolution Impact: Smart Product Based on RFID Technology. IEEE Instrum. Meas. Mag. 2017, 20, 51–56. [Google Scholar] [CrossRef]

- Engel, J.F.; Kollat, D.T.; Blackwell, R.D. Consumer Behavior; Holt, Rinehart and Winston: New York, NY, USA, 2017; Available online: http://www.worldcat.org/title/consumer-behavior/oclc/249133 (accessed on 7 May 2021).

- Adomavicius, G.; Tuzhilin, A. Recommendation Technologies: Survey of Current Methods and Possible Extensions. SSRN eLibrary 2004. [Google Scholar]

- Hu, J. Application and research of collaborative filtering in e-commerce recommendation system. In Proceedings of the 2010 3rd International Conference on Computer Science and Information Technology, Chengdu, China, 9–11 July 2010; p. 4. [Google Scholar]

- Ricci, F.; Rokach, L.; Shapira, B. Introduction to recommender systems handbook. In Recommender Systems Handbook; Springer: New York, NY, USA, 2011; pp. 1–35. [Google Scholar]

- Walek, B.; Fojtik, V. A hybrid recommender system for recommending relevant movies using an expert system. Expert Syst. Appl. 2020, 158, 113452. [Google Scholar] [CrossRef]

- Çelik Ertuğrul, D.; Elçi, A. A survey on semanticized and personalized health recommender systems. Expert Syst. 2019, 37, e12519. [Google Scholar] [CrossRef]

- Bozanta, A.; Kutlu, B. Developing a Contextually Personalized Hybrid Recommender System. Mob. Inf. Syst. 2018, 2018, 3258916. [Google Scholar] [CrossRef]

- Yang, D.H.; Gao, X. Online retailer recommender systems: A competitive analysis. Int. J. Prod. Res. 2016, 55, 4089–4109. [Google Scholar] [CrossRef]

- Hernández-Rodríguez, S.; Hernández-Lira, C.A.; Aguilar-Rico, A.; Flores-Becerra, G.; Flores-Méndez, J.; Vázquez-Cuchillo, O. A recommender system applied to the indirect materials selection process (RS-IMSP) for producing automobile spare parts. Comput. Ind. 2016, 82, 233–244. [Google Scholar] [CrossRef]

- Del Vasto-Terrientes, L.; Valls, A.; Zielniewicz, P.; Borras, J. A hierarchical multi-criteria sorting approach for recommender systems. J. Intell. Inf. Syst. 2015, 46, 313–346. [Google Scholar] [CrossRef]

- DeLone, W.H.; McLean, E.R. The DeLone and McLean Model of Information Systems Success: A ten-Year Update. J. Manag. Inf. Syst. 2003, 19, 9–30. [Google Scholar]

- Guceglioglu, A.S.; Demirors, O. Using Software Quality Characteristics to Measure Business Process Quality, International Conference on Business Process Management. Lect. Notes Comput. Sci. 2005, 3649, 374–379. [Google Scholar]

- Chen, C.Y.; Chang, R.E.; Hung, M.C.; Lin, M.H. Assessing the Quality of a Web-Based Learning System for Nurses. J. Med Syst. 2009, 33, 317–325. [Google Scholar] [CrossRef] [PubMed]

- Nindiaswari, E.; Azzahro, F.; Hidayanto, A.N.; Gitik, S.; Anussornnitisarn, P. Integration of Updated DeLone & McLean Success Model, KANO model and QFD to Analyze Quality of an Information System. In Proceedings of the 2016 International Conference on Informatics and Computing (ICIC), Mataram, Indonesia, 28–29 October 2016; pp. 361–366. [Google Scholar]

- Yang, M.; Shao, Z.; Liu, Q.; Liu, C. Understanding the Quality Factors that Influence the Continuance Intention of Students toward Participation in MOOCs’. Educ. Technol. Res. Dev. 2017, 65, 1195–1214. [Google Scholar] [CrossRef]

- Darley, W.K.; Blankson, C.; Luethge, D.J. Toward an integrated framework for online consumer behavior and decision making process: A review. Psychol. Mark. 2010, 27, 94–116. [Google Scholar] [CrossRef]

- Hsieh, M.-Y. Interdisciplinarily Exploring the Most Potential IoT Technology Determinants in the Omnichannel E-Commerce Purchasing Decision-Making Processes. Appl. Sci. 2020, 10, 603. [Google Scholar] [CrossRef] [Green Version]

- Longart, P.; Wickens, E.; Bakir, A. Consumer Decision Process in Restaurant Selection: An Application of the Stylized EKB Model. Mark. Rev. Mark. Theory Pract. 2016, 28, 173–190. [Google Scholar] [CrossRef] [Green Version]

- Helmer, O.; Dalkey, N. An Experimental Application of the Delphi Method to the Use of Expert. Manag. Sci. 1963, 9, 458–467. [Google Scholar]

- Murry, J.W.; Hammons, J.O. Delphi: A Versatile Methodology for Conducting Qualitative Research. Rev. High. Educ. 1995, 18, 423–436. [Google Scholar] [CrossRef]

- Benayoun, R.; Roy, B.; Sussman, N. Manual de Reference du Programme Electre. In Note DeSynthese et Formaton; Direction Scientifque SEMA: Paris, France, 1966; Volume 25. [Google Scholar]

- Sun, S.M. The Study of the ELECTRE Method under the Fuzzy Environment. Master’s Thesis, Tunghai University, Taichung, Taiwan, 2000, unpublished. [Google Scholar]

| Scholars | The Applications |

|---|---|

| Bogdan Walek, Vladimir Fojtik (2020) | A monolithic hybrid recommender system with a collaborative filtering used to recommend suitable movies according to the user’s favorite and least favorite genres [26]. |

| Duygu Çelik Ertuğrul, Atilla Elçi (2019) | A personalized health recommender system is web-enabled and able to construct personalized health care with the key enabling technologies and major applications from successful case studies [27]. |

| Aysun Bozanta, Birgul Kutlu (2018) | A hybrid recommendation mode that integrates user-based and item-based collaborative filtering and content-based filtering together with contextual information to recommend new venues to users according to their preferences [28]. |

| Dong-Hui Yang, Xing Gao (2016) | The recommender systems help to coordinate the online supply chain with one retailer and two manufacturers to maximize profit by providing different choices and alleviating channel conflict [29]. |

| Selene Hernández-Rodríguez et al. (2016) | A recommender system based on a non-personalized approach and similar order circumstances integrates an indirect material recommender system to assist in warehouse tasks and to help new users create certain parts [30]. |

| Luis Del Vasto-Terrientes et al. (2015) | ELECTRE-TRI-B is proposed to handle assignments of alternatives on several levels of the hierarchy into a recommender system, focused on ordered classification with multiple conflicting criteria such as content, context, or cost, to find the most suitable alternatives [31]. |

| Scholars | Associated research |

|---|---|

| Guceglioglu & Demirors (2005) | Using Software Quality Characteristics to Measure Business Process Quality [33] |

| Chen et al. (2009) | Assessing the Quality of a Web-based Learning System for Nurses [34] |

| Rana et al. (2015) | Investigating the Success of an E-Government Initiative Validation of an Integrated Information System Success Model [12] |

| Nindiaswari et al. (2016) | Integration of Updated DeLone & McLean Success Model, KANO model and QFD to Analyze the Quality of an Information System [35] |

| Yang et al. (2017) | Understanding the Quality Factors That Influence the Continuance Intention of Students Toward Participation in MOOCs [36] |

| Al-Fadhli et al. (2018) | Understanding Health Professionals’ Intention to Use Telehealth in Yemen Using the DeLone & McLean Information System Success Model [9] |

| Dimension | SFS Recommendation Indicator |

|---|---|

| Information Quality | SFS can provide complete information. |

| SFS can provide helpful information. | |

| SFS can provide up-to-date information. | |

| SFS can provide relevant information. | |

| SFS can provide understandable information. | |

| SFS can provide accurate information. | |

| System Quality | SFS can improve original production procedures. |

| SFS is reliable of its operation. | |

| SFS can yield information quickly. | |

| SFS can transmit information quickly. | |

| SFS is flexible to adapt changes of new functionalities. | |

| Service Quality | SFS Suppliers are willing to assist customers actively. |

| SFS Suppliers are reliable of their services. | |

| SFS Suppliers are trustworthy. | |

| SFS Suppliers can provide appropriate services. | |

| SFS Suppliers can provide practical assistance to solve the customer’s problems. |

| Sub-Dimension | Indicators |

|---|---|

| Prediction | SFS can automatically predict the relevant production demand information (e.g., time consumption, ingredients, cost, and expected sales revenue) based on past sales data. |

| Purchasing | SFS can automatically analyze the best ingredient suppliers based on their price and quality. |

| Production | SFS can automatically schedule. |

| SFS can automatically control ingredients use. | |

| SFS can automatically contact the supplier to order ingredients when running short. | |

| SFS can automatically generate manufacturing progress reports. | |

| Quality Control | SFS can automatically inspect and record the product’s quality (including semi-finished and finished products) in real-time. |

| SFS can automatically generate quality control reports. | |

| Putting In Storage | SFS can automatically deliver finished products to the warehouse. |

| SFS can perform specific processes depending on product properties (e.g., finished products need to be stored in a warehouse below 0 °C). | |

| Inventory Control | SFS can keep up with real-time inventory situation. |

| SFS automatically manages inventory to zero inventory requirements. | |

| Common Functionality | SFS can instantly update all object information (e.g., purchase receipt, ingredients picking and warehousing information) by scanning (e.g., RFID, NFC and barcode) and synchronize data to the Cloud Management System. |

| SFS can automatically generate reports (such as prediction reports, purchase reports, schedule reports, production progress reports, quality control reports, warehousing reports, maintenance record reports and abnormality record reports) | |

| SFS can immediately display production information and status on dashboards, screens and mobile devices. | |

| SFS can instantly display machine productivity and production load. | |

| SFS can automatically calculate the best combination of different operating machines to achieve optimal productivity, best quality, and lowest cost. | |

| SFS can record any machine events (e.g., abnormal event records, malfunction records, and regular maintenance records. | |

| SFS can automatically detect machine malfunction and ask for repair. | |

| SFS automatically issues periodic maintenance requests. | |

| SFS has abnormality self-troubleshooting mechanism. | |

| SFS can detect any source of danger and immediately issue an alert (e.g., fire, flood, and earthquake). | |

| SFS automatically analyzes the best business decision-making information. |

| Dimension | Expert A | Expert B | Expert C | Expert D | Expert E | Total | Weight |

|---|---|---|---|---|---|---|---|

| Information Quality | 5 | 5 | 5 | 3 | 6 | 24 | 0.133 |

| System Quality | 4 | 8 | 3 | 5 | 5 | 25 | 0.140 |

| Service Quality | 8 | 2 | 8 | 6 | 7 | 31 | 0.172 |

| SFS Function Characteristic | 2 | 4 | 6 | 4 | 2 | 18 | 0.100 |

| Information Security | 7 | 7 | 7 | 7 | 8 | 36 | 0.200 |

| Perceived Value | 6 | 3 | 2 | 1 | 3 | 15 | 0.083 |

| Perceived Risk | 3 | 1 | 4 | 8 | 4 | 20 | 0.111 |

| UI Design | 1 | 6 | 1 | 2 | 1 | 11 | 0.061 |

| Total | 36 | 36 | 36 | 36 | 36 | 180 | 1 |

| Indicators Code | Expert A | Expert B | Expert C | Expert D | Expert E | Total | Weight |

|---|---|---|---|---|---|---|---|

| S-01 | 4 | 3 | 3 | 5 | 3 | 18 | 0.171 |

| S-02 | 5 | 6 | 5 | 6 | 4 | 26 | 0.248 |

| S-03 | 6 | 2 | 6 | 4 | 5 | 23 | 0.219 |

| S-04 | 2 | 1 | 4 | 3 | 6 | 16 | 0.152 |

| S-05 | 1 | 5 | 2 | 2 | 1 | 11 | 0.105 |

| S-06 | 3 | 4 | 1 | 1 | 2 | 11 | 0.105 |

| Total | 21 | 21 | 21 | 21 | 21 | 105 | 1 |

| Dimension | Dimension Weight | Recommendation Indicator | Indicator Weight |

|---|---|---|---|

| Information Quality | 0.133 | SFS can provide helpful information. (S-02) | 0.248 |

| SFS can provide up-to-date information. (S-03) | 0.219 | ||

| SFS can provide complete information. (S-01) | 0.171 | ||

| SFS can provide production operation relevant information. (S-04) | 0.152 | ||

| SFS can provide understandable information. (S-05) | 0.105 | ||

| SFS can provide accurate information. (S-06) | 0.105 | ||

| System Quality | 0.140 | SFS is reliable of its operation. | 0.280 |

| SFS can yield information quickly. | 0.267 | ||

| SFS can improve original production procedures. | 0.213 | ||

| SFS can transmit information quickly. | 0.160 | ||

| SFS is flexible to add new functionalities. | 0.080 | ||

| Service Quality | 0.172 | SFS Suppliers are trustworthy. | 0.380 |

| SFS Suppliers can provide practical assistance to solve the customer’s problems. | 0.240 | ||

| SFS Suppliers are willing to assist customers actively. | 0.220 | ||

| SFS Suppliers can provide appropriate services. | 0.160 | ||

| SFS Function characteristics | 0.1 | SFS can automatically predict the relevant production demand information (e.g., time consumption, ingredients, cost, and expected sales revenue) based on past sales data. | 0.098 |

| SFS can automatically schedule. | 0.090 | ||

| SFS can automatically analyze the best ingredient suppliers based on their price and quality. | 0.065 | ||

| SFS can automatically control ingredients use. | 0.065 | ||

| SFS can automatically contact the supplier to order ingredients when running short. | 0.065 | ||

| SFS can immediately display production information and status on dashboards, screens and mobile devices. | 0.062 | ||

| SFS can detect any source of danger and immediately issue an alert (e.g., fire, flood, and earthquake). | 0.034 | ||

| SFS automatically issues periodic maintenance requests. | 0.033 | ||

| Information Security | 0.2 | SFS ensures entered data is secure. | 0.125 |

| SFS can regularly back up data in different places. | 0.116 | ||

| SFS ensures all information is accessed as it is allowed. | 0.110 | ||

| SFS can ensure no data is leaked in the Cloud when transmitting. | 0.097 | ||

| SFS can ensure information in the Cloud System is complete. | 0.092 | ||

| SFS can ensure information in the Cloud System is correct. | 0.090 | ||

| SFS can automatically detect system vulnerabilities and propose countermeasures. | 0.066 | ||

| SFS can automatically monitor all manufacturing processes and issue alerts when suspicious events (such as wasting system energy) are detected. | 0.066 | ||

| SFS has Uninterrupted Power Systems (UPS) that prevent natural accidents. | 0.064 | ||

| SFS can quickly recover after being compromised or attacked. | 0.055 | ||

| SFS can restore damaged data after being hacked or attacked. | 0.051 | ||

| SFS can automatically detect, record, and analyze intrusions or attacks and alert immediately. | 0.035 | ||

| SFS can immediately carry out protection measures when attacked or intruded. | 0.033 | ||

| Perceived Value | 0.083 | SFS can bring greater benefits far more than costs. | 0.171 |

| SFS can bring better performance in production. | 0.157 | ||

| SFS’s benefit is expectable. | 0.150 | ||

| SFS’s quality is professional and reliable. | 0.143 | ||

| SFS’s input cost is reasonable. | 0.143 | ||

| SFS’s benefit make all operators happier. | 0.129 | ||

| SFS suppliers’ prestige is the reference for purchase. | 0.107 | ||

| Perceived Risk | 0.111 | Enterprise managers worry that selecting inappropriate or wrong SFS will decrease the trust of staff and their production efficiency. | 0.219 |

| Enterprise managers worry about the uncertainty of the selected SFS that can bring unexpected results. | 0.200 | ||

| Enterprise managers worry that selecting inappropriate or wrong SFS will make them spend more time adjusting and maintaining. | 0.181 | ||

| Enterprise managers worry that selecting inappropriate or wrong SFS will cause decision-making confidence burden in future business decisions. | 0.171 | ||

| Enterprise managers worry about selecting inappropriate or wrong SFS that will cause financial loss. | 0.124 | ||

| Enterprise managers worry about selecting inappropriate or wrong SFS that will cause staff harm due to operational accidents in the process of production. | 0.105 | ||

| UI Design | 0.061 | SFS’s UI enables users to finish tasks more efficiently. | 0.293 |

| SFS’s UI is easy to learn. | 0.227 | ||

| SFS’s UI can reduce manual errors and easily recover from errors when they occur | 0.200 | ||

| SFS’s UI enables users reduce memory burden. | 0.160 | ||

| SFS’s UI can obtain user satisfaction. | 0.120 |

| Part S: | Information Quality | |

| Importance Order: VI > I > N = U = VU. | ||

| Part T: | System Quality | |

| Importance Order: VI > I > N = U = VU. | ||

| Part U: | Service Quality | Importance Order: VI > I > N = U = VU. |

| Part V: | SFS Function characteristics | Importance Order: I > VI > N > U = VU. |

| Part W: | Information Security | Importance Order: VI > I = N = U = VU. |

| Part X: | Perceived Value | Importance Order: I > VI > N = U = VU. |

| Part Y: | Perceived Risk | Importance Order: I > VI > N = U = VU. |

| Part Z: | UI Design | Importance Order: I > VI > N = U = VU. |

| Result: BB > AA > CC > DD. |

| Dimension | Alternative | Preference Rate (%) | Decimal Point | |||

|---|---|---|---|---|---|---|

| AA | BB | CC | DD | |||

| Information Quality | 0.466 | 0.581 | 0.417 | 0.405 | 13% | 0.13 |

| System Quality | 0.326 | 0.418 | 0.394 | 0.313 | 11% | 0.11 |

| Service Quality | 0.537 | 0.574 | 0.513 | 0.389 | 15% | 0.15 |

| SFS Function characteristics | 0.349 | 0.404 | 0.330 | 0.328 | 10% | 0.1 |

| Information Security | 0.809 | 0.878 | 0.740 | 0.818 | 24% | 0.24 |

| Perceived Value | 0.300 | 0.325 | 0.280 | 0.288 | 9% | 0.09 |

| Perceived Risk | 0.420 | 0.477 | 0.422 | 0.375 | 12% | 0.12 |

| UI Design | 0.211 | 0.259 | 0.210 | 0.194 | 6% | 0.06 |

| Total | 3.418 | 3.916 | 3.305 | 3.311 | 100% | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, C.-Y.; Tu, C.-A.; Huang, W.-L. Developing a Recommendation Model for the Smart Factory System. Appl. Sci. 2021, 11, 8606. https://doi.org/10.3390/app11188606

Chang C-Y, Tu C-A, Huang W-L. Developing a Recommendation Model for the Smart Factory System. Applied Sciences. 2021; 11(18):8606. https://doi.org/10.3390/app11188606

Chicago/Turabian StyleChang, Chun-Yang, Chun-Ai Tu, and Wei-Luen Huang. 2021. "Developing a Recommendation Model for the Smart Factory System" Applied Sciences 11, no. 18: 8606. https://doi.org/10.3390/app11188606

APA StyleChang, C.-Y., Tu, C.-A., & Huang, W.-L. (2021). Developing a Recommendation Model for the Smart Factory System. Applied Sciences, 11(18), 8606. https://doi.org/10.3390/app11188606