Improving the X-ray Shielding Performance of Tungsten Thin-Film Plates Manufactured Using the Rolling Technology

Abstract

:1. Introduction

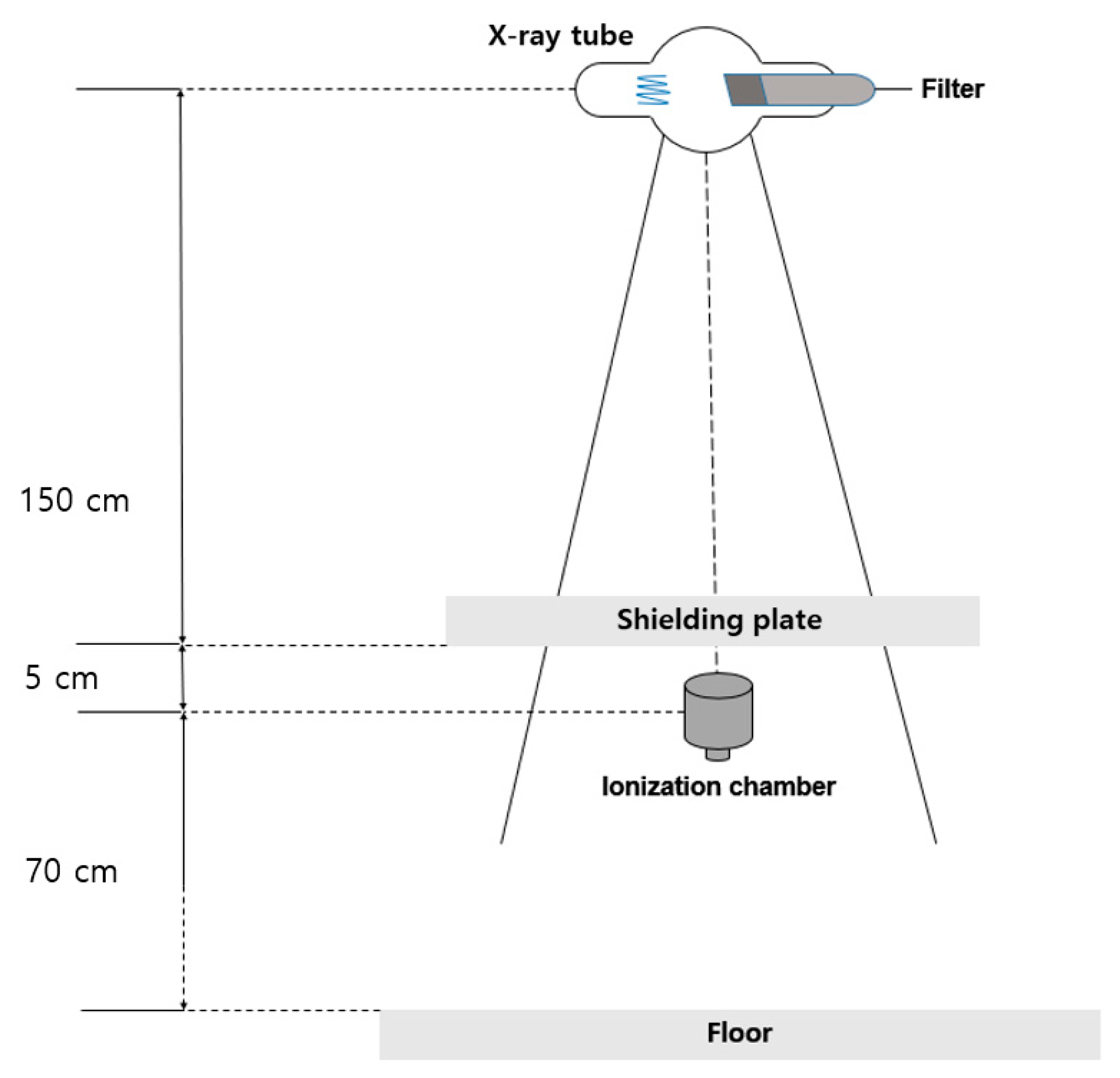

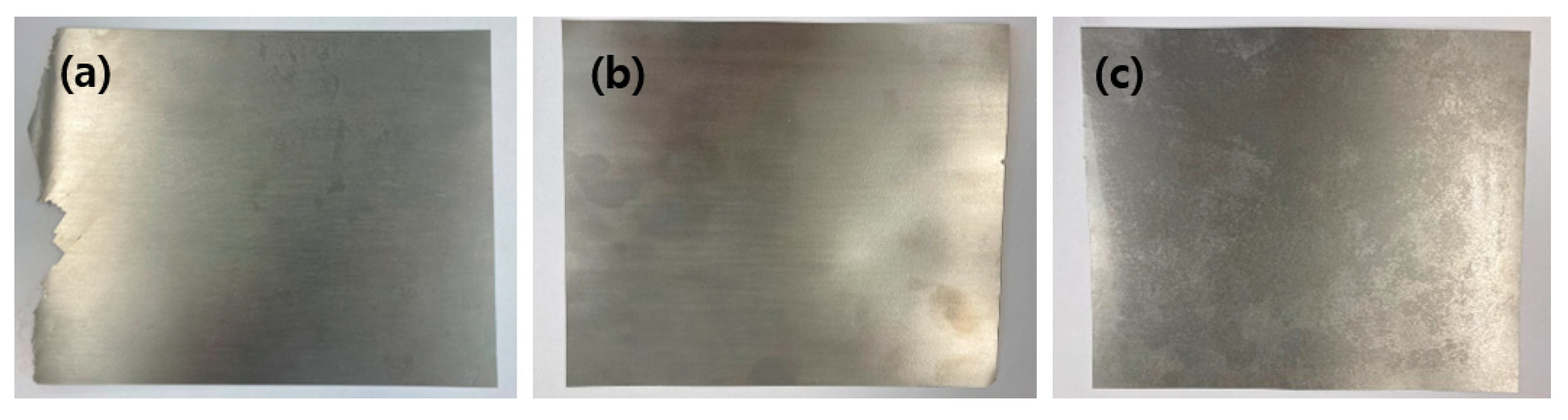

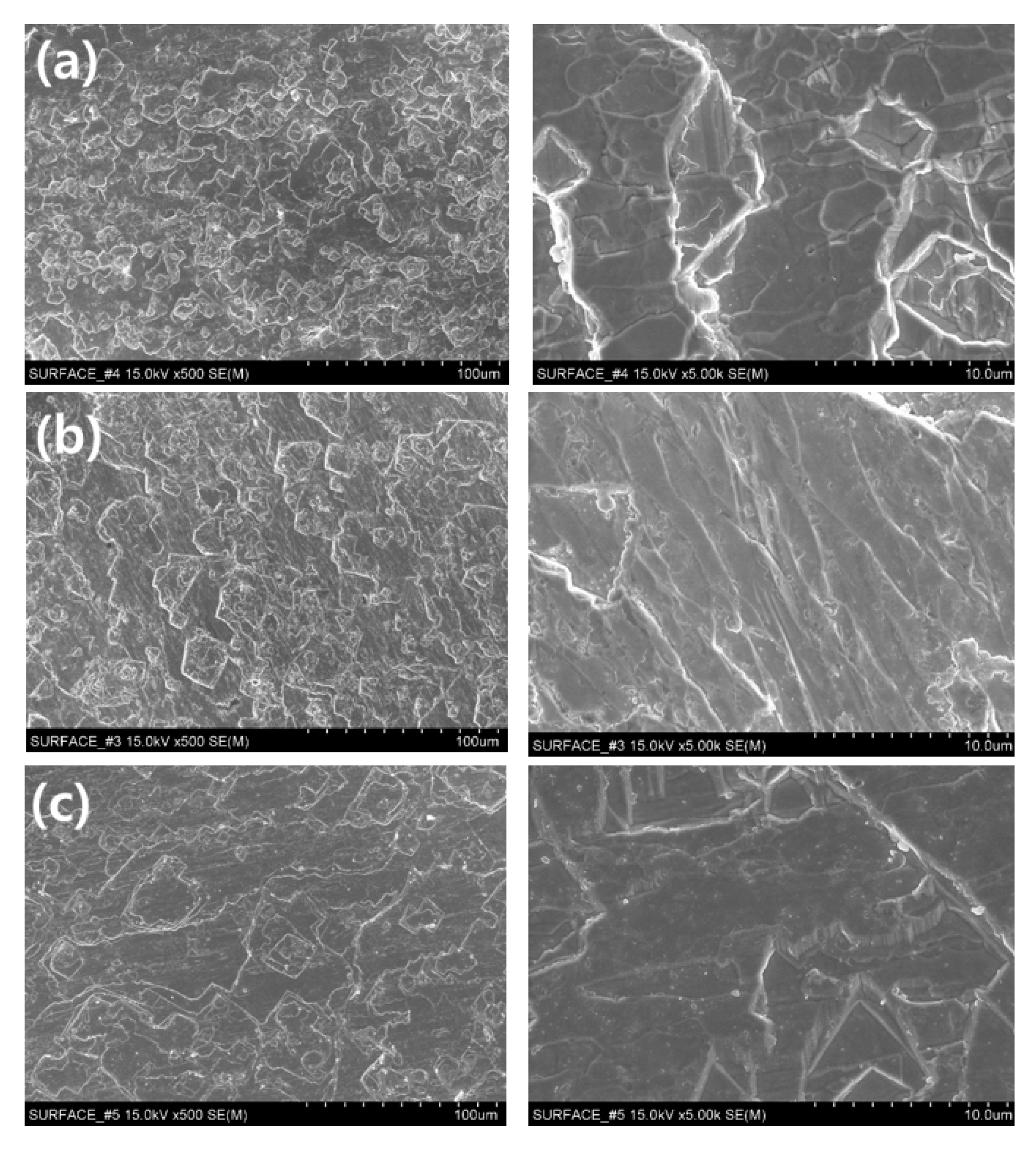

2. Materials and Methods

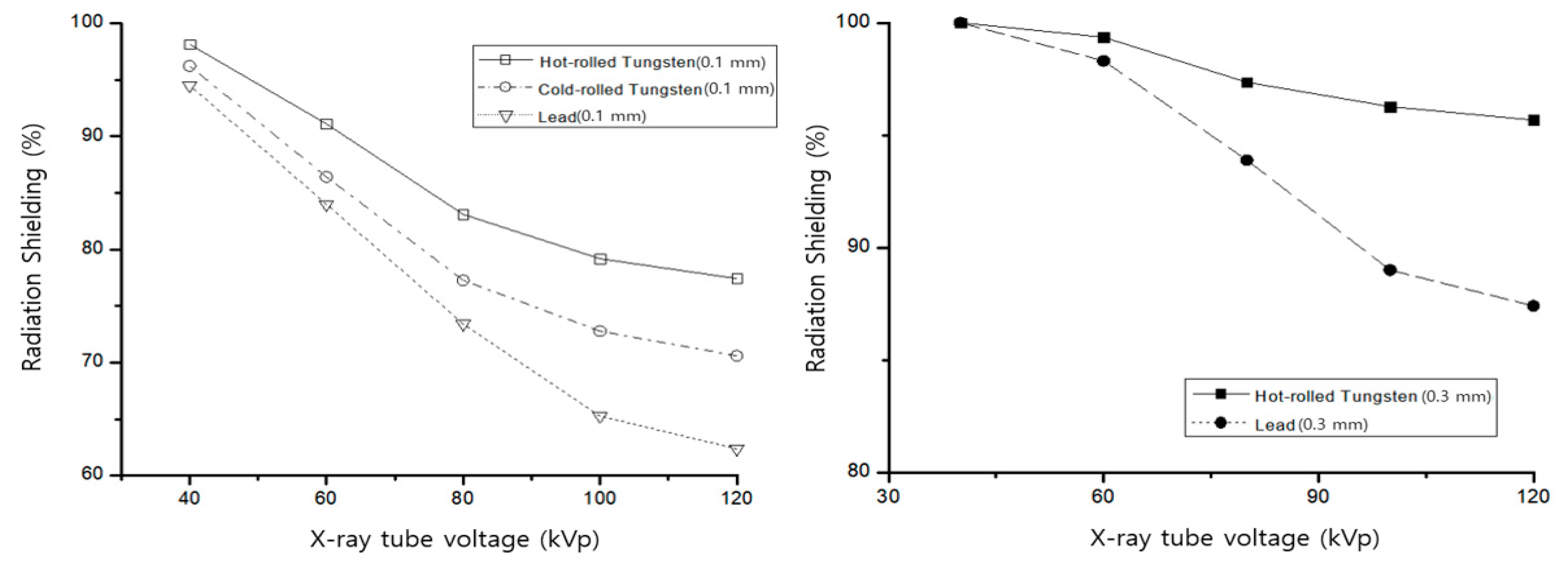

3. Results

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alalawi, A.; Al-Buriahib, M.S.; Sayyed, M.I.; Akyildirim, H.; Arslan, H.; Zaid, M.H.M.; Tonguc, B.T. Influence of Lead and Zinc Oxides on the Radiation Shielding Properties of Tellurite Glass Systems. Ceram. Int. 2020, 46, 17300–17306. [Google Scholar] [CrossRef]

- El-Fiki, S.; El Kameesy, S.U.; Nashar, D.E.E.; Abou-Leila, M.A.; El-Mansy, M.K.; Ahmed, M. Influence of Bismuth Contents on Mechanical and Gamma Ray Attenuation Properties of Silicone Rubber Composite. Int. J. Adv. Res. 2015, 3, 1035–1039. [Google Scholar]

- Soylu, H.M.; Yurt Lambrecht, F.Y.; Ersöz, O.A. Gamma Radiation Shielding Efficiency of a New Lead-Free Composite Material. J. Radioanal. Nucl. Chem. 2015, 305, 529–534. [Google Scholar] [CrossRef]

- Singh, A.K.; Singh, R.K.; Sharma, B.; Tyagi, A.K. Characterization and Biocompatibility Studies of Lead Free X-Ray Shielding Polymer Composite for Healthcare Application. Radiat. Phys. Chem. 2017, 138, 9–15. [Google Scholar] [CrossRef]

- Jamal AbuAlRoos, N.; Azman, M.N.; Baharul Amin, N.A.; Zainon, R. Tungsten-Based Material as Promising New Lead-Free Gamma Radiation Shielding Material in Nuclear Medicine. Phys. Med. 2020, 78, 48–57. [Google Scholar] [CrossRef] [PubMed]

- Mehnati, P.; Malekzadeh, R.; Sooteh, M.Y. Application of Personal Non-Lead Nano-Composite Shields for Radiation Protection in Diagnostic Radiology: A Systematic Review and Meta-Analysis. Nanomed. J. 2020, 7, 170–182. [Google Scholar]

- Habashi, F. Tungsten and the Mining Industry. J. Powder Metall. Min. 2017, 6, 1–5. [Google Scholar] [CrossRef]

- Gavrish, V.; Cherkashina, N.; Chayka, T. Investigations of the Influence of Tungsten Carbide and Tungsten Oxide Nanopowders on the Radiation Protection Properties of Cement Matrix-Based Composite Materials. J. Phys. Conf. Ser. 2020, 1652, 012008. [Google Scholar] [CrossRef]

- Enneti, R.K.; Morgan, R.; Atre, S.V. Effect of Process Parameters on the Selective Laser Melting (SLM) of Tungsten. Int. J. Refract. Met. Hard Mater. 2018, 71, 315–319. [Google Scholar] [CrossRef]

- Adlienė, D.; Gilys, L.; Griškonis, E. Development and Characterization of New Tungsten and Tantalum Containing Composites for Radiation Shielding in Medicine. Nucl. Instrum. Methods Phys. Res. B 2020, 467, 21–26. [Google Scholar] [CrossRef]

- Monzen, H.; Tamura, M.; Shimomura, K.; Onishi, Y.; Nakayama, S.; Fujimoto, T.; Matsumoto, K.; Hanaoka, K.; Kamomae, T. A Novel Radiation Protection Device Based on Tungsten Functional Paper for Application in Interventional Radiology. J. Appl. Clin. Med. Phys. 2017, 18, 215–220. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Malar, S.; Shivendra Vikram, S.; Jc Favas, P.; Perumal, V. Lead Heavy Metal Toxicity Induced Changes on Growth and Antioxidative Enzymes Level in Water Hyacinths [Eichhornia Crassipes (Mart.)]. Bot. Stud. 2016, 55, 54. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nambiar, S.; Osei, E.K.; Yeow, J.T.W. Polymer Nanocomposite-Based Shielding Against Diagnostic X-Rays. J. Appl. Polym. Sci. 2013, 127, 4939–4946. [Google Scholar] [CrossRef]

- Mansour, A.; Sayyed, M.I.; Mahmoud, K.A.; Şakar, E.; Kovaleva, E.G. Modified Halloysite Minerals for Radiation Shielding Purposes. J. Radiat. Res. Appl. Sci. 2020, 13, 94–101. [Google Scholar] [CrossRef] [Green Version]

- Monzen, H.; Kanno, I.; Fujimoto, T.; Hiraoka, M. Estimation of the Shielding Ability of a Tungsten Functional Paper for Diagnostic X-Rays and Gamma Rays. J. Appl. Clin. Med. Phys. 2017, 18, 325–329. [Google Scholar] [CrossRef]

- Eaton, D.J.; Gonzalez, R.; Duck, S.; Keshtgar, M. Radiation Protection for an Intra-Operative X-Ray Device. Br. J. Radiol. 2011, 84, 1034–1039. [Google Scholar] [CrossRef]

- Piotter, V.; Zeep, B.; Norajitra, P.; Ruprecht, R.; von der Weth, A.V.D.; Hausselt, J. Development of a Powder Metallurgy Process for Tungsten Components. Fusion Eng. Des. 2008, 83, 1517–1520. [Google Scholar] [CrossRef]

- Mao, Y.; Chen, C.; Coenen, J.W.; Riesch, J.; Sistla, S.; Almanstötter, J.; Terra, A.; Wu, Y.; Raumann, L.; Höschen, T.; et al. On the Nature of Carbon Embrittlement of Tungsten Fibers during Powder Metallurgical Processes. Fusion Eng. Des. 2019, 145, 18–22. [Google Scholar] [CrossRef]

- Bose, A. Netshaping Concepts for Tungsten Alloys and Composites. Powder Metall. 2003, 46, 121–126. [Google Scholar] [CrossRef]

- Hamidi, A.G.; Arabi, H.; Rastegari, S. A Feasibility Study of W-Cu Composites Production by High Pressure Compression of Tungsten Powder. Int. J. Refract. Met. Hard Mater. 2011, 29, 123–127. [Google Scholar] [CrossRef]

- Li, R.; Qin, M.; Liu, C.; Huang, H.; Lu, H.; Chen, P.; Qu, X. Injection Molding of Tungsten Powder Treated by Jet Mill with High Powder Loading: A Solution for Fabrication of Dense Tungsten Component at Relative Low Temperature. Int. J. Refract. Met. Hard Mater. 2017, 62, 42–46. [Google Scholar] [CrossRef]

- Wang, L.Z.; Wu, J.J.; Zhang, D.J. Properties Evolution of Additive Manufacture Used Tungsten Powders Prepared by Radio Frequency Induction Plasma. Int. J. Refract. Met. Hard Mater. 2017, 67, 90–97. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, Q.; Lang, S.; Xia, M.; Ge, C. Texture Evolution and Basic Thermal–Mechanical Properties of Pure Tungsten under Various Rolling Reductions. J. Nucl. Mater. 2016, 468, 339–347. [Google Scholar] [CrossRef]

- Lied, P.; Bonnekoh, C.; Pantleon, W.; Stricker, M.; Hoffmann, A.; Reiser, J. Comparison of K-Doped and Pure Cold-Rolled Tungsten Sheets: As-Rolled Condition and Recrystallization Behaviour After Isochronal Annealing at Different Temperatures. Int. J. Refract. Met. Hard Mater. 2019, 85, 105047. [Google Scholar] [CrossRef]

- Nogami, S.; Watanabe, S.; Reiser, J.; Rieth, M.; Sickinger, S.; Hasegawa, A. A Review of Impact Properties of Tungsten Materials. Fusion Eng. Des. 2018, 135, 196–203. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Wang, G.; Long, Y.; Yang, J.; Qin, M.; Qu, X.; So, K.P. Microstructure Evolution of Hot-Rolled Pure and Doped Tungsten Under Various Rolling Reductions. J. Nucl. Mater. 2020, 533, 152074. [Google Scholar] [CrossRef]

- Al-Hadeethi, Y.; Sayyed, M.I. A Comprehensive Study on the Effect of TeO2 on the Radiation Shielding Properties of TeO2-B2O3-Bi2O3-LiF-SrCl2 Glass System Using Phy, X/PSD Software. Ceram. Int. 2020, 46, 6136–6140. [Google Scholar] [CrossRef]

- Büermann, L.; Grosswendt, B.; Kramer, H.M.; Selbach, H.J.; Gerlach, M.; Hoffmann, M.; Krumrey, M. Measurement of the x-Ray Mass Energy-Absorption Coefficient of Air Using 3 keV to 10 keV Synchrotron Radiation. Phys. Med. Biol. 2006, 51, 5125–5150. [Google Scholar] [CrossRef] [PubMed]

- Al-Dhuhaibat, M.J.R. Study of the Shielding Properties for Some Composite Materials Manufactured from Polymer Epoxy Supported by Cement, Aluminum, Iron and Lead Against Gamma Rays of the Cobalt Radioactive Source (Co-60). Nucl. Phys. 2015, 4, 90–98. [Google Scholar]

- Chen, K.; Liu, K.; Chen, H.; Yang, Y. A Criterion for Void Closure in the Porous Model during the Forging of Steel Ingot and Its Application. Comput. Mater. Sci. 2014, 91, 303–309. [Google Scholar] [CrossRef]

- Kim, S.C.; Park, M.H. Development of Radiation Shielding Sheet with Environmentally Friendly Materials; II: Evaluation of Barum, Tourmaline, Silicon Polymers in the Radiation Shielding Sheet. J. Radiol. Sci. Technol. 2011, 34, 141–147. [Google Scholar]

- Han, S.H.; Koo, B.Y. Transmission Dose Measurement of Gamma-Ray Using Tungsten Shield. J. Korea Acad.-Ind. Coop. Soc. 2018, 19, 124–129. [Google Scholar] [CrossRef]

- Obaid, S.S.; Gaikwad, D.K.; Pawar, P.P. Determination of Gamma Ray Shielding Parameters of Rocks and Concrete. Radiat. Phys. Chem. 2018, 144, 356–360. [Google Scholar] [CrossRef]

- Zan, X.; Gu, M.; Wang, K.; Luo, L.; Zhu, X.; Wu, Y. Recrystallization Kinetics of 50% Hot-Rolled 2% Y2O3 Dispersed Tungsten. Fusion Eng. Des. 2019, 144, 1–5. [Google Scholar] [CrossRef]

- Miao, S.; Xie, Z.M.; Yang, X.D.; Liu, R.; Gao, R.; Zhang, T.; Wang, X.P.; Fang, Q.F.; Liu, C.S.; Luo, G.N.; et al. Effect of Hot Rolling and Annealing on the Mechanical Properties and Thermal Conductivity of W-0.5wt.% TaC Alloys. Int. J. Refract. Met. Hard Mater. 2016, 56, 8–17. [Google Scholar] [CrossRef]

- Roslan, M.K.A.; Ismail, M.; Kueh, A.B.H.; Zin, M.R.M. High-Density Concrete: Exploring Ferro Boron Effects in Neutron and Gamma Radiation Shielding. Constr. Build. Mater. 2019, 215, 718–725. [Google Scholar] [CrossRef]

- Palacios, T.; Reiser, J.; Hoffmann, J.; Rieth, M.; Hoffmann, A.; Pastor, J.Y. Microstructural and Mechanical Characterization of Annealed Tungsten (W) and Potassium-Doped Tungsten Foils. Int. J. Refract. Met. Hard Mater. 2015, 48, 145–149. [Google Scholar] [CrossRef] [Green Version]

- Fujimoto, T.; Monzen, H.; Nakata, M.; Okada, T.; Yano, S.; Takakura, T.; Kuwahara, J.; Sasaki, M.; Higashimura, K.; Hiraoka, M. Dosimetric Shield Evaluation with Tungsten Sheet in 4, 6, and 9-MeV Electron Beams. Phys. Med. 2014, 30, 838–842. [Google Scholar] [CrossRef] [PubMed]

- Reiser, J.; Rieth, M.; Dafferner, B.; Hoffmann, A. Charpy Impact Properties of Pure Tungsten Plate Material in as-Received and Recrystallized Condition (1h at 2000 °C (2273 K)). J. Nucl. Mater. 2013, 442, S204–S207. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Chen, D.S.; Han, W.T.; Kimura, A. Irradiation Hardening in Pure Tungsten Before and After Recrystallization. Fusion Eng. Des. 2015, 98–99, 2103–2107. [Google Scholar] [CrossRef]

- Malykhin, S.V.; Garkusha, I.E.; Makhlai, V.A.; Surovitskiy, S.V.; Herashchenko, S.S.; Girka, O.I. Mechanisms of Crack Generation in High-Pure Tungsten Exposed to High Power Density Plasma. Nucl. Instrum. Methods Phys. Res. B 2020, 481, 6–11. [Google Scholar] [CrossRef]

| Effective X-ray Energy (keV) | Peak Voltage (kVp) of the X-ray Tube | Mean of Exposure (µR) | Shielding Rate (%) | |||||

|---|---|---|---|---|---|---|---|---|

| Nothing | Hot Rolling | Cold Rolling | Hot Rolling | Cold Rolling | ||||

| 0.3 T | 0.1 T | 0.1 T | 0.3 T | 0.1 T | 0.1 T | |||

| 24.6 | 40 | 106.90 | 0 | 1.98 | 4.02 | 100 | 98.15 | 96.24 |

| 28.7 | 60 | 381.63 | 2.49 | 33.91 | 51.82 | 99.35 | 91.11 | 86.42 |

| 32.5 | 80 | 799.70 | 21.49 | 135.07 | 181.70 | 97.35 | 83.11 | 77.28 |

| 48.5 | 100 | 1318.33 | 49.23 | 274.33 | 358.90 | 96.27 | 79.19 | 72.78 |

| 54.9 | 120 | 1648.33 | 71.37 | 372.10 | 484.77 | 95.67 | 77.43 | 70.59 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-C. Improving the X-ray Shielding Performance of Tungsten Thin-Film Plates Manufactured Using the Rolling Technology. Appl. Sci. 2021, 11, 9111. https://doi.org/10.3390/app11199111

Kim S-C. Improving the X-ray Shielding Performance of Tungsten Thin-Film Plates Manufactured Using the Rolling Technology. Applied Sciences. 2021; 11(19):9111. https://doi.org/10.3390/app11199111

Chicago/Turabian StyleKim, Seon-Chil. 2021. "Improving the X-ray Shielding Performance of Tungsten Thin-Film Plates Manufactured Using the Rolling Technology" Applied Sciences 11, no. 19: 9111. https://doi.org/10.3390/app11199111

APA StyleKim, S.-C. (2021). Improving the X-ray Shielding Performance of Tungsten Thin-Film Plates Manufactured Using the Rolling Technology. Applied Sciences, 11(19), 9111. https://doi.org/10.3390/app11199111