Performance Testing and Evaluation of Drum-Type Stem-Separation Device for Pepper Harvester

Abstract

:1. Introduction

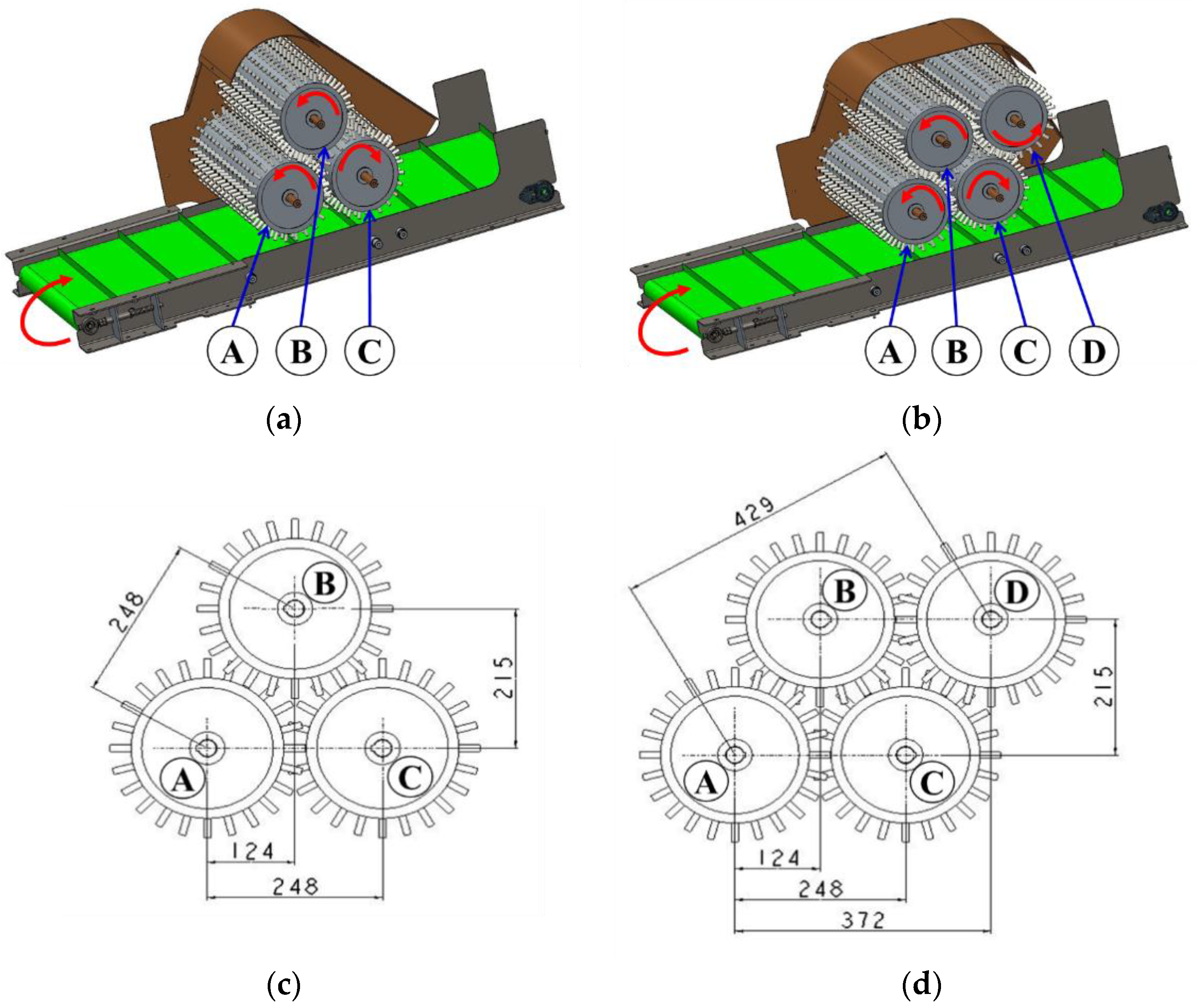

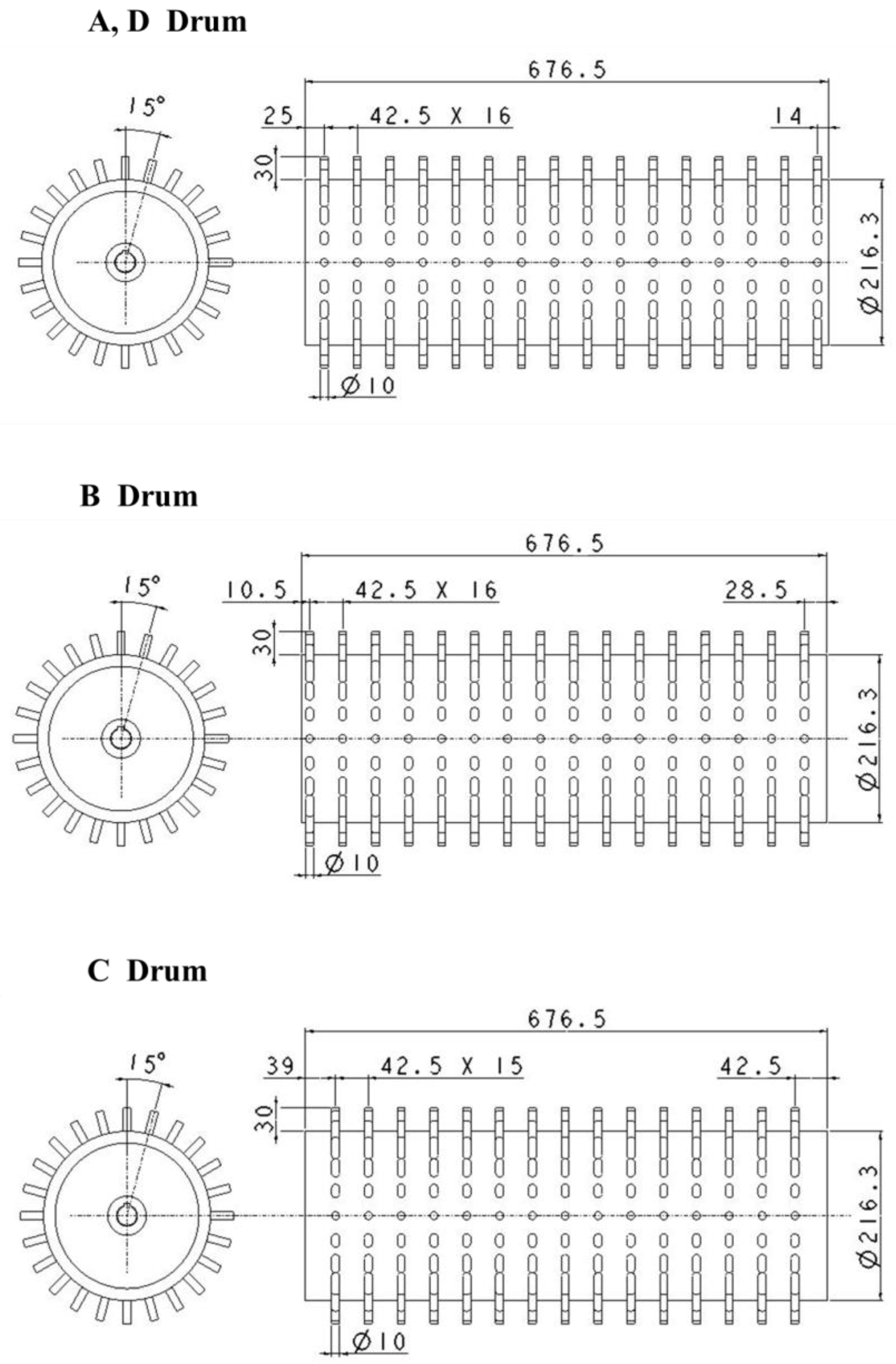

- To design and manufacture three-shaft and four-shaft drum stem-separation devices.

- To find the optimal drum rotation speed.

- To conduct a comparative performance test and evaluation of the three-shaft and four-shaft drum stem-separation devices.

2. Materials and Methods

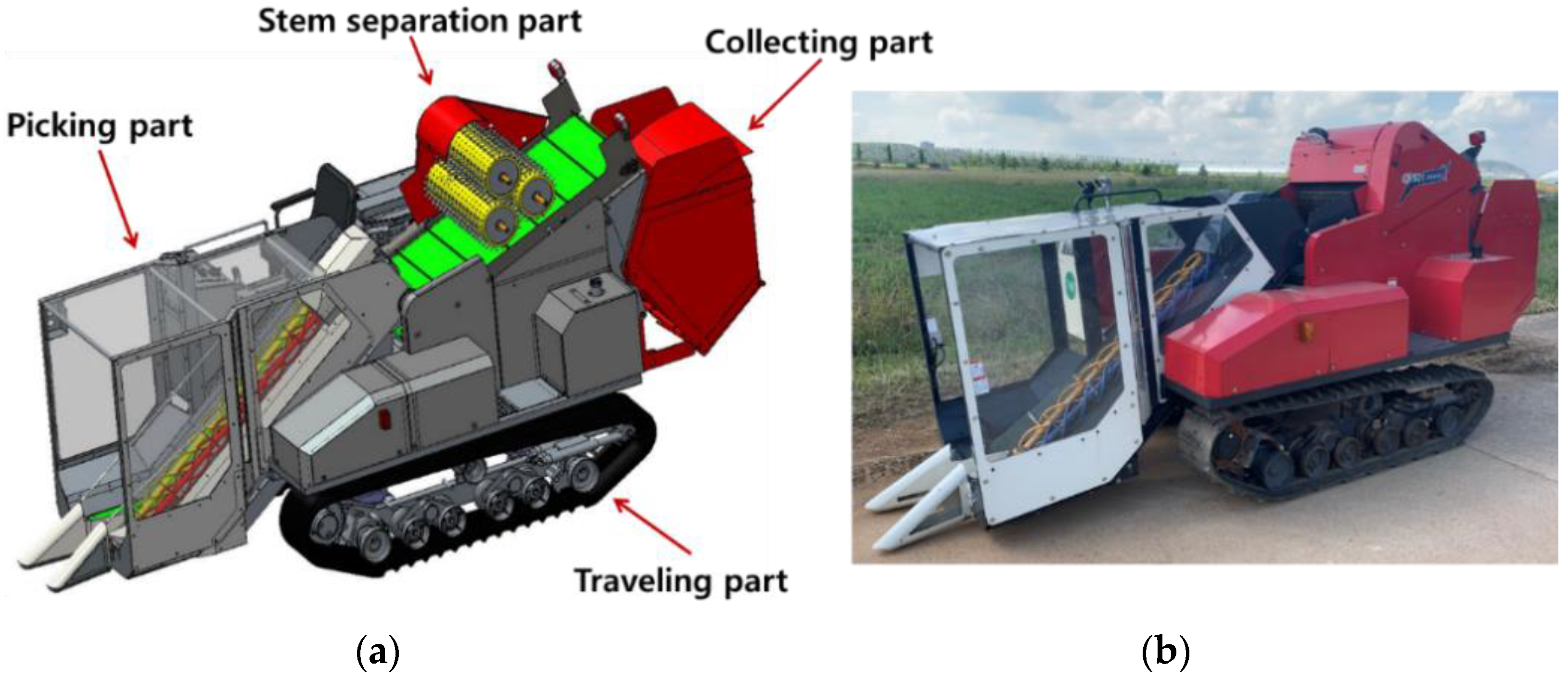

2.1. Chili Pepper Harvester

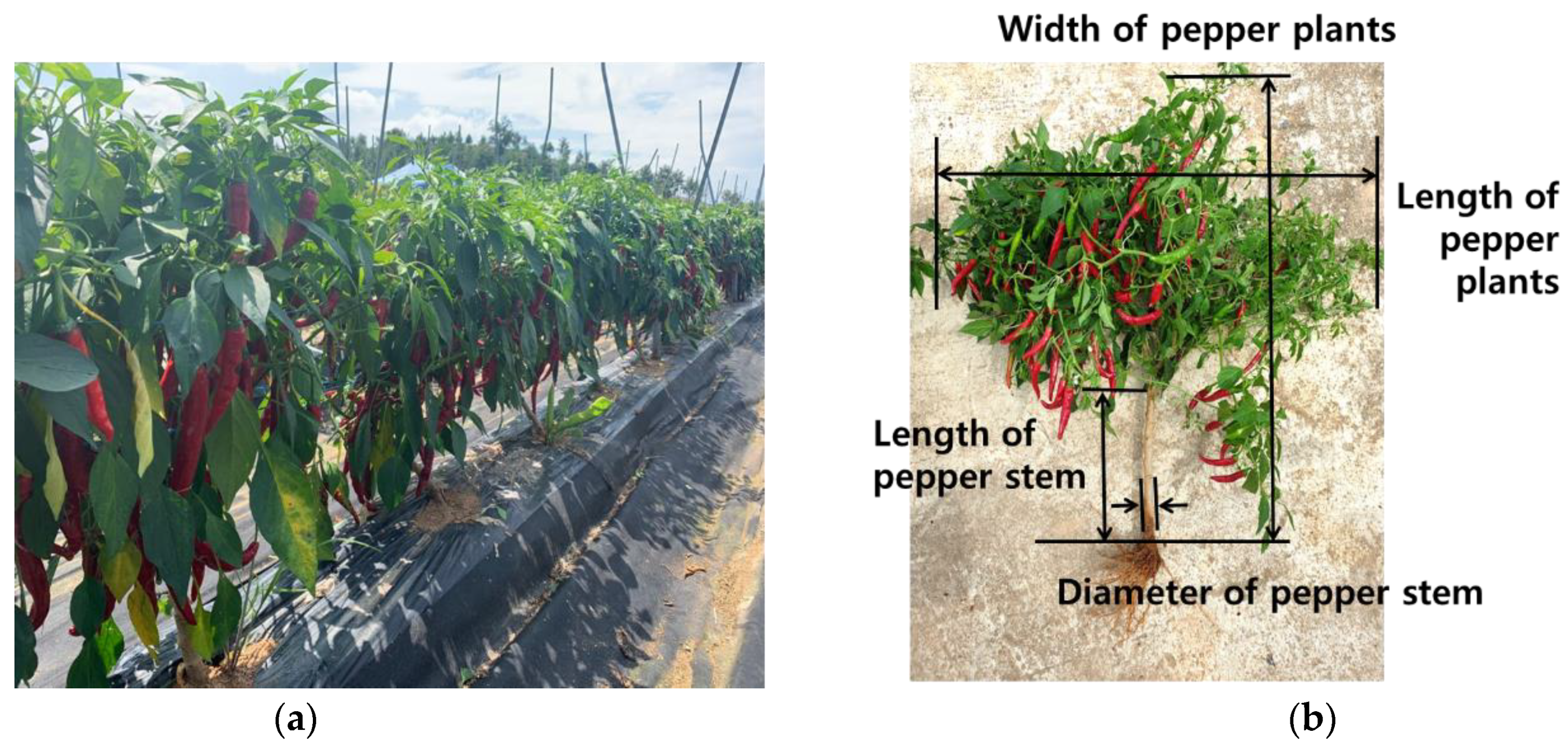

2.2. Test Sample

2.3. Field Test Method

2.4. Analysis Method

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Production of Chili Pepper. Statistics Korea. Available online: http://kostat.go.kr/portal/eng/pressReleases/1/index.board?bmode=read&aSeq=386685 (accessed on 12 August 2021).

- Agriculture in Korea 2020. Rural Economic Institute Korea. Available online: http://www.krei.re.kr/eng/researchReportView.do?key=355&pageType=010101&biblioId=527557&pageUnit=10&searchCnd=all&searchKrwd=&pageIndex=1&engView=Y (accessed on 12 August 2021).

- Funk, P.A.; Walker, S.J. Evaluation of five green chili cultivars utilizing five different harvest mechanisms. Appl. Eng. Agric. 2010, 26, 955–964. [Google Scholar] [CrossRef]

- Qin, X.; Lei, J.; Chen, Y. Design and research on key components of a novel self-propelled chile pepper harvester. Appl. Mech. Mater. 2012, 468, 794–797. [Google Scholar]

- Chen, Y.C.; Kong, L.J.; Wang, H.X.; Li, J.J.; Li, R.M. Research of mechanism and experiment of 4LZ-3.0 self-propelled pepper harvester. Appl. Mech. Mater. 2013, 419, 217–222. [Google Scholar] [CrossRef]

- Lei, J.; Qin, X.; Chen, Y. Design and analysis on key components of a novel chili pepper harvester’s picking device. Open Mech. Eng. J. 2015, 9, 540–545. [Google Scholar]

- Nishanth, M.S.; Jayan, P.R.; Pankaj, M.; Ratnakiran, D.W. Design, development and evaluation of pepper harvester. J. AgriSearch 2020, 7, 82–85. [Google Scholar]

- Kang, K.-S.; Park, H.-S.; Park, S.-J.; Kang, Y.-S.; Kim, D.-C. Study on optimal working conditions for picking head of self-propelled pepper harvester by factorial test. J. Biosyst. Eng. 2016, 41, 12–20. [Google Scholar] [CrossRef] [Green Version]

- Walker, S.J.; Funk, P.A. Mechanical harvest trials of New Mexican-type green chile (Capsicum annuum L). Hort. Sci. 2010, 45, 145–146. [Google Scholar]

- Calsoyas, I.; Walker, S.; Funk, P. Comparison of Six Green Chile (Capsicum annuum L.) Cultivars on Harvest Efficiency with Etgar® Picker. In Proceedings of the Annual Meeting of the American Society for Horticultural Science, Philadelphia, PA, USA, 3–7 January 2016; Volume 51, pp. 267–268. [Google Scholar]

- Russo, V.M. Peppers: Botany, Production and Uses; CABI Publishing: Wallingford, UK, 2012; pp. 1–280. [Google Scholar]

- Zhao, Y.; Gong, L.; Huang, Y.; Liu, C. A review of key techniques of vision-based control for harvesting robot. Comput. Electron. Agric. 2016, 127, 311–323. [Google Scholar] [CrossRef]

- Arad, B.; Balendonck, J.; Barth, R.; Ben-Shahar, O.; Edan, Y.; Hellström, T.; Hemming, J.; Kurtser, P.; Ringdahl, O.; Tielen, T.; et al. Development of a sweet pepper harvesting robot. J. Field Robot. 2020, 37, 1027–1039. [Google Scholar] [CrossRef]

- Byun, Y.H.; Oh, S.H.; Choi, M. ICT agriculture support system for chili pepper harvesting. J. Info. Proc. System. 2020, 16, 629–638. [Google Scholar]

- Masood, M.U.; Jaryani, M.H. A Study on the feasibility of robotic harvesting for chile pepper. Appl. Sci. 2021, 10, 94. [Google Scholar]

- Joukhadar, I.S.; Walker, S.J.; Funk, P. Comparative mechanical harvest efficiency of six New Mexico pod–type green chile pepper cultivars. HortTechnology 2018, 28, 310–318. [Google Scholar] [CrossRef]

- Hernandez, D.H.; Ayerdi, S.G.S.; Goni, I. Bioactive compounds of four hot pepper varieties (Capsicum annuum L.), antioxi-dant capacity, and intestinal bioaccessibility. J. Agric. Food Chem. 2010, 58, 3399–3406. [Google Scholar] [CrossRef]

- Bhandari, S.R.; Bashyal, U.; Lee, Y.-S. Variations in proximate nutrients, phytochemicals, and antioxidant activity of field-cultivated red pepper fruits at different harvest times. Hortic. Environ. Biotechnol. 2016, 57, 493–503. [Google Scholar] [CrossRef]

- Joukhadar, I.; Walker, S. Evaluation of a New Mexico landrace and two commercial chile (Capsicum annuum) cultivars under four furrow irrigation schedules. Horticulturae 2018, 4, 4. [Google Scholar] [CrossRef] [Green Version]

- Gomes, L.M.; Ribeiro, C.S.C.; Ragassi, C.F.; Silva, L.S.; Reifschneider, F.J.B. Advanced lines of Jalapeño pepper with po-tential for mechanical harvesting. J. Cienc. Rural Agric. Sci. 2019, 49, 1–6. [Google Scholar]

- Joukhadar, I.; Walker, S. Effect of stand reduction at different growth stages on yield of paprika-type chile pepper. Horticulturae 2020, 6, 16. [Google Scholar] [CrossRef] [Green Version]

- Havlik, C.D.; Walker, S.J.; Funk, P.; Marsalis, M.A. Optimum Plant Spacing for New Mexico Green Chile (Capsicum annuum) Mechanical Harvest Efficiency. In Proceedings of the Annual Meeting of the American Society for Horticultural Science, Washington, DC, USA, 30 July–3 August 2018; Volume 53, p. 358. [Google Scholar]

- Ragassi, C.F.; Zucolotto, J.; Gomes, L.M.; Ribeiro, C.S.; Madeira, N.R.; Reifschneider, F.J.B. Productivity, quality of fruits and architecture of Jalapeño pepper at different planting densities. Hortic. Bras. 2019, 37, 331–337. [Google Scholar] [CrossRef]

- Yang, B.; Luo, Y.; Tan, Y.; Kan, J. Effects of ethephon on ethephon residue and quality properties of chili pepper during pre-harvest ripening. J. Food Sci. Technol. 2021, 58, 2098–2108. [Google Scholar] [CrossRef]

- Funk, P.A.; Walker, S.J.; Herbon, R.P. A systems approach to chile harvest mechanization. Int. J. Veg. Sci. 2011, 17, 296–309. [Google Scholar] [CrossRef]

- Kong, L.; Chen, Y.; Ma, L.; Duan, Y. Research and design of line pepper’ cleaning and separating device, based on star wheel and airflow. J. Chin. Agric. Mech. 2013, 34, 102–105. [Google Scholar]

- Walker, S.J.; Funk, P.A. Mechanizing chile peppers: Challenges and advances in transitioning harvest of New Mexico’s sig-nature crop. J. Am. Soc. Hort. Sci. 2014, 24, 281–284. [Google Scholar] [CrossRef]

- Byum, J.; Nam, J.; Choe, J.; Inoue, E.; Okayasu, T.; Kim, D. Analysis of the separating performance of a card cleaner for pepper harvester using EDEM software. J. Fac. Agric. Kyushu Univ. 2018, 63, 347–354. [Google Scholar] [CrossRef]

- Jo, Y.J.; Kang, Y.S.; Nam, J.S.; Choe, J.S.; Inoue, E.; Okayasu, T.; Kim, D.C. Performance analysis for a card cleaner type sep-arating system of pepper harvester. J. Fac. Agric. Kyushu Univ. 2018, 63, 103–111. [Google Scholar]

- Shin, S.-Y.; Kim, D.-C.; Kang, Y.-S.; Cho, Y. Factorial experiment for air blower of the pepper harvester. J. Biosyst. Eng. 2020, 45, 239–248. [Google Scholar] [CrossRef]

- Kim, T.-H.; Kim, D.-C.; Cho, Y. Performance comparison and evaluation of two small chili pepper harvester prototypes that attach to walking cultivators. Appl. Sci. 2020, 10, 2570. [Google Scholar] [CrossRef] [Green Version]

- Wolf, I.; Alper, Y. Mechanization of Paprika Harvest. In Proceedings of the First International Conference on Fruit, Nut and Vegetable Harvesting Mechanization, Bet Dagan, Israel, 5–12 October 1983; American Society of Agricultural and Biological Engineers: St. Joesph, MI, USA, 1984; Volume 5, pp. 265–275. [Google Scholar]

- Esch, T.A.; Marshall, D.E. Trash removal from mechanically harvested peppers. Trans. ASAE 1987, 30, 0893–0898. [Google Scholar] [CrossRef]

- Wolf, I.; Alper, Y. Apparatus for harvesting and separation of produce. U.S. Patent No. 4,507,911, 1985. [Google Scholar]

- Seiphepi, G.; Zungeru, A.M.; Gaboitaolelwe, J.; Lebekwe, C.; Mtengi, B. Automatic bell pepper colour detector and sorting machine. Int. J. Eng. Res. Technol. 2020, 13, 3156–3166. [Google Scholar] [CrossRef]

- Gan-Mor, S.; Wiseblum, A.; Regev, R. Separation of leaves from stems with a perforated rotating drum under suction. J. Agric. Eng. Res. 1986, 34, 275–284. [Google Scholar] [CrossRef]

- Sudajan, S.; Salokhe, V.M.; Triratanasirichai, K. Effect of type of drum, drum speed and feed rate on sunflower threshing. Biosyst. Eng. 2002, 83, 413–421. [Google Scholar] [CrossRef]

- Spinelli, R.; Cavallo, E.; Eliasson, L.; Facello, A. Comparing the efficiency of drum and disc chippers. Silva. Fenn. 2013, 47, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Jyoti, B.; Karthirvel, K.; Durairaj, C. Effect of blade angles and thickness on specific cutting energy and cutting index of cassava stem. J. AgriSearch 2018, 5, 126–129. [Google Scholar] [CrossRef]

- Choi, Y. Development of Machine Harvester for Pepper. Ph.D. Thesis, Chonnam National University, Gwangju, Korea, 2006. [Google Scholar]

- Nam, J.S.; Kang, Y.S.; Kim, S.B.; Kim, D.C. Factorial experiment for drum-type secondary separating part of self-propelled pepper harvester. J. Biosyst. Eng. 2017, 42, 242–250. [Google Scholar]

- Boese, G.M. Vegetable Harvester. U.S. Patent No. 6,003,293, 1999. [Google Scholar]

- Łukasz, W.; Materusz, K.; Bartosz, W.; Piotr, K. Energy Consumption of the Wood Size Reduction Processes with Employment of a Low-Power Machines with Various Cutting Mechanisms. Renew. Energy 2021, in press. [Google Scholar] [CrossRef]

| Item | Data |

|---|---|

| Power (kW) | 22.5 |

| Weight (kg) | 2020 |

| Standard working speed (m/s) | 0.1–0.3 |

| Rated revolution per minute (rpm) | 2600 |

| Rotational speed of picking part helix (rpm) | 650 |

| Separating method | Drum type and air fan |

| Collecting tank (kg) | 220 |

| Variety | AR Legend | Jeokyoung | |||

|---|---|---|---|---|---|

| Parameter | AVE | SD | AVE | SD | |

| Plant | Length of pepper plant (mm) | 1052.5 | 136.5 | 866.6 | 90.7 |

| Width of pepper plant (mm) | 814.6 | 111.2 | 776.7 | 125.2 | |

| Length of pepper stem (mm) | 198.3 | 20.3 | 163.3 | 15.3 | |

| Diameter of pepper stem (mm) | 20.5 | 3.8 | 24.6 | 4.1 | |

| Fruit | Length (mm) | 118.3 | 13.7 | 112.8 | 20.3 |

| Maximum diameter (mm) | 23.1 | 2.1 | 22.6 | 2.7 | |

| Weight (g) | 22.4 | 2.3 | 18.7 | 3.2 | |

| Amount (ea/plant) | 88.0 | 6.5 | 96.4 | 5.8 | |

| Detachment force (kgf) | 2.3 | 0.6 | 1.4 | 0.2 | |

| Level Speed (m/s) | ||||||

|---|---|---|---|---|---|---|

| Type | 1 | 2 | 3 | 4 | 5 | 6 |

| A (1st shaft) | 0.3 | 0.4 | 0.4 | 0.5 | 0.6 | 0.9 |

| B (2nd shaft) | 0.5 | 0.7 | 0.8 | 0.9 | 1.8 | 2.7 |

| C (3rd shaft) | 0.8 | 1.1 | 1.3 | 1.3 | 1.3 | 1.3 |

| D (4th shaft) | - | - | - | - | - | 1.3 |

| Conveyor | 0.8 | 0.6 | 0.5 | 0.6 | 0.5 | 0.5 |

| Drum type | Level | AVE/SD | SSE 1 (%) | PTR 2 (%) | DR 3 (%) |

|---|---|---|---|---|---|

| 3-shaft | 1 | AVE 4 | 51.6 | 45.1 | 3.3 |

| SD 5 | 2.8 | 2.7 | 0.5 | ||

| 2 | AVE | 59.1 | 38.7 | 2.2 | |

| SD | 3.4 | 3.8 | 1.4 | ||

| 3 | AVE | 53.9 | 42.5 | 3.6 | |

| SD | 6.3 | 7.1 | 0.8 | ||

| 4 | AVE | 57.7 | 38.8 | 3.4 | |

| SD | 6.2 | 4.1 | 2.1 | ||

| 5 | AVE | 64.1 | 33.0 | 2.9 | |

| SD | 7.2 | 7.9 | 0.7 | ||

| 6 | AVE | 76.8 | 20.9 | 2.3 | |

| SD | 8.2 | 8.5 | 1.3 |

| Operating Status | Drum Type | Variety | AVE 1/SD 2 | SSE 3 | PTR 4 | DR 5 | GAR 6 | |

|---|---|---|---|---|---|---|---|---|

| (%) | (%) | (%) | (%) | |||||

| Non-picking operation | Non-moving | 3 | AR Legend | AVE | 70.0 | 26.9 | 3.1 | - |

| SD | 8.2 | 8.5 | 1.3 | - | ||||

| Jeokyoung | AVE | 69.3 | 27.7 | 3.0 | - | |||

| SD | 5.4 | 4.8 | 1.1 | - | ||||

| 4 | AR Legend | AVE | 64.0 | 25.5 | 10.5 | - | ||

| SD | 2.9 | 3.2 | 1.4 | - | ||||

| Jeokyoung | AVE | 72.3 | 17.8 | 9.9 | - | |||

| SD | 6.3 | 6.2 | 2.1 | - | ||||

| Picking operation | Non-moving | 3 | AR Legend | AVE | 86.0 | 9.3 | 4.7 | - |

| SD | 0.5 | 0.6 | 1.1 | - | ||||

| 4 | AR Legend | AVE | 90.1 | 6.2 | 3.7 | - | ||

| SD | 0.7 | 2.3 | 1.6 | - | ||||

| Moving | 3 | AR Legend | 65.7 | 22.1 | 9.5 | 2.7 | ||

| 4 | AR Legend | 69.3 | 13.0 | 11.2 | 6.5 | |||

| Non-picking operation | Non-moving | 3 | AR Legend | AVE | 70.0 | 26.9 | 3.1 | - |

| SD | 8.2 | 8.5 | 1.3 | - | ||||

| Jeokyoung | AVE | 69.3 | 27.7 | 3.0 | - | |||

| SD | 5.4 | 4.8 | 1.1 | - | ||||

| 4 | AR Legend | AVE | 64.0 | 25.5 | 10.5 | - | ||

| SD | 2.9 | 3.2 | 1.4 | - | ||||

| Jeokyoung | AVE | 72.3 | 17.8 | 9.9 | - | |||

| SD | 6.3 | 6.2 | 2.1 | - | ||||

| Picking operation | Non-moving | 3 | AR Legend | AVE | 86.0 | 9.3 | 4.7 | - |

| SD | 0.5 | 0.6 | 1.1 | - | ||||

| 4 | AR Legend | AVE | 90.1 | 6.2 | 3.7 | - | ||

| SD | 0.7 | 2.3 | 1.6 | - | ||||

| Moving | 3 | AR Legend | 65.7 | 22.1 | 9.5 | 2.7 | ||

| 4 | AR Legend | 69.3 | 13.0 | 11.2 | 6.5 | |||

| Item | Source | DF | Anova SS | Mean Square | F Value | Pr > F |

|---|---|---|---|---|---|---|

| Shaft | 1 | 99.4200 | 5.0700 | 0.2800 | 0.6140 | |

| Variety | 1 | 38.8800 | 38.8800 | 2.1500 | 0.1803 | |

| SSE 1 | Shaft*variety | 1 | 55.4700 | 55.4700 | 3.0700 | 0.1176 |

| Error | 8 | 144.3400 | 18.0425 | |||

| ⃞ | Total | 11 | 243.7600 | ⃞ | ⃞ | ⃞ |

| Shaft | 1 | 99.1875 | 99.1875 | 8.06 | 0.0219 | |

| Variety | 1 | 33.6675 | 33.6675 | 2.74 | 0.1367 | |

| PTR 2 | Shaft*variety | 1 | 52.5008 | 52.5008 | 4.27 | 0.0728 |

| Error | 8 | 98.4666 | 12.3083 | |||

| ⃞ | Total | 11 | 283.8225 | ⃞ | ⃞ | ⃞ |

| Shaft | 1 | 148.4033 | 148.4033 | 87.17 | 0.0001 | |

| Variety | 1 | 0.1633 | 0.1633 | 0.1 | 0.7647 | |

| DR 3 | Shaft*variety | 1 | 0.03 | 0.03 | 0.02 | 0.8977 |

| Error | 8 | 13.62 | 1.7025 | |||

| ⃞ | Total | 11 | 162.2166 | ⃞ | ⃞ | ⃞ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, S.-Y.; Kim, M.-H.; Cho, Y.; Kim, D.-C. Performance Testing and Evaluation of Drum-Type Stem-Separation Device for Pepper Harvester. Appl. Sci. 2021, 11, 9225. https://doi.org/10.3390/app11199225

Shin S-Y, Kim M-H, Cho Y, Kim D-C. Performance Testing and Evaluation of Drum-Type Stem-Separation Device for Pepper Harvester. Applied Sciences. 2021; 11(19):9225. https://doi.org/10.3390/app11199225

Chicago/Turabian StyleShin, Seo-Yong, Myoung-Ho Kim, Yongjin Cho, and Dae-Cheol Kim. 2021. "Performance Testing and Evaluation of Drum-Type Stem-Separation Device for Pepper Harvester" Applied Sciences 11, no. 19: 9225. https://doi.org/10.3390/app11199225

APA StyleShin, S.-Y., Kim, M.-H., Cho, Y., & Kim, D.-C. (2021). Performance Testing and Evaluation of Drum-Type Stem-Separation Device for Pepper Harvester. Applied Sciences, 11(19), 9225. https://doi.org/10.3390/app11199225