Design and Implementation of Inverse Kinematics and Motion Monitoring System for 6DoF Platform

Abstract

:1. Introduction

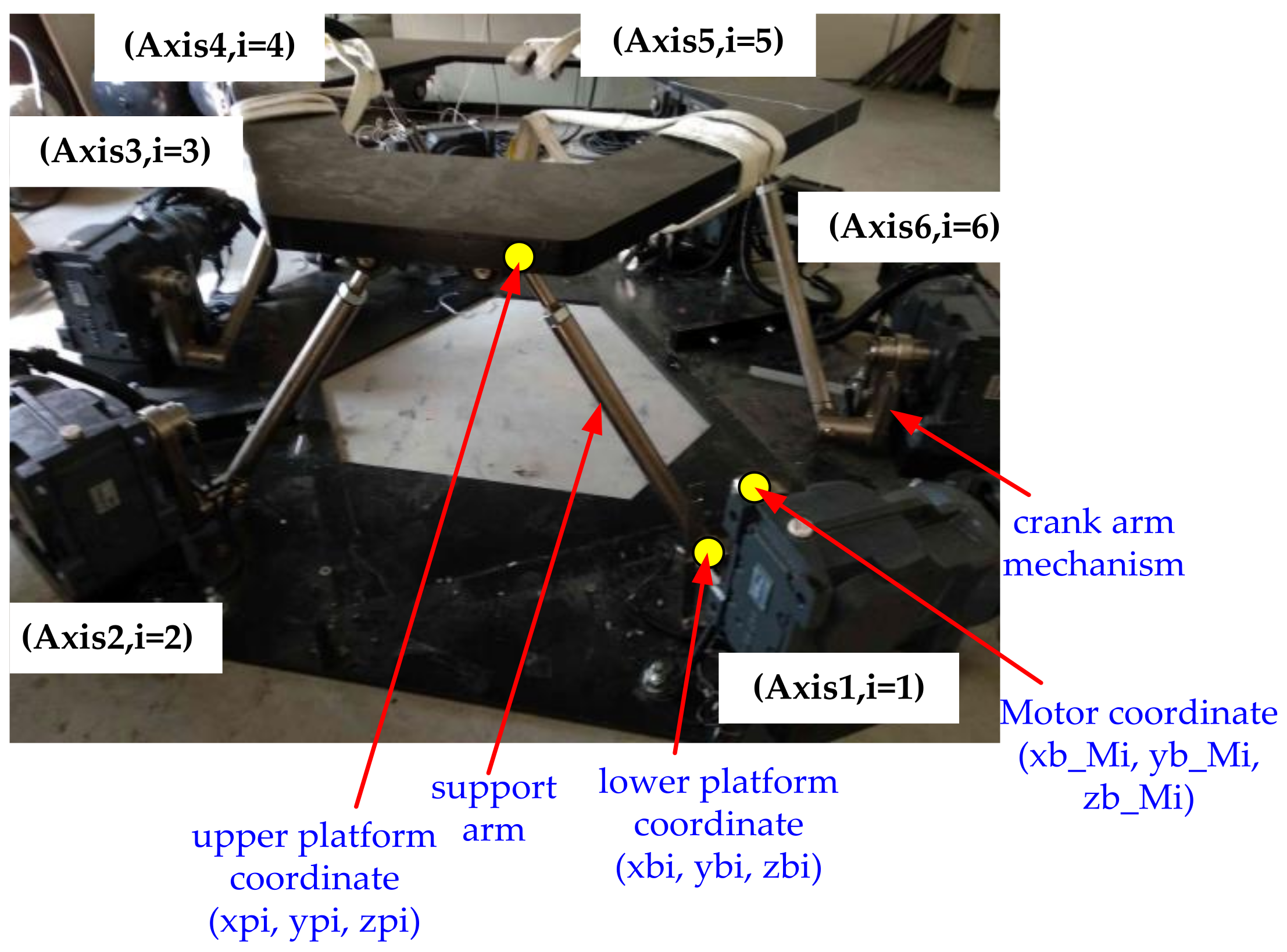

2. Inverse Kinematics Design

2.1. Traditional Inverse Kinematics

2.2. Proposed Inverse Kinematics

3. PID Controller

4. Monitoring System Design

4.1. Gyroscope and Angular Velocity Meter Jig

4.2. Laser Displacement and Angular Meters

4.3. Measurement Software

5. Implementation

6. Experimental Validation

7. Conclusions

Funding

Conflicts of Interest

References

- Urlahannan, A.; Jennings, P.; Oliveira, L.; Birrell, S. Designing an adaptive interface: Using eye tracking to classify how information usage changes over time in partially automated vehicles. IEEE Trans. Access 2020, 8, 16865–16875. [Google Scholar] [CrossRef]

- He, Z.; Lian, B.; Li, Q.; Zhang, Y.; Song, Y.; Yang, Y.; Sun, T. An error identification and compensation method of a 6-DoF parallel kinematic machine. IEEE Trans. Access 2020, 8, 119038–119047. [Google Scholar] [CrossRef]

- Nabi, H.N.; Ullah, S.; Munir, A. Kinematics analysis of three-degree-of freedom parallel manipulator with crank arm actuator. In Proceedings of the 2014 11th International Bhurban Conference on Applied Sciences & Technology (IBCAST), Islamabad, Pakistan, 14–18 January 2014; pp. 182–188. [Google Scholar]

- Pan, C.T.; Sun, P.Y.; Li, H.J.; Hsieh, C.H.; Hoe, Z.Y.; Shiue, Y.L. Development of multi-axis crank linkage motion system for synchronized flight simulation with VR immersion. Appl. Sci. 2021, 11, 3596. [Google Scholar] [CrossRef]

- Stewart, D. A platform with six degrees of freedom. Proc. Inst. Mech. Eng. 1965, 180, 371–386. [Google Scholar] [CrossRef]

- Fichtert, E.F. A Stewart platform-based manipulator: General theory and practical construction. Int. J. Robot. Res. 1986, 5, 157–182. [Google Scholar] [CrossRef]

- Mohammed, M.G.; Duffy, J. A direct determination of the instantaneous kinematics of fully parallel manipulators. ASME J. Mech. Transm. Autom. Des. 1986, 107, 226–229. [Google Scholar] [CrossRef]

- Liu, K.; Fitzgerald, J.M.; Lewis, F.L. Kinematic analysis of a Stewart platform manipulator. IEEE Trans. Ind. Electron. 1993, 40, 282–293. [Google Scholar] [CrossRef]

- Ji, C.Y.; Chenand, T.C.; Lee, Y.L. Investigation of kinematic analysis and applications for a 3-RRPS parallel manipulator. J. Chin. Soc. Mech. Eng. 2007, 28, 623–632. [Google Scholar]

- Mohammed, A.M.; Li, S. Dynamic neural networks for kinematic redundancy resolution of parallel Stewart platforms. IEEE Trans. Cybern. 2016, 46, 1538–1550. [Google Scholar] [CrossRef] [PubMed]

- Lara-Molina, F.A.; Rosario, J.M.; Dumur, D. Architecture of predictive control for a Stewart platform manipulator. In Proceedings of the 2010 8th World Congress on Intelligent Control and Automation, Jinan, China, 7–9 July 2010; pp. 6584–6589. [Google Scholar]

- Bruschetta, M.; Maran, F.; Beghi, A. A Nonlinear, MPC-based motion cueing algorithm for a high-performance, nine-DoF dynamic simulator platform. IEEE Trans. Control Syst. Technol. 2017, 25, 686–694. [Google Scholar] [CrossRef]

- Asadi, H.; Mohammadi, A.; Mohamed, S.; Qazani, M.R.C.; Lim, C.P.; Khosravi, A.; Nahavandi, S. A model predictive control-based motion cueing algorithm using an optimized nonlinear scaling for driving simulators. In Proceedings of the 2019 IEEE International Conference on Systems, Man and Cybernetics (SMC), Bari, Italy, 6–9 October 2019; pp. 1245–1250. [Google Scholar]

- Tang, Z.; Hu, M.; Pei, Z.; Liu, L.; Zhang, J. A new numerical method for Stewart platform forward kinematics. In Proceedings of the 2016 35th Chinese Control Conference (CCC), Chengdu, China, 27–29 July 2016; pp. 6311–6316. [Google Scholar]

- Lou, J.H.; Tseng, S.P. Developing a real-time serial servo motion control system for electric Stewart platform. In Proceedings of the 2014 International Conference on Advanced Robotics and Intelligent Systems (ARIS), Taipei, Taiwan, 6–8 June 2014; pp. 66–71. [Google Scholar]

- Qazani, M.R.C.; Asadi, H.; Khoo, S.; Nahavandi, S. A linear time-varying model predictive control-based motion cueing algorithm for hexapod simulation-based motion platform. IEEE Trans. Syst. Man Cybern. Syst. 2019, 51, 6096–6110. [Google Scholar] [CrossRef]

- Asadi, H.; Lim, C.P.; Mohamed, S.; Nahavandi, D.; Nahavandi, S. Increasing motion fidelity in driving simulators using a fuzzy-based washout filter. IEEE Trans. Intell. Veh. 2019, 4, 298–308. [Google Scholar] [CrossRef]

- Available online: https://docplayer.net/34514506-How-to-build-an-arduino-powered-6dof-motion-platform.html (accessed on 26 August 2021).

- Urlahannan, A.; Jennings, P.; Oliveira, L.; Birrell, S. A efficient numerical method for forward kinematics of parallel robots. IEEE Trans. Access 2019, 7, 128758–128766. [Google Scholar]

- Jia, G.; Pan, G.; Gao, Q.; Zhang, Y. Research on position inverse solution of electric-driven Stewart platform based on Simulink. J. Eng. 2019, 2019, 379–383. [Google Scholar] [CrossRef]

- Sciavicco, L.; Siciliano, B. Modelling and Control of Robot Manipulators; Springer: London, UK, 2000. [Google Scholar]

| Pole Number | 8 Pole |

|---|---|

| Power dissipation | 5.0 kW |

| Rated voltage | 220 V |

| Rated load current | 25.9 A |

| Rotor inertia | 0.00488 Kg-m2 |

| Rated speed | 2000 r/min |

| Maximum speed | 3000 r/min |

| Rated torque | 23.9 N.m |

| Maximum torque | 71.6 N.m |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, M.-Y. Design and Implementation of Inverse Kinematics and Motion Monitoring System for 6DoF Platform. Appl. Sci. 2021, 11, 9330. https://doi.org/10.3390/app11199330

Wei M-Y. Design and Implementation of Inverse Kinematics and Motion Monitoring System for 6DoF Platform. Applied Sciences. 2021; 11(19):9330. https://doi.org/10.3390/app11199330

Chicago/Turabian StyleWei, Ming-Yen. 2021. "Design and Implementation of Inverse Kinematics and Motion Monitoring System for 6DoF Platform" Applied Sciences 11, no. 19: 9330. https://doi.org/10.3390/app11199330