Modelling the Demand for AM Technologies in Polish Manufacturing Enterprises Using Bayesian Networks

Abstract

:1. Introduction

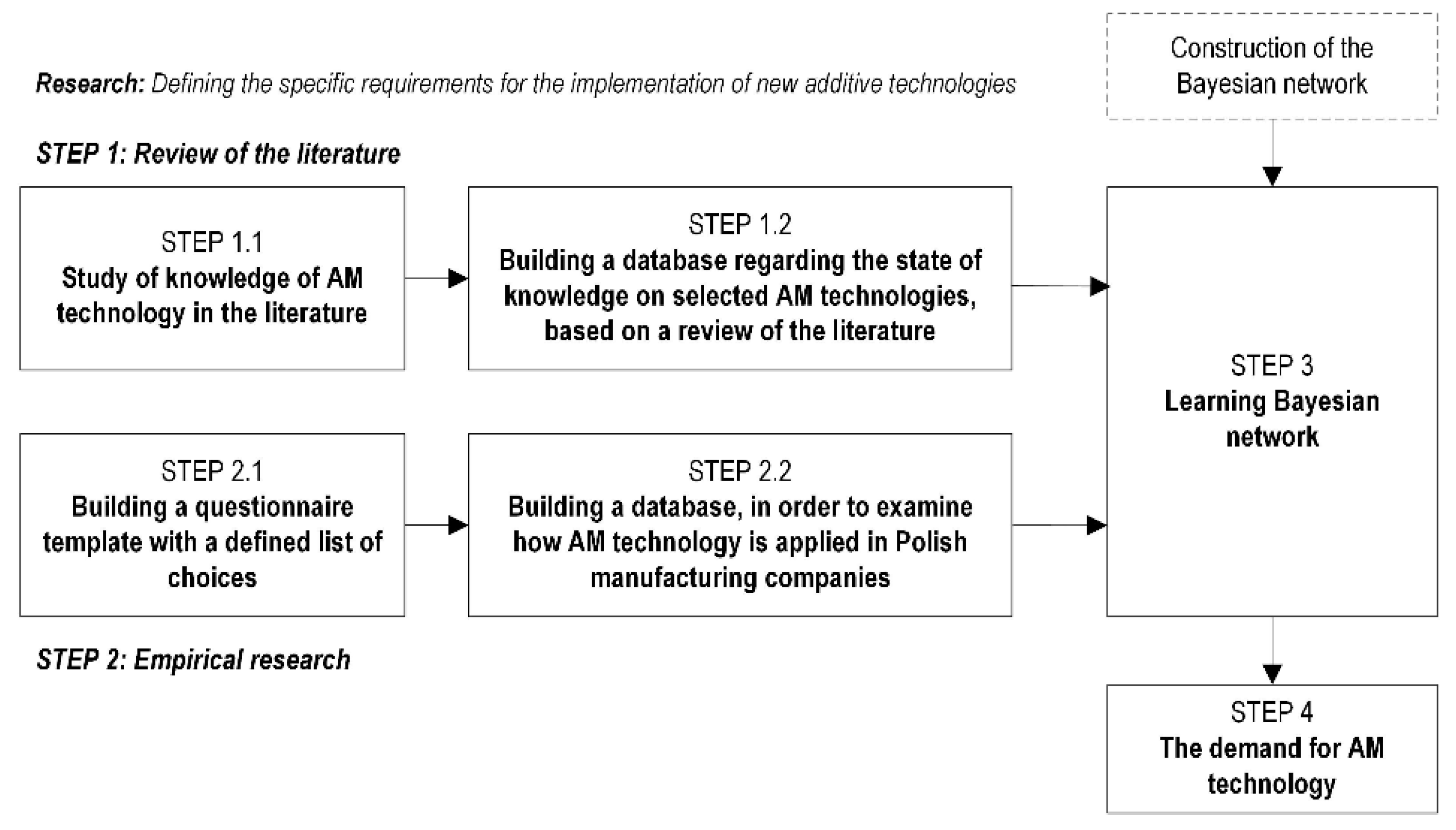

2. Materials and Methods

2.1. Step 1: A Review of the Literature

2.2. Step 2: Empirical Research

2.3. Step 3: The Use of Bayesian Networks

- P(Y\Z)—the ‘a posteriori’ probability of Y, due to evidence of Z,

- P(Y)—the ‘a priori’ probability of Y, before the evidence Z,

- P(Z\Y)—the probability of the Z evidence, if Y was true,

- P(Z)—the probability of the Z evidence.

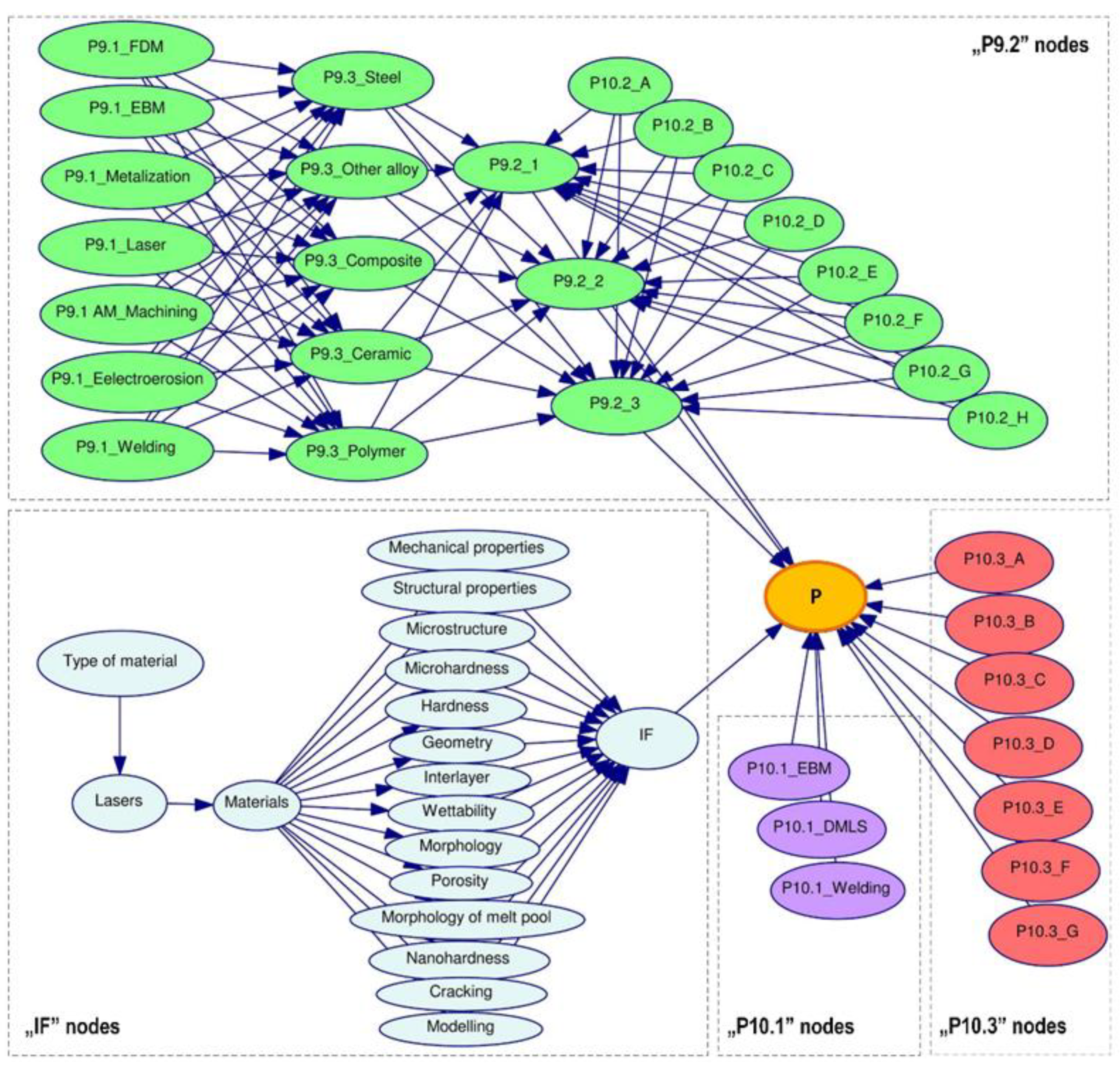

- X1 “Type of material”, x ∈ {powder; filament},

- X2 “Lasers”, x∈{SLM; Nd/Yd:YAG; CO2; High-power diode; Self-development; Hybrid; Fiber},

- X3 “Materials”: Fe alloy, Ti alloy, Cu alloy, Cr Ni alloy, Ceramic, Al Alloy, Hi speed steel, Stainless steel, Special alloy, Tool steel, Super alloy, YCF101, where x ∈ {State0;State1},

- X4-X17 “Tested properties”: Mechanical properties, Structural properties, Microstructure, Micro-hardness, Hardness, Geometry, Interlayer, Wettability, Morphology, Porosity, Morphology of melt pool, Nano-hardness, Cracking, Modelling, where x ∈ {State0;State1},

- X18 “IF”, impact factor for the analysed articles, x ∈ {A; B; C; D; E}.

- Xi-Xn “P9.1 AM technologies used”: FDM, EBM, Metalization, Laser, Machining, Electroerosion, Welding,

- Xi-Xn “P9.3 Material used”: Steel (alloys mainly based on Fe), Other alloy, Composite, Ceramic, Polymer,

- Xi-Xn “P9.2 Goal for implement”: Prototyping, Production, Revitalisation,

- Xi-Xn “P10.1 Interest of using AM technology”: EBM, DMLS, Welding,

- Xi-Xn “P10.2 Determinant” of using AM technologies: Determinant A (reduction of production costs), B (effective use of material), C (freedom in product design), D (no assembly), E (product personalisation), F (quick response to market needs), G (optimization of product functions), H (other),

- Xi-Xn “P10.3 Factor of implement AM technology”: Factor A (competition), B (material innovations on the market), C (the tendency of competing companies to adopt new manufacturing technologies), D (high production costs), E (demand for personalised products), F (high risk related to the lack of suitable suppliers), G (reduce the waiting time).

3. Research Results

- P(P = State0)—the probability of the occurrence of State 0 of “P” node,

- P(P = State1)—the probability of the occurrence of State 1 of “P” node.

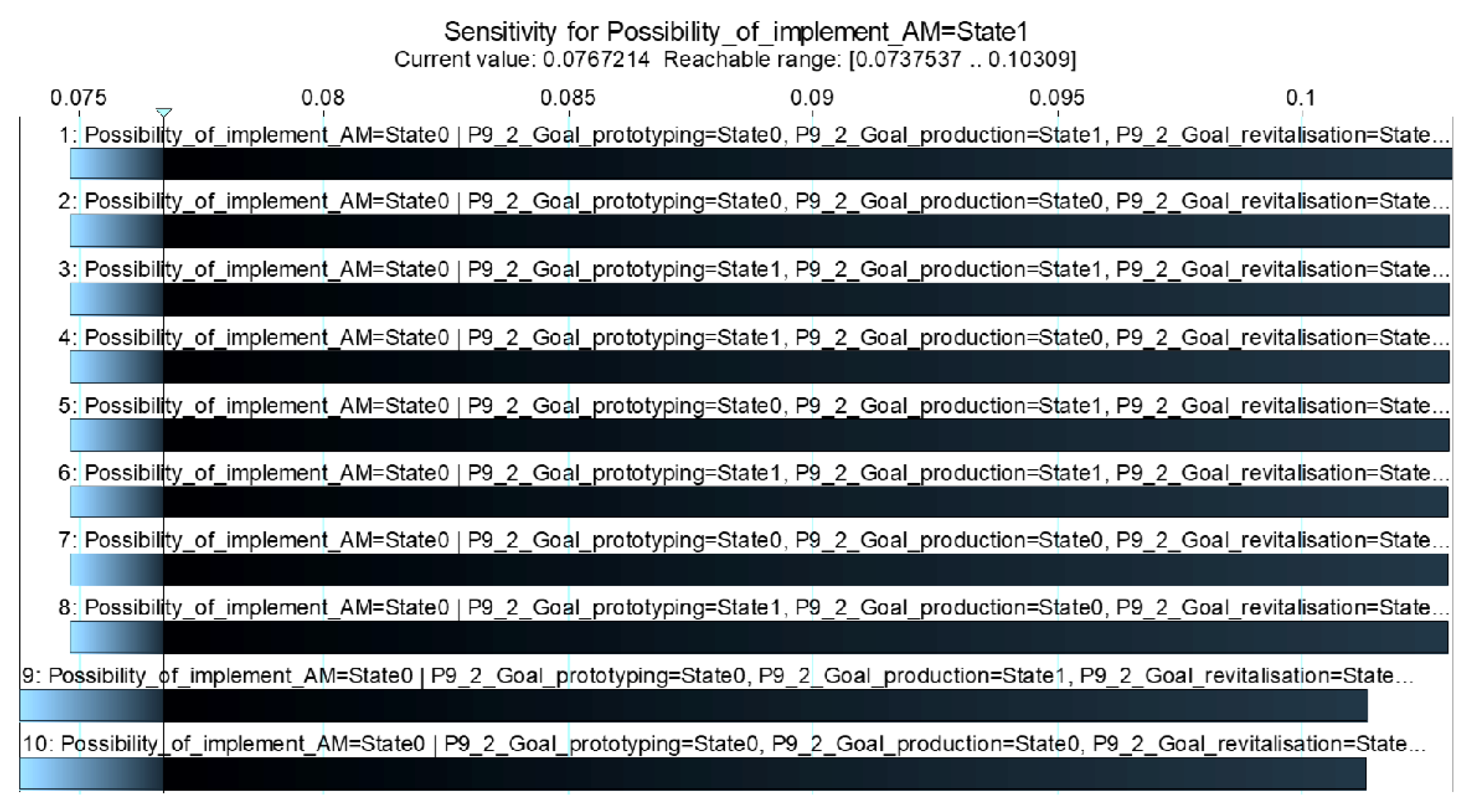

3.1. Experiment 1

- P(P = State1)—the probability of the occurrence of State 1 of “P” node,

- S9.2i—the alternative state in 9.2i nodes (State 1/0), where i {1, 2, 3: n ϵ N},

- w9.2i—the weight assigned to the P9.2 nodes i {1, 2, 3: n ϵ N},

- WIFi—the weight assigned to the alternative i {1, …, 5: n ϵ N}, of “IF” node.

3.2. Experiment 2

- P(P = State1)—the probability of the occurrence of State 1 of “P” node,

- S10.1i—the alternative state in 10.1i nodes (State 1/0), where i {1, 2, 3: n ϵ N},

- W10.1i—the weight assigned to the 10.1 nodes i {1, 2, 3: n ϵ N},

- WIFi—the weight assigned to the alternative i {1, …, 5: n ϵ N}, of “IF” node.

3.3. Experiment 3a

- P(P = State1)—the probability of the occurrence of State 1 of “P” node,

- S9.2i—the alternative state in 9.2i nodes (State 1/0), where i {1, 2, 3: n ϵ N},

- S10.3i—the alternative state in 10.3i nodes (State 1/0), where i {1, …, 7: n ϵ N},

- W9.2i—the weight assigned to the 10.1 nodes i {1, 2, 3: n ϵ N},

- W10.3i—the weight assigned to the 10.3 nodes i {1, …, 7: n ϵ N},

- WIFi—the weight assigned to the alternative i {1, …, 5: n ϵ N}, of “IF” node.

3.4. Experiment 3b

- P(P = State1)—the probability of the occurrence of State 1 of “P” node,

- S10.1i—the alternative state in 10.1i nodes (State 1/0), where i {1, 2, 3: n ϵ N},

- S10.3i—the alternative state in 10.3i nodes (State 1/0), where i {1, …, 7: n ϵ N},

- W10.1i—the weight assigned to the 10.1 nodes i {1, 2, 3: n ϵ N},

- W10.3i—the weight assigned to the 10.3 nodes i {1, …, 7: n ϵ N},

- WIFi—the weight assigned to the alternative i {1, …, 5: n ϵ N}, of “IF” node.

4. Discussion

- Management sees the rationale for implementation of AM technologies in the production area and by using the proposed model (results of experiment 1 and 2) it is possible to determine the type of AM technology needing to be implemented (in our case study it is DMLS technology).

- The key determinants that influence the decision to adopt AM technology in the company is the need of customers to reduce the waiting time for the product and their demand for personalised products.

- There is a need to build a customer-oriented, knowledge-driven framework in order to implement AM technology

- The most hardly accessible knowledge of articles from Journals corresponding to the highest Impact Factor, i.e., IF > 5, does not affect the successful implementation of AM technology within a manufacturing company, in contrast to the positive impact on the implementation of AM technology with readily available knowledge.

- Smoothing the distribution and the small variability in the results, in the case of research conducted with “AM implementation motive”, means that it should not be directly related to the success of the implementation of AM technologies or that key industry determinants should not coincide with the real objectives of individual enterprises.

- The practical needs of enterprises, symbolised by the achievement of goals, contributes to success in implementing AM technology.

- The research questions indicated in the research methodology should be put to managers in the company.

- The answers obtained should then be added to the database on which the model is currently built.

- The Bayesian network will be again subjected to training.

- Finally, the manager receives a recommendation to choose an area of AM technology to apply (results of experiment 1) along with a specific type of technology (results of experiment 2).

- Possibility for managers to assess the decision vis-à-vis the implementation of AM technologies, based on the knowledge gained from literature and the knowledge received through empirical study.

- Ease with which the model can be adapted to the needs of a given company by adding a response from the given experts to the database.

- Posssibility of defining the recommended AM technology to be implemented within a company.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cichon, K.; Brykalski, A. The use of 3D printers in industry. Electrotech. Rev. 2017, 3, 156–158. [Google Scholar]

- Patalas, M.J.; Topczak, M.; Kłos, S. The Level of the Additive Manufacturing Technology Use in Polish Metal and Automotive Manufacturing Enterprises. Appl. Sci. 2020, 10, 735. [Google Scholar] [CrossRef] [Green Version]

- Low, Z.X.; Chua, Y.T.; Ray, B.M.; Mattia, D.; Metcalfe, I.S.; Patterson, D.A. Perspective on 3D printing of separation membranes and comparison to related unconventional fabrication techniques. J. Memb. Sci. 2017, 523, 596–613. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, N. Direct metal fabrication in rapid prototyping: A review. J. Manuf. Process. 2019, 42, 167–191. [Google Scholar] [CrossRef]

- Gao, J.; Folkes, J.; Yilmaz, O.; Gindy, N. Investigation of a 3D non-contact measurement based blade repair integration system. Aircr. Eng. Aerosp. Technol. 2017, 77, 34–41. [Google Scholar] [CrossRef]

- Uenal, T.; Gahn, L.; Kittel, J.; Gasser, A.; Schleifenbaum, J. Process Development for Tip Repair of Complex Shaped Turbine Blades with IN718. Procedia Manuf. 2020, 47, 1050–1057. [Google Scholar] [CrossRef]

- Nagarajan, B.; Hu, Z.; Song, X.; Zhai, W.; Wei, J. Development of Micro Selective Laser Melting: The State of the Art and Future Perspectives. Engineering 2019, 5, 702–720. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106. [Google Scholar] [CrossRef]

- Nowotny, S.; Scharek, S.; Beyer, E.; Richter, K.H. Laser Beam Build-Up Welding: Precision in Repair, Surface Cladding, and Direct 3D Metal Deposition. J. Therm. Spray Technol. 2007, 16, 344–348. [Google Scholar] [CrossRef]

- Patalas, M.J.; Feldshtein, E.; Devojno, O.; Śliwa, M.; Kardapolava, M.; Lutsko, N. Single Tracks as a Key Factor in Additive Manufacturing Technology-Analysis of Research Trends and Metal Deposition Behavior. Materials 2020, 13, 1115. [Google Scholar] [CrossRef] [Green Version]

- Qi, Q.; Pagani, L.; Scott, P.; Jiang, X. A categorical framework for formalising knowledge in additive manufacturing. Procedia CIRP 2018, 75, 87–91. [Google Scholar] [CrossRef]

- Bikas, H.; Koutsoukos, S.; Stavropoulos, P. A decision support method for evaluation and process selection of Additive Manufacturing. Procedia CIRP 2019, 81, 1107–1112. [Google Scholar] [CrossRef]

- Rosário, C.R.; Kipper, L.M.; Frozza, R.; Mariani, B. Modeling of tacit knowledge in industry: Simulations on the variables of industrial processes. Expert Syst. Appl. 2015, 42, 1613–1625. [Google Scholar] [CrossRef]

- Liang, S.J. An ontology-oriented knowledge methodology for process planning in additive layer manufacturing. Robot. Comput. Integr. Manuf. 2018, 53, 28–44. [Google Scholar] [CrossRef]

- Oyesola, M.O.; Mpofu, K.; Mathe, N.R.; Daniyan, I. Development of an integrated design methodology model for quality and throughput of Additive Manufacturing processes. Procedia CIRP 2019, 84, 688–693. [Google Scholar] [CrossRef]

- Müller, S.; Westkämper, E. Modelling of Production Processes: A Theoretical Approach to Additive Manufacturing. Procedia CIRP 2018, 72, 1524–1529. [Google Scholar] [CrossRef]

- Sanfilippo, E.M.; Belkadi, F.; Bernard, A. Ontology-based knowledge representation for additive manufacturing. Comput. Ind. 2019, 109, 182–194. [Google Scholar] [CrossRef]

- Hertlein, N.; Deshpande, S.; Venugopal, V.; Kumar, M.; Anand, S. Prediction of selective laser melting part quality using hybrid Bayesian network. Addit. Manuf. 2020, 32, 101089. [Google Scholar] [CrossRef]

- Beniak, J.; Holdy, M.; Križan, P.; Matúš, M. Research on parameters optimization for the Additive Manufacturing process. Transp. Res. Procedia 2019, 40, 144–149. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, G.; He, J.; Li, Z.; Cheng, W. A data- and knowledge-driven framework for digital twin manufacturing cell. Procedia CIRP 2019, 83, 345–350. [Google Scholar] [CrossRef]

- Brough, D.W.; Wheeler, D.; Warren, J.A.; Kalidindi, S.R. Microstructure-based knowledge systems for capturing process-structure evolution linkages. Curr. Opin. Solid State Mater. Sci. 2017, 21, 129–140. [Google Scholar] [CrossRef]

- Guo, Y.; Jia, L.; Kong, B.; Wang, N.; Zhang, H. Single track and single layer formation in selective laser melting of niobium solid solution alloy. Chin. J. Aeronaut. 2018, 31, 860–866. [Google Scholar] [CrossRef]

- Shrestha, S.; Chou, K. Single track scanning experiment in laser powder bed fusion. Procedia Manuf. 2018, 26, 857–864. [Google Scholar] [CrossRef]

- Aversa, A.; Moshiri, M.; Librera, E.; Hadi, M.; Marchese, G.; Manfredi, D.; Lorusso, M.; Calignano, F.; Sara Biamino, S.; Lombardi, M.; et al. Single scan track analyses on aluminium based powders. J. Mater. Process. Technol. 2018, 255, 17–25. [Google Scholar] [CrossRef]

- Rahman, R.R.A.; Abaspour, S.; Palanisamy, S.; Matthews, N.; Dargusch, M.S. Metallurgical and geometrical characterisation of the 316L stainless steel clad deposited on a mild steel substrate. Surf. Coat. Technol. 2017, 327, 174–184. [Google Scholar] [CrossRef]

- Andreaua, O.; Koutirib, I.; Peyreb, P.; Penota, J.D.; Saintierc, N.; Pessardd, E.; Terrisb, T.; Dupuyb, C.; Baudine, T. Texture control of 316L parts by modulation of the melt pool morphology in selective laser melting. J. Mater. Process. Tech. 2019, 264, 21–31. [Google Scholar] [CrossRef] [Green Version]

- Chao, Q.; Guo, T.; Jarvis, T.; Wu, X.; Hodgson, P.; Fabijanic, D. Direct laser deposition cladding of Al x CoCrFeNi high entropy alloys on a high-temperature stainless steel. Surf. Coat. Technol. 2017, 332, 440–451. [Google Scholar] [CrossRef]

- Criales, L.E.; Arısoy, Y.M.; Lane, B.; Moylan, S.; Donmez, A.; Özel, T. Predictive modeling and optimization of multi-track processing for laser powder bed fusion of nickel alloy 625. Addit. Manuf. 2017, 13, 14–36. [Google Scholar] [CrossRef]

- Darvish, K.; Chen, Z.W.; Pasang, T. Reducing lack of fusion during selective laser melting of CoCrMo alloy: Effect of laser power on geometrical features of tracks. Mater. Des. 2016, 112, 357–366. [Google Scholar] [CrossRef]

- Stašić, J.; Božić, D. The effect of NiB additive on surface morphology and microstructure of 316L stainless steel single tracks and layers obtained by SLM. Surf. Coat. Technol. 2016, 307, 407–417. [Google Scholar] [CrossRef]

- Ansari, M.; Shoja, R.R.; Barekat, M. An empirical statistical model for coaxial laser cladding of NiCrAlY powder on Inconel 738superalloy. Opt. Laser Technol. 2016, 86, 136–144. [Google Scholar] [CrossRef]

- Cai, Y.; Chen, Y.; Luo, Z.; Gao, F.; Li, L. Manufacturing of FeCoCrNiCu x medium-entropy alloy coating using laser cladding technology. Mater. Des. 2017, 133, 91–108. [Google Scholar] [CrossRef]

- Du, L.; Gu, D.; Dai, D.; Shi, Q.; Ma, C.; Xia, M. Relation of thermal behavior and microstructure evolution during multi-track laser melting deposition of Ni-based material. Opt. Laser Technol. 2018, 108, 207–217. [Google Scholar] [CrossRef]

- Nabhani, M.; Razavi, R.S.; Barekat, M. An empirical-statistical model for laser cladding of Ti-6Al-4V powder on Ti-6Al-4V substrate. Opt. Laser Technol. 2018, 100, 265–271. [Google Scholar] [CrossRef]

- Barekat, M.; Razavi, R.S.; Ghasemi, A. Nd:YAG laser cladding of Co–Cr–Mo alloy on γ-TiAl substrate. Opt. Laser Technol. 2016, 80, 145–152. [Google Scholar] [CrossRef]

- Vala, J.; Arias, G.F.; Barro, O.; Riveiro, A.; Comesaña, R.; Penide, J.; Lusquiños, F.; Bountinguiza, M.; Quintero, F.; Pou, J. Functionally graded 3D structures produced by laser cladding. Procedia Manuf. 2017, 13, 169–176. [Google Scholar]

- Salman, O.O.; Gammer, C.; Eckert, J.; Salih, M.Z.; Abdulsalam, E.H.; Prashanth, K.G.; Scudino, S. Selective laser melting of 316L stainless steel: Influence of TiB2 addition on microstructure and mechanical properties. Mater. Today Commun. 2019, 21, 100615. [Google Scholar] [CrossRef]

- Seo, J.Y.; Shim, D.S. Effect of track spacing on porosity of metallic foam fabricated by laser melting deposition of Ti6Al4V/TiH 2 powder mixture. Vacuum 2018, 154, 200–207. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, X.; Cao, Y.; Liu, F.; Huang, W. Formation of anomalous eutectic in Ni-Sn alloy by laser cladding. Opt. Laser Technol. 2018, 99, 154–159. [Google Scholar] [CrossRef]

- Devojno, O.G.; Feldshtein, E.; Kardapolava, M.A.; Lutsko, N.I. On the formation features, microstructure and microhardness of single laser tracks formed by laser cladding of a NiCrBSi self-fluxing alloy. Opt. Lasers Eng. 2018, 106, 32–38. [Google Scholar] [CrossRef]

- Fan, Z.; Lu, M.; Huang, H. Selective laser melting of alumina: A single track study. Ceram. Int. 2018, 44, 9484–9493. [Google Scholar] [CrossRef] [Green Version]

- Barroi, A.; Gonçalves, D.A.; Hermsdorf, J.; Kaierle, S.; Overmeyer, L. Influence of Laser Power on the Shape of Single Tracks in Scanner Based Laser Wire Cladding. Phys. Procedia 2016, 83, 667–673. [Google Scholar] [CrossRef] [Green Version]

- Riquelme, A.; Rodrigo, P.; Escalera, R.M.D.; Rams, J. Analysis and optimization of process parameters in Al–SiCp laser cladding. Opt. Lasers Eng. 2016, 78, 165–173. [Google Scholar] [CrossRef]

- Arias, G.F.; Val, J.; Comesaña, R.; Penide, J.; Lusquiños, F.; Quintero, F.; Riveiro, A.; Boutinguiza, M.; Pou, J. Fiber laser cladding of nickel-based alloy on cast iron. Appl. Surf. Sci. 2016, 374, 197–205. [Google Scholar] [CrossRef]

- Liu, H.; Qin, X.; Huang, S.; Hu, Z.; Ni, M. Geometry modeling of single track cladding deposited by high power diode laser with rectangular beam spot. Opt. Lasers Eng. 2018, 100, 38–46. [Google Scholar] [CrossRef]

- Lu, M.; Cormick, P.; Zhao, Y.; Fan, Z.; Huang, H. Laser deposition of compositionally graded titanium oxide on Ti6Al4V alloy. Ceram. Int. 2018, 44, 20851–20861. [Google Scholar] [CrossRef]

- Lei, K.; Qin, X.; Liu, H.; Ni, M. Analysis and modeling of melt pool morphology for high power diode laser cladding with a rectangle beam spot. Opt. Lasers Eng. 2018, 110, 89–99. [Google Scholar] [CrossRef]

- Shi, X.; Ma, S.; Liu, C.; Wu, Q. Parameter optimization for Ti-47Al-2Cr-2Nb in selective laser melting based on geometric characteristics of single scan tracks. Opt. Laser Technol. 2017, 90, 71–79. [Google Scholar] [CrossRef]

- Nie, X.; Zhang, H.; Zhu, H.; Hu, Z.; Ke, L.; Zeng, X. Analysis of processing parameters and characteristics of selective laser melted high strength Al-Cu-Mg alloys: From single tracks to cubic samples. J. Mater. Process. Technol. 2018, 256, 69–77. [Google Scholar] [CrossRef]

- Wei, K.; Wang, Z.; Zeng, X. Preliminary investigation on selective laser melting of Ti-5Al-2.5Sn α-Ti alloy: From single tracks to bulk 3D components. J. Mater. Process. Technol. 2017, 244, 73–85. [Google Scholar] [CrossRef]

- Zheng, H.; Li, H.; Lang, L.; Gong, S.; Ge, Y. Effects of scan speed on vapor plume behavior and spatter generation in laser powder bed fusion additive manufacturing. J. Manuf. Process. 2018, 36, 60–67. [Google Scholar] [CrossRef]

- Metelkova, J.; Kinds, Y.; Kempen, K.; Formanoir, C.; Witvrouw, A.; Hooreweder, B. On the influence of laser defocusing in Selective Laser Melting of 316L. Addit. Manuf. 2018, 23, 161–169. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yang, H.; Li, F.; Wang, Z.; Zeng, X. Prediction of microstructure in selective laser melted Tie6Ale4V alloy by cellular automaton. J. Alloys Compd. 2018, 748, 281–290. [Google Scholar] [CrossRef]

- Bennett, J.L.; Wolff, S.J.; Hyatt, G.; Ehmann, K.; Cao, J. Thermal effect on clad dimension for laser deposited Inconel 718. J. Manuf. Process. 2017, 28, 550–557. [Google Scholar] [CrossRef]

- Bax, B.; Rajput, R.; Kellet, R.; Reisacher, M. Systematic evaluation of process parameter maps for laser cladding and directed energy deposition. Addit. Manuf. 2018, 21, 487–494. [Google Scholar] [CrossRef]

- Pariona, M.M.; Taques, A.F.; Woiciechowski, L.A. The Marangoni effect on microstructure properties and morphology of laser-treated Al-Fe alloy with single track by FEM: Varying the laser beam velocity. Int. J. Heat Mass Transf. 2018, 119, 10–19. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. On the formation of AlSi10Mg single tracks and layers in selective laser melting: Microstructure and nano-mechanical properties. J. Mater. Process. Technol. 2016, 230, 88–98. [Google Scholar] [CrossRef]

- Zhou, Z.; Huang, L.; Shang, Y.; Li, Y.; Jiang, L.; Lei, Q. Causes analysis on cracks in nickel-based single crystal superalloy fabricated by laser powder deposition additive manufacturing. Mater. Des. 2018, 160, 1238–1249. [Google Scholar] [CrossRef]

- Liu, J.; Yu, H.; Chen, C.; Weng, F.; Dai, J. Research and development status of laser cladding on magnesium alloys: A review. Opt. Lasers Eng. 2017, 93, 195–210. [Google Scholar] [CrossRef]

- Chen, C.; Lian, G.; Jiang, J.; Wang, Q. Simplification and experimental investigation of geometrical surface smoothness model for multi-track laser cladding processes. J. Manuf. Process. 2018, 36, 621–628. [Google Scholar] [CrossRef]

- Pei, W.; Zhengying, W.; Zhen, C.; Jun, D.; Yuyang, H.; Junfeng, L.; Yatong, Z. The AlSi10Mg samples produced by selective laser melting: Single track, densification, microstructure and mechanical behavior. Appl. Surf. Sci. 2017, 408, 38–50. [Google Scholar] [CrossRef]

- Bertoli, U.S.; Wolfer, A.J.; Mathhhews, M.J.; Delplanque, M.J.P.; Schoenung, J.M. On the limitations of Volumetric Energy Density as a design parameter for Selective Laser Melting. Mater. Des. 2017, 113, 331–340. [Google Scholar] [CrossRef] [Green Version]

- Yu, T.; Zhao, Y.; Sun, J.; Chen, Y.; Qu, W. Process parameters optimization and mechanical properties of forming parts by direct laser fabrication of YCF101 alloy. J. Mater. Process. Tech. 2018, 262, 75–84. [Google Scholar] [CrossRef]

- Bailey, N.S.; Katinas, C.; Shin, Y.C. Laser direct deposition of AISI H13 tool steel powder with numerical modeling of solid phase transformation, hardness, and residual stresses. J. Mater. Process. Tech. 2017, 247, 223–233. [Google Scholar] [CrossRef]

- Arias, G.F.; Val, J.; Comesaña, R.; Penide, J.; Lusquiños, F.; Quintero, F.; Riveiro, A.; Boutinguiza, M.; Pou, J. Production of phosphor bronze coatings by laser cladding. Procedia Manuf. 2017, 13, 177–182. [Google Scholar] [CrossRef]

- Kotoban, D.; Nazarov, A.; Shishkovsky, I. Comparative Study of Selective Laser Melting and Direct Laser Metal Deposition of Ni3Al Intermetallic Alloy. Procedia IUTAM 2017, 23, 138–146. [Google Scholar] [CrossRef]

- Xu, X.; Mi, G.; Luo, Y.; Jiang, P.; Shao, X.; Wang, C. Morphologies, microstructures, and mechanical properties of samples produced using laser metal deposition with 316 L stainless steel wire. Opt. Lasers Eng. 2017, 94, 1–11. [Google Scholar] [CrossRef]

- Tang, C.; Tan, J.L.; Wong, C.H. A numerical investigation on the physical mechanisms of single track defects in selective laser melting. Int. J. Heat Mass Transf. 2018, 126, 957–968. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef] [Green Version]

- Panwisawas, C.; Qiu, C.; Anderson, M.J.; Sovani, Y.; Turner, R.P.; Attallah, M.M.; Brooks, J.W.; Basoalto, H.C. Mesoscale modelling of selective laser melting: Thermal fluid dynamics and microstructural evolution. Comput. Mater. Sci. 2017, 126, 479–490. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Z. Effect of substrate preset temperature on crystal growth and microstructure formation in laser powder deposition of single-crystal superalloy. J. Mater. Sci. Technol. 2018, 34, 2116–2124. [Google Scholar] [CrossRef]

- Li, Y.; Hu, Y.; Cong, W.; Zhi, L.; Guo, Z. Additive manufacturing of alumina using laser engineered net shaping: Effects of deposition variables. Ceram. Int. 2017, 43, 7768–7775. [Google Scholar] [CrossRef]

- Chen, Q.; Guillemot, G.; Gandin, C.A.; Bellet, M. Numerical modelling of the impact of energy distribution and Marangoni surface tension on track shape in selective laser melting of ceramic material. Addit. Manuf. 2018, 21, 713–723. [Google Scholar] [CrossRef]

- Aguilera, P.A.; Fernandez, A.; Fernandez, R.; Rumi, R.; Salmeron, A. Bayesian networks in environmental modelling. Environ. Model. Softw. 2011, 26, 1376–1388. [Google Scholar] [CrossRef]

- Wieleba, R. Knowledge Engineering in the expert systems. Sci. Noteb. Wars. Univ. Inf. Technol. 2011, 5, 95–216. [Google Scholar]

- Ramírez, N.A.; Juárez, R.R.; Martínez, R.Y. Evaluation module based on Bayesian networks to Intelligent Tutoring Systems. Int. J. Inf. Manag. 2017, 37, 1488–1498. [Google Scholar] [CrossRef]

- Dahire, S.; Tahir, F.; Jiao, Y.; Liu, Y. Bayesian Network inference for probabilistic strength estimation of aging pipeline systems. Int. J. Press. Vessel. Pip. 2018, 162, 30–39. [Google Scholar] [CrossRef]

- Patalas, M.J.; Śliwa, M. An Approach to Tacit Knowledge Classification in a Manufacturing Company. Teh. Vjesn. 2019, 26, 650–657. [Google Scholar] [CrossRef]

- BAYESFUSION, LLC. Data Analytics, Modeling, Decision Support. Available online: https://www.bayesfusion.com (accessed on 10 July 2020).

- Landuyt, D.; Broekx, S.; Hondt, R.; Engelen, G.; Aertsens, J.; Goethals, P.L.M. A review of Bayesian belief networks in ecosystem service modelling. Environ. Model. Softw. 2013, 46, 1–11. [Google Scholar] [CrossRef]

- Harvey, H.B.; Sotardi, S.T. The Pareto Principle. J. Am. Coll. Radiol. 2018, 15. [Google Scholar] [CrossRef]

- Patalas, M.J.; Krebs, I. Decision model for the use of the application for knowledge transfer support in manufacturing enterprises. In Proceedings of the Lecture Notes in Business Information Processing, International Workshops on Business Information Systems Workshops, Poznan, Poland, 24–25 June 2015; Volume 228, pp. 48–55. [Google Scholar] [CrossRef]

| Area of Knowledge about AM Technologies | Methods/Tools | Results | References |

|---|---|---|---|

| Product design | Formalising AM knowledge based on descriptive logics (DLs), Design for Additive Manufacturing (DfAM). | Obtaining and analyzing data on the mutual influence of geometric design and process parameters in order to meet the requirements of AM technology specificity. | [11] |

| Implementation of the best technology | Method to self-evaluate the potential of AM, accompanied by a method to validate the technical feasibility of AM—AHP (Analytic Hierarchy Process). | Stage analysis and selection of the right AM process for the needs of the company. | [12] |

| Manufacturing planning process with various AM systems | The IDEF0 diagrams, Pareto chart, Ishikawa diagram. | Process planning and defining the sequence of tasks and the messages flow. | [13,14] |

| Quality and throughput of AM processes. | DfAM, AHP, Multi-Attribute Decision Making, Multiple Objective Optimization (MOO), Integrated Product and Process Development (IPPD) method, Formal Concept Analysis (FCA). | Data analysis to use the integrated process chain, from component design to pre-treatment, production (construction of the laser unit), finishing and finished parts. | [15] |

| The identification of effect mechanisms and key factors in the production process | The method identifies key parameters and impacts and finds new expected correlations using similar and related technologies. | Design a basic theoretical approach for a process model of additive manufacturing with metals, analysis a changes taking place when moving from a solid phase to a liquid phase or back again., analysis a interaction between the laser beam and the powder material. | [16] |

| Management of data that is generated in the AM value chain. | Ontology-based modeling approach: Basic Formal Ontology (BFO), Information Artifact Ontology (IAO), Common Core Ontology (CCO). | Backbone structure to organize AM data and automatically reason over experts’ knowledge for data validation, ultimately supporting the development of algorithms and applications for decision making. | [17] |

| Prediction of selective laser melting part quality | Designs of experiments (DOEs), model that relates process parameters to part quality—hybrid Bayesian, another Bayesian network. | analysis of the relationship between AM process parameters and various parts quality characteristics | [18] |

| Final quality of produced parts | Digital models, numerical modeling. | analysis of operational parameters which influence the production process in additive manufacturing and quality of produced components by AM technology. | [19] |

| Smart manufacturing | Knowledge-driven framework for digital twin manufacturing cell (DTMC). | Data analysis and support autonomous manufacturing by an intelligent perceiving, simulating, understanding, predicting, optimizing and controlling strategy. | [20] |

| Materials | The MKS (Materials Knowledge Systems) framework. | Gathering and analysis of knowledge about materials: mechanical properties, microhardness, material structure, etc. | [21] |

| Area of demand and application of AM technology | Bayesian networks | Gathering of knowledge about demand and application of AM technology within a manufacturing company, support a mangers to take the decision to implement AM technologies. | This paper |

| Test No. | Observed Alternatives of Nodes | Target P (P = State1) | Test No. | Observed Alternatives of Nodes | Target P (P = State1) |

|---|---|---|---|---|---|

| 0 | - | 0.08 | 10 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 1; IF = E | 0.01 |

| 11 | 9.2.1 = 0; 9.2.2 = 1; IF = A | 0.25 | |||

| 1 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 1 | 0.05 | 12 | 9.2.1 = 0; 9.2.2 = 1; IF = B | 0.07 |

| 2 | 9.2.1 = 0; 9.2.2 = 1 | 0.09 | 13 | 9.2.1 = 0; 9.2.2 = 1; IF = C | 0.11 |

| 3 | 9.2.2 = 1 | 0.09 | 14 | 9.2.1 = 0; 9.2.2 = 1; IF = D | 0.03 |

| 4 | 9.2.1 = 1 | 0.08 | 15 | 9.2.1 = 0; 9.2.2 = 1; IF = E | 0.01 |

| 5 | 9.2.2 = 1; 9.2.3 = 0 | 0.13 | 16 | 9.2.1 = 1; IF = A | 0.19 |

| 6 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 0; IF = A | 0.48 | 17 | 9.2.1 = 1; IF = B | 0.07 |

| 7 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 1; IF = B | 0.07 | 18 | 9.2.1 = 1; IF = C | 0.11 |

| 8 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 1; IF = C | 0.11 | 19 | 9.2.1 = 0; IF = D | 0.03 |

| 9 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 1; IF = D | 0.03 | 20 | 9.2.1 = 0; IF = E | 0.01 |

| Test No. | Observed Alternatives of Nodes | Target P (P = State1) |

|---|---|---|

| 0 | - | 0.07 |

| 1 | P10.1EBM = 0; 10.1DMLS = 1; P10.1Welding = 0; IF = A | 0.04 |

| 2 | P10.1EBM = 0; 10.1DMLS = 1; P10.1Welding = 0; IF = B | 0.07 |

| 3 | P10.1EBM = 0; 10.1DMLS = 1; P10.1Welding = 0; IF = C | 0.11 |

| 4 | P10.1EBM = 0; 10.1DMLS = 1; P10.1Welding = 0; IF = D | 0.03 |

| 5 | P10.1EBM = 0; 10.1DMLS = 1; P10.1Welding = 0; IF = E | 0.01 |

| Test No. | Observed Alternatives of Nodes | Target P (P = State1) | Test No. | Observed Alternatives of Nodes | Target P (P = State1) |

|---|---|---|---|---|---|

| 0 | - | 0.04 | 13 | 9.2.1 = 0; 9.2.2 = 1; IF = C | 0.07 |

| 1 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 1 | 0.04 | 14 | 9.2.1 = 0; 9.2.2 = 1; IF = D | 0.02 |

| 2 | 9.2.1 = 0; 9.2.2 = 1 | 0.04 | 15 | 9.2.1 = 0; 9.2.2 = 1; IF = E | 0.01 |

| 3 | 9.2.2 = 1 | 0.04 | 16 | 9.2.1 = 1; IF = A | 0.06 |

| 4 | 9.2.1 = 1 | 0.04 | 17 | 9.2.1 = 1; IF = B | 0.05 |

| 5 | 9.2.2 = 1; 9.2.3 = 0 | 0.04 | 18 | 9.2.1 = 1; IF = C | 0.07 |

| 6 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 0; IF = A | 0.07 | 19 | 9.2.1 = 0; IF = D | 0.02 |

| 7 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 1; IF = B | 0.05 | 20 | 9.2.1=0; IF=E | 0.01 |

| 8 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 1; IF = C | 0.07 | 21 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 0; P10.3Factor A- E = 0; IF = A | 0.15 |

| 9 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 1; IF = D | 0.02 | 22 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 0; P10.3Factor A- E = 0; IF = B | 0.05 |

| 10 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 1; IF = E | 0.01 | 23 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 0; P10.3Factor A = 0; P10.3Factor A-E = 0; IF = C | 0.07 |

| 11 | 9.2.1 = 0; 9.2.2 = 1; IF = A | 0.06 | 24 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 0; P10.3Factor A-E = 0; IF = D | 0.02 |

| 12 | 9.2.1 = 0; 9.2.2 = 1; IF = B | 0.05 | 25 | 9.2.1 = 0; 9.2.2 = 1; 9.2.3 = 0; P10.3Factor A-E = 0; IF = E | 0.01 |

| Test No. | Observed Alternatives of Nodes | Target P (P = State1) |

|---|---|---|

| 0 | - | 0.04 |

| 1 | P10.1EBM = 0; 10.1DMLS = 1; P10.1Welding = 0; IF = A | 0.07 |

| 2 | P10.1EBM = 0; 10.1DMLS = 1; P10.1Welding = 0; IF = B | 0.05 |

| 3 | P10.1EBM = 0; 10.1DMLS = 1; P10.1Welding = 0; IF = C | 0.07 |

| 4 | P10.1EBM = 0; 10.1DMLS = 1; P10.1Welding = 0; IF = D | 0.02 |

| 5 | P10.1EBM = 0; 10.1DMLS = 1; P10.1Welding = 0; IF = E | 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patalas-Maliszewska, J.; Śliwa, M.; Topczak, M. Modelling the Demand for AM Technologies in Polish Manufacturing Enterprises Using Bayesian Networks. Appl. Sci. 2021, 11, 601. https://doi.org/10.3390/app11020601

Patalas-Maliszewska J, Śliwa M, Topczak M. Modelling the Demand for AM Technologies in Polish Manufacturing Enterprises Using Bayesian Networks. Applied Sciences. 2021; 11(2):601. https://doi.org/10.3390/app11020601

Chicago/Turabian StylePatalas-Maliszewska, Justyna, Małgorzata Śliwa, and Marcin Topczak. 2021. "Modelling the Demand for AM Technologies in Polish Manufacturing Enterprises Using Bayesian Networks" Applied Sciences 11, no. 2: 601. https://doi.org/10.3390/app11020601

APA StylePatalas-Maliszewska, J., Śliwa, M., & Topczak, M. (2021). Modelling the Demand for AM Technologies in Polish Manufacturing Enterprises Using Bayesian Networks. Applied Sciences, 11(2), 601. https://doi.org/10.3390/app11020601