Sustainable Development of Concrete through Aggregates and Innovative Materials: A Review

Abstract

:1. Introduction

2. Recycled Materials

2.1. Recycled Building Materials

2.2. Recycled Tire Rubber

2.3. Recycled Plastic

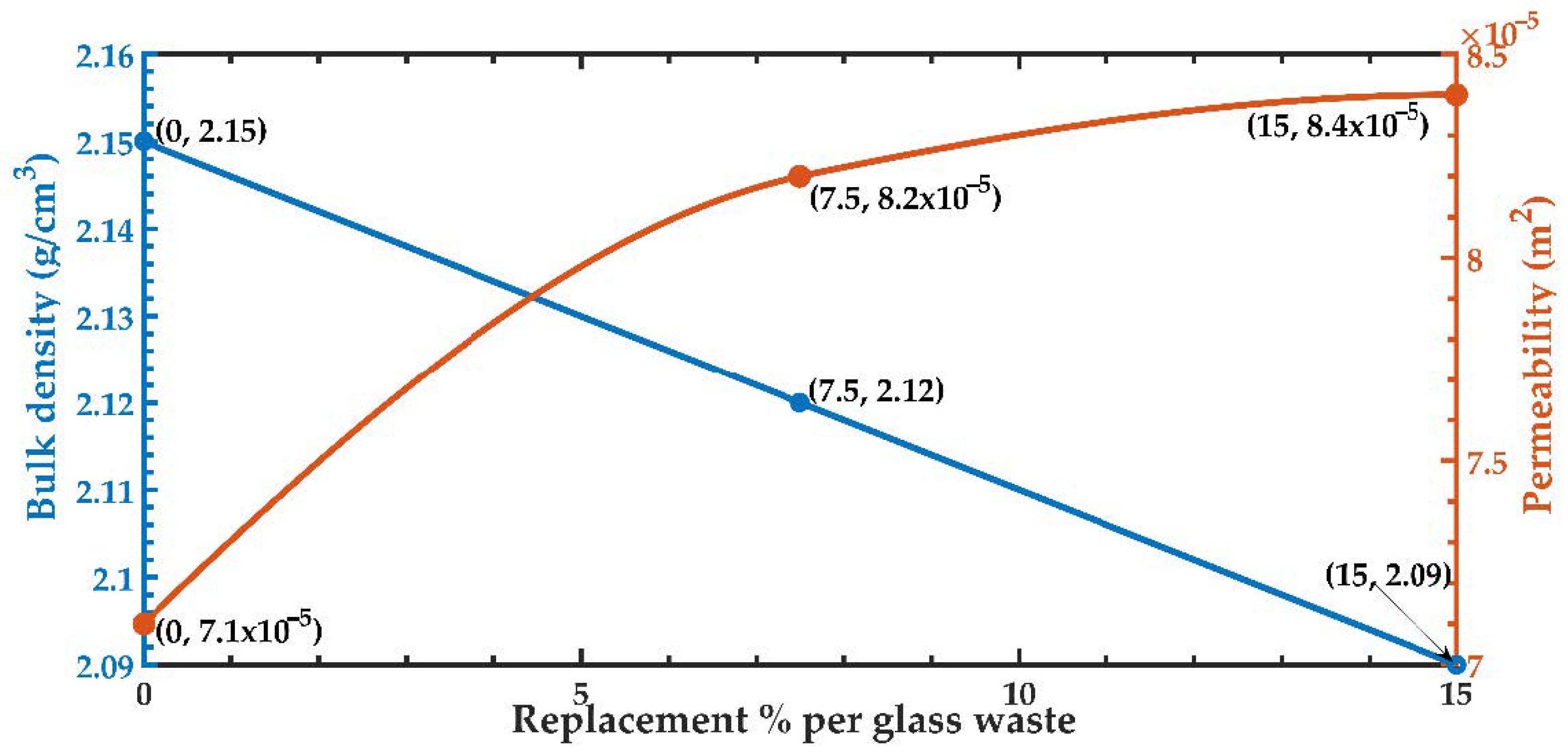

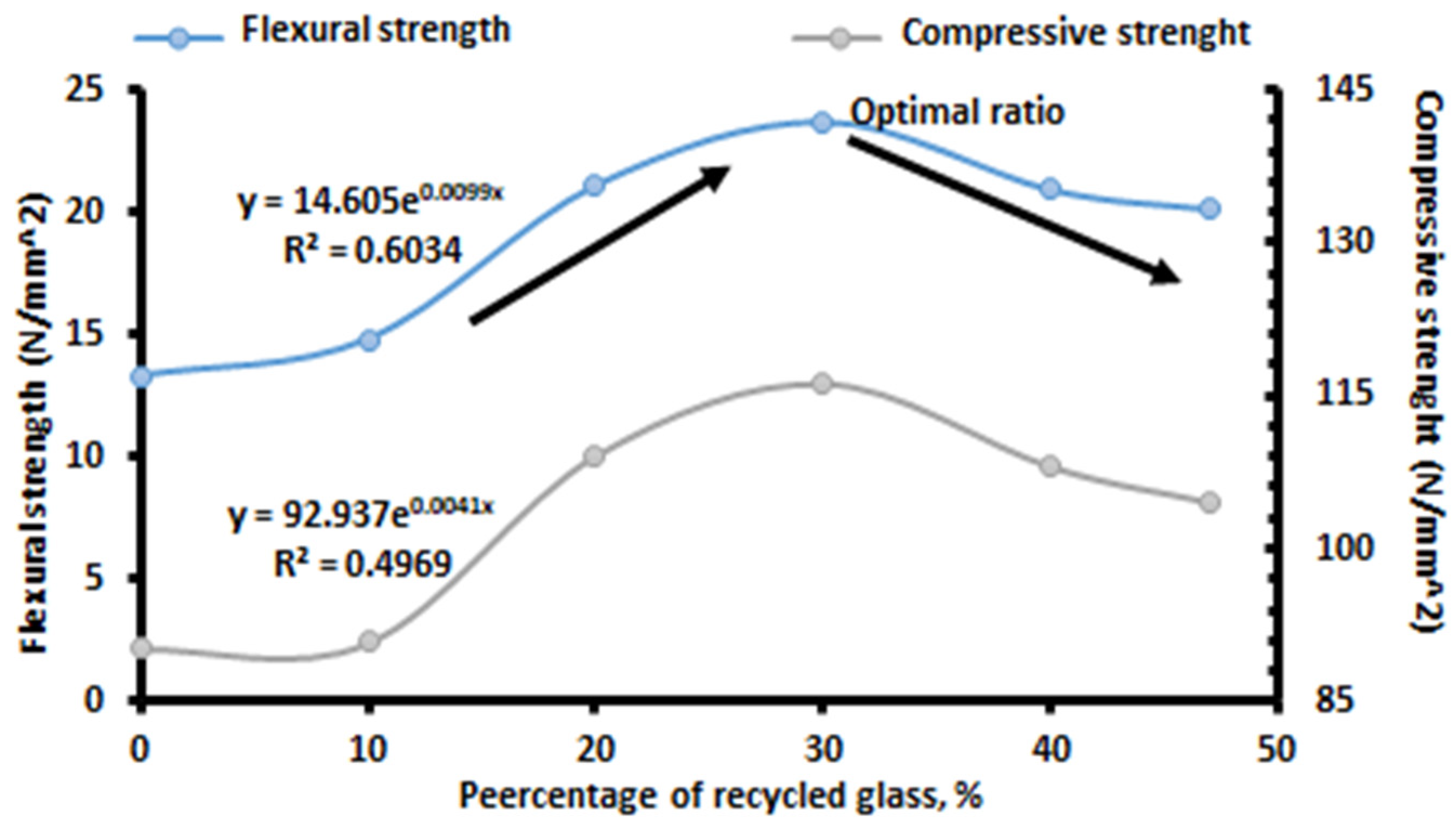

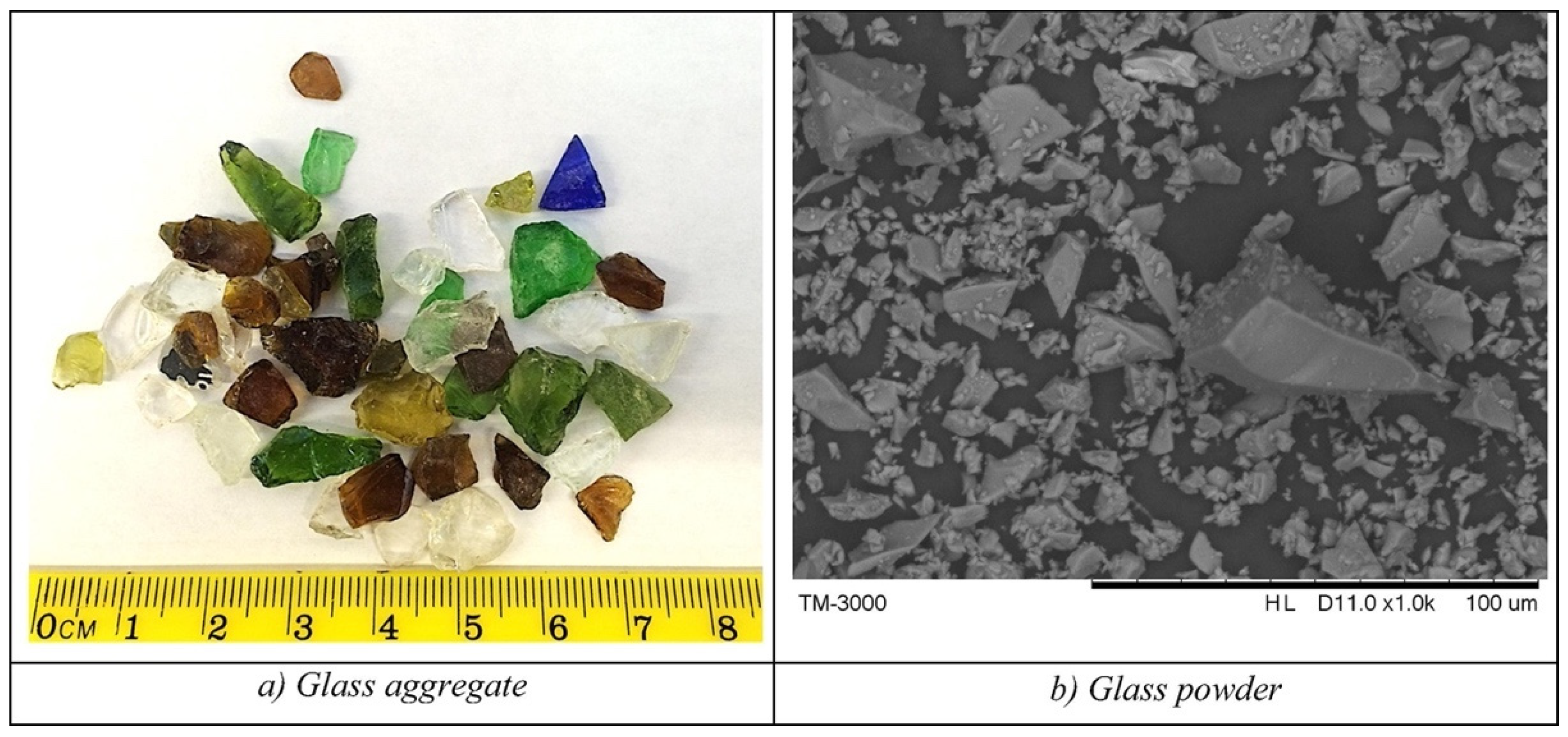

2.4. Crushed Glass

2.5. Blocks Manufacturing

2.6. Industrial Waste

3. Synthetic Fibers

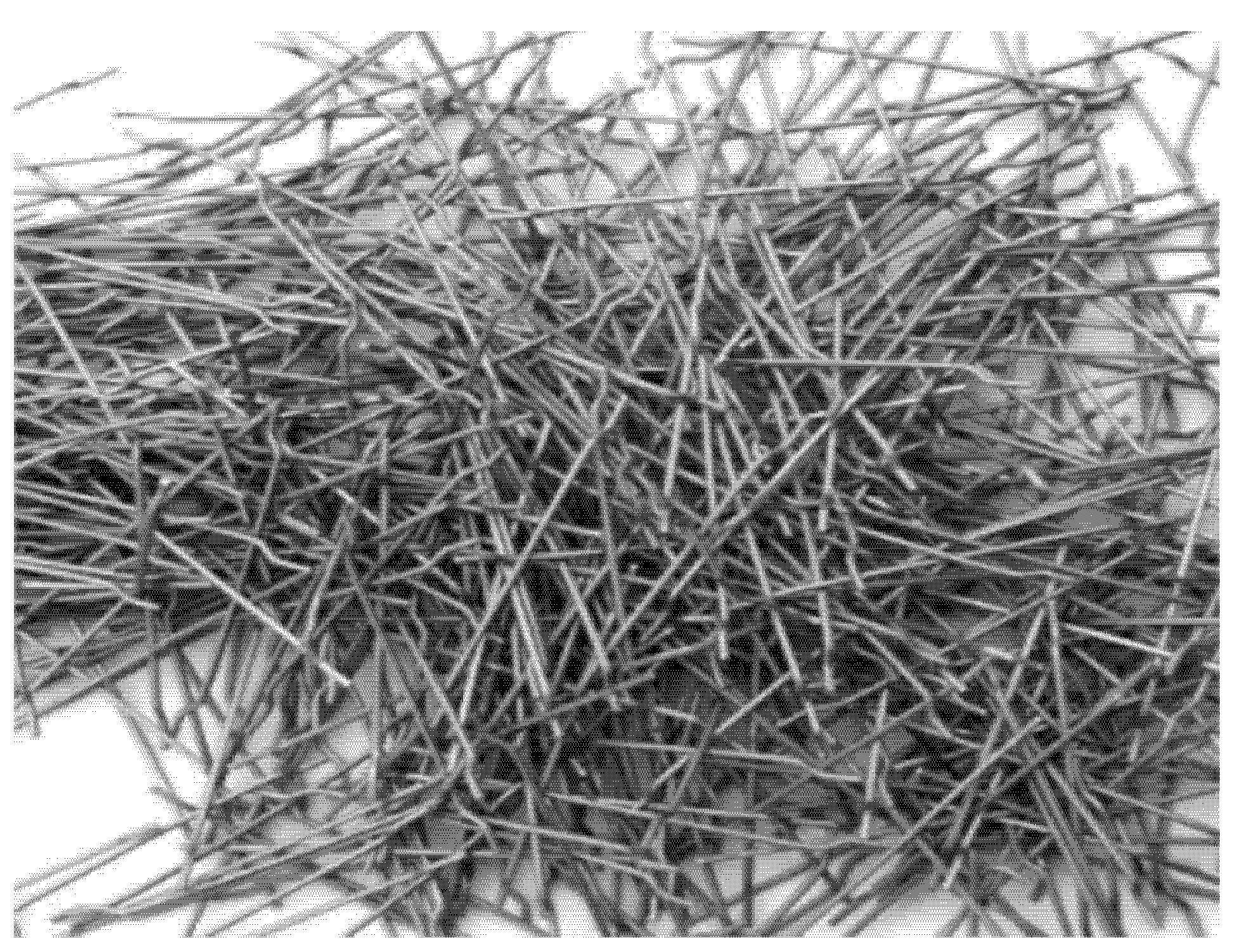

3.1. Steel Fibers

3.2. Glass Fibers

3.3. Carbon Fiber Reinforced Polymers

3.4. Textile Fibers and Reinforcements

3.5. Epoxy Resins

3.6. Mineral Fibers

4. Organic Aggregates

4.1. Bamboo

4.2. Coconut Fiber

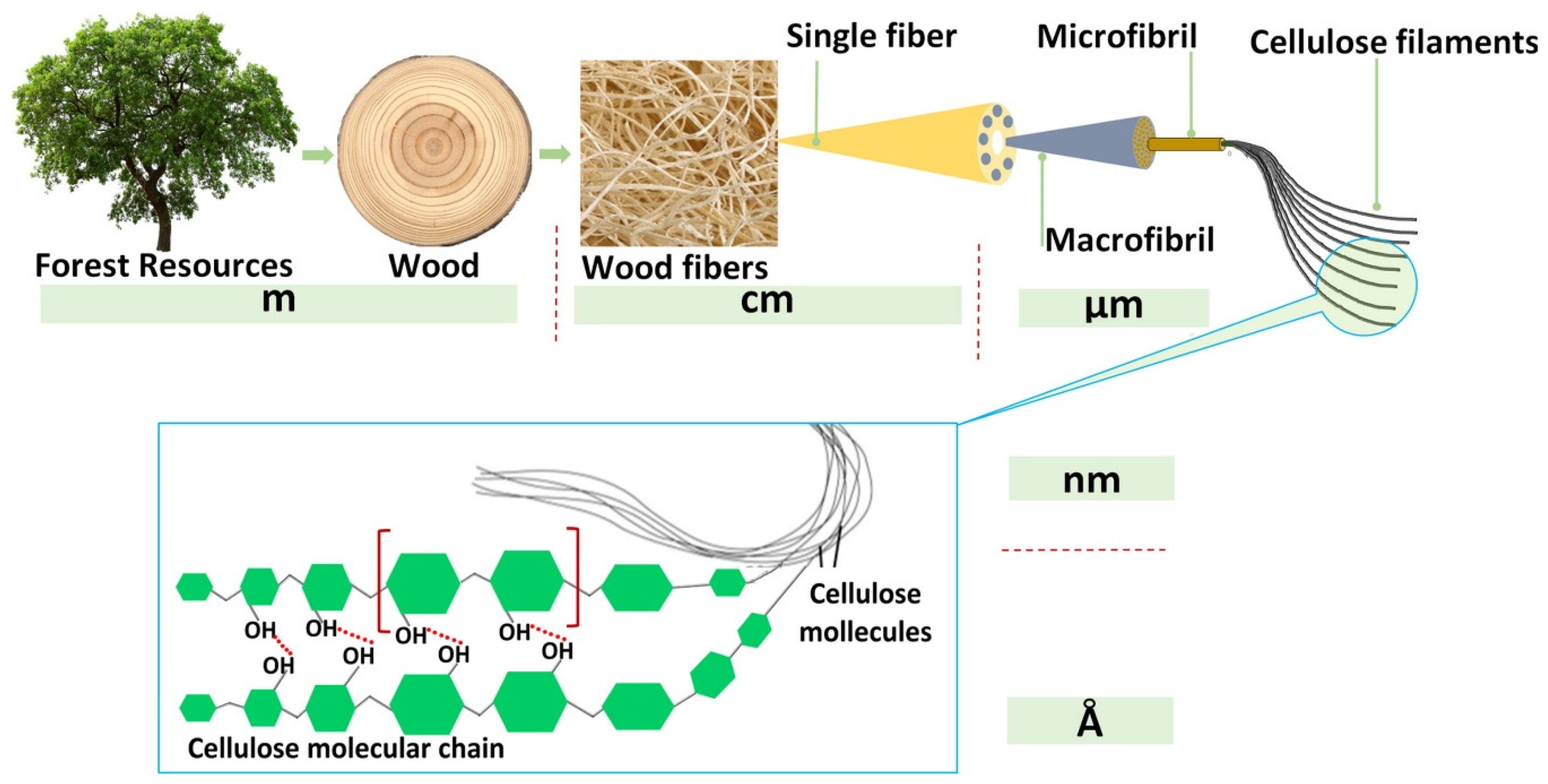

4.3. Nanocellulose

5. Recommendations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nagrockienė, D.; Girskas, G.; Skripkiūnas, G. Properties of concrete modified with mineral additives. Constr. Build. Mater. 2017, 135, 37–42. [Google Scholar] [CrossRef]

- Sharma, N.K.; Kumar, P.; Kumar, S.; Thomas, B.S.; Gupta, R.C. Properties of concrete containing polished granite waste as partial substitution of coarse aggregate. Constr. Build. Mater. 2017, 151, 158–163. [Google Scholar] [CrossRef]

- Yang, S.T.; Li, K.F.; Li, C.Q. Numerical determination of concrete crack width for corrosion-affected concrete structures. Comput. Struct. 2018, 207, 75–82. [Google Scholar] [CrossRef] [Green Version]

- McGinnis, M.J.; Davis, M.; de la Rosa, A.; Weldon, B.D.; Kurama, Y.C. Strength and stiffness of concrete with recycled concrete aggregates. Constr. Build. Mater. 2017, 154, 258–269. [Google Scholar] [CrossRef]

- Tiwari, A.; Singh, S.; Nagar, R. Feasibility assessment for partial replacement of fine aggregate to attain cleaner production perspective in concrete: A review. J. Clean. Prod. 2016, 135, 490–507. [Google Scholar] [CrossRef]

- Rashid, K.; Razzaq, A.; Ahmad, M.; Rashid, T.; Tariq, S. Experimental and analytical selection of sustainable recycled concrete with ceramic waste aggregate. Constr. Build. Mater. 2017, 154, 829–840. [Google Scholar] [CrossRef]

- Kubissa, W.; Jaskulski, R.; Reiterman, P.; Supera, M. Ecological high performance concrete. Procedia Eng. 2017, 172, 595–603. [Google Scholar] [CrossRef]

- Torres, A.; Bartlett, L.; Pilgrim, C. Effect of foundry waste on the mechanical properties of Portland Cement Concrete. Constr. Build. Mater. 2017, 135, 674–681. [Google Scholar] [CrossRef]

- Markiv, T.; Sobol, K.; Franus, M.; Franus, W. Mechanical and durability properties of concretes incorporating natural zeolite. Arch. Civil. Mech. Eng. 2016, 16, 554–562. [Google Scholar] [CrossRef]

- Prusty, J.K.; Patro, S.K.; Basarkar, S.S. Concrete using agro-waste as fine aggregate for sustainable built environment—A review. Int. J. Sustain. Built Environ. 2016, 5, 312–333. [Google Scholar] [CrossRef] [Green Version]

- Matar, W.; Elshurafa, A.M. Striking a balance between profit and carbon dioxide emissions in theSaudi cement industry. Int. J. Greenh. Gas Control 2017, 61, 111–123. [Google Scholar] [CrossRef]

- Parthiban, K.; Mohan, K.S.R. Influence of recycled concrete aggregates on the engineering and durability properties of alkali activated slag concrete. Constr. Build. Mater. 2017, 133, 65–72. [Google Scholar] [CrossRef]

- Fan, X.; Zhang, M. Behaviour of inorganic polymer concrete columns reinforced with basalt FRP bars under eccentric compression: An experimental study. Compos. Part B 2016, 104, 44–56. [Google Scholar] [CrossRef] [Green Version]

- Elmoaty, A.E.M.A. Mechanical properties and corrosion resistance of concrete modified with granite dust. Constr. Build. Mater. 2013, 47, 743–752. [Google Scholar] [CrossRef]

- Popek, M.; Sadowskia, L. Selected physical properties of concrete modified using mineral Powders. Procedia Eng. 2017, 172, 891–896. [Google Scholar] [CrossRef]

- Maier, P.L.; Durham, S. Beneficial use of recycled materials in concrete mixtures. Constr. Build. Mater. 2012, 29, 428–437. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. Performance of sustainable concretes containing very high volume Class-F fly ash and ground granulated blast furnace slag. J. Clean. Prod. 2017, 162, 1407–1417. [Google Scholar] [CrossRef]

- Bulut, H.A.; Sahin, R. A study on mechanical properties of polymer concrete containing electronic plastic waste. Compos. Struct. 2017, 178, 50–62. [Google Scholar] [CrossRef]

- Fallah, S.; Nematzadeh, M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Torring, M.; Ravindra, E.L.; Dyer, T.D.; Halliday, J. Total recycling opportunities—Tasting the topics for the conference session. In Challenges of Concrete Construction: Sustainable Concrete Construction Pt. 1, v. 5: Proceedings of the International Conference Held at the University of Dundee, Scotland, UK, 9–11 September 2002; Halliday, J.E., Ed.; ICE Publishing: London, UK, 2002; pp. 501–510. [Google Scholar] [CrossRef]

- Mohammed, T.U.; Hasnat, A.; Awal, M.A.; Bosuni, S.Z. Recycling of brick aggregate concrete as coarse aggregate. J. Mater. Civ. Eng. 2015, 27, B401005. [Google Scholar] [CrossRef]

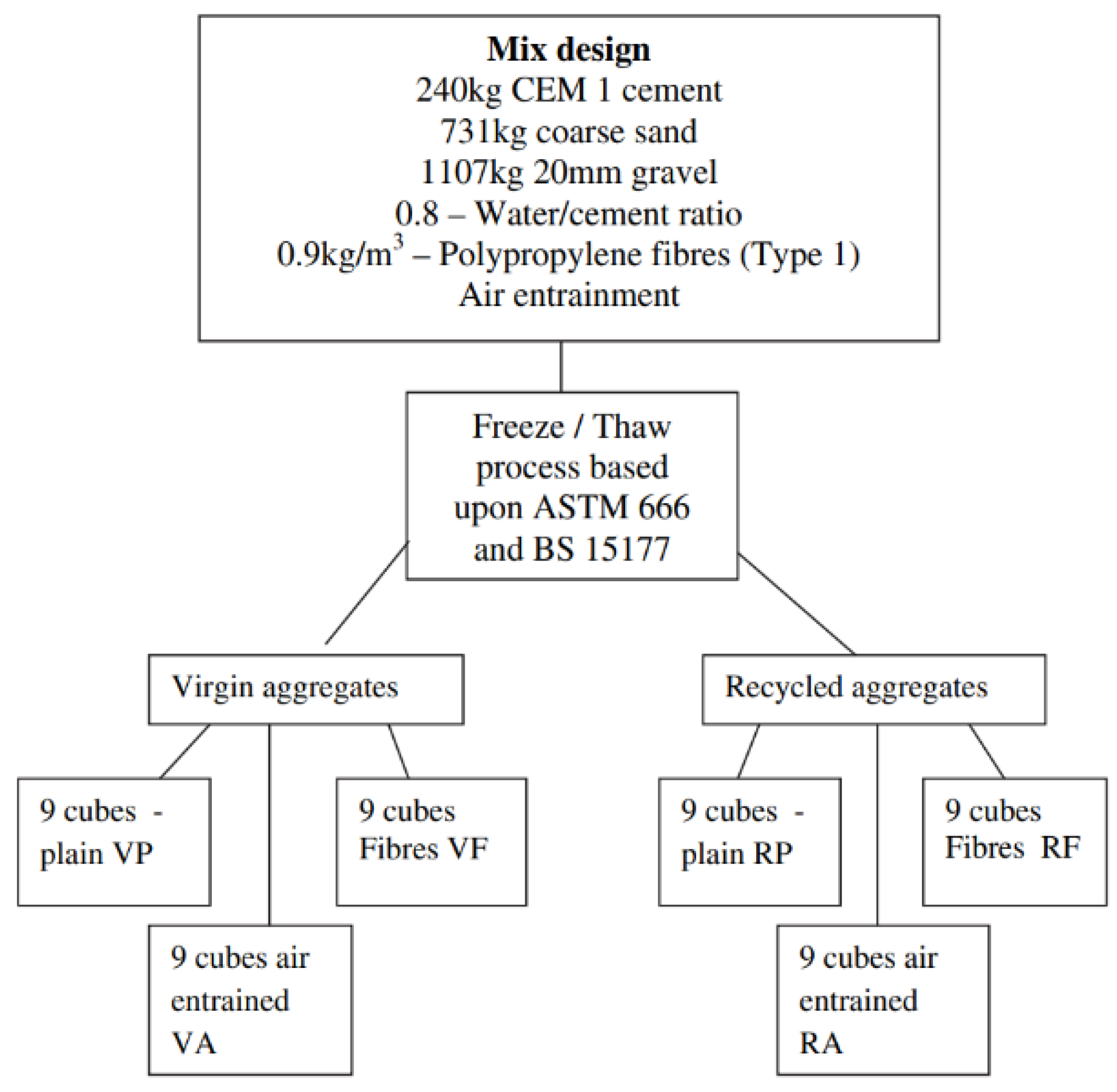

- Richarson, A.; Covertry, K.; Bacon, J. Freeze/thaw durability of concrete with recycled demolition aggregate compared to virgin aggregate concrete. J. Clean. Prod. 2011, 19, 272–277. [Google Scholar] [CrossRef]

- Šeps, K.; Fládr, J.; Broukalová, I. Resistance of recycled aggregate concrete to freeze-thaw and deicing salts. Procedia Eng. 2016, 151, 329–336. [Google Scholar] [CrossRef] [Green Version]

- Gao, C.; Huang, L.; Yan, L.; Kasal, B.; Li, W. Behavior of glass and carbon FRP tube encased recycled aggregate concrete with recycled clay brick aggregate. Compos. Struct. 2016, 155, 245–254. [Google Scholar] [CrossRef]

- Yang, J.; Du, Q.; Bao, Y. Concrete with recycled aggregate and crushed clay bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Baena, M.; Torre, L.; Turon, A.; Llorens, M.; Barris, C. Bond behaviour between recycled aggregate concrete and glass fibre reinforced polymer bars. Constr. Build. Mater. 2016, 106, 449–460. [Google Scholar] [CrossRef] [Green Version]

- Seara-Paz, S.; González-Fonteboa, B.; Martínez-Abella, F.; González-Taboada, I. Time-dependent behaviour of structural concrete made with recycled coarse aggregates. Creep and shrinkage. Constr. Build. Mater. 2016, 122, 95–109. [Google Scholar] [CrossRef]

- Guo, S.; Dai, Q.; Si, R.; Sun, X.; Lu, C. Evaluation of properties and performance of rubber-modified concrete for recycling of waste scrap tire. J. Clean. Prod. 2017, 148, 681–689. [Google Scholar] [CrossRef]

- Siddique, R.; Naik, T.R. Properties of concrete containing scrap-tire rubber—An overview. Waste Manag. 2014, 6, 563–569. [Google Scholar] [CrossRef]

- Liu, L.; Cai, G.; Zhang, J.; Liu, X.; Liu, K. Evaluation of engineering effect of recycled waste tire-sand/soil in geotechnical engineering: A compressive review. Renew. Sustain. Energy Rev. 2020, 126, 109831. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Rcycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Asutkar, P.; Shinde, S.B.; Patel, R. Study on the behaviour of rubber aggregates concrete beams using analytical approach. Eng. Sci. Technol. Int. J. 2017, 20, 151–159. [Google Scholar] [CrossRef] [Green Version]

- Thomas, B.S.; Gupta, R.C. Properties of high strength concrete containing scrap tire rubber. J. Clean. Prod. 2016, 113, 86–92. [Google Scholar] [CrossRef]

- Medina, N.F.; Medina, D.F.; Hernández-Olivares, F.; Navacerrada, M.A. Mechanical and thermal properties of concrete incorporating rubber and fibres from tyre recycling. Constr. Build. Mater. 2017, 144, 563–573. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C. A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energy Rev. 2016, 54, 1323–1333. [Google Scholar] [CrossRef]

- Bompa, D.V.; Elghazouli, A.Y. Creep properties of recycled tyre rubber concrete. Constr. Build. Mater. 2019, 209, 126–134. [Google Scholar] [CrossRef] [Green Version]

- Law, K.L.; Starr, N.; Siegler, T.R.; Jambeck, J.R.; Mallos, N.J.; Leonard, G.H. The United States’ contribution of plastic waste to land and ocean. Sci. Adv. 2020, 6, eabd0288. [Google Scholar] [CrossRef]

- Dalhat, M.A.; Wahhab, H.I.A.-A. Cement-less and asphalt-less concrete bounded by recycled plastic. Constr. Build. Mater. 2016, 119, 206–214. [Google Scholar] [CrossRef]

- Choi, Y.-W.; Moon, D.-J.; Chung, J.-S.; Cho, S.-K. Effects of waste PET bottles aggregate on the properties of concrete. Cem. Concr. Res. 2005, 35, 776–781. [Google Scholar] [CrossRef]

- Islam, M.J.; Meherier, M.S.; Islam, A.K.M.R. Effects of waste PET as coarse aggregate on the fresh and harden properties of concrete. Constr. Build. Mater. 2016, 125, 946–951. [Google Scholar] [CrossRef]

- Lucano, F.; Liguori, B.; Caputo, D.; Colangelo, F.; Coiffi, R. Recycled plastic aggregate in mortars composition: Effect of physical and mechanical properties. Mater. Des. 2013, 52, 916–922. [Google Scholar] [CrossRef]

- Mohammed, A.A. Modelling the mechanical properties of concrete containing PET waste aggregate. Constr. Build. Mater. 2017, 150, 595–605. [Google Scholar] [CrossRef]

- Bui, N.C.; Satomi, T.; Takahashi, H. Recycling woven plastic sack waste and PET bottle waste as fiber in recycled aggregate concrete: An experimental study. Waste Manag. 2018, 78, 79–93. [Google Scholar] [CrossRef] [PubMed]

- Žlebek, T.; Hodul, J.; Drochytka, R. Experimental Testing Suitability of the Waste Glass into the Polymer Anchor Materials Based on Epoxy Resin. Procedia Eng. 2017, 195, 220–227. [Google Scholar] [CrossRef]

- Cota, F.P.; Melo, C.C.D.; Panzera, T.H.; Araújo, A.G.; Borges, P.H.R.; Scarpa, F. Mechanical properties and ASR evaluation of concrete tiles with waste glass aggregate. Sustain. Cities Soc. 2015, 16, 49–56. [Google Scholar] [CrossRef]

- Rashad, A.M. Recycled waste glass as fine aggregate replacement in cementitious materials based on Portland cement. Constr. Build. Mater. 2014, 72, 340–357. [Google Scholar] [CrossRef]

- De Castro, S.; De Brito, J. Evaluation of the durability of concrete made with crushed glass aggregates. J. Clean. Prod. 2013, 41, 7–14. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Static Segregation of Self Consolidating Concrete Using Column Technique; ASTM C1610; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Ali, E.E.; Al-Tersawy, S.H. Recycled glass as a partial replacement for fine aggregate in self compacting concrete. Constr. Build. Mater. 2012, 35, 785–791. [Google Scholar] [CrossRef]

- Cassar, J.; Camilleri, J. Utilisation of imploded glass in structural concrete. Constr. Build. Mater. 2012, 29, 299–307. [Google Scholar] [CrossRef]

- Saribiyik, M.; Piskin, A.; Saribiyik, A. The effects of waste glass powder usage on polymer concrete properties. Constr. Build. Mater. 2013, 47, 840–844. [Google Scholar] [CrossRef]

- Afshinnia, K.; Rangaraju, P.R. Impact of combined use of ground glass powder and crushed glass aggregate on selected properties of Portland cement concrete. Constr. Build. Mater. 2016, 117, 263–272. [Google Scholar] [CrossRef]

- Soliman, N.A.; Tagnit-Hamou, A. Development of ultra-high-performance concrete using glass powder—Towards ecofriendly concrete. Constr. Build. Mater. 2016, 125, 600–612. [Google Scholar] [CrossRef]

- Lee, G.; Poon, C.S.; Wong, Y.L.; Ling, T.C. Effects of recycled fine glass aggregates on the properties of dry-mixed concrete blocks. Constr. Build. Mater. 2013, 38, 638–643. [Google Scholar] [CrossRef]

- Chidiac, S.E.; Mihaljevic, S.N. Performance of dry cast concrete blocks containing waste glass powder or polyethylene aggregates. Cem. Concr. Compos. 2011, 33, 855–863. [Google Scholar] [CrossRef]

- de Rosso, L.C.; de Melo, J.V.S. Impact of incorporing recycled glass on the photocatalytic capacity of paving concrete blocks. Constr. Build. Mater. 2020, 259, 119778. [Google Scholar] [CrossRef]

- Bostanci, S.C. Use of waste marble dust and recycled glass for sustainable concrete production. J. Clean. Prod. 2020, 251, 119785. [Google Scholar] [CrossRef]

- Dash, M.K.; Patro, S.K.; Rath, A.K. Sustainable use of industrial-waste as partial replacement of fine aggregate for preparation of concrete—A review. Int. J. Sustain. Built Environ. 2016, 5, 484–516. [Google Scholar] [CrossRef] [Green Version]

- De Almeida-Lima, D.; Zulanas, C. Use of Contaminated Sludge in Concrete. Procedia Eng. 2016, 45, 1201–1208. [Google Scholar] [CrossRef]

- Lee, T.-C.; Lin, K.-L.; Su, X.-W.; Lin, K.-K. Recycling CMP sludge as a resource in concrete. Constr. Build. Mater. 2012, 30, 243–251. [Google Scholar] [CrossRef]

- Sharmila, P.; Dhinakaran, G. Compressive strength, porosity and sorptivity of ultra fine slag based high strength concrete. Constr. Build. Mater. 2016, 120, 48–53. [Google Scholar] [CrossRef]

- Xu, B.W.; Shi, H.S. Correlations among mechanical properties of steel fibre reinforced concrete. Constr. Build. Mater. 2009, 23, 3468–3474. [Google Scholar] [CrossRef]

- Biskri, Y.; Achoura, D.; Chelghoum, N.; Mouret, M. Mechanical and durability characteristics of High Performance Concrete containing steel slag and crystalized slag as aggregates. Constr. Build. Mater. 2017, 150, 167–178. [Google Scholar] [CrossRef]

- Sengul, O. Mechanical behavior of concretes containing waste steel fibers recovered from scrap tires. Constr. Build. Mater. 2016, 122, 649–658. [Google Scholar] [CrossRef]

- Yu, X.; Tao, Z.; Song, T.-Y.; Pan, Z. Performance of concrete made with steel slag and waste glass. Constr. Build. Mater. 2016, 114, 737–746. [Google Scholar] [CrossRef]

- Pogorelov, S.N.; Semenyak, G.S. Frost Resistance of the Steel Fiber Reinforced Concrete Containing Active Mineral Additives. Procedia Eng. 2016, 150, 1491–1495. [Google Scholar] [CrossRef] [Green Version]

- Roslan, N.H.; Ismail, M.; Abdul-Majid, Z.; Ghoreishiamiri, S.; Muhammad, B. Performace of steel slag and steel sludge in concrete. Constr. Build. Mater. 2016, 104, 16–24. [Google Scholar] [CrossRef]

- Choun, Y.-S.; Park, H.-K. Containment performance evaluation of prestressed concrete containment vessels with fiber reinforcement. Nucl. Eng. Technol. 2015, 47, 884–894. [Google Scholar] [CrossRef] [Green Version]

- Carrillo, J.; Aperador, W.; González, G. Correlations between Mechanical Properties of Steel Fiber Reinforced Concrete. Ing. Investig. Tecnol. 2013, 14, 435–450. Available online: https://www.sciencedirect.com/science/article/pii/S140577431372256X (accessed on 25 October 2020).

- Chaboki, H.R.; Ghalehnovi, M.; Karimipour, A.; de Brito, J.; Khatibinia, M. Shear behaviour of concrete beams with recycled aggregate and steel fibres. Constr. Build. Mater. 2019, 204, 809–827. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Shah, S.H.A.; Rehman, S.U.; Hussain, I.; Iqbal, M. A step towards durable, ductile and sustainable concrete: Simultanueous, incorporation of recycled aggregates, glass fiber and fly ash. Constr. Build. Mater. 2020, 251, 118980. [Google Scholar] [CrossRef]

- Moghadam, M.A.; Izadifard, R.A. Effects of steel and glass fibers on mechanical and durability properties of concrete exposed to high temperatures. Fire Saf. J. 2020, 113, 102978. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.R. The impact resistance and mechanical properties of reinforced self- compacting concrete with recycled glass fibre reinforced polymers. J. Clean. Prod. 2016, 124, 312–324. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Use of glass and nylon fibers in concrete for controlling early age micro cracking in bridge decks. Constr. Build. Mater. 2016, 125, 800–808. [Google Scholar] [CrossRef]

- Jarek, B.; Kubik, A. The examination of the glass fiber reinforced polymer composite rods in terms of the application for concrete reinforcement. Procedia Eng. 2015, 108, 394–401. [Google Scholar] [CrossRef] [Green Version]

- Rezazadehm, N. Innovative Methodologies for the Enhancement of the Flexural Strengthening Performance of NSM CFRP Technique for RC Beams. Ph.D. Dissertation, University of Minho, Azurém, Guimarães, Portugal, 2015. [Google Scholar]

- Camata, G.; Spacone, E.; Zarnic, R. Experimental and nonlinear finite element studies of RC beams strengthened with FRP plates. Compos. Part B Eng. 2007, 38, 277–288. [Google Scholar] [CrossRef]

- Tahsiri, H.; Sedehi, O.; Khaloo, A.; Raisi, E.M. Experimental study of RC jacketed and CFRP strengthened RC beams. Constr. Build. Mater. 2015, 95, 476–485. [Google Scholar] [CrossRef]

- Cheng, D.; Yang, Y. Design method for concrete columns strengthened with prestressed CFRP sheets. Constr. Build. Mater. 2017, 151, 331–344. [Google Scholar] [CrossRef]

- Rodrigues, H.; Furtado, A.; Arêde, A. Experimental evaluation of energy dissipation and viscous damping of repaired and strengthened RC columns with CFRP jacketing under biaxial load. Eng. Struct. 2017, 145, 162–175. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Z.; Smith, S.T.; Yu, T. Seismic performance of CFRP-confined circular high-strength concrete columns with high axial compression ratio. Constr. Build. Mater. 2017, 134, 91–103. [Google Scholar] [CrossRef]

- Kong, K.; Mesticou, Z.; Michel, M.; Larbi, A.S.; Junes, A. Comparative characterization of the durability behaviour of textile-reinforced concrete (TRC) under tension and bending. Compos. Struct. 2017, 179, 107–123. [Google Scholar] [CrossRef]

- D’Antino, T.; Papanicolaou, C. Mechanical characterization of textile reinforced inorganic-matrix composites. Compos. Part B Eng. 2017, 127, 78–91. [Google Scholar] [CrossRef]

- De Santis, S.; Carozzi, F.G.; de Felice, G.; Poggi, C. Test methods for textile reinforced mortar systems. Compos. Part B Eng. 2017, 127, 121–132. [Google Scholar] [CrossRef]

- Valeri, P.; Guaita, P.; Baur, R.; Ruiz, M.F.; Fernández-Ordónez, D.; Muttoni, A. Textile reinforced concrete for sustainable structures: Future perspectives and application to a prototype pavilion. Struct. Concr. 2020, 1–17. [Google Scholar] [CrossRef]

- Jing, L.; Yin, S.; Aslani, F. Experimental investigation on compressive performance of masonry columns confined with textile-reinforced concrete. Constr. Build. Mater. 2020, 269, 121270. [Google Scholar] [CrossRef]

- Peña-Pichardo, P.; Martínez-Barrera, G.; Martínez-López, M.; Ureña-Núñez, F.; dos Reis, J.M.L. Recovery of cotton fibers from waste Blue-Jeans and its use in polyester concrete. Constr. Build. Mater. 2018, 177, 409–416. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A.; Sapidis, G.; Papastergiadis, E. Fundamental properties of epoxy resin-modified cement grouts. Constr. Build. Mater. 2016, 125, 184–195. [Google Scholar] [CrossRef]

- Ariffin, N.F.; Hussin, M.W.; Sam, A.R.M.; Bhutta, M.A.R.; Khalid, N.H.A.; Mirza, J. Strength properties and molecular composition of epoxy-modified mortars. Constr. Build. Mater. 2015, 94, 315–322. [Google Scholar] [CrossRef] [Green Version]

- Ferdous, W.; Manalo, A.; Aravinthan, T.; Erp, G.V. Properties of epoxy polymer concrete matrix: Effect of resin-to-filler ratio and determination of optimal mix for composite railway sleepers. Constr. Build. Mater. 2016, 124, 287–300. [Google Scholar] [CrossRef]

- Toufigh, V.; Hosseinali, M.; Shirkhorshidi, S.M. Experimental study and constitutive modeling of polymer concrete’s behavior in compression. Constr. Build. Mater. 2016, 112, 183–190. [Google Scholar] [CrossRef]

- Zhong, K.; Yang, X.; Wei, X. Investigation on surface characteristics of epoxy asphalt concrete pavement. Int. J. Pavement Res. Technol. 2017, 10, 545–552. [Google Scholar] [CrossRef]

- Nagrockienė, D.; Girskas, G. Research into the properties of concrete modified with natural zeolite addition. Constr. Build. Mater. 2016, 113, 964–969. [Google Scholar] [CrossRef]

- Popek, M.; Sadowski, L.; Szymanowski, J. Abrasion resistance of concrete containing selected mineral powders. Procedia Eng. 2016, 153, 617–622. [Google Scholar] [CrossRef] [Green Version]

- Atutis, E.; Valivonis, J.; Atutis, M. Experimental study of concrete beams prestressed with basalt fiber reinforced polymers under cyclic load. Compos. Struct. 2018, 183, 389–396. [Google Scholar] [CrossRef]

- Sardinha, M.; de Brito, J.; Rodrigues, R. Durability properties of structural concrete containing very fine aggregates of marble sludge. Constr. Build. Mater. 2016, 119, 45–52. [Google Scholar] [CrossRef]

- Javadian, A.; Wielopolski, M.; Smith, I.F.; Hebel, D.E. Bond-behavior study of newly developed bamboo-composite reinforcement in concrete. Constr. Build. Mater. 2016, 122, 110–117. [Google Scholar] [CrossRef]

- Wahyuni, A.S.; Supriani, F.; Elhusna; Gunawan, A. The performance of concrete with rice husk ash sea Shell ash and bamboo fibre addition. Procedia Eng. 2014, 95, 473–478. [Google Scholar] [CrossRef] [Green Version]

- Ghavami, K. Bamboo as reinforcement in structural concrete elements. Cem. Concr. Compos. 2005, 27, 637–649. [Google Scholar] [CrossRef]

- Agarwal, A.; Nanda, B.; Maity, D. Experimental investigation on the chemically treated bamboo reinforced concrete beams and columns. Constr. Build. Mater. 2014, 71, 610–617. [Google Scholar] [CrossRef]

- Moroz, J.G.; Lissel, S.L.; Hagel, M.D. Performance of bamboo reinforced concrete masonry shear walls. Constr. Build. Mater. 2014, 61, 125–137. [Google Scholar] [CrossRef]

- Mali, P.R.; Datta, D. Experimental evaluation of bamboo reinforced concrete slab panels. Constr. Build. Mater. 2018, 188, 1092–1100. [Google Scholar] [CrossRef]

- Munawar, S.S.; Umemura, K.; Kawai, S. Characterization of the morphological, physical, and mechanical properties of seven nonwood plant fiber bundles. J. Wood Sci. 2007, 53, 108–113. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Tran, V.-A.; Hong, J.-W.; Hiseh, Y.-C. Effects of short coconut fiber on the mechanical properties, plastic cracking behavior, and impact resistance of cementitious composites. Constr. Build. Mater. 2016, 127, 984–992. [Google Scholar] [CrossRef]

- Jayaprithika, A.; Sekar, S.K. Stress-strain characteristics and flexural behaviour of reinforced Eco-friendly coconut shell concrete. Constr. Build. Mater. 2016, 117, 244–250. [Google Scholar] [CrossRef]

- Lertwattanaruk, P.; Suntijitto, A. Properties of natural fiber cement materials containing coconut coir and oil palm fibers for residential building applications. Constr. Build. Mater. 2015, 94, 664–669. [Google Scholar] [CrossRef]

- Ali, M.; Gultom, R.J.; Chouw, N. Capacity of innovative interlocking blocks under monotonic loading. Constr. Build. Mater. 2012, 37, 812–821. [Google Scholar] [CrossRef]

- Ali, M.; Chouw, N. Experimental investigations on coconut-fibre rope tensile strength and pullout from coconut fibre reinforced concrete. Constr. Build. Mater. 2013, 41, 681–690. [Google Scholar] [CrossRef]

- Ali, M. Seismic performance of coconut-fibre-reinforced-concrete columns with different reinforcement configurations of coconut-fibre ropes. Constr. Build. Mater. 2014, 70, 226–230. [Google Scholar] [CrossRef]

- Wang, W.; Chouw, N. The behaviour of coconut fibre reinforced concrete (CFRC) under impact loading. Constr. Build. Mater. 2017, 134, 452–461. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R. Macro and nanodimensional plant fiber reinforcements for cementitious composites. In Sustainable and Nonconvencional Construction Materials Using Inorganic Bonded Fiber Composites; Woodhead Publishing: Sawston, UK, 2017; Volume 10, pp. 343–382. [Google Scholar] [CrossRef]

- Salas, C.; Nypelö, T.; Rodriguez-Abreu, C.; Carrillo, C.; Rojas, O.J. Nanocellulose properties and applications in colloids and interfaces. Curr. Opin. Colloid Interface Sci. 2014, 19, 383–396. [Google Scholar] [CrossRef]

- Aitomäki, Y.; Oksman, K. Reinforcing efficiency of nanocellulose in polymers. React. Funct. Polym. 2014, 85, 151–156. [Google Scholar] [CrossRef]

- Ruiz-Palomero, C.; Soriano, M.L.; Valcárcel, M. Nanocellulose as analyte and analytical tool: Opportunities and Challenges. Trends Anal. Chem. 2017, 87, 1–18. [Google Scholar] [CrossRef]

- Tardy, B.L.; Yokota, S.; Ago, M.; Xiang, W.; Kondo, T.; Bordes, R.; Rojas, O.J. Nanocellulose–surfactant interactions. Curr. Opin. Colloid Interface Sci. 2017, 29, 57–67. [Google Scholar] [CrossRef]

- Wu, H.-L.; Bremner, D.H.; Wang, H.; Wu, J.-Z.; Li, H.-Y.; Wu, J.; Niu, S.-W.; Zhu, L.-M. Fabrication and investigation of a biocompatible microfilament with high mechanical performance based on regenerated bacterial cellulose and bacterial cellulose. Mater. Sci. Eng. C 2017, 79, 516–524. [Google Scholar] [CrossRef] [Green Version]

- Kong, L.; Zhang, B.; Fang, J. Study on the applicability of bactericides to prevent concrete microbial corrosión. Constr. Build. Mater. 2017, 149, 1–8. [Google Scholar] [CrossRef]

- Islam, M.U.; Ullah, M.W.; Khan, S.; Shah, N.; Park, J.K. Strategies for cost-effective and enhanced production of bacterial cellulose. Int. J. Biol. Macromol. 2017, 102, 1166–1173. [Google Scholar] [CrossRef] [PubMed]

- Cengiz, A.; Kaya, M.; Bayramgil, N.P. Flexural stress enhancement of concrete by incorporation of algal cellulose nanofibers. Constr. Build. Mater. 2017, 149, 289–295. [Google Scholar] [CrossRef]

- Lee, K.-Y.; Aitomäki, Y.; Berglund, L.A.; Oksman, K.; Bismarck, A. On the use of nanocellulose as reinforcement in polymer matrix Composites. Compos. Sci. Technol. 2014, 105, 15–27. [Google Scholar] [CrossRef] [Green Version]

- de Koster, S.A.L.; Mors, R.M.; Nugteren, H.W.; Jonkers, H.M.; Meesters, G.M.H.; van Ommena, J.R. Geopolymer coating of bacteria-containing granules for use in self-healing concrete. Procedia Eng. 2015, 102, 475–484. [Google Scholar] [CrossRef] [Green Version]

- Hisseine, O.A.; Wilson, W.; Sorelli, L.; Tolnai, B.; Tagnit-Hamou, A. Nanocellulose for improved concrete performance: A macro-to-micro investigation for disclosing the effects of cellulose filaments on strength of cement systems. Constr. Build. Mater. 2019, 206, 84–96. [Google Scholar] [CrossRef]

| Replacement % | Cement (kg) | Water in Liters (W/c = 0.50) | Fine Aggregates (kg) | Coarse Aggregates (kg) | Rubber Aggregates (kg) |

|---|---|---|---|---|---|

| 0% | 364.81 | 225.17 | 610.43 | 1239.64 | - |

| 5% | 437.77 | 224.2 | 590.03 | 1177.65 | 23.30 |

| 10% | 437.77 | 224.2 | 590.03 | 1115.67 | 46.73 |

| 15% | 437.77 | 224.2 | 590.03 | 1053.69 | 70.101 |

| 20% | 437.77 | 224.2 | 590.03 | 991.71 | 93.46 |

| Material | Specific Gravity | Bulk Density (kg/m3) |

|---|---|---|

| Rubber aggregates | 1.10 | 650 |

| Fine aggregates | 2.6 | 1650 |

| Coarse aggregates | 2.8 | 1720 |

| % of Replacement | Ultimate Load (kN) | Compressive Strength (MPa) | Weight of Cubes (kg) | Density (kg/m3) |

|---|---|---|---|---|

| 0% | 713.25 | 31.7 | 8.15 | 24,141.81 |

| 5% | 657.67 | 29.23 | 7.56 | 2240.702 |

| 10% | 576.22 | 25.61 | 7.23 | 2143.14 |

| 15% | 480.05 | 21.34 | 6.51 | 1928.88 |

| 20% | 373.72 | 16.61 | 6.34 | 1879.933 |

| Composition by Weight | FCR (% Weight) | CR (% Weight) |

|---|---|---|

| Rubber | 50.35 | 96.90 |

| Textile fiber | 2.07 | 0.01 |

| Steel fiber | 5.04 | 0.00 |

| Rubber linked to steel fiber | 9.43 | 1.67 |

| Rubber + textile fiber + steel fiber | 5.81 | 0.01 |

| Rubber linked to textile fiber | 27.00 | 1.41 |

| Powder | 0.30 | 0.00 |

| Rubber | Cement 42.5 MPa | Aggregate 4–8 mm | Recycled Rubber 4–8 mm | Sand 0–4 mm | Water |

|---|---|---|---|---|---|

| Substitution (CR and FCR) (% Volume) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) |

| 0% (Ref. concrete) | 360 | 1103.0 | 0.0 | 722.8 | 180 |

| 20% | 360 | 882.4 | 84.5 | 722.8 | 180 |

| 40% | 360 | 661.8 | 169.0 | 722.8 | 180 |

| 60% | 360 | 441.2 | 253.5 | 722.8 | 180 |

| 80% | 360 | 220.6 | 338.1 | 722.8 | 180 |

| 100% | 360 | 0.0 | 422.6 | 722.8 | 180 |

| Rubber | Bulk Density | Ultrasonic Modulus | Bulk Porosity | Compressive Strength | Young’s Modulus | Bending Strength | Toughness | TI |

|---|---|---|---|---|---|---|---|---|

| Substitution (% Volume) | (kg/m3) | (GPa) | (%) | (MPa) | (GPa) | (MPa) | (kJ) | |

| 0% (Ref. concrete) | 2422 (15.2) | 49.5 (12.10) | 9.04 (15.8) | 47.78 (12.6) | 8.88 | 4.75 (14.5) | 6970 | 1 |

| 20% CR | 2264 (16.2) | 42.1 (11.50) | 8.97 (15.9) | 27.71 (15.3) | 5.91 | 3.75 (18.6) | 5500 | 1 |

| 40% CR | 2156 (17.5) | 31.2 (9.80) | 9.29 (18.2) | 17.71 (16.8) | 3.93 | 2.90 (17.8) | 2610 | 1 |

| 60% CR | 2026 (14.5) | 27.5 (11.6) | 9.11 (14.8) | 13.58 (19.5) | 3.80 | 2.75 (22.5) | 7120 | 1 |

| 80% CR | 1858 (18.5) | 18.9 (14.6) | 9.68 (18.6) | 8.60 (25.5) | 1.06 | 2.05 (19.9) | 1490 | 1 |

| 100% CR | 1742 (21.3) | 13.4 (10.2) | 11.54 (20.8) | 6.33 (26.8) | 0.39 | 1.86 (22.6) | 1810 | 1 |

| 20% FCR | 2313 (17.5) | 44.0 (11.4) | 9.17 (17.6) | 30.09 (18.9) | 5.71 | 4.30 (19.2) | 6120 | 1 |

| 40% FCR | 2139 (16.4) | 34.4 (16.5) | 11.38 (16.8) | 22.84 (19.5) | 4.63 | 3.43 (21.5) | 6280 | 3.70 |

| 60% FCR | 2032 (17.1) | 28.5 (17.8) | 14.01 (17.9) | 15.82 (20.6) | 3.60 | 3.32 (20.3) | 3430 | 7.16 |

| 80% FCR | 1851 (18.2) | 22.3 (15.6) | 18.31 (17.9) | 9.60 (20.5) | 2.05 | 3.24 (28.5) | 8410 | 2.54 |

| 100% FCR | 1668 (19.5) | 7.3 (18.9) | 21.37 (19.6) | 4.64 (28.5) | 0.77 | 1.68 (22.8) | 4910 | 1.56 |

| Type of Treatment | Properties | Reference |

|---|---|---|

| Steel fibers recovered from tire waste | The use of fibers affects the mechanical properties of concrete, affecting the toughness of the concrete. Use of waste fibers can optimize to produce reinforced concrete. | [64] |

| Steel fibers | As the content of steel fibers increases, the compressive strength of concrete decreases to an almost constant value. The modulus of elasticity decreases as the content of steel fibers increases. The Poisson’s modulus decreases to a nearly constant value as the steel fiber content increases. | [69] |

| Fiberglass Reinforced Ceramic Concrete | Resistance to compression, flexion and shear toughness increased with increasing fiber. Workability decreased with increasing fiber. Adding fiberglass modified the elastic modulus very little. | [72] |

| Textile-reinforced concrete | The durability of concrete against aging processes is compared. From tensile tests, changes in the stress–strain behavior are observed in the development of the cracking pattern. | [82] |

| Epoxy resin (bisphenol A-type) | Produces high resistance to compression and flexural stress with an addition of 10%. The workability of the concrete decreases after 10% replacement. | [89] |

| Epoxy polymer | They decreased the physical, mechanical properties and durability with 30 to 50% replacement. The density of the polymer increased by 33.9%. The porosity of the mixture is generally low. | [90] |

| Epoxy resin in concrete pavement | It has low permeability. Slip resistance is low. The surface texture is very fine. High resistance to demolition. | [92] |

| Using mineral additives (natural zeolite) | Compressive strength is increased by 10%. It increases in density. Water absorption is reduced. | [1,9,93] |

| Substitution of aggregate for granite residues | Optimal results are obtained by replacing 20% in aggregates. Decreases resistance to compression, flexion and tension. The density of the concrete increases. It presents an increase in water absorption, abrasion and permeability. The workability of concrete increases with increasing replacement of stone material. It can be used in all engineering works applications. In proportions of 20% to 40%, it can be used in nonstructural elements such as pavements. | [2] |

| Corrosion resistance replacing cement with granite powder | Using the 5.0% substitution increases corrosion cracking. There are no changes in the chemical properties of the mixture. The optimum percentage of substitution is 10% for positive effects of tensile stress. | [14] |

| Mineral powders (basalt, quartz, feldspar) | There is an increase or decrease in abrasion resistance. Depending on the percentage of substitution and the type of mineral. The addition of 20% quartz increases resistance to abrasion. | [94] |

| Type of Treatment | Properties | Reference |

|---|---|---|

| Efficiency of concrete with bamboo fiber | The concrete added with bamboo fiber to reinforce the concrete and the mixture of rice hull ash and sea shell ash was added. Tensile strength is comparable to conventional concrete. | [97] |

| Bamboo fiber | It is a sustainable material to be used in the construction sector. This material is used in structural elements as beams, slabs and columns. | [99] |

| Bamboo reinforcing masonry walls | Viable alternative to be applied in low-cost housing where bamboo is more profitable than steel. | [100] |

| Bamboo reinforced concrete slabs | Bamboo is analyzed as a sustainable, removable and ecological material that aims to replace steel. Pull-out tests were performed to test efficacy. There is a significant improvement in flex performance. | [102] |

| Coconut fiber reinforced concrete | The results of the deflection and the width of the crack are comparable for conventional concretes. | [105] |

| Coconut fiber analysis | The morphology and the physical and mechanical properties of the coconut fibers were analyzed. The area of the coconut fibers was studied using SEM images. The densities of the fibers decreased as the diameters increased. | [106] |

| Behavior of coconut fiber reinforced concrete under impact load | Coconut fiber reinforced concrete was tested using cyclical impact loads. Based on the results obtained, an empirically derived equation was proposed. | [110] |

| Cellulose nanofibers from algae waste | Increases flexural strength of concrete. | [119] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zamora-Castro, S.A.; Salgado-Estrada, R.; Sandoval-Herazo, L.C.; Melendez-Armenta, R.A.; Manzano-Huerta, E.; Yelmi-Carrillo, E.; Herrera-May, A.L. Sustainable Development of Concrete through Aggregates and Innovative Materials: A Review. Appl. Sci. 2021, 11, 629. https://doi.org/10.3390/app11020629

Zamora-Castro SA, Salgado-Estrada R, Sandoval-Herazo LC, Melendez-Armenta RA, Manzano-Huerta E, Yelmi-Carrillo E, Herrera-May AL. Sustainable Development of Concrete through Aggregates and Innovative Materials: A Review. Applied Sciences. 2021; 11(2):629. https://doi.org/10.3390/app11020629

Chicago/Turabian StyleZamora-Castro, Sergio A., Rolando Salgado-Estrada, Luis Carlos Sandoval-Herazo, Roberto Angel Melendez-Armenta, Erick Manzano-Huerta, Enriqueta Yelmi-Carrillo, and Agustín L. Herrera-May. 2021. "Sustainable Development of Concrete through Aggregates and Innovative Materials: A Review" Applied Sciences 11, no. 2: 629. https://doi.org/10.3390/app11020629

APA StyleZamora-Castro, S. A., Salgado-Estrada, R., Sandoval-Herazo, L. C., Melendez-Armenta, R. A., Manzano-Huerta, E., Yelmi-Carrillo, E., & Herrera-May, A. L. (2021). Sustainable Development of Concrete through Aggregates and Innovative Materials: A Review. Applied Sciences, 11(2), 629. https://doi.org/10.3390/app11020629