Featured Application

Agrifood industries may benefit from investing in energy efficiency and diversifying into new business models (distributed cogeneration and biochar production) through waste gasification, while promoting circular economy and environmental sustainability.

Abstract

This research work presents a techno-economic analysis of a biomass gasification plant fueled with residues from the olive oil and almond industries for combined heat and power generation in the agrifood sector. The experimental plant consists of a downdraft fixed bed gasifier, a producer gas cleaning and cooling system and a spark-ignition engine–generator set as a power generation unit, which generates about 10–12 kW of rated electric power. With an average consumption between 13–14 kg/h of exhausted olive pomace pellets as feedstock, the producer gas volumetric flow rate was 31 Nm3/h (vol. %: 19.2 H2, 12.9 CO, 1.9 CH4, 19.2 CO2, 46.7 N2). The average cold gas efficiency was nearly 63%. This work also addresses the characterization and potential application of the carbonaceous solid residue (biochar), discharged from the gasifier at 1.7 kg/h. Finally, an economic feasibility analysis was developed, wherein the payback period ranges between 5–9 years.

1. Introduction

Agriculture and agrifood processing activities generate vast amounts of wastes worldwide and concurrently demand considerable amounts of electrical and/or thermal energy. These wastes are typically not valorized, leading to significant negative impacts on the global sustainability of the agrifood sector. The olive tree (Olea europaea L.) and the almond tree (Prunus dulcis) are two of the most extensive and widespread crops in Mediterranean countries. Although virgin olive oil and almond products stand out for their excellent nutritional properties, both generate large amounts of wastes and by-products throughout their respective supply chains. In both cases, it is estimated that around 80% by weight of the total amount collected per annual harvest represents wastes.

1.1. Olive Oil Industry Wastes

The cultivation of olive trees for the production of olive oil is a well-known and established practice in the Mediterranean region for millennia. The largest area under olive groves worldwide is located in Spain, with over 2.5 million hectares [1], accounting for more than half of the total area dedicated to this crop in Europe, followed by Italy and Greece. In terms of olive oil production, Spain is also the world’s leading country, with a yearly production of about 1.35 million tonnes on average in the last ten years [2].

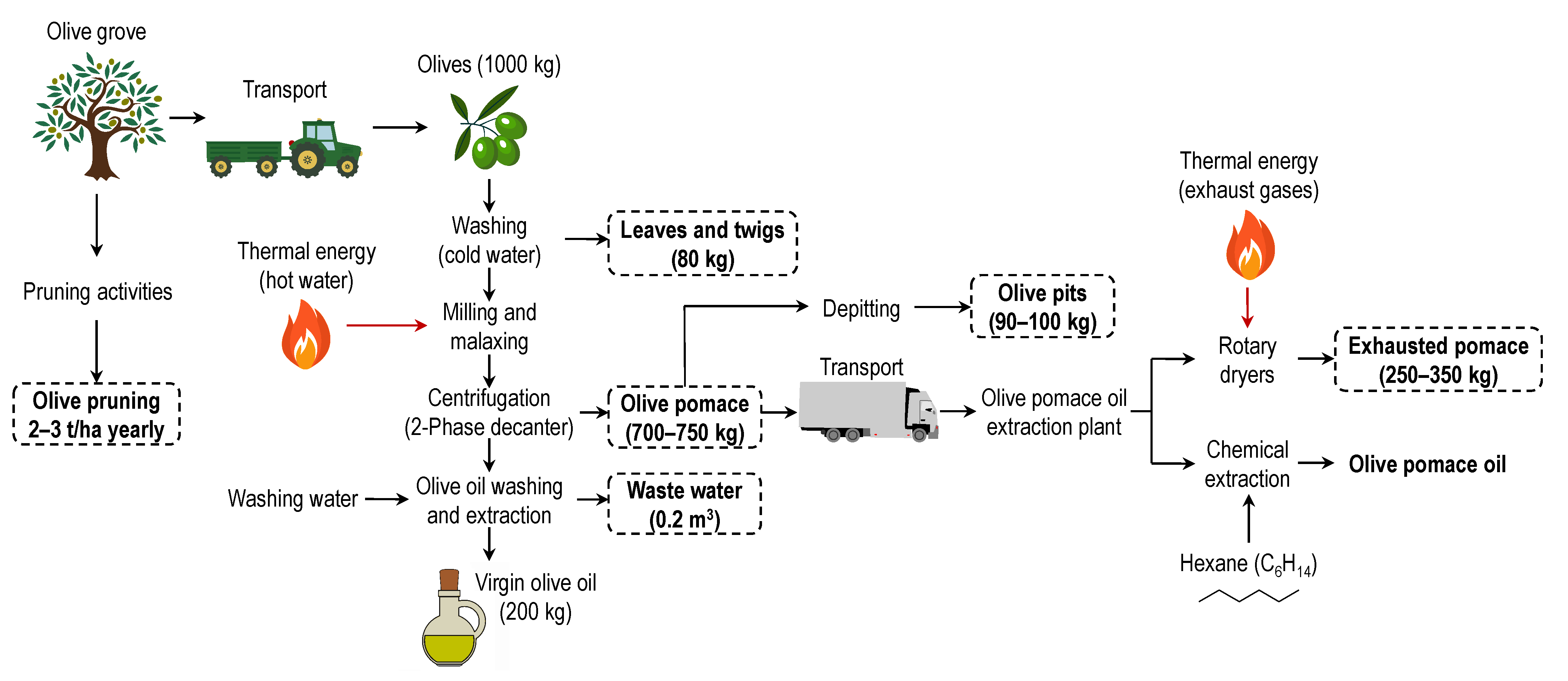

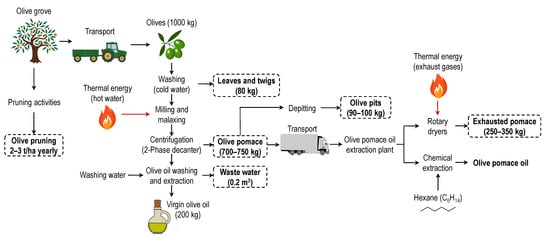

The olive oil supply chain generates a wide variety of by-products, particularly during the agricultural and oil production phases, which are currently not suitably managed and usually dealt with as waste. The amount and physicochemical properties of these wastes depend on the olive oil extraction method. Figure 1 shows the main products and by-products of the most common and efficient olive oil extraction process in Spain (continuous two-phases). It is estimated that for every 100 kg of olives harvested, approximately 80 kg represent wastes: olive leaves and twigs (∼8 kg), olive pits (9–10 kg), olive pomace (70–75 kg) and waste water [3]. The two-phase olive pomace from oil mills is deposited and dried in large ponds for subsequent extraction of crude olive pomace oil, generating exhausted olive pomace as a by-product. Olive oil industry wastes not only include those generated in the oil mill, but also those originated in the olive grove after the pruning activities, which represent another abundant source of wastes in the olive oil value chain. On average, the residual woody biomass from olive pruning in Mediterranean areas ranges between 2.31 t/ha for irrigated olive groves in annual pruning and 4.52 t/ha for rainfed olive groves in biennial pruning [4]. As a result, the yearly production of olive tree pruning in Spain can be estimated at roughly 5–7 million tonnes.

Figure 1.

Products and by-products of the olive oil industry supply chain (two-phase extraction process).

Table 1 summarizes the main characteristics of the different by-products generated in the olive oil supply chain, as well their production rate, current management status, market price and some of their physicochemical properties [3,4,5,6,7].

Table 1.

Main properties of olive oil industry by-products (two-phase extraction process).

In the past years, the olive oil sector has experienced important investments in the modernization of oil mills that led to many of the older, traditional mat presses being replaced by more efficient, high volume continuous flow plants for centrifugal separation (two or three phases) of the oil from the rest of the olive fruit. As a result, there are currently over 1800 olive mills operating in Spain [8], of which more than 90% are based on the two-phase extraction process. However, the olive oil sector is nowadays facing several additional challenges toward environmental sustainability concerning waste management and recovery, as well as energy efficiency improvement.

1.2. Almond Industry Wastes

The cultivation of almond trees has been for centuries a significant economic activity in Mediterranean dry areas. Nowadays, almond tree cultivation is concentrated in three main regions: California, Southeastern Australia and the Mediterranean countries. The Almond tree currently represents the second fruit-bearing tree in terms of cultivated land in Spain, after the olive tree, with over 650,000 hectares under cultivation [1]. Although far behind California in terms of almond production, Spain leads the Mediterranean region, with a yearly production of about 225,000 tons of unshelled almonds on average in the last ten years [1].

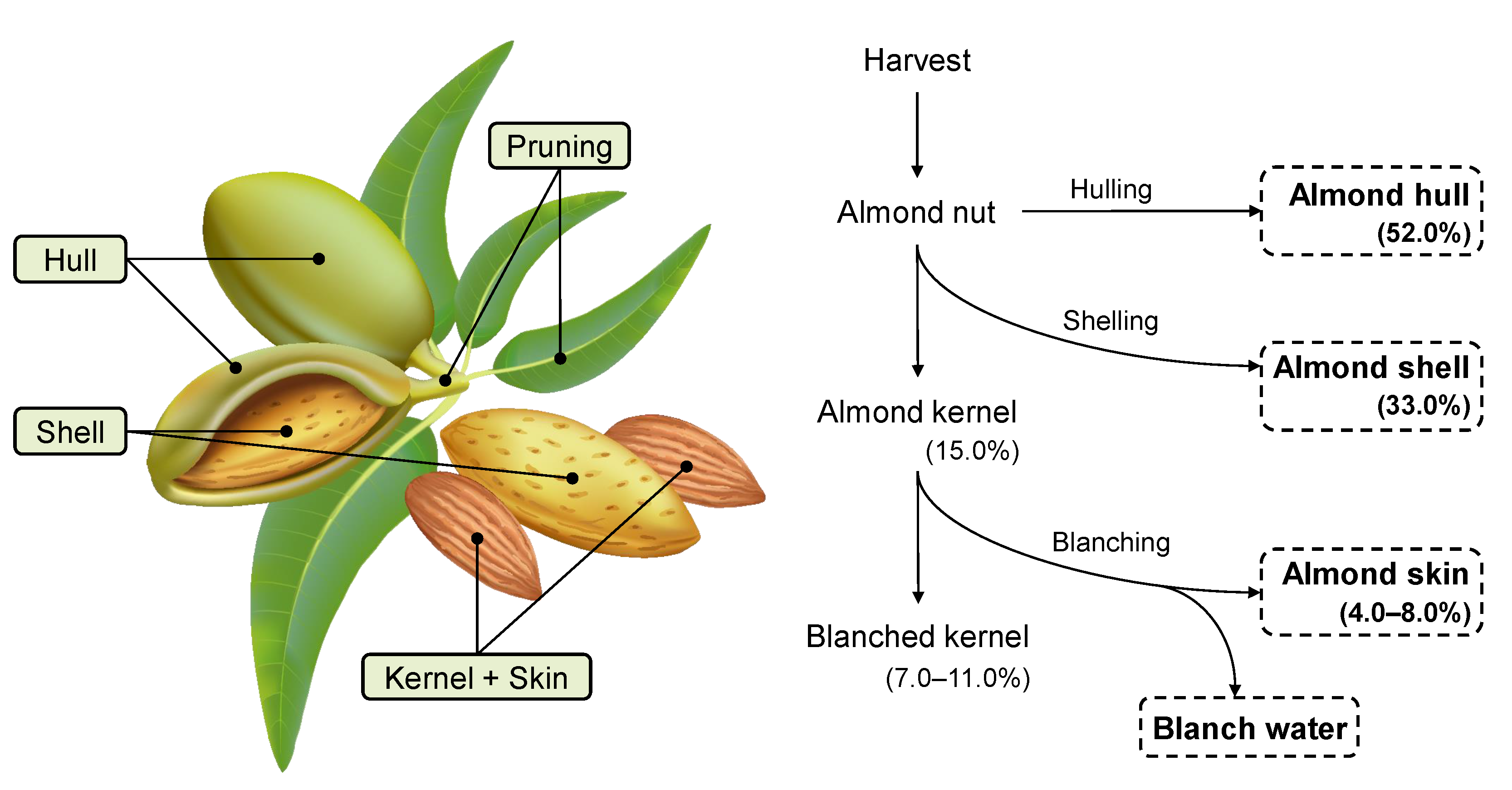

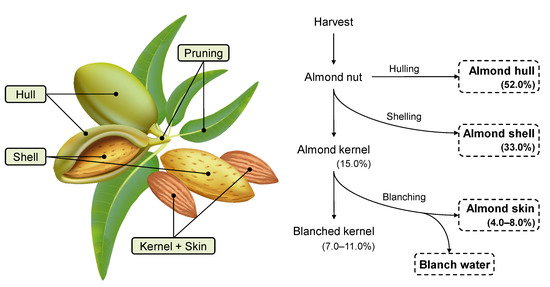

Almond production leads to a large amount of by-products (Figure 2): hull, shell and skin. It is estimated that for every 100 kg of almonds harvested, around 70–85 kg represent wastes at the end of the supply chain [9]. Considering the physicochemical properties of the diverse solid wastes from almond processing, the brownish–green hull accounts for an average of 52% of the total fresh weight; whereas the shell and kernel (including skin) represent around 33% and 15% of the total fresh weight, respectively [9]. Moreover, during the industrial process of skin removal in the blanching process, two additional types of wastes are produced: blanched skin (4–8% of the total shelled almond fresh weight) and blanch water (wastewater) [9]. Finally, almond-tree pruning activities generate large amounts of woody biomass available in the field, which in most cases are left on the land and incorporated into the soil as an amendment or incinerated, leading to air pollution and fire risks [10]. Almond groves in Mediterranean areas produce annually on average 1.34 tonnes of residual woody biomass on a dry basis per hectare after pruning [11]. Therefore, the yearly Spanish production of almond-tree pruning is estimated at about 870,000 tonnes on a dry basis.

Figure 2.

Parts of almond fruit (left) and almond processing by-products (right).

1.3. Gasification for Distributed Cogeneration

A mature and efficient technology currently available in some countries such as India, China and the USA for successful biomass waste management and valorization is gasification. This technology involves the production of a gaseous fuel, usually referred to as producer gas or synthesis gas (syngas), whose main components are hydrogen, carbon monoxide, methane, water, nitrogen and carbon dioxide [12,13]. The producer gas can be used for distributed cogeneration, defined as the simultaneous generation of electrical and thermal power in the close vicinity of end-users. Additionally, the solid remnant residue from gasification, known as biochar, has a potential application as soil enhancer.

During the gasification process inside the reactor, a gasifying agent (air, pure oxygen and/or steam) is required so as to transform the feedstock into producer gas through a series of exothermic and endothermic reactions [12], which determine four different stages depending on the temperature at which they occur: drying, pyrolysis, combustion/oxidation and reduction [13]. Gasification is an autothermal process, through which the exothermic combustion reactions provide enough energy for the endothermic reactions responsible for the producer gas formation to take place.

Gasifiers are generally classified according to the contact between the gas-solid medium (bed) and the gasifying agent. Thus, they can be grouped into three main types: fixed or moving bed, fluidized bed and entrained flow [12,13]. Each type of gasifier is used in a given range of thermal power output [13]. For gasification plants on a distributed generation scale with small thermal power (10 kWth–10 MWth), fixed bed gasifiers are generally more suitable because of their simplicity and ability to generate a moderately energy-dense producer gas (4–6 MJ/Nm3). Fixed bed gasifiers are further classified as updraft and downdraft gasifiers, depending on whether the gasifying agent is supplied from the bottom (counter-current) or the top of the reactor (co-current), respectively [13,14]. Updraft gasifiers are typically more efficient than downdraft gasifiers, but lead to a producer gas with a greater tar content (30–150 g/Nm3) [14], which hampers its use in internal combustion engines. Downdraft gasifiers, however, are able to generate a producer gas with much lower tar content (<3 g/Nm3) [14], since tars are cracked down in the combustion zone. For intermediate thermal powers (5 MWth–100 MWth), fluidized bed gasifiers are a better choice; whereas for large powers (>50 MWth), entrained flow gasifiers are the most appropriate reactor configuration [13]. Table 2 shows a comparison of the most relevant operating parameters for each type of gasifier and their power application range [13,14].

Table 2.

Operating parameters for different types of gasifiers.

There are already numerous theoretical and simulation studies of gasifiers coupled to small-scale power plants and distributed generation technologies such as gas microturbines [15,16], gas engines [17,18], external combustion turbines [19,20] and steam engines based on organic Rankine cycles [21,22,23]. Although the electricity generation efficiency of this technology is relatively low (around 15–20%), CHP efficiencies over 50% can be achieved. Biomass gasification is slightly less efficient than combustion, with conversion efficiencies up to about 85%. However, it has greater application potential, since it allows using raw materials with higher moisture and ash content. Biomass gasification also leads to significantly lower emissions of carbon dioxide, particulate matter and even nitrogen oxides, since the reaction temperature is lower than that of combustion [13].

The fixed-bed gasification technology also produces a solid residue with a high carbon content commonly referred to as biochar. This by-product, which can represent about 15–25% by weight of the input biomass, is characterized by the following properties [24,25]:

- Extremely high porosity. If deposited in agricultural soil, biochar can absorb water including dissolved nutrients up to five times its own weight.

- High cation exchange capacity, which avoids the leaching of mineral nutrients and ensures greater availability of them in the soil.

- Biochar benefits microbial life and increases the potential of microorganisms and roots.

2. Materials and Methods

2.1. Description and Characteristics of the Gasification Plant

The gasification plant consists of a downdraft fixed bed reactor, a producer gas cooling and cleaning system and a spark-ignition engine–generator set as a power generation unit. The choice of a downdraft fixed bed gasifier is perfectly justified for these main reasons:

- Compared to fluidized bed and entrained flow gasifiers, fixed bed gasifiers are fairly simpler reactors and involve a considerably lower investment cost.

- Fixed bed gasifiers are generally intended for small-scale power and distributed generation applications, since agrifood processing facilities usually require electric powers below 1 MW.

- Fixed bed gasifiers are more suitable for coarse and non-fine particles (between 3 and 51 mm). This property is very important in the agrifood industry, since one of the most abundant residues, tree pruning, can be directly fed into this type of gasifiers after a mild crushing pretreatment.

- As opposed to updraft gasifiers, a downdraft reactor configuration leads to a cleaner producer gas with considerably lower tar content (<3 g/Nm3) and thus more suitable for being supplied to internal combustion engines.

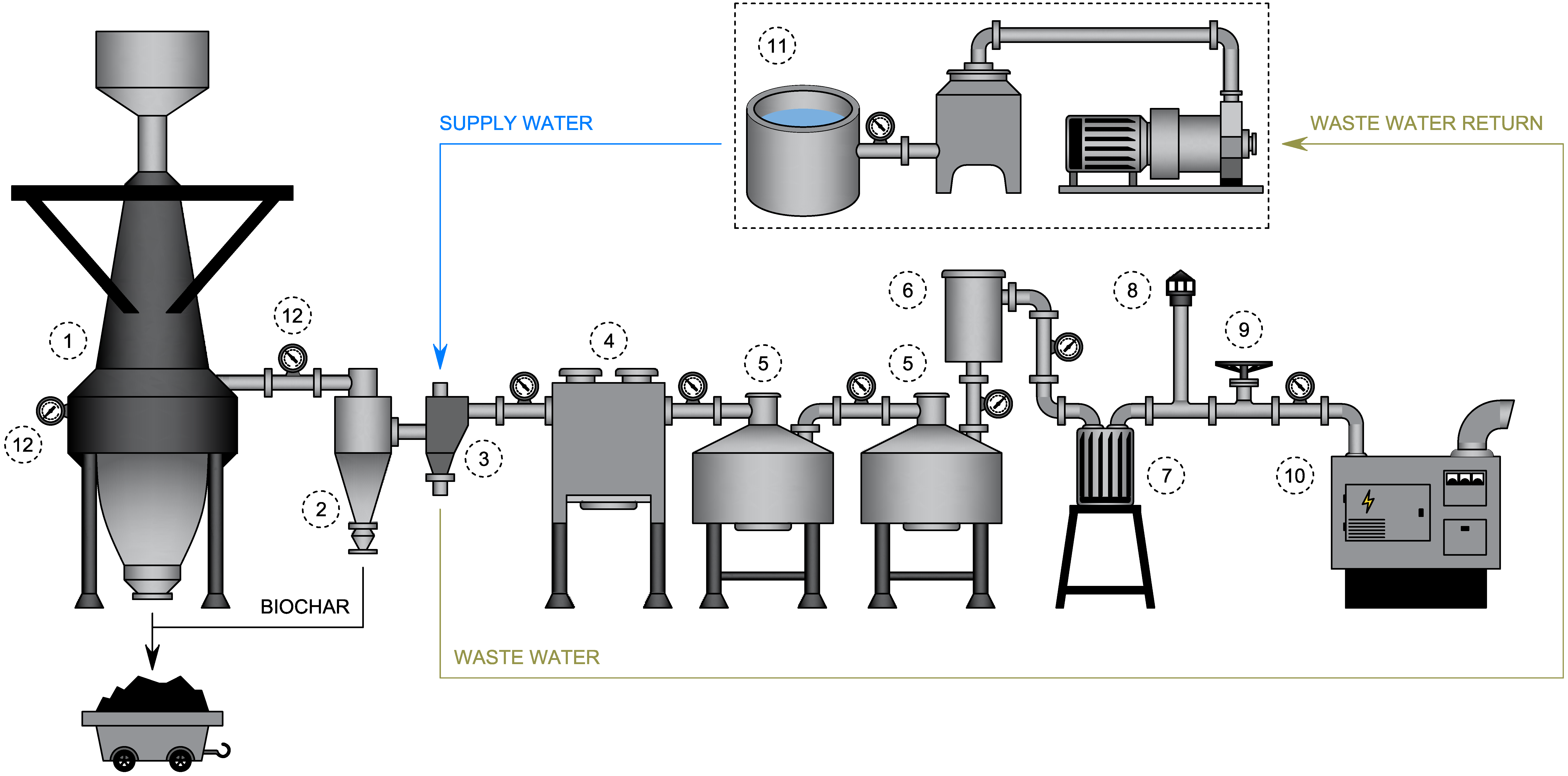

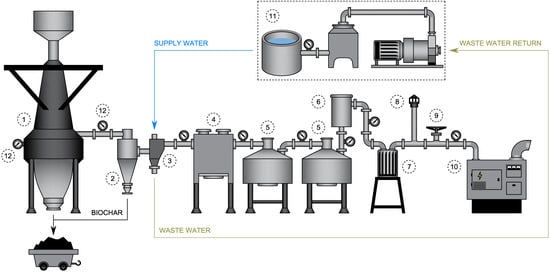

Figure 3 shows a general layout of the experimental gasification plant. The residues from the olive oil and almond industries are loaded through the upper hopper into the downdraft gasifier (1), while the gasifying agent (air) is introduced through a small injector. In the upper part of the gasifier, the drying, pyrolysis and combustion stages occur; whereas the endothermic reduction reactions responsible for the formation of the producer gas take place in the lower part of the gasifier. The general chemical equation of the gasification process can be expressed as follows [5,13]

Figure 3.

Layout of the gasification plant. (1) Downdraft fixed bed gasifier; (2) cyclone; (3) Venturi scrubber; (4) moisture and particle filter; (5) fine filters; (6) safety filter; (7) air blower; (8) flare stack; (9) engine feed valve; (10) spark-ignition engine–generator set; (11) waste water treatment unit; (12) pressure and temperature gauges.

The first element symbolizes the chemical composition of the biomass feedstock based on the ultimate analysis (CHNS), where subscripts are the number of hydrogen, oxygen, nitrogen and sulfur atoms, respectively. The second element represents the moisture content of the biomass feedstock and the third term is the airflow rate on a mass basis. On the products side, coefficients – stand for the chemical composition of the producer gas, which depends on the feedstock properties, such as moisture, ash, LHV and particle size.

The producer gas at the outlet of the downdraft gasifier is at high temperature (>400 °C) and contains impurities (particles, dust, etc.) and tar (liquid particles with CxHy chemical composition). Under these conditions, the producer gas is not suitable for use in internal combustion engines, so it must be cooled and cleaned up to a certain extent according to the manufacturer’s specifications. For this purpose, the gasification plant has a producer gas cleaning and cooling system with the following units: a cyclone (2) that separates a large part of the particulate matter; a Venturi scrubber (3) that drastically reduces the gas temperature and also removes the tars by spraying a pressurized water jet; moisture removal filters (units 4 and 5) and a safety filter (6) that ensures a thorough cleanliness of the producer gas before entering the power generation unit (10). Additionally, the gasification plant has a waste-water treatment unit (11) for recirculating the process water into the Venturi scrubber and several pressure and temperature gauges (12) to continuously monitor the gasification process. The characteristics of the gasification plant are summarized in Table 3 (information provided by the manufacturer for rice husk).

Table 3.

Rated operating parameters of the gasification plant.

Finally, a spark-ignition internal combustion engine was used as a power generation unit. The producer gas at room temperature, free of dirt and tar, is eventually introduced at atmospheric pressure into a natural gas engine, whose carburetor was modified to work with the producer gas from gasification. The technical specifications of the engine–generator set are presented in Table 4, which shows that the engine running on natural gas is able to generate a total net electric power of 20 kWe.

Table 4.

Technical specifications of the engine–generator set.

2.2. Physicochemical Properties of Agrifood Industry Wastes

The next step for validating the gasification technology is to determine the physicochemical properties of the different residues from the olive oil and almond industries. For this purpose, their proximate and ultimate analyses (CHNS), particle size, bulk density and heating value were determined and reported in Table 5.

Table 5.

Proximate, ultimate analysis and other properties of olive oil and almond industry wastes.

Exhausted olive pomace is one the most suitable by-products from the olive oil industry to be fed into the gasifier, mainly due to its massive rate of production in oil mills, for which it represents a huge economic, environmental and energy burden. Additionally, exhausted olive pomace has a high carbon and hydrogen content, low ash and moisture content and substantial heating value. Therefore, it was used as feedstock for the gasification tests. However, the exhausted olive pomace had to be pelletized in advance because its raw particle size is smaller than 3 mm and hence, not recommendable for direct load into the gasifier. Fine particles in downdraft fixed bed gasifiers favor the formation of ash clinkers [26], which disturb the optimal fuel and airflow in the gasifier bed (bottom), causing pressure drop problems, low temperatures in the reduction zone and unstable operation.

One of the objectives of this research work was to ensure the correct operation of the downdraft gasifier fueled with exhausted olive pomace pellets. The results may represent an attractive opportunity to promote distributed cogeneration systems in Spain, providing techno-economic and environmental benefits to agrifood industries.

2.3. Experimental Procedure

In order to monitor the performance of the gasification plant, a series of temperature and pressure sensors, a portable gas chromatograph (Varian CP4900) and a gas flow meter were installed.

Type K thermocouples were installed to measure the temperatures (up to 1000 °C) at different points of the gasifier: two thermocouples inside the reactor (drying and pyrolysis zone), one thermocouple just at the outlet of the reactor and another one after the Venturi scrubber.

A pressure sensor was placed in the reactor bed to monitor the gasification process. The pressure difference between the bed pressure and the atmospheric pressure indicates the pressure drop in the reaction zone. This is an essential parameter to monitor the performance of the gasification process and, therefore, it must remain within the pressure limits established by the manufacturer (40–90 mmH2O).

A Venturi flow meter, placed before the portable gas chromatograph (GC), and a differential pressure sensor (Omega PX653) were used to monitor the producer gas flow. The gas flow measurement was placed after the safety filter and before the main gas flare (between units 6 and 8 of Figure 3). The portable GC was used to determine the volumetric composition of the producer gas and was calibrated using the following gas mixture (vol. %): CO: 19%, H2: 18%, CH4: 3%, CO2: 10%, O2: 1%, N2: 50%. The calibration mixture was injected into a Molsieve column (channel 1), using argon as the carrier gas. Channel 2 was equipped with a Cp-PoraPlot U column to detect CO2 in the gas sample. The sampling point was located immediately after the safety filter, recording the gas composition every 25–30 min. Only H2, CO, CO2, CH4, N2 and O2 were the gases considered. Data sampling began when the plant reached steady-state conditions (∼20 min). Data were recorded in 3 test runs of 4 h each.

The system start-up process begins with the weighing and loading of the feedstock (exhausted olive pomace pellets) into the gasifier through the upper hopper. In the first start-up, the gasifier requires external heat input, which is supplied with a blowtorch or a hand torch. Approximately 10 min after ignition, and with the inlet valve to the engine gas closed (unit 9, Figure 3), the producer gas begins to form and evacuate through the main gas flare (unit 8, Figure 3). At this time, using a small torch, the gas flare is lit. In steady-state conditions, the flare is colorless or may exhibit a blue hue if the ignition is performed at night. A colorless or blue flame indicates that the producer gas is clean and free of tars. After 5–10 min of flare ignition, the next step is the progressive opening of the inlet valve to the combustion engine and the gradual closing of the main gas flare valve. At this stage, the gas engine is started by opening the inlet valve until reaching the rated electric power of the gasification plant.

Finally, in order to determine the electrical parameters of the gasification plant (active power, frequency, current injected into the power grid, voltage, etc.) a three-phase network analyzer (Chauvin Arnoux CA 8331) was used. This device was connected to the output of the engine–generator set, which in turn was connected to the power supply to the oil mill.

The lower heating value of the producer gas (LHV) was determined by gas chromatography using the Equation (2), which takes into account the mass fraction () of each of the fuel components that make up the producer gas (H2, CO and CH4) [5,27,28].

The gasification efficiency () after the gas cleaning and cooling stage (cold gas efficiency) was determined as shown in the next expression:

where and represent the mass flows of producer gas and biomass feedstock, respectively.

Once the operating parameters (producer gas composition, heating values, mass flows, etc.) were determined, the net electrical efficiency of the gasification plant () was calculated according to the following expression:

The three-phase active electric power () developed by the engine–generator set was determined as follows:

where U represents the generator output line voltage (V), I is the line current (A) and is the power factor (PF). These electrical parameters were measured by installing a network analyzer at the output of the engine–generator set.

3. Results and Discussion

3.1. Gasification Performance Parameters

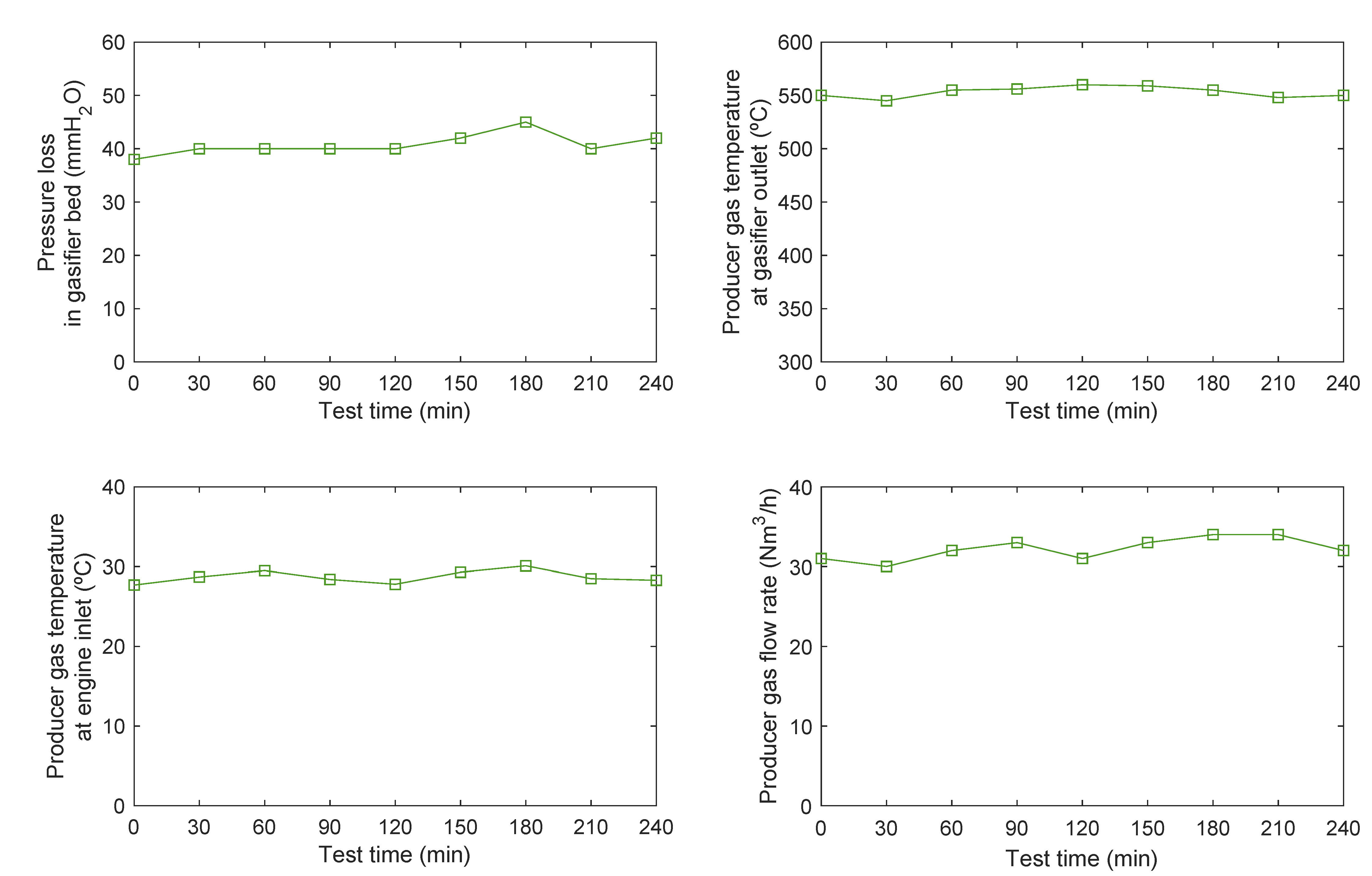

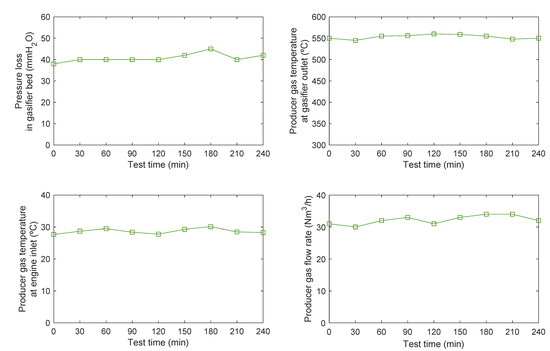

The preliminary tests consisted of monitoring and recording various performance parameters every 30 min for 4 h of continuous operation. These tests were performed in triplicate after the plant had reached steady-state operation (∼20 min) using exhausted olive pomace pellets as feedstock. Figure 4 shows the evolution of the pressure loss in the gasifier bed, the producer gas temperature at the gasifier outlet, the producer gas temperature at the engine inlet and the producer gas flow rate.

Figure 4.

Monitored operating parameters of the gasification plant.

The pressure drop across the downdraft gasifier bed was 38–45 mmH2O, which lies near the lower limit set by the manufacturer (40–90 mmH2O). This relatively low-pressure drop indicates that the feedstock particle size was adequate, as well as the reactions originating in the reduction zone (lower part of the gasifier).

The producer gas temperature at the gasifier outlet was around 550 °C, slightly above the temperature range recommended by the manufacturer (400–500 °C). This minor deviation did not have any significant impact on the operation of the gasification plant, only leading to a small increase in the producer gas temperature after the cleaning and cooling stage. However, the producer gas temperature at the engine inlet (cold gas temperature) was maintained at around 29 °C in accordance with the technical specifications of the combustion engine (<40 °C, Table 4).

During the gasification process of exhausted olive pomace pellets, the producer gas volumetric flow was kept between 30–34 Nm3/h. This value is remarkably below the rated value set by the manufacturer (60 Nm3/h, Table 3). The main reason behind this is the difference in composition between rice husk and exhausted olive pomace pellets. Rice husk has an LHV equal to 12.0 MJ/kg [29]; whereas that of exhausted olive pomace pellets is 16.1 MJ/kg. Therefore, the amount of air necessary to reach the optimum gasification temperature (1000 °C) is much lower with exhausted olive pomace pellets as feedstock, and hence, the lower mass flow of producer gas generated. It is noteworthy that the gasification temperature was maintained at around 1000 °C in order to reduce the production of tars and promote their cracking. Tars are very damaging to the internal combustion engine and the different units and devices that make up the gasification plant, leading to severe corrosion problems and lifespan reduction [21]. Table 6 shows the average producer gas composition, heating values and other efficiency parameters of the three tests performed in the gasification plant.

Table 6.

Composition of the producer gas and efficiency parameters of the gasification plant.

The performance of the gasification system was evaluated in terms of the producer gas composition, heating value, volumetric flow rate and cold gas efficiency.

The gas chromatography results showed a very promising producer gas composition with a high hydrogen content (19.7%). In addition, the contents of methane (1.7%) and carbon monoxide (13.1%) are acceptable. The average LHV of the three tests was 4.39 MJ/m3, which is included within the usual range for downdraft gasifiers (4–6 MJ/Nm3) [14,30]. The average biomass consumption (13.3 kg/h), was lower than that set by the manufacturer (25–30 kg/h). This is mainly due to the higher energy density of exhausted olive pomace pellets compared to that of rice husk. Therefore, it follows that the higher the LHV, the lower the biomass feedstock consumption, the higher the energy content of the producer gas and the lower the volumetric flow generated by the gasifier. Another relevant parameter in the gasification process is the producer gas yield, which is defined as the ratio between the producer gas volumetric flow rate (Nm3/h) and the feedstock consumption rate (kg/h). The average producer gas yield was 2.3 Nm3/kg, which agrees with the typical range of producer gas yield values reported for wood gasification in downdraft gasifiers (2–3 Nm3/kg) [30].

The gasification process is governed by the equivalence ratio (ER), which is the amount of air supplied to the downdraft gasifier in relation to the amount of air required for stoichiometric combustion [5]. Atmospheric air with an oxygen concentration of roughly 21% by volume was supplied to the gasification plant with a blower (unit 7, Figure 3). The volumetric flow rate of air supplied to the downdraft gasifier was not measured onsite. However, as the equivalence ratio (ER) in fixed bed gasifiers is directly related to the producer gas yield [30], it was estimated at about 0.30–0.35 as shown in [31]. This means that the volumetric airflow rate supplied to the downdraft gasifier was about 30–35% with respect to that necessary for stoichiometric combustion [30]. This parameter lies within the usual range in downdraft gasifiers (ER = 0.2–0.4) [30] and is in accordance with the equivalence ratios reported for olive pit (ER = 0.31) and olive tree pruning (ER = 0.32) in a 70 kWe downdraft gasification plant [5].

On analysis about the overall performance of the gasification process, the average cold gas efficiency () achieved by the plant was 62.9%. This parameter represents the available energy in the cold producer gas related to the LHV of the feedstock supplied to the gasifier through the upper hopper, as shown earlier in Equation (3). In general, the efficiency of a gasification process is greater than that of other thermochemical conversion processes, such as direct combustion [18]. For biomass gasification in downdraft gasifiers, the cold gas efficiency typically ranges between 50–70% [18,30]. The average cold gas efficiency lies within this range and is in accordance with the value indicated by the manufacturer (∼65%), demonstrating a correct operation of the gasification plant with exhausted olive pomace pellets as feedstock.

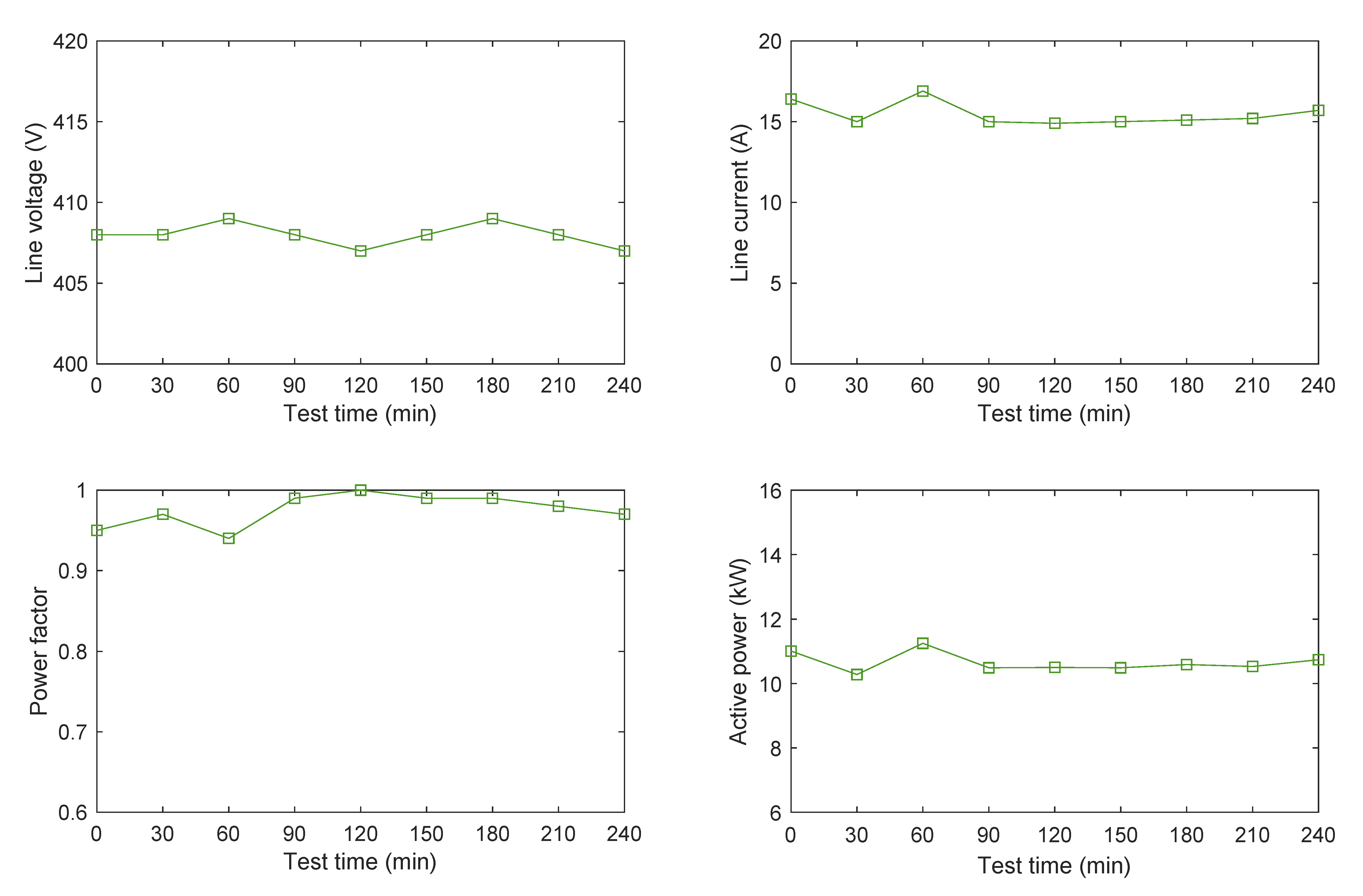

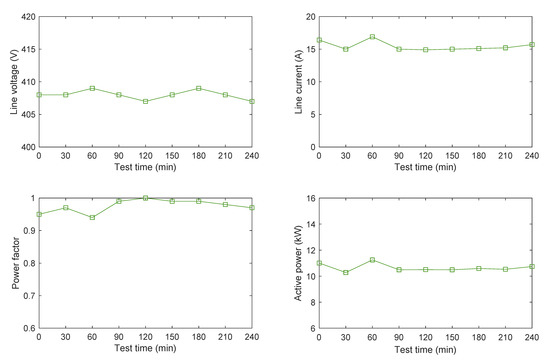

Figure 5 presents the electrical parameters of the engine–generator set connected to an olive oil mill’s low voltage electrical network in self-consumption mode. The objective of these measurements was to demonstrate the stable operation of the generator coupled to the power grid.

Figure 5.

Electrical parameters measured at the output of the engine–generator set.

Figure 5 shows the electrical variables measured in one of the tests during 4 h of operation. The two remaining tests showed similar values. The three-phase output voltage of the engine–generator set is perfectly coupled to the voltage of the olive oil mill, synchronizing with the network correctly (408 V). The current generated by each phase (equal to the line current in star-connected generators) ranged between 15.0 and 16.4 A. The electrical frequency of the engine–generator set was kept constant during all the tests and equal to 50 Hz. The three-phase active electric power was determined according to Equation (5), ranging from 10.3 kW to 11.3 kW, being the average value equal to 10.6 kW. These results confirm that the electrical energy production of the gasification plant is slightly higher than that set by the manufacturer with rice husks as feedstock (limited to a rated electric power of 10 kW). Finally, the spark-ignition–engine generator set was able to reach a relatively high efficiency of energy conversion into electricity ().

Table 7 summarizes the most important performance parameters of the gasification plant operating with residues from the olive oil industry (exhausted olive pomace pellets) and their comparison with those provided by the manufacturer. Gasification of exhausted olive pomace pellets improved nearly all performance parameters compared to gasification of rice husk. Two parameters stand out, the lower feedstock consumption of the plant (13.3 kg/h) and the higher electric power generation (10.6 kW). All this is due to the excellent energy properties of the exhausted olive pomace pellets in comparison with those of rice husk. The electrical efficiency of the gasification plant increased by 4.7 percentage points up to 17.8%. The main drawback observed during the experimental validation of the plant was the lower production of biochar as a result of the lower feedstock consumption.

Table 7.

Gasification performance parameters with residues from the olive industry and manufacturer specifications for rice husk.

Gasification processes for power generation are environmentally friendlier than direct combustion processes, since not only do they perform more efficiently, but also lead to lower emissions of greenhouse and other polluting gases into the atmosphere. This is due to the fact that combustion of gaseous fuels is inherently more efficient than that of solid fuels and also because the producer gas from biomass gasification is generally purified before being combusted in spark-ignition engines [13].

Table 8 provides the exhaust gas composition from the 10 kWe engine–generator set running on the producer gas from gasification of exhausted olive pomace pellets.

Table 8.

Exhaust gas composition from the spark–ignition engine running on the producer gas from gasification of exhausted olive pomace pellets.

The European Directive (EU) 2015/2193 lays down rules to control or monitor emissions of sulfur dioxide (SO2), nitrogen oxides (NOX), dust and carbon monoxide (CO) into the air from combustion plants with a total rated thermal power between 1 MWth and 50 MWth, irrespective of the type of fuel they use [32]. The content of this European Directive was transposed into Spanish law by means of Royal Decree 1042/2017 [33]. As stated therein, the emission limit value of nitrogen oxides (NOX) for new engines running on gaseous fuels other than natural gas is 190 mg/Nm3. Emissions of carbon monoxide (CO) must be monitored, but so far no specific emission limit values have been set for them. Therefore, even though the rated thermal power of the gasification plant under assessment is much lower than 1 MWth, the emissions of polluting gases are still below any limit values established in the current legislation. Additionally, there is a substantial reduction of CO2 emissions as a result of installing and operating the 10 kWe gasification plant fueled with exhausted olive pomace pellets, taking into account that biomass gasification emits around 10% less CO2 into the atmosphere than direct combustion and considering the advantages derived from self-consumption of renewable electricity.

3.2. Biochar Characterization

Biochar is a by-product of the gasification process at high temperatures (>700 °C). This by-product has a high carbon content and offers a very important and yet unknown potential for farmers in the agrifood sector. Due to its macroscopic structure and composition, it acts as an amendment to the soil, returning the carbon captured by olive trees to the soil and providing the following benefits:

- Biochar boosts the growth of plants and roots. The use of biochar improves the rhizosphere, supporting the development and activity of a huge and diversified microbial community, which includes microorganisms capable of promoting plant growth [34,35].

- Due to its porous structure, biochar can absorb up to five times its own weight. Therefore, it retains nutrients and water, avoiding leaching and soil erosion [36].

- Biochar from gasification at temperatures above 700 °C leads to the formation of macroscopic structures with high conductivity and cation exchange capacity (graphene). This type of biochar facilitates and promotes ion exchange, benefiting the microbial life of the soil and increasing the potential for microorganisms and roots [37].

- Finally, from an environmental sustainability point of view, biochar captures carbon in agricultural soil. Therefore, the carbon that was earlier retained by the olive tree is later returned to the soil, avoiding its emission into the atmosphere in the form of carbon dioxide [24].

The biochar produced during the gasification process of exhausted olive pomace pellets was physicochemically characterized. Table 9 shows the main physicochemical properties of this by-product, such as proximate analysis, ash elemental analysis, particle size or heating value.

Table 9.

Physicochemical properties and sample of biochar from exhausted olive pomace gasification.

Another essential aspect of biochar is its current market price. The sale price of biochar in England ranges between €162–480/t [38]; while other publications estimate its price at around €150/t [39]. These values are very attractive to boost the economy of the agrifood sector with new business models.

3.3. Profitability Assessment and Economic Impact

This section aims to demonstrate the economic viability of gasification technology in the agrifood sector. The economic feasibility analysis was developed for a 125 kWe gasification plant fueled with exhausted olive pomace pellets and applied to a real olive oil mill in Spain. The economic analysis involved the calculation of an objective function known as profitability index (PI) [5], defined as the ratio between the net present value (NPV) and the initial investment (INV):

The net present value (NPV) is a standard method for the financial appraisal of investments. It involves discounting the net cash flows and making the sum over the plant lifespan period as follows:

where n is the total number of periods of one year that make up the useful lifespan of the gasification plant, i is the discount rate (real interest rate) and NCF are the net cash flows in each period.

The internal rate of return (IRR) is the discount rate for which the NPV is equal to zero. Its calculation was done iteratively by variation of the discount rate using the Newton–Raphson method.

Before showing the results of the economic feasibility assessment, it is essential to consider the following assumptions, which are conveniently summarized in Table 10.

Table 10.

Input parameters and results of the economic feasibility assessment of the gasification plant.

- The gasification plant, in addition to electricity, generates waste heat in the form of hot water at 90 °C and combustion gases at 350 °C. This source of thermal energy is used to produce the hot water required for the milling and malaxing stages of the virgin olive oil extraction process, avoiding the burning of a substantial part of olive pits from the oil mill, which can later be sold at about €60/t.

- Currently, there are non-refundable subsidies from the Regional Government of Andalusia (in Spanish, Junta de Andalucía) for sustainable small–medium size enterprises, which can amount up to a 40% of the total investment [40]. In this study, a 35% non-refundable subsidy was considered.

- Annual discount rate equal to a real interest rate of 1%.

- The gasification plant was installed in self-consumption mode, according to Royal Decree 244/2019 [41], largely reducing the variable term of the olive oil mill’s cost of electricity.

- The gasification plant operates for 4.5 months in total, during the entire production season from October to March. The plant requires two stops per month for maintenance works.

- The operation and maintenance of the gasification plant may require the creation of a permanent part-time technical job. A skilled labor cost of €15,000/year has been considered.

- Finally, the cost of the gasification technology was consulted directly with the manufacturer (€2500/kWe). Therefore, for a 125 kWe gasification plant with a 35% non-refundable subsidy, the capital expenditures were determined as€203,125. The initial investment (INV) takes into account both the fixed costs of the whole gasification plant and the installation costs (civil, electrical and mechanical works).

Table 10 shows that the payback period or return on investment is 8–9 years when deciding to hire new part-time maintenance personnel and the net present value (NPV) is roughly €100,000. On the other hand, if the maintenance personnel already available in oil mills are trained on this type of technology, the payback period can be reduced down to 5–6 years. Under these circumstances, the investment would provide a net present benefit of around €300,000 (NPV) during the plant lifespan and a profitability index (PI) higher than 1.5.

4. Conclusions

This research work aimed at performing a techno-economic feasibility assessment for applying the gasification technology in the agrifood industry. The main findings are summarized below:

- Gasification is already a mature and developed technology in some countries such as India, China and the USA. However, its penetration in the Spanish market is negligible or very incipient. The residues from the olive oil and almond industries with potential use as feedstock in the gasification process are the following: exhausted olive pomace, olive pit, olive tree pruning, almond shell, almond hull and almond tree pruning.

- A small-scale gasification plant was installed for power generation and biochar production using exhausted olive pomace pellets as feedstock. The plant was capable of generating 10–12 kW of rated electric power with an average biomass consumption of 13.3 kg/h. Most of the operating parameters have improved compared to those reported by the manufacturer, leading to a lower feedstock consumption and a higher net electrical efficiency ().

- In addition to the electrical energy generated for self-consumption, the gasification plant produces two additional outputs. One of them is thermal energy in the form of hot water and combustion gases from the engine. Another by-product of gasification is biochar, an extremely porous activated carbon that can absorb water including dissolved nutrients up to five times its own weight when deposited in agricultural soil. Additionally, it has a high cation exchange capacity, avoiding the leaching of mineral nutrients and ensuring greater availability of them in the soil. It also benefits microbial life and increases the potential of microorganisms and roots. Its sale price in international markets ranges between €150–200/t.

- Finally, profitability analysis of the gasification technology for a real olive oil mill in Spain was developed. For an initial investment of approximately €200,000, the payback period is 5–9 years. This technology generates direct employment (operation and maintenance work) and about 10–15 indirect jobs during the installation phase that are technical in nature.

The results of this research work demonstrate a feasible and attractive possibility for the Spanish agri-food sector to invest in energy efficiency through waste gasification, improving environmental and economic sustainability, diversifying into new business models and promoting a circular economy.

Author Contributions

Conceptualization, R.A. and D.V.; methodology, R.A. and D.V.; validation, F.J., R.A. and D.V.; investigation, R.A., D.V. and J.P.T.; writing—original draft preparation, R.A. and D.A.L.-G.; writing—review and editing, R.A., D.V., D.A.L.-G. and J.P.T.; supervision, F.J.; project administration, D.V.; funding acquisition, D.V. and F.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research work was supported by the Project “Opportunities for olive oil value chain enhancement through the by-products valorization (OLIVEN)”, funded through the ARIMNet2 2017 Joint Call by the Agencia Estatal de Investigación (Spain) under the reference number: PCI2018-093255. ARIMNet2 (ERANET) has received funding from the European Union within the Seventh Framework Program for research, technological development and demonstration activities under grant agreement no. 618127. Additionally, R.A. gratefully acknowledges financial support from Ministerio de Universidades under the FPU Program (ref. FPU19/00930).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CHP | Combined heat and power |

| ER | Equivalence ratio |

| GC | Gas chromatograph |

| I | Current (A) |

| INV | Initial investment |

| IRR | Internal rate of return |

| LHV | Lower heating value |

| Mass flow (kg s−1) | |

| NCF | Net cash flow |

| NPV | Net present value |

| P | Power (kW) |

| PF | Power factor (cos ϕ) |

| PI | Profitability index |

| U | Voltage (V) |

| y | Mass fraction |

| η | Efficiency |

References

- FAO (Food and Agriculture Organization of the United Nations), Statistics Division (FAOSTAT). Available online: https://fao.org/faostat (accessed on 18 December 2020).

- IOC World Olive Oil Figures. Available online: https://www.internationaloliveoil.org/what-we-do/economic-affairs-promotion-unit (accessed on 18 December 2020).

- García-Maraver, A.; Zamorano, M.; Ramos-Ridao, A.; Díaz, L.F. Analysis of olive grove residual biomass potential for electric and thermal energy generation in Andalusia (Spain). Renew. Sustain. Energy Rev. 2012, 16, 745–751. [Google Scholar] [CrossRef]

- Velázquez-Martí, B.; Fernández-González, E.; López-Cortés, I.; Salazar-Hernández, D.M. Quantification of the residual biomass obtained from pruning of trees in Mediterranean olive groves. Biomass Bioenergy 2011, 35, 3208–3217. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; Margaritis, N.K.; Grammelis, P. Experimental and economic study of a gasification plant fuelled with olive industry wastes. Energy Sustain. Dev. 2014, 23, 247–257. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; De Mena, B.; Hernández, J.C. A distributed generation hybrid system for electric energy boosting fueled with olive industry wastes. Energies 2019, 12, 500. [Google Scholar] [CrossRef]

- Malheiro, R.; Rodrigues, N.; Manzke, G.; Bento, A.; Pereira, J.A.; Casal, S. The use of olive leaves and tea extracts as effective antioxidants against the oxidation of soybean oil under microwave heating. Ind. Crops Prod. 2013, 44, 37–43. [Google Scholar] [CrossRef]

- Patsios, S.I.; Kontogiannopoulos, K.N.; Banias, G.F. Bio-Economy and Agri-Production; Bochtis, D., Achillas, C., Banias, G., Lampridi, M., Eds.; Academic Press: New York, NY, USA, 2020; Volume 2, Chapter 5; pp. 83–110. [Google Scholar]

- Prgomet, I.; Gonçalves, B.; Domínguez-Perles, R.; Pascual-Seva, N.; Barros, A. Valorization Challenges to Almond Residues: Phytochemical Composition and Functional Application. Molecules 2017, 22, 1774. [Google Scholar] [CrossRef]

- Aguado, R.; Cuevas, M.; Pérez-Villarejo, L.; Martínez-Cartas, M.L.; Sánchez, S. Upgrading almond-tree pruning as a biofuel via wet torrefaction. Renew. Energy 2020, 145, 2091–2100. [Google Scholar] [CrossRef]

- Velázquez-Martí, B.; Fernández-González, E.; López-Cortés, I.; Salazar-Hernández, D.M. Quantification of the residual biomass obtained from pruning of trees in Mediterranean almond groves. Renew. Energy 2011, 36, 621–626. [Google Scholar] [CrossRef]

- Higman, C.; Van der Burgt, M. Gasification, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction, 2nd ed.; Academic Press: Boston, MA, USA, 2010. [Google Scholar]

- Ruiz, J.A.; Juárez, M.C.; Morales, M.P.; Muñoz, P.; Mendívil, M.A. Biomass gasification for electricity generation: Review of current technology barriers. Renew. Sustain. Energy Rev. 2013, 18, 174–183. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; Panopoulos, K.D.; Grammelis, P. Modelling of biomass gasifier and microturbine for the olive oil industry. Int. J. Energy Res. 2012, 36, 355–367. [Google Scholar] [CrossRef]

- Camporeale, S.M.; Pantaleo, A.M.; Ciliberti, P.D.; Fortunato, B. Cycle configuration analysis and techno-economic sensitivity of biomass externally fired gas turbine with bottoming ORC. Energy Convers. Manag. 2015, 105, 1239–1250. [Google Scholar] [CrossRef]

- Vera, D.; De Mena, B.; Jurado, F.; Schories, G. Study of a downdraft gasifier and gas engine fueled with olive oil industry wastes. Appl. Therm. Eng. 2013, 51, 119–129. [Google Scholar] [CrossRef]

- Chaves, L.I.; da Silva, M.J.; de Souza, S.N.M.; Secco, D.; Rosa, H.A.; Nogueira, C.E.C.; Frigo, E.P. Small-scale power generation analysis: Downdraft gasifier coupled to engine generator set. Renew. Sustain. Energy Rev. 2016, 58, 491–498. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; Carpio, J. Study of a downdraft gasifier and externally fired gas turbine for olive industry wastes. Fuel Process. Technol. 2011, 92, 1970–1979. [Google Scholar] [CrossRef]

- Datta, A.; Ganguly, R.; Sarkar, L. Energy and exergy analyses of an externally fired gas turbine (EFGT) cycle integrated with biomass gasifier for distributed power generation. Energy 2010, 25, 341–350. [Google Scholar] [CrossRef]

- De Mena, B.; Vera, D.; Jurado, F.; Ortega, M. Updraft gasifier and ORC system for high ash content biomass: A modelling and simulation study. Fuel Process. Technol. 2017, 156, 394–406. [Google Scholar] [CrossRef]

- Kalina, J. Integrated biomass gasification combined cycle distributed generation plant with reciprocating gas engine and ORC. Appl. Therm. Eng. 2011, 31, 2829–2840. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; Carpio, J.; Kamel, S. Biomass gasification coupled to an EFGT-ORC combined system to maximize the electrical energy generation: A case applied to the olive oil industry. Energy 2018, 144, 41–53. [Google Scholar] [CrossRef]

- You, S.; Sik, Y.; Chen, S.S.; Tsang, D.C.W.; Kwon, E.E.; Lee, J.; Wang, C. A critical review on sustainable biochar system through gasification: Energy and environmental applications. Bioresour. Technol. 2017, 246, 242–253. [Google Scholar] [CrossRef]

- Zabaniotou, A.; Rovas, D.; Libutti, A.; Monteleone, M. Boosting circular economy and closing the loop in agriculture: Case study of a small-scale pyrolysis–biochar based system integrated in an olive farm in symbiosis with an olive mill. Environ. Dev. 2015, 14, 22–36. [Google Scholar] [CrossRef]

- Patel, V.R.; Upadhyay, D.S.; Patel, R.N. Gasification of lignite in a fixed bed reactor: Influence of particle size on performance of downdraft gasifier. Energy 2014, 78, 323–332. [Google Scholar] [CrossRef]

- Lee, U.; Balu, E.; Chung, J.N. An experimental evaluation of an integrated biomass gasification and power generation system for distributed power applications. Appl. Energy 2013, 101, 699–708. [Google Scholar] [CrossRef]

- Weiland, F.; Nordwaeger, M.; Olofsson, I.; Wiinikka, H.; Nordin, A. Entrained flow gasification of torrefied wood residues. Fuel Process. Technol. 2014, 125, 51–58. [Google Scholar] [CrossRef]

- ECN.TNO. Phyllis2, Database for the Physico-Chemical Composition of (Treated) Biomass, Algae, Feedstocks for Biogas Production and Biochar. Available online: https://phyllis.nl/ (accessed on 18 December 2020).

- Martínez, J.D.; Mahkamov, K.; Andrade, R.V.; Silva Lora, E.E. Syngas production in downdraft biomass gasifiers and its application using internal combustion engines. Renew. Energy 2012, 38, 1–9. [Google Scholar] [CrossRef]

- Sheth, P.N.; Babu, B.V. Experimental studies on producer gas generation from wood waste in a downdraft biomass gasifier. Bioresour. Technol. 2009, 100, 3127–3133. [Google Scholar] [CrossRef]

- Directive, C. Official Journal of the European Union. Directive (EU) 2015/2193 of the European Parliament and of the Council of 25 November 2015 on the limitation of emissions of certain pollutants into the air from medium combustion plants. Off. J. Eur. Union 2015, 313, 1–19. [Google Scholar]

- Boletín Oficial del Estado. Real Decreto 1042/2017, de 22 de diciembre, sobre la limitación de las emisiones a la atmósfera de determinados agentes contaminantes procedentes de las instalaciones de combustión medianas y por el que se actualiza el anexo IV de la Ley 34/2007, de 15 de noviembre, de calidad del aire y protección de la atmósfera. BOE 2017, 311, 127839–127861. [Google Scholar]

- Kammann, C.I.; Schmidt, H.; Messerschmidt, N.; Linsel, S.; Steffens, D.; Müller, C.; Koyro, H.; Conte, P.; Joseph, S. Plant growth improvement mediated by nitrate capture in co-composted biochar. Sci. Rep. 2015, 5, 11080. [Google Scholar] [CrossRef]

- Vacheron, J.; Desbrosses, G.; Bouffaud, M.L.; Touraine, B.; Moënne-Loccoz, Y.; Muller, D.; Legendre, L.; Wisniewski-Dyé, F.; Prigent-Combaret, C. Plant growth-promoting rhizobacteria and root system functioning. Front. Plant Sci. 2013, 4, 356. [Google Scholar] [CrossRef]

- Hagemann, N.; Joseph, S.; Schmidt, H.; Kammann, C.I.; Harter, J.; Borch, T.; Young, R.B.; Varga, K.; Taherymoosavi, S.; Elliott, K.W. Organic coating on biochar explains its nutrient retention and stimulation of soil fertility. Nat. Commun. 2017, 8, 1089. [Google Scholar] [CrossRef]

- Sun, T.; Levin, B.D.A.; Guzmán, J.J.L.; Enders, A.; Muller, D.A.; Angenent, L.T.; Lehmann, J. Rapid electron transfer by the carbon matrix in natural pyrogenic carbon. Nat. Commun. 2017, 8, 14873. [Google Scholar] [CrossRef] [PubMed]

- Shackley, S.; Hammond, J.; Gaunt, J.; Ibarrola, R. The feasibility and costs of biochar deployment in the UK. Carbon Manag. 2014, 2, 335–356. [Google Scholar] [CrossRef]

- Vochozka, M.; Marouskova, A.; Vachal, J.; Strakova, J. Biochar pricing hampers biochar farming. Clean Technol. Environ. 2016, 18, 1225–1231. [Google Scholar] [CrossRef]

- Boletín Oficial de la Junta de Andalucía. Orden de 23 de diciembre de 2016, por la que se aprueban las bases reguladoras para la concesión de incentivos para el desarrollo energético sostenible de Andalucía en el período 2017–2020. BOJA 2016, 249, 77–336. [Google Scholar]

- Boletín Oficial del Estado. Real Decreto 244/2019, de 5 de abril, por el que se regulan las condiciones administrativas, técnicas y económicas del autoconsumo de energía eléctrica. BOE 2019, 83, 35674–35719. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).