1. Introduction

Concrete is a non-homogenous and brittle material, vulnerable to tensile forces and stresses, especially at high strength [

1,

2]. In the search for concrete with improved qualities such as higher fracture toughness [

3,

4], it was possible to overcome its fragileness by reinforcing the fibers embedded into the material to provide a better control of cracks [

5]. The use of fiber reinforced concrete has gained popularity due to improvements in the fracture behavior of concrete [

6,

7], and also to the successful utilization for the production of shotcrete, which has been used for reparation, rehabilitation, tunneling, stabilization, etc. [

8].

Steel fiber has been used for reinforcement in concrete structures because of its superior mechanical properties to each of the concrete ingredients. Steel fibers allow provision of the capability to bear higher load during the fracture process of concrete. Polymeric fibers have also been used as an alternative to steel fibers because of a relatively low cost and better construction behavior, having some useful properties such as deformability and corrosion resistance [

5,

9]. However, due to their weaker mechanical properties than those of steel fibers, polymeric fibers do not provide higher mechanical performance than steel fibers when incorporated into concrete for reinforcement [

10].

For applications in marine infrastructures, use of steel fiber is not a good option due to its susceptibility to corrosion. In such cases, combined use of different types of fibers, for example a mixture of polymer and steel fiber to obtain corrosion resistance while maintaining the proper level of mechanical performance, can be considered. The works by Banthia et al. [

2] and Dongqing et al. [

11] utilized three types of fiber combinations (polymer-ceramic, ceramic-steel, and steel-polymer) in order to find the best option for synergy in performance. It was reported that the effectiveness of fiber hybridization depends on factors intrinsic of the material and production process [

3,

12,

13], but if not well designed, a reduction in some of the mechanical properties of concrete occurred.

This work was initiated for the development of shotcrete that can be used for stabilizing marine underground tunnels. The amount of steel fiber needed to be minimized in order to reduce the risk associated with corrosion. Therefore, polyolefin fiber was chosen as a replacement material of steel fiber. Since the mechanical performance of concrete using polyolefin fiber is lower than that made of conventional steel fibers, a hybridization strategy was required to obtain both mechanical performance and resistance against corrosion induced by chloride ion penetration.

Finding a proper mixing ratio between polyolefin and steel fiber for shotcrete and verifying it through evaluation of its mechanical performance, especially on its flexural strength and flexural toughness, would allow a hybrid fiber composed of steel and polyolefin fibers to be used successfully for shotcreting purposes. Different proportions of steel and polyolefin fibers were added for formulation of the high-strength shotcrete mixture. Considering earlier findings that beneficial enhancement on durability was obtained from fiber reinforced concrete with the addition of supplementary cementitious materials [

14,

15,

16], 40 wt% of the Portland cement was replaced with ground granulated blast furnace slag. Finally, the chloride ion penetration resistance of the base concretes was quantitatively evaluated using standard test procedures.

2. Experimental Procedure

We studied base concrete designed for the use of shotcrete because production of shotcrete with a set accelerator in a laboratory facility is very difficult.

2.1. Materials

Ordinary type I Portland cement (OPC), conforming to the KS L 5201 standard (equivalent to ASTM C 150), was used for preparation of the base concrete. Ground granulated blast furnace slag (GGBFS), conforming to KS F 2563 (equivalent to ASTM C 989), was replaced 40% by weight of the Portland cement. The GGBFS used in this work was reported to contain calcium sulfate anhydrite as an activator. The chemical compositions of cementitious materials used in this work are shown in

Table 1.

The photographic images of steel and polyolefin fibers used in this work are presented in

Figure 1. Natural sand with a fineness modulus of 2.64 was used as fine aggregate. The crushed stone with nominal maximum size of 10 mm was used as coarse aggregate.

2.2. Mixing and Curing

The mix proportions of the base concrete are shown in

Table 2. Note that the weight proportion of sand in the aggregate was set to 60%. This is because smaller maximum sized aggregate with higher sand ratio would facilitate the spraying of the shotcrete during construction. The volume proportions of polyolefin fiber to steel fiber were 0, 25, 50, 75, and 100%, respectively. The fiber content of the base concrete was 0.54% and 1.08% by volume of concrete, respectively. Since the density of polyolefin fiber was 0.92 kg/m

3, the weight of 100% polyolefin fiber that was incorporated into the base concrete mixtures was 4.9 kg/m

3 for 0.54 vol%. In the same manner, the weight of 100% steel fiber that was incorporated into the base concrete was 42.35 kg/m

3 for 0.54 vol% using density of steel fiber of 7.85 kg/m

3. Using the weight differences of each fiber, the volume proportion of polyolefin fiber to steel fiber and the volume fraction of hybrid fiber in the mixture were adjusted. All mixtures had the same amount of sand, aggregate, water, cement, and GGBFGS. The only difference was the amount and the type of fibers for the hybrid combination.

A standard type pan mixer was used for preparation of the base concrete reinforced with hybrid fiber. All the dry ingredients (cement, blast furnace slag, fine aggregate, coarse aggregate, and fiber) were added and dry-mixed together for a minute. Water was added and mixed for 30 s. The mixer was stopped for a minute to scrape down the materials which were stuck on the side, bottom, and corner of the pan mixer. After removal of the attached concrete, the mixing was begun again, and a poly-carboxylate based superplasticizer was added to ensure proper dispersion of the base concrete and the hybrid fibers. The amount of superplasticizer is given as a percentage of the total weight of the cementitious material (cement + GGBFS) and is shown in

Table 2. After addition of superplasticizer, additional mixing was performed for 90 s.

As soon as mixing was finished, the base concrete reinforced with hybrid fibers was cast in a 100 mm × 200 mm cylindrical mold for compressive strength and chloride ion penetration tests. In addition, 150 mm × 150 mm × 550 mm prismatic specimens were prepared for flexural strength and toughness measurements. For casting, one third of concrete was filled in the mold, rodded with steel bar, and vibrated using a rubber mallet. This process was repeated until the molds were completely filled with base concrete. After casting was finished, the top portion of the specimen was screed, covered with plastic wrap, and stored in the laboratory environment for a day. The mold was removed after a day, and the base concrete was immersed into the 23 ± 1 °C saturated lime solution for 27 days to meet a total of 28 days curing.

2.3. Mechanical Performance

ASTM C39/C39 M, “Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens” was used to determine 28-day compressive strength of base concrete mixed with hybrid fibers. At the 28-day, base concrete was placed on the compression testing machine, HS-1472 (Hanshin Kumpung, Gimpo, Gyeonggi-do, Korea), and loaded. The loading rate was controlled at 0.2 MPa/s.

The 28-day-age flexural strength and flexural toughness of the concrete were measured following the ASTM C1609/1609M “Standard Test Method for Flexural Performance of Fiber Reinforced Concrete”, using 150 mm × 150 mm × 550 mm test specimens by the four-point bending method. The photographic images of test configuration used to measure flexural strength and flexural toughness are shown in

Figure 2a. After accurately marking the neutral axis of the prismatic specimen, specimens were placed on the roller of the bottom jig, whose span length was 450 mm. Two guide bars were fixed at the neutral axis on both sides of the specimens, and linear variable displacement transducer (LVDT) was placed at the center of the guide bar for deflection measurements. Finally, the upper jig, whose rollers are located at 1/3 (150 mm) and 2/3 (300 mm) of the span length, was placed on top of the beam specimen before loading. The loading was applied using an MTS 244.41 hydraulic actuator (MTS System, Eden Prairie, MN, USA). The loading speed was fixed at 0.15 mm/min, and the mid-span deflection was measured by averaging the values from each LVDT until it reached 3 mm, which is 1/150 of the span length (

L) as suggested by the ASTM C 1609. Flexural strength was calculated using Equation (1), where

P is the maximum load on the load-deflection curve,

L is the span length (450 mm) of the specimen,

b and

h are the width and height of the specimen, respectively. The area under the load-deflection curve was calculated to obtain the flexural toughness. The shape of the test specimen after the test was completed is shown in

Figure 2b.

2.4. Chloride Ion Penetration

To measure the chloride ion penetration of the base concrete, the ASTM C 1202 “Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration” and the NT Build 492 “Chloride Migration Coefficient from Non-Steady-State Migration Experiments” were used. The use of two different testing procedures was to comprehensively understand the chloride ion penetration resistance of the fiber reinforced base concrete because the amount of charge passed was found to be affected by the presence of the conductive material (steel fiber) in the concrete [

10].

The cylindrical base concrete test specimen was cut into the size specified in both standards (100 mm × 50 mm). Subsequently, the sliced specimen was inserted into the cell designed for each of the standard test procedures. For the ASTM C 1202 test, a 0.3 N NaOH solution was injected into the anode, a 3% NaCl solution was injected into the cathode, and a voltage difference of 60 V (DC ± 30 V) was maintained for 6 h using PERMATM (Giatec Scientific, Ottawa, ON, Canada).

The test configuration of the NT-Build 492 is shown in

Figure 3. In this case, a 0.3 N NaOH solution was placed into the anode (on top of specimen) and 10% NaCl solution was poured into the cathode (outside container). The test was conducted using PROOVE’IT (Germann Instruments, Copenhagen, Denmark). A 30 V (DC ± 30 V) voltage was applied to the cell and the initial current amount was measured. The voltage for the overall measurement was adjusted according to the recommendation in NT-Build 492. The results from the initial current measurements (at 30 V) and adjusted voltage values that were used for the overall measurement are summarized in

Table 3. The test was conducted for a total of 24 h after the initial measurement process was completed.

To measure the penetration depth of chloride ions, the tested specimen (by NT-Build 492) was split into two pieces using a compression testing machine after the test was completed. A 0.1 M silver nitrate solution was sprayed onto the surface of the split specimen. In this case, the free chloride ions present inside the base concrete react with silver nitrate to form insoluble silver chloride (silver color), making it easier to measure the penetration depth of chloride ion. The average penetration depth was used to calculate the diffusivity of chloride ion by Equation (2).

where,

Dnssm: non-steady-state migration coefficient (×10

−12 m

2/s),

U: absolute value of applied voltage (V),

T: average value of initial and final temperatures in the anolyte solution (°C),

L: thickness of the specimen (mm),

xd: average value of the penetration depths (mm), and

t: test duration (h), respectively.

3. Results and Discussion

3.1. Compressive Strength

Figure 4 shows the compressive strengths of 28-day old base concrete containing hybrid fibers. When the vol% of the hybrid fibers was 0.54%, there was no significant correlation on compressive strength with the amount of polyolefin fiber in the hybrid fiber. In the case of 0% polyolefin fibers (100% steel fibers), the compressive strength was 48.99 MPa. The strength reduced to 41.24 MPa in the case of 25% polyolefin fibers (75% steel fibers). However, at 50% polyolefin fibers (steel fibers 50%), polyolefin fibers 75% (steel fiber 25%), and polyolefin fiber 100% (steel fiber 0%), the compressive strengths increased to 48.07 MPa, 48.43 MPa, and 50.69 MPa, respectively. At 0.54% fiber content, the ratio between polyolefin and steel fiber does not significantly affect the compressive strength of base concrete.

When the vol% of base concrete increased to 1.08%, a clear correlation on compressive strength on the amount of polyolefin fiber in the hybrid fiber was observed. As the amount of polyolefin fiber in the hybrid fiber increased, the 28-day compressive strength of base concrete generally decreased. The compressive strength of base concrete with 0% polyolefin fiber (100% steel fiber) was 56.20 MPa and decreased to 55.53 MPa, 52.18 MPa, and 46.39 MPa, as the volume proportion of polyolefin fiber increased from 25%, 50%, and 75%, respectively. The compressive strength of the base concrete with 100% polyolefin showed higher compressive strength (51.07 MPa) than the base concrete with 75% polyolefin fiber (46.39 MPa).

Base concrete with a higher amount of fiber showed a higher compressive strength up to 50% of replacement with polyolefin fiber. When the volume proportion of polyolefin fiber was 75%, the compressive strength did not show any difference as the volume of fiber increased. This indicates that polyolefin fibers contribute much less to the compressive strength than steel fibers. Taking this finding into consideration, in terms of compressive strength, the amount of polyolefin fiber should not exceed 50% for successful hybridization of steel and polyolefin fibers.

3.2. Flexural Strength

Figure 5 shows the flexural strengths of 28-day old base concrete. When the vol% of hybrid fiber was 0.54%, the flexural strength generally decreased as the volume proportion of polyolefin fiber increased. With 0% polyolefin fiber (100% steel fiber), the flexural strength of the base concrete was 7.1 MPa. As the volume proportion of polyolefin fiber increased to 25%, the flexural strength of the base concrete decreased to 6.38 MPa. The flexural strengths of base concrete with 50% and 75% polyolefin fiber slightly increased to 6.72 and 6.74 MPa, respectively, but it was still less than that with 0% polyolefin fiber. The flexural strength of the base concrete with 100% polyolefin fiber (0% steel fiber) was 5.85 MPa, showing the lowest flexural strength.

In the case of base concrete with a fiber content of 1.08 vol%, the flexural strength of base concrete was 7.92 MPa for 0% of polyolefin fiber and increased to 8.55 and 8.56 MPa as the incorporation ratio of polyolefin fiber increased to 25% and 50%, respectively. A synergetic effect was observed up to 50% polyolefin fiber replacement although there was some level of standard deviation in the flexural strength data. An interpretation of such a result is that, at a total fiber content of 1.08%, a steel fiber ratio up to 50% did not decrease the flexural strength as much, and some contribution from the polyolefin fiber was present to increase the flexural strength. When the amount of polyolefin fiber exceeded 75%, a considerable drop in flexural strength was observed. The flexural strengths of base concrete with 75% and 100% polyolefin fiber were 6.78 and 6.32 MPa, respectively.

The flexural strength generally increased as the total volume of fiber increased up to 50% of polyolefin fiber reinforcement. When the amount of polyolefin fiber was 75%, the differences in the flexural strengths with an increase in the total amount of fiber were considerably reduced. This phenomenon was identical to the case of compressive strength, indicating that polyolefin fiber also contributes much less to flexural strength than steel fiber. Consequently, considering the data obtained from the compressive strength and flexural strength, it was confirmed that the amount of polyolefin fiber should not exceed 50% of replacement when designing optimal proportions of hybrid fiber composed of steel and polyolefin fiber.

3.3. Flexural Load-Deflection Behavior

Figure 6 shows the flexural load-deflection curves of the base concrete containing steel and polyolefin fibers at fiber contents of 0.54% and 1.08%, respectively. At a fiber content of 0.54%, a large drop in deflection was observed after maximum peak load. However, in the case of 1.08% fiber content, even when 100% polyolefin fiber was used, there was a recovery of the load after the first decrease in the load, which indicated considerable toughness could be secured by addition of fiber.

The load-deflection curve of the base concrete with 100% steel fiber showed gradual decrease after the peak load. In case of base concrete with 100% polyolefin fiber, a rapid drop was observed after the peak, but an intensive load recovery was also observed after the rapid drop. As the volume proportion of polyolefin fiber increased to 25%, 50%, and 75%, the base concrete showed a considerable increase in flexural toughness. This phenomenon was observed for both fiber contents (0.54 and 1.08 vol%), but the trend was more evident in the case of 1.08 vol%.

When steel and polyolefin fiber were hybridized, the positive effects seemed to be combined. As a result, the base concrete showed higher load carrying capability. For example, in the case of 50% replacement with polyolefin fiber at 1.08 vol%, the load continued to increase after the first crack and sustained a similar level of the load until the termination of the test. The advantages that can be obtained from each of the fibers, (1) higher peak load from steel fiber and (2) load recovery from polyolefin fiber, seemed to combine and show a synergetic effect. Such an effect was also observed at a fiber content of 0.54 vol%, but it was not as synergetic as at the fiber content of 1.08 vol%. In general, hybridization of steel and polyolefin fibers provided higher peak load as well as higher capability to sustain the load after the breakage of the concrete. However, the fact that the flexural toughness of the test specimen with 100% steel fiber ratio was observed as being rather low is somewhat contrary to the predicted result. It is thought that some problems occurred with the agglomeration or dispersion between the fibers in the specimen.

3.4. Flexural Toughness

Figure 7 shows the flexural toughness of 28-day old base concrete with hybrid fibers. When the fiber content was 0.54%, the increase in the volume proportion of polyolefin fiber clearly decreased the flexural toughness of the base concrete. With 0% polyolefin fiber, the flexural toughness was 99.16 kN·mm, and decreased to 85.34 kN·mm, 78.49 kN·mm, 80.05 kN·mm, 70.58 kN·mm, as the volume proportion of polyolefin fiber increased to 25%, 50%, 75%, and 100%, respectively. This means that, as in the case of flexural strength at a fiber content of 0.54 vol%, the amount of steel fiber has a more significant influence on the flexural behavior of the base concrete.

As fiber content increased from 0.54% to 1.08%, the flexural toughness of the base concrete increased. Similar to the case of flexural strength, a synergetic effect was observed by hybridization of the steel and polyolefin fibers. The synergetic effect seems to be associated with the increase in the amount of polyolefin fiber because the flexural toughness of the base concrete with 100% polyolefin fiber (137.94 kN·mm) was higher than that with 100% steel fiber (123.53 kN·mm). Due to the higher contribution of polyolefin fiber to flexural toughness, the flexural toughness of the concrete increased to 123.53 kN·mm, 170.18 kN·mm, and 179.11 kN·mm, as the volume proportion of polyolefin fiber increased from 0%, 25%, to 50%, respectively. At 75% and 100% with polyolefin fiber, flexural toughness was reduced to 138.15 kN·mm and 137.94 kN·mm, but these values were still higher than that with 100% steel fiber.

Considering these findings, the synergetic effect starts to occur after the necessary amount of fiber is incorporated into the base concrete. The synergetic effect was maximized at 50% steel fiber and 50% polyolefin fiber hybridization. It should be noted that the aspect ratio of the fiber is a very important factor, so that the fiber content and hybrid proportion where the synergetic effect occurs may change as fibers with different aspect ratios are used.

3.5. Chloride Ion Penetration Resistance and Chloride Ion Diffusion

Table 4 presents the average value of charge passed obtained from the ASTM C 1202 test procedure. Regardless of the fiber content, the amount of charge passed decreased as the volume proportion of polyolefin fiber increased. It should be noted that there were some cases of test termination due to the excessive current flow from the specimen. These cases were more evident from specimens with higher steel fiber content (lower polyolefin fiber content).

The higher charge passed values observed here were directly related to the electrical conductivity of steel fiber [

10]. This is because (1) the same base concrete mix design was used, (2) the increase in charge passed is solely related to the increase in the amount of steel fiber in the base concrete, and (3) the average charge passed value of base concrete with 100% polyolefin fiber did not show clear differences with the increase in fiber volume. This proves that the rapid ASTM C 1202 test procedure, which uses 60 V voltage difference, cannot be applied to evaluate the chloride ion penetration resistance of concrete that contains material with higher electrical conductivity.

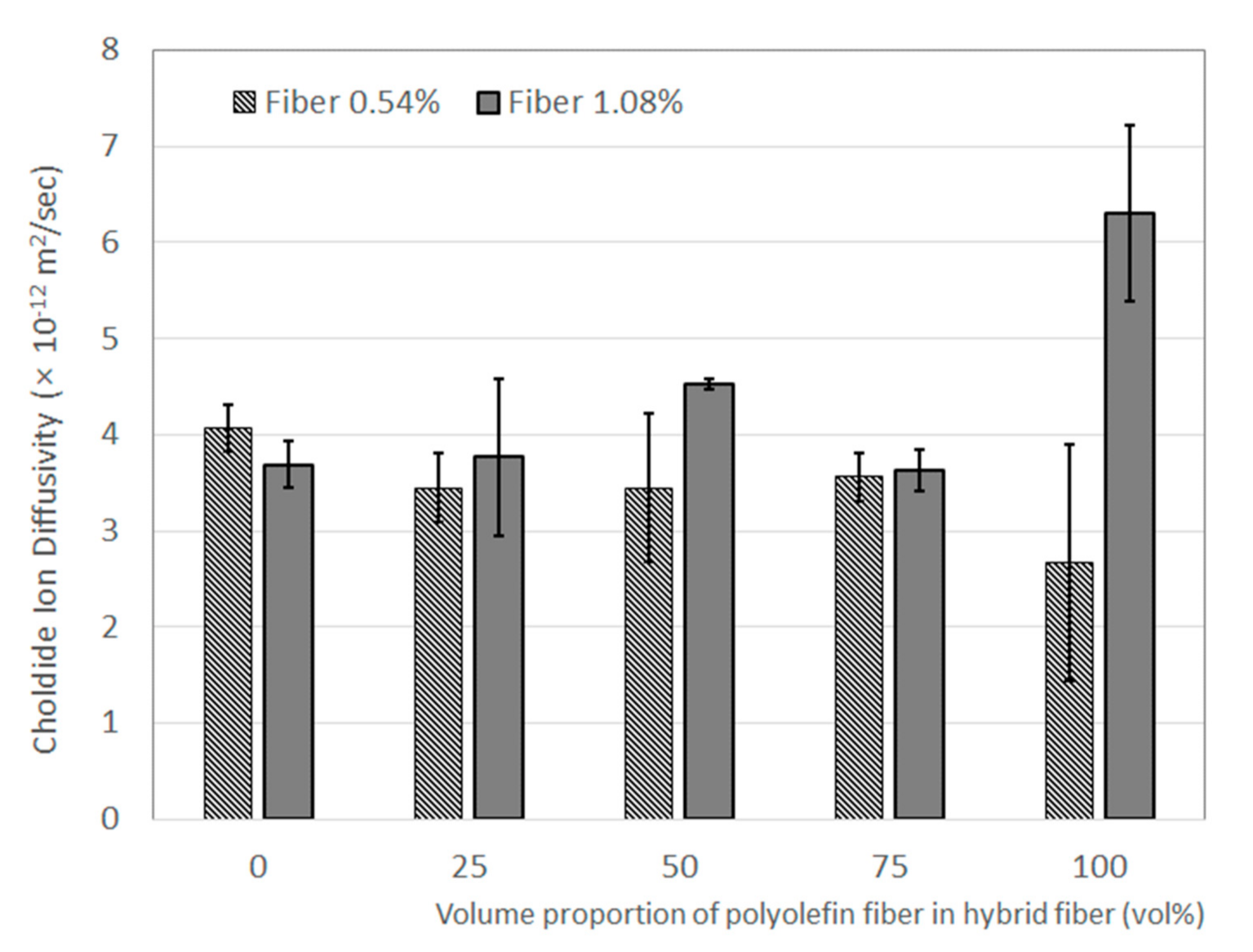

To complement the results of the ASTM C 1202 test method, the NT-Build 492 test procedure was performed, and the results are presented in

Figure 8. As mentioned earlier, the setting of the measurement voltage for the NT-Build 492 test was determined by the initial current value (

Table 3) of the base concrete. The test was performed at higher voltage with 0.54% fiber content. As the fiber content increased from 0.54% to 1.08%, the initial current from the base concrete increased, and thus the test had to be performed at relatively lower voltage. As a result, the NT-Build 492 test procedure is much less affected by the presence of conductive material in the concrete because a lower voltage can be used.

Figure 8 shows the chloride ion diffusivity of the base concrete with hybrid fibers. When the total fiber amount was 0.54%, the chloride ion diffusivity gradually decreased as the volume proportion of polyolefin fiber increased. On the contrary, in the case of a fiber content at 1.08 vol%, as the volume proportion of polyolefin fiber increased, the chloride ion diffusivity generally increased. The base concrete with 100% polyolefin fiber showed relatively higher chloride ion diffusivity than the other base concrete specimens. This seems to be associated with the agglomeration or arrangement of fibers within the specimen. Overall, the chloride ion diffusion coefficient values ranged from 2.67 to 6.30 × 10

−12 m

2/s, indicating a significant degree of salt resistance when using the combination.