Optimization Design of Extrusion Roller of RP1814 Roller Press Based on ANSYS Workbench

Abstract

:1. Introduction

2. Force Analysis of Extrusion Roller of RP1814 Roller Press

2.1. Interference Connection of Extrusion Roller

2.2. Extrusion Force of Extrusion Roller

3. Finite Element Analysis of Extrusion Roller

3.1. Establishment of Finite Element Model

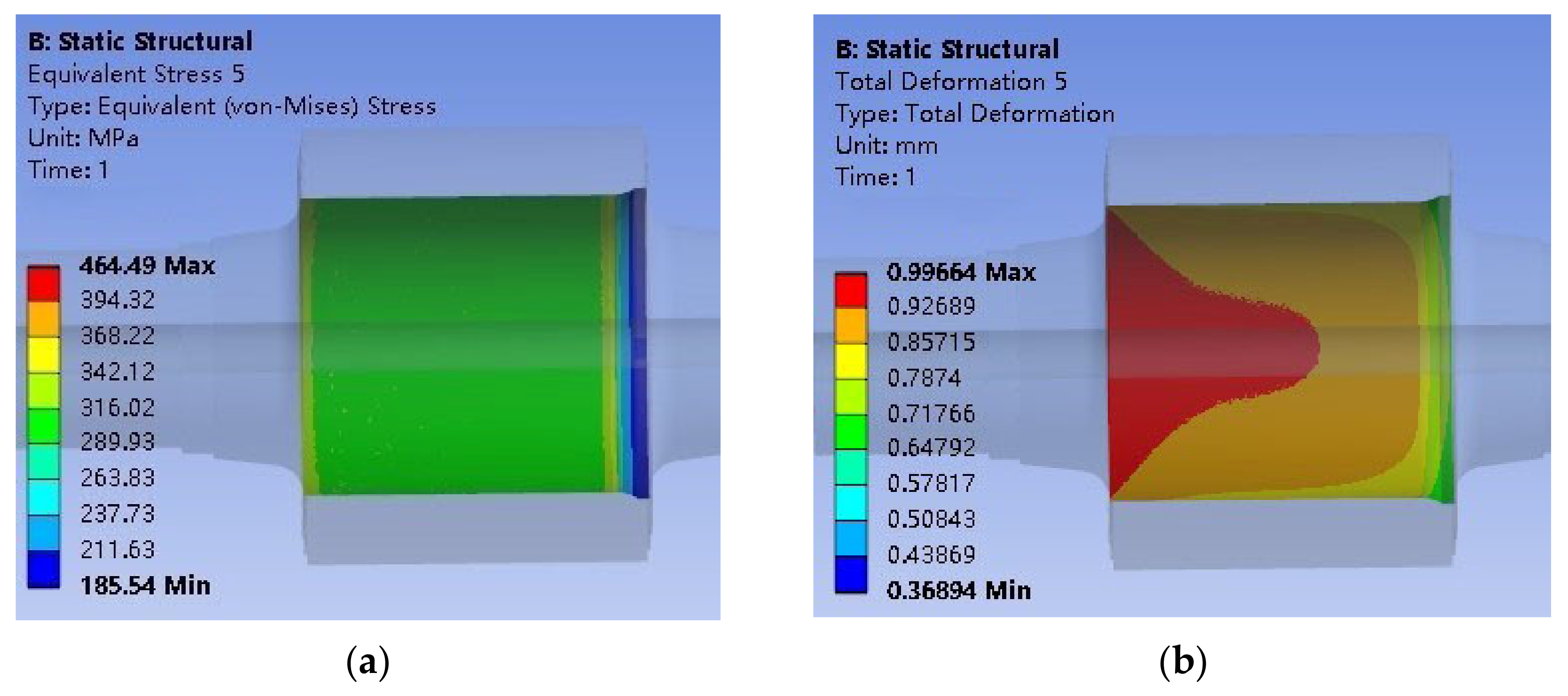

3.2. Static Analysis of Extrusion Roller

4. Initial Optimization Design of Extrusion Roller

4.1. Initial Optimization Scheme

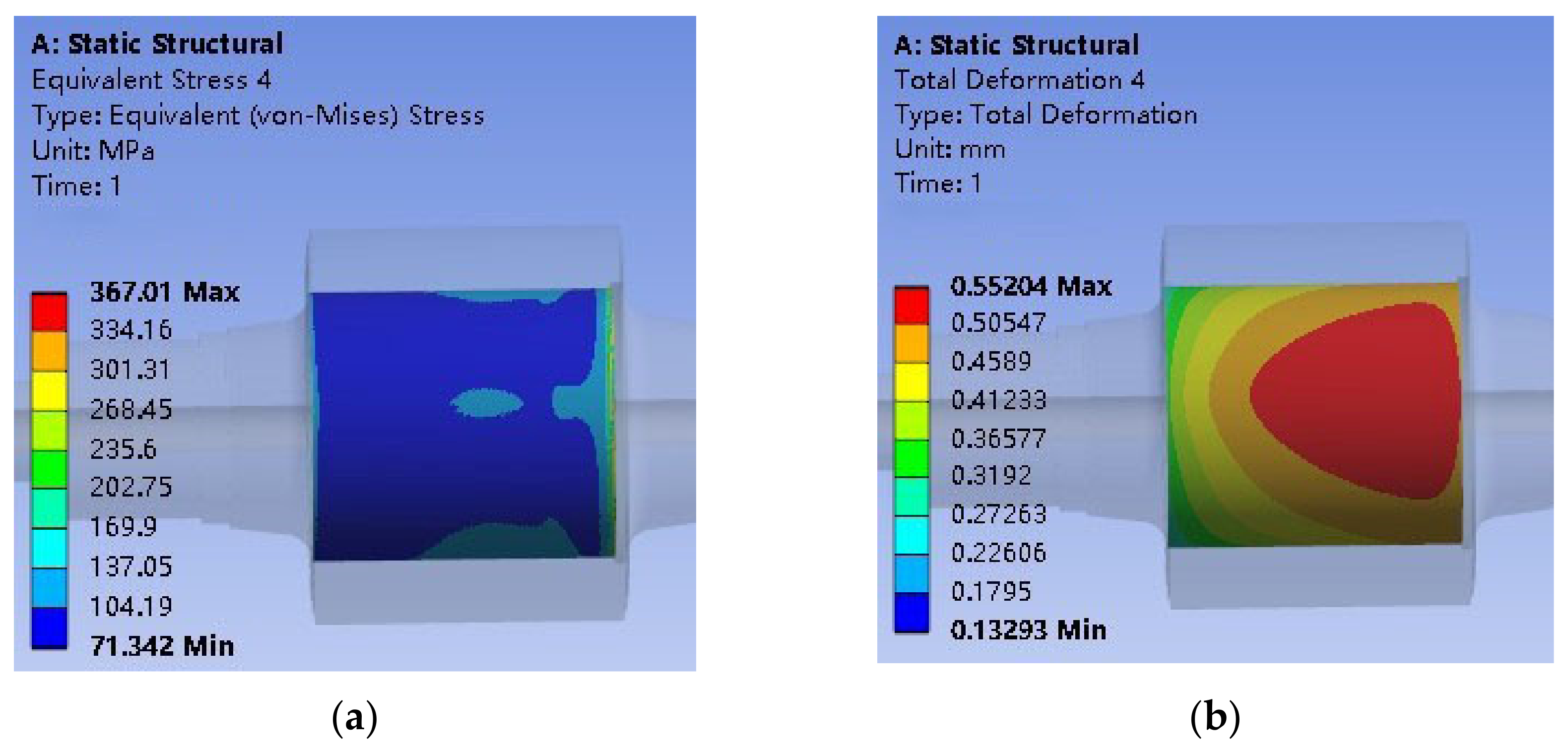

4.2. Analysis of Results of Initial Optimization

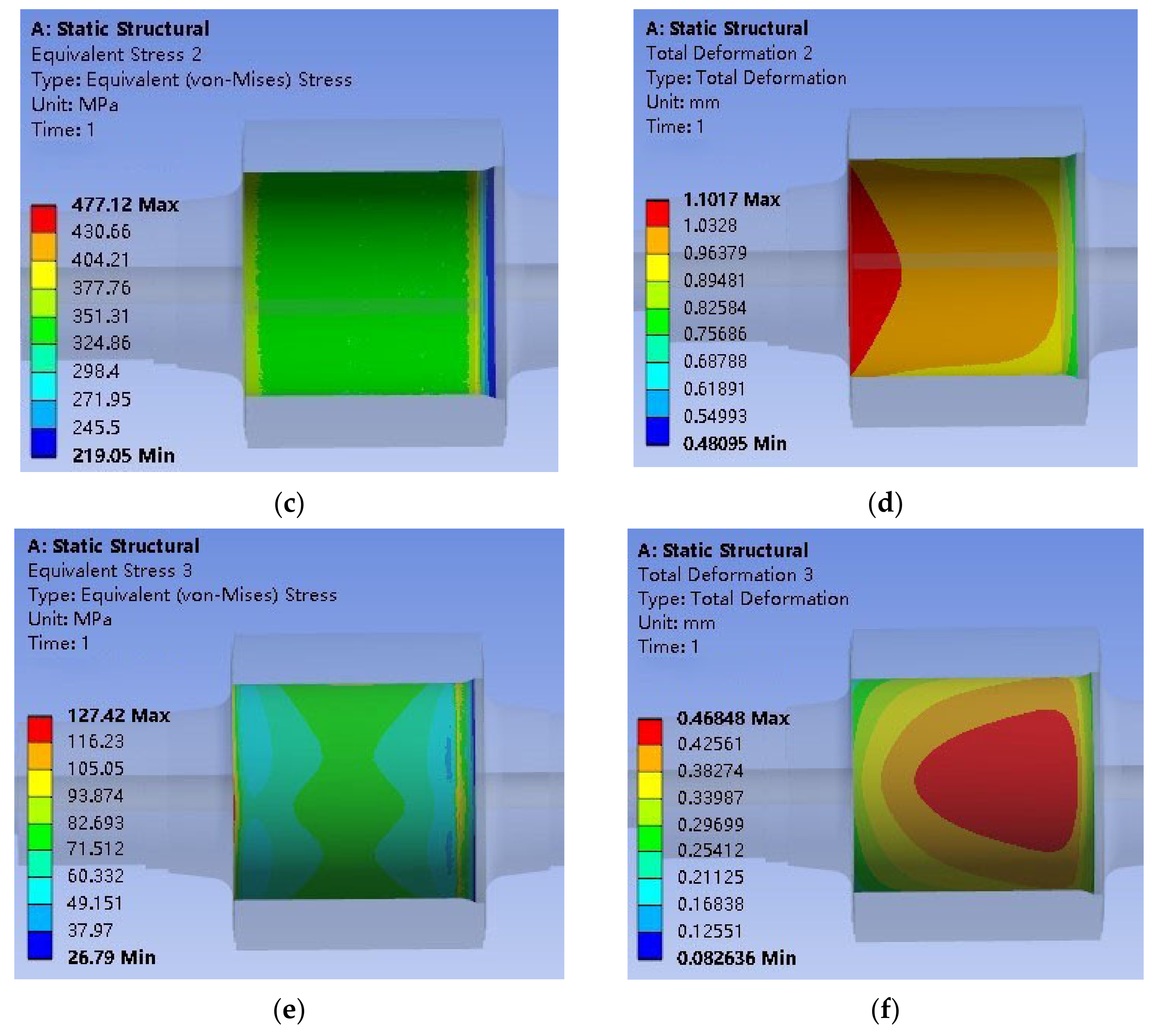

5. Further Optimization Based on Direct Optimization Module

5.1. Design Parameters of Extrusion Roller

- (1)

- Design variable: The design variables of extrusion roller optimization design are x1 and x2.x1: Length of transition arc at contact step between roller shaft and roller sleeve; the initial value is 85 mm.x2: Transition arc radius at the contact step between roller shaft and roller sleeve; the initial value is 157 mm.Constrain the size range of each design variable: 85 mm ≤ x1 ≤ 95 mm, 157 mm ≤ x2 ≤ 193 mm.After selecting the design variables of direct optimization design of extrusion roller and constraining each design variable, the design variables can be expressed as vectors:

- (2)

- Optimization objectives: Under the premise of meeting the structural strength, the maximum equivalent stress of the roller sleeve is set at the minimum value of the objective function. Therefore, when optimizing the length and radius of the transition arc, the maximum equivalent stress is taken as the objective function of the direct optimization design of the extrusion roller. The objective function is expressed by the size parameters as follows:

- (3)

- Constraint conditions: When setting the optimal design constraint conditions, the strength of the extrusion roller must meet the stress constraint conditions. The maximum equivalent stress of the optimized extrusion roller must not exceed the allowable stress of the material. Therefore, the strength constraints to be met are as follows:

- (4)

- Set candidate points: Select the best result of candidate points as the current point and substitute it into the model for calculation. Finally, the feasibility of the model is confirmed.

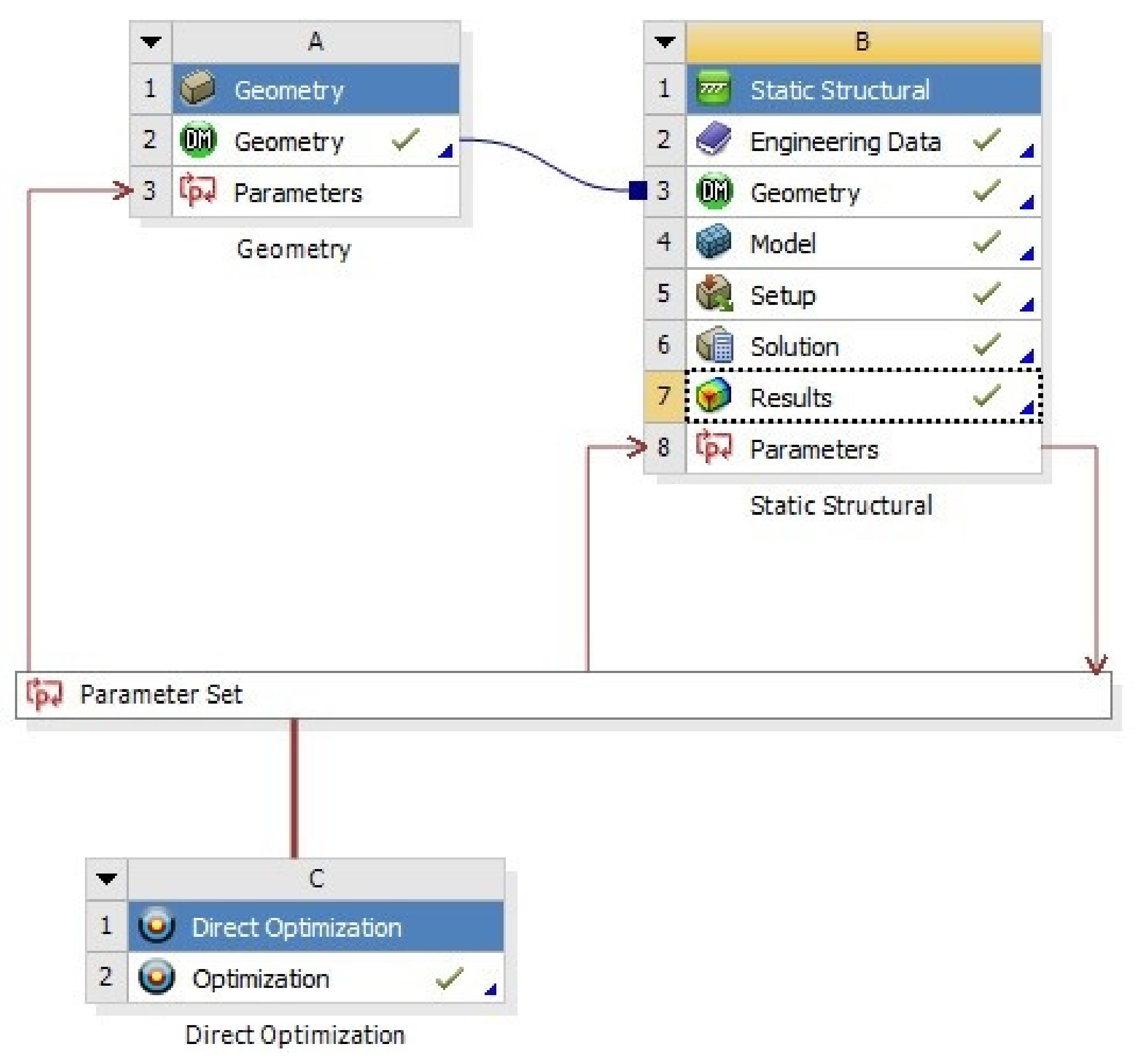

5.2. Analysis of the Further Optimization Results

6. Conclusions

- (1)

- Under actual working conditions, the extrusion roller is mainly affected by the contact stress between the roller shaft and the roller sleeve, and the extrusion force between the roller sleeve and the material. Based on the compression and rebound characteristics of the material, the extrusion pressure on the surface of the extrusion roller is calculated, and the normal direction stress pγ(α,λ) = 102.05 MPa and the tangential stress p𝜏(α,λ) = 2.31 MPa.

- (2)

- According to the finite element analysis results of the extrusion roller, the maximum deformation of the extrusion roller occurs at the non-stepped end of the inner ring of the roller sleeve, and the value is 1.379 mm. The maximum equivalent stress of the extrusion roller is located at the step of the contact surface between the roller sleeve and the roller shaft, and the value is 651.03 MPa. The maximum stress is on the brink of the allowable yield strength of the roller sleeve, so it is necessary to optimize the design.

- (3)

- The initial optimization of the extrusion roller structure is carried out by the method of size optimization, and the scheme of setting the transition arc at the step of the contact surface between the roller shaft and the roller sleeve is proposed. The simulation results show that the maximum equivalent stress is reduced by 26%, and the maximum deformation is decreased by 20%, which initially achieves the purpose of improving the structural strength and reducing the deformation. However, the decreasing trend of the maximum equivalent stress in the optimization scheme did not stop, and the transition arc parameters can still be refined and optimized further.

- (4)

- The extrusion roller is further optimized by using the Direct Optimization module of ANSYS Workbench to obtain the optimal solution of the transition arc. By comparing the data before and after optimization, the contact stress of extrusion roller is reduced by 17%, the contact sliding distance is decreased by 83%, the maximum equivalent stress is reduced by 29%, and the maximum deformation is decreased by 28%. This scheme is expected to improve the bearing capacity of the extrusion roller, reduce the production cost of the roller press, and provide a reference basis for the design of the extrusion roller.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Esnault, V.; Michrafy, A.; Heitzmann, D.; Michrafy, M.; Oulahna, D. Processing fine powders by roll press. Powder Technol. 2015, 270, 484–489. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Zhang, Z.; Yang, H.; Wang, S. Fatigue and fracture failure analysis of a twin-roll press. Eng. Fail. Anal. 2018, 90, 585–596. [Google Scholar] [CrossRef]

- Cheng, X.; Liu, J.; Ding, Q.; Song, L.; Wang, Z. Simulation on Extrusion Comminution Model of Roller Press. In Advanced Materials Research, Proceedings of the 2010 International Conference on Advances in Materials and Manufacturing Processes, ICAMMP 2010, Shenzhen, China, 6–8 November 2010; Trans Tech Publications: Shenzhen, China, 2011; pp. 1702–1707. [Google Scholar] [CrossRef]

- Xi, P.; Cong, Q.; Teng, F.; Guo, H. Design and experiment of bionics pit shape grinding roller for improving wear resistance and crushability. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2018, 34, 55–61. [Google Scholar] [CrossRef]

- Zhang, Y.; McClain, B.; Fang, X.D. Design of interference fits via finite element method. Int. J. Mech. Sci. 2000, 42, 1835–1850. [Google Scholar] [CrossRef]

- Muliadi, A.R.; Litster, J.D.; Wassgren, C.R. Modeling the powder roll compaction process: Comparison of 2-D finite element method and the rolling theory for granular solids (Johanson’s model). Powder Technol. 2012, 221, 90–100. [Google Scholar] [CrossRef]

- Bao, J.-H.; Wang, Y.; Cai, J. The Temperature Field Analysis about the Thermal Assembly Process of the Roller Sleeve of HFCG160 Roller Press. In Applied Mechanics and Materials, Proceedings of the 2014 4th International Conference on Mechanical Science and Engineering, ICMSE 2014, Sanya, Hainan Island, China, 2–4 January 2014; Trans Tech Publications Ltd.: Sanya, China, 2014; pp. 131–135. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, G.; Xue, Y.; Li, J. Finite Element Simulation and Analysis to Strength of Roller of Roller Mill. Min. Process. Equip. 2007, 35, 100–102. (In Chinese) [Google Scholar]

- Peral, L.B.; Zafra, A.; Belzunce, J.; Rodriguez, C. Effects of hydrogen on the fracture toughness of CrMo and CrMoV steels quenched and tempered at different temperatures. Int. J. Hydrog. Energy 2019, 44, 3953–3965. [Google Scholar] [CrossRef]

- Jiang, J.F.; Bi, Y.B. An Elastic-Plastic Analysis of Interference Fit Connection. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 2nd International Workshop on Materials Science and Mechanical Engineering, IWMSME 2018, Qingdao, China, 26–28 October 2018; IOP Publishing Ltd: Qingdao, China, 2019; p. 012071. [Google Scholar] [CrossRef]

- Yu, J.; Teng, Y.; Chu, X. Stress Analysis of Interference Fit of Roller for Roller Press Based on ANSYS Workbench. Cem. Technol. 2015, 1, 38–40. (In Chinese) [Google Scholar] [CrossRef]

- Hyodo, M.; Wu, Y.; Aramaki, N.; Nakata, Y. Undrained monotonic and cyclic shear response and particle crushing of silica sand at low and high pressures. Can. Geotech. J. 2017, 54, 207–218. [Google Scholar] [CrossRef]

- Wei, W.; Peng, Y.; Du, L.; Cai, Y. Design and mechanical behavior analysis of two-stall cement rotary kiln cylinder. Int. J. Perform. Eng. 2020, 16, 883–895. [Google Scholar] [CrossRef]

- Frohlich, B.; Gade, J.; Geiger, F.; Bischoff, M.; Eberhard, P. Geometric element parameterization and parametric model order reduction in finite element based shape optimization. Comput. Mech. 2019, 63, 853–868. [Google Scholar] [CrossRef]

- Chen, J.; Fu, Y.; Qian, N.; Ching, C.Y.; Ewing, D.; He, Q. A study on thermal performance of revolving heat pipe grinding wheel. Appl. Therm. Eng. 2021, 182, 116065. [Google Scholar] [CrossRef]

- Jensen, W.A. Open problems and issues in optimal design. Qual. Eng. 2018, 30, 583–593. [Google Scholar] [CrossRef]

- Zheng, W.; Sun, J.; Niu, T.; Ma, C.; Yu, Q.; Zhang, Y. Structural Optimization and Heat Transfer Performance Analysis of a Cone-Column Combined Heat Sink. J. Heat Transf. 2020, 142, 004504. [Google Scholar] [CrossRef]

- Shi, L.; Chen, Y. A Multi-Objective Genetic Algorithm Based on Objective-Layered to Solve Network Optimization Design. In International Conference on Information Science and Control Engineering, Proceedings of the 4th International Conference on Information Science and Control Engineering, ICISCE 2017, Changsha, Hunan, China, 21–23 July 2017; Institute of Electrical and Electronics Engineers Inc.: Changsha, China, 2017; pp. 55–59. [Google Scholar] [CrossRef]

- Zhao, J.; Ma, C.; Hu, L. Lightening Structure Optimization of Turbine Wheel of Vehicular Turbocharger. Chin. Intern. Combust. Engine Eng. 2008, 29, 48–51. [Google Scholar] [CrossRef]

| Material | Density ρ (kg/m3) | Elastic Modulus E (Pa) | Poisson’s Ratio μ | Yield Strength σs (MPa) |

|---|---|---|---|---|

| 42CrMo | 7850 | 2.12 e11 | 0.280 | 930 |

| 34CrNiMoA | 7850 | 2.10 e11 | 0.275 | 835 |

| Group | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| L (mm) | 25 | 35 | 45 | 55 | 65 | 75 | 85 |

| R (mm) | 25 | 37 | 53 | 73 | 97 | 125 | 157 |

| σmax (MPa) | 579.87 | 585.32 | 589.87 | 565.32 | 518.71 | 490.59 | 477.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, W.; Peng, F.; Li, Y.; Chen, B.; Xu, Y.; Wei, Y. Optimization Design of Extrusion Roller of RP1814 Roller Press Based on ANSYS Workbench. Appl. Sci. 2021, 11, 9584. https://doi.org/10.3390/app11209584

Wei W, Peng F, Li Y, Chen B, Xu Y, Wei Y. Optimization Design of Extrusion Roller of RP1814 Roller Press Based on ANSYS Workbench. Applied Sciences. 2021; 11(20):9584. https://doi.org/10.3390/app11209584

Chicago/Turabian StyleWei, Weihua, Fangxu Peng, Yingli Li, Bingrui Chen, Yiqi Xu, and Yu Wei. 2021. "Optimization Design of Extrusion Roller of RP1814 Roller Press Based on ANSYS Workbench" Applied Sciences 11, no. 20: 9584. https://doi.org/10.3390/app11209584

APA StyleWei, W., Peng, F., Li, Y., Chen, B., Xu, Y., & Wei, Y. (2021). Optimization Design of Extrusion Roller of RP1814 Roller Press Based on ANSYS Workbench. Applied Sciences, 11(20), 9584. https://doi.org/10.3390/app11209584