A Computational Study on the Aeroacoustics of a Multi-Rotor Unmanned Aerial System

Abstract

:1. Introduction

2. Materials and Methods

2.1. CFD Method

2.2. Acoustics Method

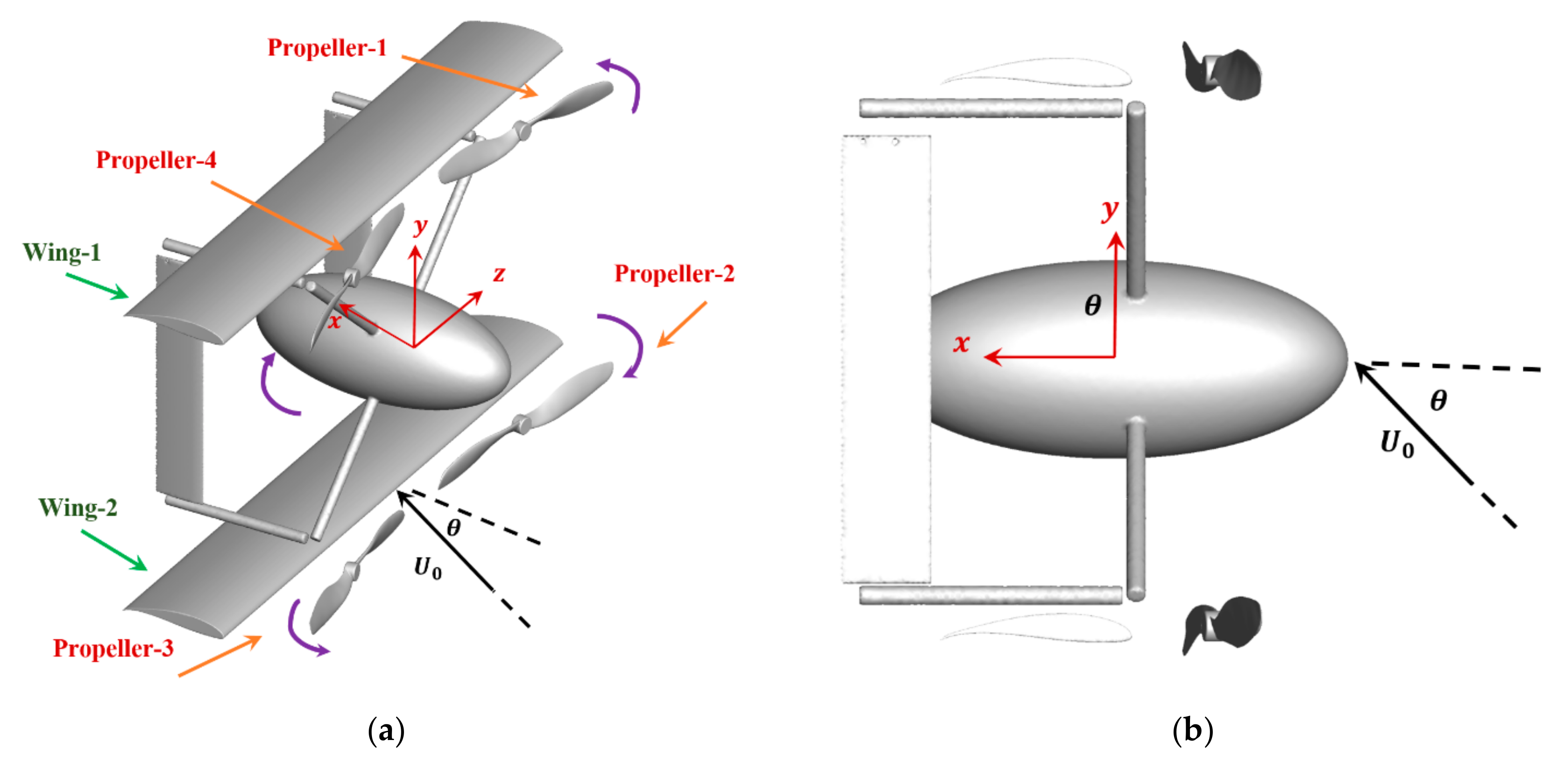

2.3. CRC-3 Geometry

2.4. Simulation Conditions

2.5. Computational Domain, Grids, and Boundary Conditions

2.6. Grid Verification Study

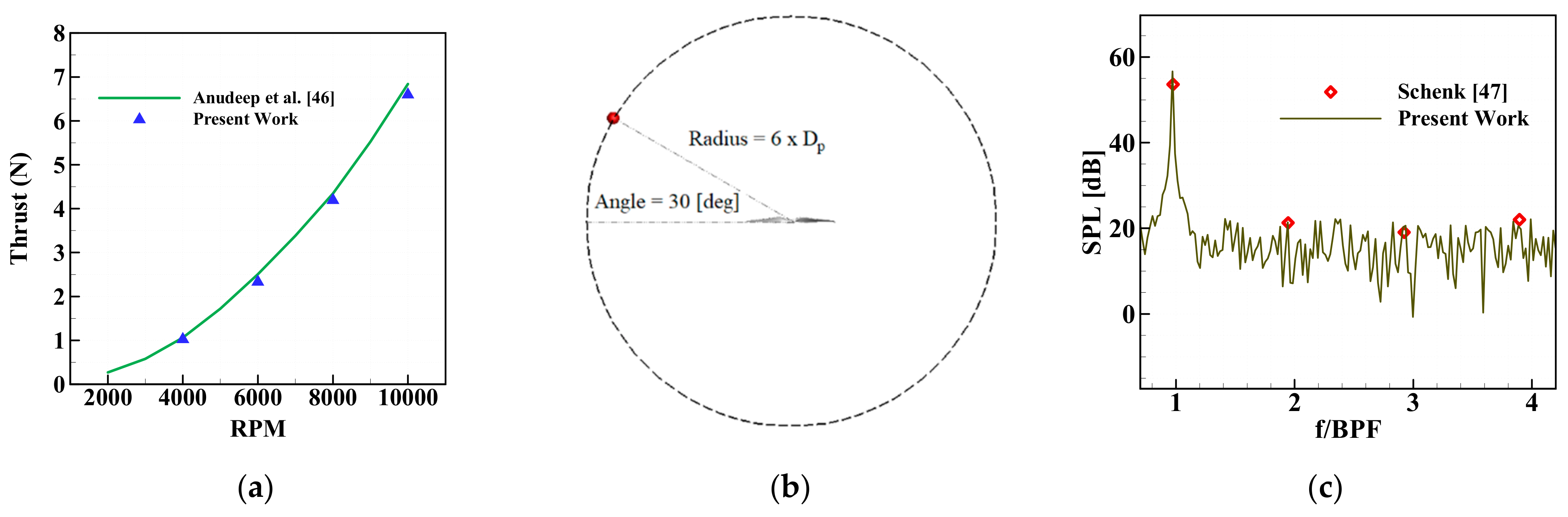

2.7. Validation

3. Results and Discussion

3.1. Sound Pressure Level

3.1.1. Interaction Effects

3.1.2. Effect of Pitch

3.1.3. Effect of Velocity and RPM

3.1.4. Noise on the Wings and Fuselage

3.2. Local Flow

3.2.1. Noise Sources

3.2.2. Level of Unsteadiness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Phillips, B.; Hrishikeshavan, V.; Rand, O.; Chopra, I. Design and development of a scaled quadrotor biplane with variable pitch proprotors for rapid payload delivery. Annu. Forum Proc. AHS Int. 2016, 1, 302–315. [Google Scholar]

- Reddinger, J.-P.; McIntosh, K.; Zhao, D.; Mishra, S. Modeling and Trajectory Control of a Transitioning Quadrotor Biplane Tailsitter. In Proceedings of the Vertical Flight Society 75th Annual Forum, Philadelphia, PA, USA, 13–16 May 2019. [Google Scholar]

- Avera, M.; Singh, R. Scalability of Hybrid-Electric Propulsion for VTOL UAS. In Proceedings of the NATO Research Symposium on Hybrid/Electric Aero-Propulsion Systems for Military Applications, Trondheim, Norway, 7–9 October 2019. AVT-RSY-323. [Google Scholar]

- Nyadanu, S.D.; Tessema, G.A.; Mullins, B.; Kumi-Boateng, B.; Bell, M.L.; Pereira, G. Ambient Air Pollution, Extreme Temperatures and Birth Outcomes: A Protocol for an Umbrella Review, Systematic Review and Meta-Analysis. Int. J. Environ. Res. Public Health 2020, 17, 8658. [Google Scholar] [CrossRef] [PubMed]

- Van Kempen, E.; Casas, M.; Pershagen, G.; Foraster, M. WHO environmental noise guidelines for the European region: A systematic review on environmental noise and cardiovascular and metabolic effects: A summary. Int. J. Environ. Res. Public Health 2018, 15, 379. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Clark, C.; Crumpler, C.; Notley, H. Evidence for environmental noise effects on health for the United Kingdom policy context: A systematic review of the effects of environmental noise on mental health, wellbeing, quality of life, cancer, dementia, birth, reproductive outcomes, and cognition. Int. J. Environ. Res. Public Health 2020, 17, 393. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ditmer, M.A.; Vincent, J.B.; Werden, L.K.; Tanner, J.C.; Laske, T.G.; Iaizzo, P.A.; Garshelis, D.L.; Fieberg, J.R. Bears show a physiological but limited behavioral response to unmanned aerial vehicles. Curr. Biol. 2015, 25, 2278–2283. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Torija, A.J.; Clark, C. A psychoacoustic approach to building knowledge about human response to noise of Unmanned Aerial Vehicles. Int. J. Environ. Res. Public Health 2021, 18, 682. [Google Scholar] [CrossRef] [PubMed]

- Brocklehurst, A.; Barakos, G.N. A review of helicopter rotor blade tip shapes. Prog. Aerosp. Sci. 2013, 56, 35–74. [Google Scholar] [CrossRef]

- Wang, Z.; Pandey, A.; Sutkowy, M.; Harter, B.; McCrink, M.; Gregory, J.W.; Zhuang, M.A. A comprehensive approach to study aerodynamic and aeroacoustic performances of small multicopter unmanned aerial systems. In Community and UAV Noise, Proceedings of 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018; American Institute for Aeronautics and Astronautics: Reston, VA, USA, 2018; Volume 1, p. 1. [Google Scholar]

- Henricks, Q.M. Computational Aerodynamic and Aeroacoustic Study of Small-Scale Rotor Geometries; The Ohio State University: Columbus, OH, USA, 2019. [Google Scholar]

- Boltezar, M.; Mesaric, M.; Kuhelj, A. The influence of uneven blade spacing on the SPL and noise spectra radiated from radial fans. J. Sound Vib. 1998, 216, 697–711. [Google Scholar] [CrossRef]

- Cattanei, A.; Ghio, R.; Bongiovı, A. Reduction of the tonal noise annoyance of axial flow fans by means of optimal blade spacing. Appl. Acoust. 2007, 68, 1323–1345. [Google Scholar] [CrossRef]

- Floros, M.W. Performance and Acoustics of Small Rotors with Non-Uniform Blade Spacing. In Proceedings of the Vertical Flight Society’s 75th Annual Forum & Technology Display, Philadelphia, PA, USA, 13–16 May 2019. [Google Scholar]

- Uehara, D.; Sirohi, J. Quantification of Swirl Recovery in a Coaxial Rotor System. In Proceedings of the American Helicopter Society 73rd Annual Forum, Fort Worth, TX, USA, 9–11 May 2017. [Google Scholar]

- Bhagwat, M. Co-rotating and Counter-rotating Coaxial Rotor Performance. In Proceedings of the AHS Aeromechanics Design for Transformative Vertical Flight, San Francisco, CA, USA, 16–18 January 2018. [Google Scholar]

- Misiorowski, M.; Gandhi, F.; Anusonti-Inthra, P. Comparison of Acoustic Predictions Using Distributed and Compact Airloads. In Proceedings of the Vertical Flight Society’s 75th Annual Forum & Technology Display, Philadelphia, PA, USA, 13–16 May 2019. [Google Scholar]

- Yang, Y.; Liu, Y.; Li, Y.; Arcondoulis, E.; Wang, Y. Aerodynamic and aeroacoustic performance of an isolated multicopter rotor during forward flight. AIAA J. 2020, 58, 1171–1181. [Google Scholar] [CrossRef]

- Kloet, N.; Watkins, S.; Wang, X. Aeroacoustic investigation of multirotor unmanned aircraft system (UAS) propellers and the effect of support structure. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference, Madrid, Spain, 16–19 June 2019; pp. 3329–3340. [Google Scholar]

- Pandey, A.P. Investigation of Propeller Characteristics at Low Reynolds Number with an Angle of Attack: A Computational Aeroacoustic Study; Delft University of Technology: Delft, The Netherlands, 2021. [Google Scholar]

- Glegg, S.; Devenport, W. Aeroacoustics of Low Mach Number Flows: Fundamentals, Analysis, and Measurement; Elsevier Academic Press: London, UK, 2017. [Google Scholar]

- Intaratep, N.; Alexander, W.N.; Deveport, W.J.; Grace, S.M.; Dropkin, A. Experimental study of quadcopter acoustics and performance at static thrust conditions. In Propeller and Rotor Noise I, Proceedings of the 22nd AIAA/CEAS Aeroacoustics Conference, Lyon, France, 30 May–1 June 2016; American Institute for Aeronautics and Astronautics: Reston, VA, USA, 2016. [Google Scholar] [CrossRef] [Green Version]

- Unruh, J.F. Installation effects on propeller wake/vortex-induced structure-borne noise transmissions. J. Aircr. 1990, 27, 444–448. [Google Scholar] [CrossRef]

- Martinez, R. Predictions of Unsteady Wing and Pylon Forces Caused by Propeller Installation; NASA Contractor Report 178288; NASA: Cambridge, MA, USA, 1987.

- Zawodny, N.S.; Boyd, D.D. Investigation of Rotor–airframe Interaction Noise Associated with Small-Scale Rotary-Wing Unmanned Aircraft Systems. J. Am. Helicopter Soc. 2020, 65, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Johnston, R.T.; Sullivan, J.P. Unsteady wing surface pressures in the wake of a propeller. J. Aircr. 1993, 30, 644–651. [Google Scholar] [CrossRef]

- Moroianu, D.; Fuchs, L. LES of the flow and acoustics generated by a wing installed aircraft propeller running in the vicinity of the ground. In Rotorcraft and Prop/Fan Noise, Proceedings of the 11th AIAA/CEAS Aeroacoustics Conference, Monterey, California, USA, 23–25 May 2005; American Institute for Aeronautics and Astronautics: Reston, VA, USA, 2005. [Google Scholar] [CrossRef]

- Durbin, P.A.; Groeneweg, J.F. Rough analysis of installation effects on turboprop noise. J. Acoust. Soc. Am. 1982, 72, S71. [Google Scholar] [CrossRef]

- Sinnige, T. Aerodynamic and Aeroacoustic Interaction Effects for Tip-Mounted Propellers: An Experimental Study; Delft University of Technology: Delft, The Netherlands, 2018. [Google Scholar]

- Tanna, H.K.; Burrin, R.H.; Plumblee, H.E., Jr. Installation effects on propeller noise. J. Aircr. 1981, 18, 303–309. [Google Scholar] [CrossRef]

- Heidelberg, L.; Woodward, R. Advanced turboprop wing installation effects measured by unsteady blade pressure and noise. In Proceedings of the 11th Aeroacoustics Conference, Palo Alto, CA, USA, 19–21 October 1987. [Google Scholar] [CrossRef] [Green Version]

- Akkermans, R.A.; Pott-Pollenske, M.; Buchholz, H.; Delfs, J.; Almoneit, D. Installation effects of a propeller mounted on a high-lift wing with a Coanda flap. Part I: Aeroacoustic experiments. In Low Noise Systems Integration, Proceedings of the 20th AIAA/CEAS Aeroacoustics Conference, Atlanta, GA, USA, 16–20 June 2014; American Institute for Aeronautics and Astronautics: Reston, VA, USA, 2014. [Google Scholar]

- Boots, D.A. Numerical Predictions of Propeller-Wing Interaction Induced Noise in Cruise and Off-Design Conditions; Carleton University: Ottawa, IM, Canada, 2016. [Google Scholar]

- Zhou, T.; Fattah, R. Tonal Noise Acoustic Interaction Characteristics of Multi-Rotor Vehicles. In Small Propeller-Rotor Noise II, Proceedings of the 23rd AIAA/CEAS Aeroacoustics Conference, Denver, Colorado, 5–9 June 2017; American Institute for Aeronautics and Astronautics: Reston, VA, USA, 2017. [Google Scholar]

- Lee, H.; Lee, D.J. Rotor interactional effects on aerodynamic and noise characteristics of a small multirotor unmanned aerial vehicle. Phys. Fluids 2020, 32, 047107. [Google Scholar] [CrossRef] [Green Version]

- Bernardini, G.; Centracchio, F.; Gennaretti, M.; Iemma, U.; Pasquali, C.; Poggi, C.; Rossetti, M.; Serafini, J. Numerical characterisation of the aeroacoustic signature of propeller arrays for distributed electric propulsion. Appl. Sci. 2020, 10, 2643. [Google Scholar] [CrossRef] [Green Version]

- Chirico, G.; Barakos, G.N.; Bown, N. Propeller installation effects on turboprop aircraft acoustics. J. Sound Vib. 2018, 424, 238–262. [Google Scholar] [CrossRef] [Green Version]

- Kingora, K.; Sadat, H. Hybrid immersed boundary method for general purpose CFD simulation. In Proceedings of the 73rd Annual Meeting of the APS Division of Fluid Dynamics, Chicago, IL, USA, 22–24 June 2020. [Google Scholar]

- Heydari, M.; Sadat-Hosseini, H. Analysis of propeller wake field and vortical structures using k− ω SST Method. Ocean Eng. 2020, 204, 107247. [Google Scholar] [CrossRef]

- Epikhin, A.; Evdokimov, I.; Kraposhin, M.; Kalugin, M.; Strijhak, S. Development of a dynamic library for computational aeroacoustics applications using the OpenFOAM open source package. Procedia Comput. Sci. 2015, 66, 150–157. [Google Scholar] [CrossRef] [Green Version]

- Willams, J.E.F.; Hawkings, D.L. Sound Generated by Turbulence and Surfaces in Arbitrary Motion. Philos. Trans. R. Soc. Lond. Ser. A Math. Physical Sci. 1969, 264, 321–342. [Google Scholar]

- Lighthill, M.J. On sound generated aerodynamically I. General theory. Proc. R. Soc. London Ser. A Math. Phys. Sci. 1952, 211, 564–587. [Google Scholar]

- Brentner, K.S.; Farassat, F. Modeling aerodynamically generated sound of helicopter rotors. Prog. Aerosp. Sci. 2003, 39, 83–120. [Google Scholar] [CrossRef] [Green Version]

- Junger, C. Computational Aeroacoustics for the Characterization of Noise Sources in Rotating Systems. Ph.D. Thesis, Technical University of Vienna, TU Wien, Vienna, Austria, 2019. [Google Scholar]

- Xing, T.; Stern, F. Factors of safety for Richardson extrapolation. J. Fluids Eng. 2010, 132, 061403. [Google Scholar] [CrossRef] [Green Version]

- Anudeep, M.; Diwakar, G.; Katukam, R. Design of a quad copter and fabrication. Int. J. Innov. Eng. Technol. 2014, 4, 59–65. [Google Scholar]

- Schenk, A.R. Computational Investigation of the Effects of Rotor-on-Rotor Interactions on Thrust and Noise; Brigham Young University: Provo, UT, USA, 2020. [Google Scholar]

- Hanson, D.B.; Fink, M.R. The importance of quadrupole sources in prediction of transonic tip speed propeller noise. J. Sound Vib. 1979, 62, 19–38. [Google Scholar] [CrossRef] [Green Version]

- Heydari, M.; Sadat, H.; Singh, R. Propeller-Wing Interaction Effects on Aerodynamics of an Unmanned Aerial System; Department of Mechanical Engineering, University of North Texas: Denton, TX, USA, 2021; to be submitted. [Google Scholar]

| Propellers | ||||

| Type | No. | Axis | Direction | COR (m) 1 |

| RAYCorp 8045 | 1 | (0.99, 0, 0.17) | CCW | (−0.003, −0.22, 0.128) |

| 2 | (−0.99, 0, −0.17) | CW | (−0.003, 0.22, 0.128) | |

| 3 | (0.99, 0, −0.17) | CCW | (−0.003, 0.22, −0.128) | |

| 4 | (−0.99, 0, 0.17) | CW | (−0.003, -0.22, −0.128) | |

| Wings | ||||

| Type | Size | |||

| Wortmann FX 63-137 | 87.28 × 490 mm (Chord × Span) | |||

| Fuselage/Structure | ||||

| Size (fuselage, mm) | Weight (structure) | |||

| , , | 12 (N) | |||

| Case | RPM | ||

|---|---|---|---|

| C1 | 6000 | 7 | 0 |

| C2 | 6000 | 7 | 15 |

| C3 | 6000 | 7 | 35 |

| C4 | 6000 | 7 | 55 |

| C5 | 6000 | 7 | 75 |

| C6 | 6000 | 4 | 15 |

| C7 | 6000 | 13 | 15 |

| C8 | 12,000 | 7 | 15 |

| Part | Surface Mesh |

|---|---|

| Propeller 1, 2, 3, 4 | 64 thousand (80 on the chord and 220 on the span) |

| Wing 1, 2 | 300 thousand (600 on the chord and 1100 on the span) |

| Other appendages | 44 thousand (94 in vertical direction and 86 in horizontal direction on the fuselage) |

| Case Label | Propeller | Wing |

|---|---|---|

| C1 | 2.22 | 2.62 |

| C2 | 1.67 | 1.60 |

| C3 | 2.08 | 2.37 |

| C4 | 2.09 | 2.23 |

| C5 | 2.46 | 1.72 |

| C6 | 2.00 | 1.57 |

| C7 | 1.75 | 1.30 |

| C8 | 0.57 | 1.01 |

| Variable | Far-Field Boundary | Propeller | Wing | Other Surfaces |

|---|---|---|---|---|

| Uniform | No-slip | No-slip | No-slip | |

| Wall function | ||||

| Wall function |

| OASPLave | Average | |||

|---|---|---|---|---|

| 0.47 | 0.68 | 0.48 | 0.54 | |

| 2.16 | 2.45 | 2.12 | 2.24 | |

| 1.75 | 4.4 | 4.4 | 3.5 | |

| 1.23 | 1.86 | 3.34 | 2.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heydari, M.; Sadat, H.; Singh, R. A Computational Study on the Aeroacoustics of a Multi-Rotor Unmanned Aerial System. Appl. Sci. 2021, 11, 9732. https://doi.org/10.3390/app11209732

Heydari M, Sadat H, Singh R. A Computational Study on the Aeroacoustics of a Multi-Rotor Unmanned Aerial System. Applied Sciences. 2021; 11(20):9732. https://doi.org/10.3390/app11209732

Chicago/Turabian StyleHeydari, Morteza, Hamid Sadat, and Rajneesh Singh. 2021. "A Computational Study on the Aeroacoustics of a Multi-Rotor Unmanned Aerial System" Applied Sciences 11, no. 20: 9732. https://doi.org/10.3390/app11209732